10 minute read

LIVE HEEL ........................................................................................................................P R E L I M I N AR Y

Tigercat T250D Track Loader

Before moving the machine to the work site, check to ensure that all doors, panels, and access covers are installed properly and secured.

CAB EXITS

There are 2 ways to exit the cab in case of an emergency. 1. Side Door – This is the main point of entry used under normal operating conditions to enter or leave the cab. This door is not equipped with a safety interlock switch and therefore when left open will not deactivate the pilot controls in the cab. The left armrest is equipped with a safety interlock switch that prevents machine operation when the armrest is raised. See SAFETY INTERLOCK SWITCH

ON LEFT ARMREST for more details.

ALWAYS shut OFF engine before using the side door exit. 2. Side Window – This is a second cab exit for use if the side door exit becomes blocked.

This window is not equipped with a safety interlock switch and therefore when left open will not deactivate the pilot controls in the cab.

ALWAYS shut OFF engine before using the side window as an escape hatch exit. It is important that the operator of the machine be familiar with these emergency exits and how to use them. All operators should practice using all the cab exits to become familiar with escape procedures should they need to perform them in the dark, when the machine is in a rolled position, or other possible adverse condition. The exits should be checked to make sure that they are operational and will function in an emergency. For additional information, refer to EMERGENCY EXITS in SECTION 2.

Safety

SAFETY INTERLOCK SWITCH ON LEFT ARMREST

The left arm rest is equipped with a safety interlock switch (1) to prevent the machine from being operated while the armrest is in the raised position (pilot system is shut off). NOTE: The engine can be started but the machine functions cannot be operated with the left arm rest up.

ARMREST

L.H. ARM REST IN DOWN POSITION AND LIMIT SWITCH ON 1

LIMIT SWITCH ACTUATING LEVER ON SEAT BASE

T250D-013

PILOT SYSTEM SHUT OFF

To operate:

1. With the engine running and the left arm rest

DOWN, push the pilot reset switch. 2. Once the safety interlock system has been activated, the safety of both the operator and all persons outside the cab becomes the responsibility of the operator. 3. The left arm rest safety interlock switch (pilot system shut off limit switch) and the pilot reset switch are a safety feature and their function must not be defeated in any way. 4. When the engine is running, DO NOT allow anyone in areas of the machine where they may be crushed by moving components.

5. Maintain a safe operating distance between the machine and other personnel. Never operate the boom or attachment over the heads of bystanders.

WARNING

Tigercat T250D Track Loader

1. Never travel near co-workers or other pieces of equipment with attachment running. 2. Do not allow people or other pieces of equipment near the harvesting operation.

WARNING

3. Do not turn on attachment until machine is at the harvesting site. 4. Use only prearranged and approved signalling practices. Do not open an escape hatch or the cab doors to increase ventilation when operating the machine. Keep the cab doors closed when driving or steering the machine to prevent accidental entry of branches and debris into the cab.

CAUTION

Do not open cab doors or window screens when cab is on a slope. The doors and screens are heavy and could swing out with considerable force. Anyone in the path of swing could be injured. Anyone opening the door or screen and holding on to it could be pulled out of the cab and injured.

Keep the cab doors closed and use seat belt when driving or steering the machine to prevent being thrown from the operator's cab. Secure loose items in the cab. Prior to commencing work, check all equipment controls to ensure that the machine responds correctly. Make sure that all safety screens and guards including the skylight are installed and properly secured. Always rest the attachment on the ground when operation is stopped, regardless if the engine is running or shut off. Operate the machine only from a seated position in the operator’s seat. Watch for ground hazards such as metal debris, wire fencing or rocks. When travelling position attachment and boom so as not to impair vision. If vision is limited by dust, smoke, fog, rain or

Safety

snow, stop the machine until visibility is restored. If saw guard has been installed, DO NOT REMOVE until at the cutting site. Remove guard before starting engine. Park machine at least 15 m (50 ft) away from other equipment and in a cleared area. In the event of a fire, this distance will minimize the chance of the fire spreading to other equipment. Before leaving operator's cab, lower the felling attachment onto the ground. If out of the operator's cab for an extended period shut the machine off.

PARKING THE MACHINE

Park the machine in a cleared area at least 15 m (50 ft) away from other equipment. In the event of a fire, this distance will minimize the chance of the fire spreading to other equipment. Before leaving the cab for any reason, always lower the attachment onto the ground. • Park on level ground only and engage the swing brake. • Do not park on a hillside or incline. • Lower attachment onto level ground. • Stop the engine. • Turn the battery disconnect switch off if the vehicle is to be parked for an extended period of time (Example - overnight).

T250D-001

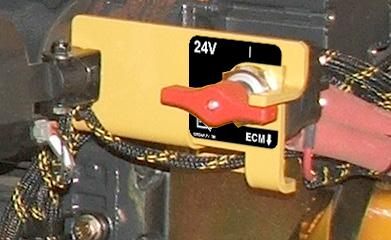

BATTERY DISCONNECT SWITCH

NOTE:

Wait 30 seconds after engine shut down before turning off battery disconnect switch. If battery disconnect is turned off before this the engine ECU (Engine Control Unit) will register a fault. When transporting the machine watch that enough clearance is available on both sides and above the machine or any of its attachments to avoid contact with power or telephone lines, bridge structures, etc. Before transporting the machine check to

Tigercat T250D Track Loader

ensure that all doors, panels and access covers are installed properly and secured. Improperly secured doors or panels pose a serious danger to pedestrians and other vehicles.

NOTE: This machine is equipped with an After Run/ Accessory Relay which delays the power disconnect to engine related fuses and relays (ECU /ATS relay, NOx Sensor relay, NOx Sensor fuse, ECU Power fuse, DCU fuse). Whenever the engine is stopped all DEF solution is pumped back to tank before the engine power system is turned off. This process takes approximately 90

seconds.

Refer to AFTERTREATMENT SYSTEM in SECTION 3 for more information.

Safety

WARNING

DO NOT operate this machine to lift or move any objects other than what it is designed to lift or move.

• Do not use the boom to service other

equipment.

• Do not use the boom to lift items such

as tires, engines, cylinders, boom components, etc.

• Do not modify the boom system. • Do not add hooks or lugs to the boom for

the purpose of attaching lifting rigging.

• Do not use the attachment for any purpose other than the intended function.

Maintain a safe operating distance between the machine and workers and all other personnel. It is the duty of the operator to ensure that no person approach the machine while in use. Failure to follow the above instructions could result in serious injury or death.

Tigercat T250D Track Loader

SERVICING SAFETY PRECAUTIONS

Conduct maintenance inspections at least as frequently as recommended in SECTION 3 of the THIS MANUAL.

When servicing or repairing equipment, shut the engine down. Turn Battery Disconnect switch OFF and lock out the switch in accordance with local regulations. This machine is equipped with a remotely operated battery disconnect relay. Some wiring on the machine is live even when the battery disconnect switch is off. When servicing the electrical system, remove the battery cables from the batteries disconnecting the negative cables first.

T250D-001

BATTERY DISCONNECT SWITCH Safety

Before performing maintenance or repair work on any equipment, consult the manufacturer’s instruction manual and follow recommended procedures.

The radiator and the engine cooling system should be cleaned and serviced daily to maintain moderate engine temperatures.

WARNING

WARNING, HOT FLUIDS AND HOT MACHINE SURFACES CAN CAUSE SERIOUS BURNS!

• Before servicing the machine, allow the

engine cooling system, fuel system, exhaust system, hydraulic system and machine surfaces to cool down.

• Use a thermometer to check surface and

system temperatures to ensure it is safe to begin service work.

• DO NOT begin service work until the

surface or system temperature has cooled down to below 38°C (100°F)!

Install a 'DO NOT START ENGINE' sign on the operator’s cab door and in the engine compartment when making repairs to the machine.

Tigercat T250D Track Loader

Prior to welding on any part of the machine, the repair area should be cleaned and a fire extinguisher should be made available at the welding location. Care must be taken in attaching the welding machine grounding clamp so current does not pass through bearings, especially the swing bearing. Disconnect the negative (-) battery cable from all the batteries. This machine is equipped with sensitive electronic control equipment, prior to welding:

1

2

Safety

250CT-001

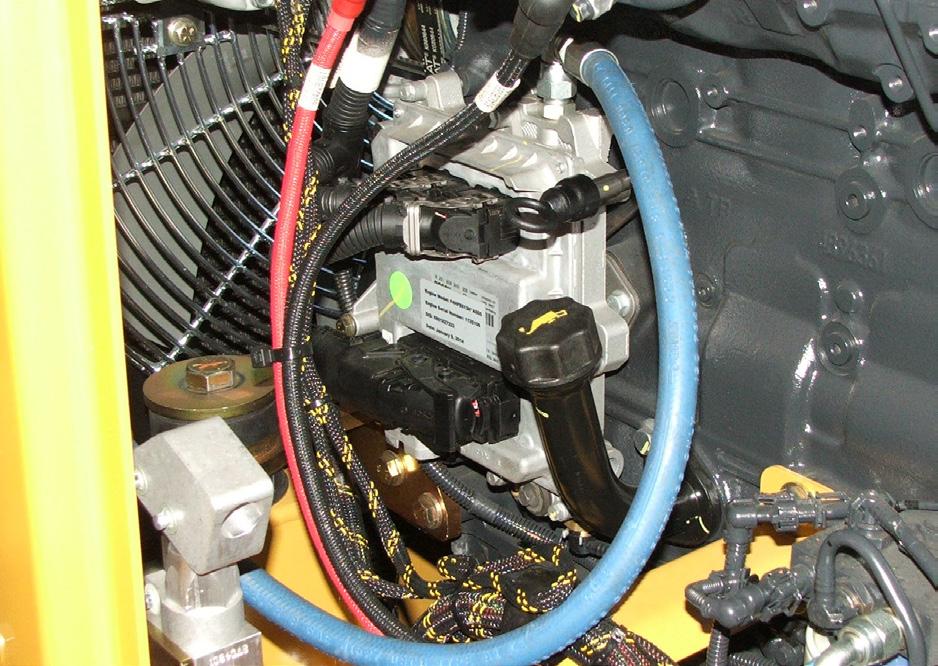

COMPUTER CONTROL MODULE

Disconnect the computer control module connector (under platform).

WARNING

Diesel fuel or hydraulic fluid under pressure can penetrate the skin and cause serious personal injury, blindness, or death. If any fluid is injected into the skin, it must be surgically removed within a few hours by a doctor familiar with treating this type of injury.

T250D-010

ENGINE CONTROL UNIT

Disconnect the engine ECU (Engine Control Unit) by unplugging the two engine connectors (1) and the multi-pin connector (2). Never use your bare hand to check for fluid leaks. Fluid leaks under pressure may not be visible. When searching for leaks, wear work gloves and use a wrench or piece of wood to move hydraulic hoses. Do not grab hold of hydraulic hoses. Wear safety goggles for eye protection.

Pressure can be maintained in a hydraulic system long after the power source and pump have been shut down. Lower the attachment to the ground, stop engine and relieve trapped pressure before performing work on components, or disconnecting any hoses. Accumulators will self-drain within 2 minutes of stopping the engine.

250D-012

DOSING CONTROL MODULE

Disconnect the dosing control module connector from the back of the module.

Tigercat T250D Track Loader Safety

Explosive release of fluids from pressurized cooling system can cause serious burns. Shut off engine. Only remove coolant filler cap when cool enough to touch with bare hands. Slowly loosen cap to first stop to relieve pressure before removing completely.

Do not change any pressure or relief setting unless Tigercat authorized instruction has been obtained. Use the proper tool for the job. Repair or replace worn or damaged tools including lifting equipment immediately. Keep your hands, feet, head, and loose clothing away from power driven parts. Tie long hair behind your head. Remove rings and other jewelry to prevent electrical shorts and entanglement in moving parts. Always be aware of machine pinch points that could cause injury. Never place body parts within the range of motion of the working parts of the machine. Never stand under an object supported with hydraulics. Always use safety stands or a locking device.

WARNING

DO NOT operate this machine to lift or move any objects other than what it is designed to lift or move.

• Do not use the boom to service other

equipment.

• Do not use the boom to lift items such

as tires, engines, cylinders, boom components, etc.

• Do not modify the boom system. • Do not add hooks or lugs to the boom for

the purpose of attaching lifting rigging.

• Do not use the attachment for any