3 minute read

ATTACHMENT DRIVE

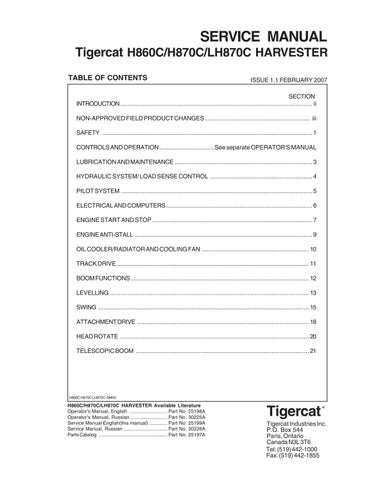

Tigercat H860C/H870C/LH870C Harvester Safety

OPERATING SAFETY PRECAUTIONS continued

WARNING

DO NOT operate this machine to lift or move any objects other than what it is designed to lift or move. The boom system is intended for use in the tree felling applications only. • Do not use the boom to service other equipment. • Do not use the boom to lift items such as tires, engines, cylinders, boom components, etc. • Do not modify the boom system. • Do not add hooks or lugs to the boom for the purpose of attaching lifting rigging. • Do not use the attachment for any purpose other than the intended felling function.

Maintain a safe operating distance between the machine and workers and all other personnel. It is the duty of the operator to ensure that no person approach the machine while in use. Failure to follow the above instructions could result in serious injury or death.

Never use this machine to clear a logging deck on a new tract of timber when the rest of the equipment and operators are also moving in. Preplan to clear decks in advance before other equipment arrives. Never work alone. Regularly inform other crew members of your intentions, location and length of time to perform duties. Stop the attachment before leaving the harvesting area. Park machine at least 50 feet (15 meters) away from other equipment and in a cleared area. In the event of a fire, this distance will minimize the chance of the fire spreading to other equipment. Before leaving operator's cab, lower the felling attachment onto the ground. If out of the operator's cab for an extended period shut the machine off.

When parking the machine:

• Park on level ground only and engage the swing brake. • Do not park on a hillside or incline. • Lower attachment onto level ground. • Stop the engine. • Turn the battery disconnect switch OFF if the vehicle is to be parked for an extended period of time (Example - overnight).

NOTE:

Wait 30 seconds after engine shut down before turning off battery disconnect switch. If battery disconnect is turned off before this the engine ECM (Engine Control Module) will register a fault. When transporting the machine watch that enough clearance is available on both sides and above the machine or any of its attachments to avoid contact with power or telephone lines, bridge structures, etc. Before transporting the machine check to ensure that all doors, panels and access covers are installed properly and secured. Improperly secured doors or panels pose a serious danger to pedestrians and other vehicles.

24863A

Tigercat H860C/H870C/LH870C Harvester Safety

SERVICING SAFETY PRECAUTIONS

WARNING

Conduct maintenance inspections at least as frequently as recommended in section 3 of the THIS MANUAL.

When servicing or repairing equipment, shut the engine down. Turn Battery Disconnect switch OFF and lock out the switch in accordance with local regulations. This machine is equipped with a remotely operated battery disconnect relay. Some wiring on the machine is live even when the battery disconnect switch is off. When servicing the electrical system, remove the battery cables from the batteries disconnecting the negative cables first. Install a “DO NOT START ENGINE” sign on the operator’s cab door and in the engine compartment when making repairs to the machine.

Before performing maintenance or repair work on any equipment, consult the manufacturer’s instruction manual and follow recommended procedures.

24863A

WARNING, HOT FLUIDS AND HOT MACHINE SURFACES CAN CAUSE SERIOUS BURNS!

• Before servicing the machine, allow the engine cooling system, fuel system, exhaust system, hydraulic system and machine surfaces to cool down.

• Use a thermometer to check surface and system temperatures to ensure it is safe to begin service work. • DO NOT begin service work until the surface or system temperature has cooled down to below 100°F (38°C)!

DISCONNECT THE MULTI-PIN PLUG FROM THE ENGINE ANTI-STALL CONTROLLER

822C-03 ENGINE ANT-STALL DISCONNECT

The radiator and the engine cooling system should be cleaned and serviced daily to maintain moderate engine temperatures.

Prior to welding on any part of the machine, the repair area should be cleaned and a fire extinguisher should be made available at the welding location. Care must be taken in attaching the welding machine grounding clamp so current does not pass through bearings, especially the swing bearing. Disconnect the negative (-) battery cable from all the batteries. This machine is equipped with sensitive electronic control equipment, prior to welding:-

Disconnect the multi-pin plug from the engine

anti-stall controller located inside the cab, mounted on the rear electrical cover door.