6 minute read

SWING

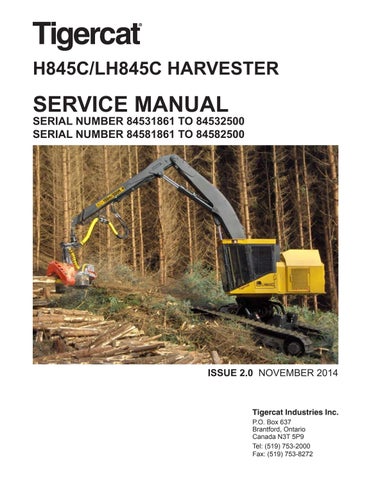

Tigercat H845C/LH845C Harvester

KEEP BACK 150 m (500 ft)

The following diagram illustrates the HAZARD ZONE. All personnel should be kept clear of this zone while the harvesting head is operating. The HAZARD ZONE should be considered off limits to all individuals.

150 m (500 ft) 150 m (500 ft)

150 m (500 ft)

150 m (500 ft)

860C-039

HAZARD ZONE

DANGER

The safety of persons outside the cab is the responsibility of the machine operator.

When approaching an operating machine on foot, stay at least 150 m (500 ft) away until the operator recognizes your presence. Make sure that all harvesting equipment is shut down before advancing to the machine.

NOTE: Opening the cab front door will stop machine functions. Opening the cab side door will NOT stop machine functions. Safety

Wear a suitable hearing protective device such as earmuffs or earplugs to protect against noise. Prolonged exposure to loud noise can cause impairment or loss of hearing. This machine exceeds 70 dB(A) in the cab and exceeds 85 dB(A) when servicing machine engine. Always use the handrails and steps provided when mounting and dismounting from the machine. Do not jump off the machine at any time. Do not try to climb onto or off of a moving machine. Do not use the seat armrest or joystick as handles when entering or leaving the cab. Do not use the machine foot controls as steps.

When mounting or dismounting the machine always use the three point technique; use one hand with two feet or two hands with one foot.

WARNING

Avoid mounting or dismounting the machine in areas with slippery surfaces. Dry, deice, clean up or cover slippery surfaces with an anti-slip material before mounting or dismounting the machine.

Safety

WARNING

Do not walk on machine surfaces with steel cleated foot wear. Steel cleats on steel surfaces are slippery and do not provide a safe foot hold.

WARNING

It is not recommended to walk on machine surfaces that are not designated walking areas. No attempt should be made to walk on angled steel surfaces or surfaces that are irregular in shape. Walking surfaces on the machine must be covered with anti-slip materials to provide a safe foot hold and prevent slipping. These anti-slip surfaces should be maintained on a regular basis. If the surface shows signs of wear, the anti-slip material must be replaced immediately.

To reduce risk of fire, machines should be completely cleaned of debris at least daily, particularly around the engine exhaust components. Hydraulic oil leaks, excess grease, fuel and oil accumulation (including spillage) should be eliminated immediately, always shut off engine before cleaning machine. Maintain a clean cab interior, clear away trash or debris. Machine should be washed completely at every major service. Inspect the machine daily for signs of damage or unusual wear, to structures. Check for fluid leaks, or faulty operation. Repair or replace malfunctioning parts and systems immediately. Check windows and door guards for damage. Check protective windows for cracks, a damaged window has reduced strength to stop flying objects. All damaged windows must be replaced with original equipment. Check windows for scratching, crazing and cloudiness that could impair clear visibility all around the machine.

Tigercat H845C/LH845C Harvester

Do not operate the machine with any defective or inoperable components. Check all fluid levels. Do not operate the machine with any of the exhaust system, safety covers, oil shields, or other devices removed.

Keep a first aid kit in an easily accessible location on the vehicle at all times.

Working with oil

Direct contact with oil implies a risk of skin complaints (example: eczema). Strict hygiene should always be observed. Some advice which should be observed: • Oils used in this machine may be hot enough to cause serious burns. • Avoid contact with oil, particularly heated oil. • Oil on the skin should be washed off immediately with soap and water. • Wear protective gloves. Hands should be clean before putting on gloves. Apply protective cream to the hands to make washing easier. • Don't put oily rags in your pockets. • Oil soiled clothing should be changed as soon as possible. • Always keep an extra overall handy, but not in the machine where it can become dirty. • Cuts and abrasions must be attended to immediately. Clean them and apply first-aid. • Avoid breathing in oil fumes. • Wash hands and arms frequently (example: at each meal break or as often as possible). • Any cloths, residue and gloves must be safely discarded after use. Read, understand and follow all general safety precautions specified by harvesting head manufacturer.

Tigercat H845C/LH845C Harvester

Safety Hazards - Viton Seals

O-rings and other seals manufactured of Viton material (fluorine rubber) produce a highly corrosive acid (Hydrofluoric) when subjected to temperatures above 315°C (600°F). This contamination can have extreme consequences on human tissue since it is almost impossible to remove after contact. The following procedures are recommended when inspecting equipment that has been subjected to high temperatures such as fire: • Visually inspect any seals or gaskets which have suffered from heat; they will appear black and sticky. • If these are found, Do Not Touch!!! • Determine the material composition of any seals or gaskets. If fluoro-elastomer seals (Viton, fluorel, or tecmoflon) have been used, the affected area must be decontaminated before undertaking further work. Natural rubber and nitrile materials are not hazardous. • Disposable heavy duty gloves (neoprene) must be worn and the affected area decontaminated by washing thoroughly with limewater (Calcium Hydroxide solution). • Any cloths, residue and gloves must be safely discarded after use. NOTE: Burning discarded items is not recommended except in an approved incineration process where the dangerous products are treated by alkaline scrubbing.

Safety Hazards - Operating

Maintain a charged fire extinguisher on the vehicle at all times and KNOW HOW TO USE IT. Do not carry passengers either in the cab or anywhere else on the machine. The vehicle is provided and approved with seating for the operator only. Do not allow anyone to operate the machine who may not be physically fit or who may be under the influence of alcohol or drugs. When moving the machine, watch that enough clearance is available on both sides and above the machine or any of its attachments. Extra clearance may be required particularly where the ground is uneven. Approach with extreme caution any area where overhanging electrical power lines are present. Serious injury or death by electrocution can result if the machine or any of its attachments are not kept a safe distance from these lines. Maintain a distance of 3 m (10 ft) between the machine or boom and any power line carrying up to 50,000 volts or less plus 10 mm (½ in.) for each additional 1,000 volts above the 50,000 volt level. If State/Provincial, local or job site regulations require even greater safety distances than stated above, adhere strictly to these regulations for your own protection. If the machine must be transported, make sure that it is adequately secured to the transporting vehicle. Refer to VEHICLE MOVING INSTRUCTIONS in SECTION 2 of the OPERATOR'S MANUAL. Stopping the engine immediately after it has been working under load can result in overheating and premature wear of the engine components. Reduce engine speed to LOW IDLE and let run for approximately five minutes to allow gradual dissipation of heat and also to reduce turbo speed. This will also prevent loss of coolant by after boil and possible hot spot damage to the engine.

Be aware when performing service and maintenance tasks that surfaces and grab handles in and around the engine and cooling system may become very hot when the engine has been running. Contact with hot surfaces may cause injury. Comply with instructions in this manual and also your company’s regulations for the operation of this machine. Read, understand and follow all general safety precautions specified by harvesting head manufacturer.