6 minute read

TELESCOPIC BOOM

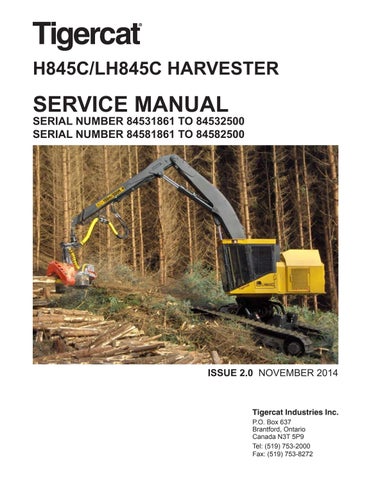

Tigercat H845C/LH845C Harvester

MACHINE STABILITY AND TRACTION MACHINES WITHOUT LEVELER

When working on slopes, travel straight up or down the slope to prevent roll-over. NEVER travel across a STEEP slope or side hill: • As a load is added to the harvesting head the handling and the stability of the machine will change. • To avoid tip over, keep the harvesting head as low as possible to maintain a low centre of gravity. • Always be prepared to dump the load in case of an emergency. • DO NOT overload the machine as this can create an unstable condition and cause a roll-over.

Safety

Safety

MACHINE STABILITY AND TRACTION MACHINES WITH LEVELER

This machine is designed to operate on rough terrain and slopes commonly found in forestry applications. However, ground conditions vary greatly with changing soil types, slope angles, moisture, snow and ice, rocks, boulders and stumps, and fallen trees. All of these factors affect the machine’s stability against tip-over and traction to resist slipping. This machine may

not be capable of operating on some ground

conditions, and must be used with caution. Whenever possible work within the normal working range of the boom system as shown in FIG. 1. NOTE: In any boom position, both inside and outside of the normal operating range, there is a risk of instability and tipping. When it is necessary to work outside of the normal working range, be aware that the stability of the machine is reduced. The risk of tipping

is increased while operating in the reduced stability working range.

NORMAL WORKING RANGE OF BOOM SYSTEM

UPHILL

REDUCED STABILITY WORKING RANGE

TRACK GEAR BOX AT REAR OF UNDERCARRIAGE

860C-030

FIG. 1 - WORKING RANGES

Be aware that the machine is in its least stable position on a slope with the boom to the rear.

All efforts have been made in the design of the machine to reduce the risk of tipping, however it is not possible to eliminate the risk of tipping.

Tigercat H845C/LH845C Harvester

860C-009 20°

860C-010 16°

FIG. 2 - UNDERCARRIAGE LEVELING ANGLES

To minimize the risk of tipping observe the following: • DO NOT attempt to operate this machine on slopes without first receiving proper training. • Learn the stability limits or “feel” of the machine by first working on gentle slopes and by positioning the boom to reduce the risk of tipping. Gain experience over time by gradually increasing the angle of the slopes on which you are working. • Keep the attachment as close to the ground as possible to increase machine stability, and to allow the boom to be quickly lowered to the ground should the machine begin to tip. • Always use the LOW speed setting for the track drives when on slopes. • Travelling at an angle to the slope other than straight up and down decreases the traction of the tracks. Increasing the angle to the slope away from straight up and down can cause the machine to slide sideways downhill and/or possibly tip over.

Tigercat H845C/LH845C Harvester

• NEVER travel across a STEEP slope or side hill. • Always carry any load on the uphill side of the machine. • DO NOT lift or move objects that exceed machine stability. • Always be prepared to release the load in case it causes the machine to tip. • Always position the cab so that you have a clear view in the direction of travel. Be aware of ground conditions and obstacles in the machine’s path before moving the machine. • When crossing obstacles (boulders, stumps, ditches etc.) the machine can shift rapidly, greatly affecting the stability of the machine.

Move slowly over obstacles, and position the boom against the ground to reduce the risk of the machine shifting rapidly. • Backing over obstacles unexpectedly while travelling down a slope poses a tipping risk.

Know the path of the tracks whenever the machine is moved. • When climbing a slope the boom should face uphill and the harvesting head should be kept close to the ground (FIG. 3). When descending a slope the boom should face down hill and the harvesting head should be kept close to the ground (FIG. 4). Be particularly aware of machine stability when changing directions on, or travelling back down a slope. • As you gain experience, recognize that the maximum slope on which the machine can operate cannot be defined simply by an angle value. Variables in surface terrain, soil types, rocks, boulders, stumps, and fallen trees, changing weather conditions, and first and foremost the operator’s experience and skill levels greatly affect the maximum slope limitations. Be aware that these factors can result in a shallow slope posing greater risk than a relatively steeper slope. DO NOT

attempt to work on slopes beyond your personal capability level.

BOOM TO FRONT

Safety

KEEP HARVESTING HEAD CLOSE TO GROUND

860C-034 TRACK GEAR BOX AT REAR OF UNDERCARRIAGE

FIG. 3 - CLIMBING SLOPE

KEEP HARVESTING HEAD CLOSE TO GROUND

860C-033

FIG. 4 - DESCENDING SLOPE

Safety

HARVESTING HEAD –GENERAL SAFETY

Improper operation, maintenance or repair of this product can be dangerous and could result in injury or death. Do not operate or perform any maintenance or repair of this product until you have read and understood the operation and repair information contained in the manuals provided by the harvesting head manufacturer. The following are general safety guidelines for harvesting heads. Note the design, operation, and maintenance of harvesting heads varies among manufacturers. Always follow the specific safety, maintenance, and operating procedures provided by the harvesting head manufacturer. The operator of the carrier and harvesting head must be properly trained in the operation of the equipment and its safety requirements.

PRIOR TO STARTING OPERATION:

• Ensure no one is near the machine where the risk of personal injury is present. • Ensure no one is in the line of the chain saw when starting or operating the harvesting head. The hydraulically driven saw chain reaches high speeds and is an extreme hazard if the chain breaks.

• Regularly inspect, check and maintain the saw guide (bar), the saw chain and sprocket, ensuring that all components are secure and not damaged as detailed in the harvesting head operator’s manual. • Ensure that all safety equipment upgrades available from the harvesting head manufacturer have been installed.

• Before starting each shift the operator must test ALL functions of the carrier and harvesting head to ensure that they are in proper working order.

OPERATION:

Felling trees with the harvester is very dangerous and should be done only by properly trained and experienced operators.

WARNING

The harvesting head may release held trees when the cab front door is opened, the pilot system is turned off or the fire suppression system is activated. Never exit the cab with a tree suspended in the harvesting head. Tigercat H845C/LH845C Harvester

WARNING

The operator must release trees from the harvesting head, place the harvesting head on the ground, and shut the pilot system off if someone enters into the hazard zone.

• Lower harvesting head to the ground and turn pilot system off whenever machine is not in use.

• Always fell trees in the direction that they are leaning. • NEVER fell trees close to overhead power lines, vehicles, houses, roads/pathways, etc. • NEVER fell trees when there are personnel on the ground within the 150 m (500 ft)

“hazard zone”.

• During operation do not allow anyone within the safety zone of at least 150 m (500 ft) from the machine.

• NEVER fell trees in the direction of the operator’s cab.