10 minute read

HARVESTING ATTACHMENT

Tigercat 1165 Harvester

READ THIS MANUAL FIRST SAFETY SYMBOLS

Safety

Study these instructions carefully and use them as a reference when disassembling, inspecting, repairing or assembling this unit. The information contained in this manual is current at the time of printing. Tigercat reserves the right to make changes to the axles or manuals at any time. Changes to the manuals will not be reflected until the next revision of the document or will be issued in the form of service bulletins. Every effort is made to deliver updates on a regular basis. Report discrepancies between the manual and actual parts and processes to the Tigercat service department. The date of manufacture and the date of release of this document may differ. This safety alert symbol means ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

The safety alert symbol identifies important safety messages on machines, safety signs, in manuals, or elsewhere. When you see this symbol, be alert to the possibility of personal injury or death. Follow the instructions in the safety message.

SIGNAL WORDS

DANGER

DANGER indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury.

WARNING

WARNING indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury.

CAUTION

CAUTION indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate injury.

NOTICE

NOTICE indicates a potentially damaging situation which, if not avoided, may result in property damage and is not related to personal injury.

Safety

GENERAL SAFETY PRECAUTIONS

Safety is a prime responsibility of all. To minimize risks and promote safety at all times, this section of the manual details safety rules which should always be followed and obeyed. These safety rules highlight both general and specific measures the operator should be familiar with and adhere to. More specific measures are illustrated with pictograms which may also be attached to the machine in locations pertinent to their respective message. Keep safety labels in good condition. Repair or replace damaged labels.

LOCK OUT/TAG OUT

WARNING

DO NOT remove a lock or tag that does not belong to you. Removing a lock or tag may enable a hazardous energy source, causing the machine or machine components to move.

Lock Out/Tag Out is a safety procedure used to isolate and disable sources of hazardous energy so that they cannot be accidentally activated. Hazardous energy includes but is not limited to: electricity, pneumatics, hydraulics, temperature extremes, gravity, kinetic energy (springs), physical restrictions, fumes/gases, liquids, other moving parts.

D A

B

Personal protective equipment is provided to eliminate or control the danger of personal injury or health risks. Know what PPE is required and use it. If unsure of safety requirements or procedures, contact your supervisor or Health and Safety representative. As a minimum, workers must wear approved safety footwear, protective glasses and protective gloves. A first aid kit and charged fire extinguishers must be readily available.

COMPETENT PERSON

A competent person is defined as a worker with adequate knowledge, training and experience who knows the laws and regulations, can recognize unsafe conditions, practices, equipment or situations and can competently organize the work in a safety minded environment.

C

1000563

A Battery Disconnect Switch B Tag Out Tag C Lock Out Lock D Lock Tab

A lock is placed on the device enabling the hazardous energy along with a tag identifying the owner of the lock. The lock owner is the only person allowed to remove the lock. Often a sign will accompany a lock out/ tag out to identify hazardous energy locations. Multiple locks may be placed on a single device using a hasp or similar gang device to permit multiple persons to work on a machine safely. To lock out/tag out a hazardous energy source:

1. Announce shut off 2. Identify the energy source(s) 3. Isolate the energy source(s) 4. Lock and Tag the energy source(s) 5. Prove (try) the equipment isolation to show it is effective.

Tigercat 1165 Harvester

When maintenance or service is complete and prior to returning the machine to active duty: 1. Verify that service components are correctly installed and secured. 2. Verify that connectors, caps and fittings are secured. 3. Verify that tools and maintenance/service materials are removed from the machine. 4. Verify that locks and tags are removed. 5. Verify that access covers and panels are secured. 6. Announce clearly that the machine is to be powered

ON. 7. Sound the horn to indicate that start up is commencing. 8. Start the machine. Refer to STARTING THE

MACHINE on page 1.21. For further information regarding lock out/ tag out review local, regional, provincial, state and national safety regulations.

HAZARDOUS MATERIALS

WARNING

Hazardous solvents, oils, fuels and materials are present or are used to service the 1165 Harvester. Read and understand MSDS/PSDS literature and follow recommended handling procedures.

Read and understand Material Safety Data Sheets (MSDS)/Product Safety Data Sheets (PSDS) literature regarding chemicals, fuels, solvents and noxious materials.

• Handle and dispose of materials in keeping with local, regional and national laws and regulations.

In lieu of such laws and regulations, dispose of materials as suggested in the MSDS/PSDS literature. • Store materials to be disposed of in appropriate vessels with the materials clearly identified.

DO NOT pour fluids into a sewage system, on the ground, or in a stream, pond or lake.

Safety

LEGISLATIVE AUTHORITY

In the event of contradictory information regarding health and safety, transport or operation of 1165 Harvester machines, follow laws and regulations established by federal, provincial/state/regional and local agencies.

In the event that the rules and information in the manual are more stringent than legislative sources, Tigercat recommends adherence to the more stringent measures as a best practice measure to provide optimal protection and productivity for workers, the company and equipment.

Safety

HAZARDS

FLAMMABILITY

Use proper storage and handling for flammable solvents, oils, fuels and materials as indicated by MSDS/PSDS literature.

Smoking, welding, poor electrical connections, hot equipment, open flames and static discharge are external ignition sources that represent a serious safety hazard.

For information about fire prevention, refer to FIRE PREVENTION on page 1.33.

EXHAUST FUMES AND GASES

WARNING

Engine exhaust, some of its constituents, and certain vehicle components contain or emit chemicals known to the State of California to cause cancer and birth defects or other reproductive harm.

WARNING

DO NOT burn discarded items except in an approved incineration process. Burning such items creates hazardous fumes. Tigercat 1165 Harvester

LIQUID NITROGEN

WARNING

Only workers trained in handling liquid nitrogen may do so. See the MSDS or PSDS for proper handling and storage of liquid nitrogen. Do not attempt to use liquid nitrogen until you have received proper training.

Liquid nitrogen is used to shrink-fit bearing races, bushings, pins, shafts etc. It is extremely dangerous if not handled properly. It can cause severe frostbite and cold burns. Nitrogen gas can act as an asphyxiate. Super cooled gas can severely damage the respiratory tract.

COMPRESSED AIR

Compressed air is a concentrated, high pressure, high speed stream of air that can seriously injure or kill. Air pressures of 5–10 psi can cause serious injury. Most pneumatic tools operate at 80–120 psi. Follow acceptable Health and Safety protocols for using compressed air. • DO NOT clean clothing or skin using compressed air. • Verify the air stream is not aimed at a fellow worker or positioned in a way to cause debris to strike someone or other equipment. • Use a chip guard. • Air pressure of 30 psi (at the nozzle) is permitted to dry objects.

Hazardous gases, fumes and vapours are the byproducts of internal combustion engines, solvents and cleansers.

• Verify your work area is adequately ventilated. • Wear appropriate PPE as required. • DO NOT run the engine in enclosed spaces. Provide sufficient ventilation to prevent the build-up of toxic exhaust fumes. Use exhaust extensions to the outdoors or open the shop doors. • Run the engine only when it is necessary for testing or adjustments.

Tigercat 1165 Harvester

HOT SURFACES AND FLUIDS

WARNING

• Before servicing the machine, allow the engine cooling system, fuel system, exhaust system, hydraulic system and machine surfaces to cool down.

• Use a thermometer to check surface and system temperatures to ensure it is safe to begin service work. • DO NOT begin service work until the surface or system temperature has cooled down to below 38°C (100°F).

The engine, cooling system, exhaust system, fuel system and certain surfaces and handles may be very hot if the machine has been running. Allow the machine to cool to the touch prior to maintaining or servicing the machine.

Only remove the hydraulic coolant fill cap when it is cool enough to touch with bare hands. Slowly loosen the fill cap to the first stop to relieve pressure before removing the fill cap completely.

VITON SEALS Safety

WARNING

Viton Fluroelastomers contain constituents harmful to unprotected skin and respiratory tracts. Follow all MSDS recommendations for handling and disposing of Viton manufactured components.

O-rings and seals manufactured with Viton material (fluorine rubber) produce a highly corrosive acid (Hydrofluoric) when subjected to temperatures above 315°C (600°F). Seals appear black and sticky. This acid is extremely difficult to remove after it adheres to skin and can cause extensive tissue damage. Follow these procedures when inspecting equipment that has been subjected to high temperatures such as fire:

• Visually inspect any seals or gaskets which have been exposed to high heat; they will appear black and sticky. • DO NOT touch seals or gaskets that appear black and sticky. • Determine the material composition of any seals or gaskets. If fluro-elastomer seals (Viton, Fluorel, or

Tecnoflon) have been used, the affected area must be decontaminated before undertaking further work. • Wear disposable, acid resistant, heavy duty gloves and clothing (neoprene). Wear eye and respiratory protection. • Neutralize the affected area by washing it thoroughly using large quantities of lime water (Calcium

Hydroxide) solution. • Discard contaminated materials, rags and gloves in accordance with MSDS recommendations and industry best practice.

Safety

ELECTRICAL HAZARDS

WARNING 24 VOLT ELECTRICAL SYSTEM

WARNING

DO NOT attempt to charge a frozen battery. It can explode.

WARNING

DO NOT short the battery terminals. Serious burns or an explosion can result.

BATTERY

CAUTION

Lead-acid batteries contain sulfuric acid which can severely damage eyes or skin on contact. Always wear a safety face shield, rubber gloves and protective clothing to reduce risk of accidents.

Lead-acid batteries produce flammable and explosive gases. Keep arcs, sparks, open flames and lighted tobacco a safe distance from the batteries.

WARNING

Battery posts, terminals and related accessories contain lead, lead compounds and chemicals known to the State of California to cause cancer and birth defects or other reproductive harm. Wash hands after handling.

Wear appropriate PPE. If acid is accidentally splashed into your eyes, flush immediately with clean water and get medical attention. Refer to BATTERY CARE on page 3.78.

Tigercat 1165 Harvester

DISCONNECTING THE BATTERY

Disconnect the battery before working on electrical systems and prior to welding: 1. Turn OFF the battery disconnect switch. 2. Disconnect the negative starter motor cable from the battery.

PRIOR TO WELDING

Prior to welding on any part of the machine: 1. Prepare the machine as outlined in

PREPARING THE MACHINE FOR

MAINTENANCE on page 1.25. 2. Clean the machine of flammable debris. 3. Make a fire extinguisher readily available. 4. Connect the welding machine's grounding clamp so that current does not pass through bearings, especially the swing bearing. 5. Connect the grounding clamp as close as possible to the area being welded. 6. Disconnect the negative (–) battery cable from all of the batteries. 7. Put the automatic fire suppression system into

Isolation Mode (if equipped).

Refer to ISOLATION MODE in Section 25 of the

Service Manual for more information.

8. Disable the engine coolant heater (if equipped).

Refer to DISABLING THE ENGINE COOLANT

HEATER on page 3.63.

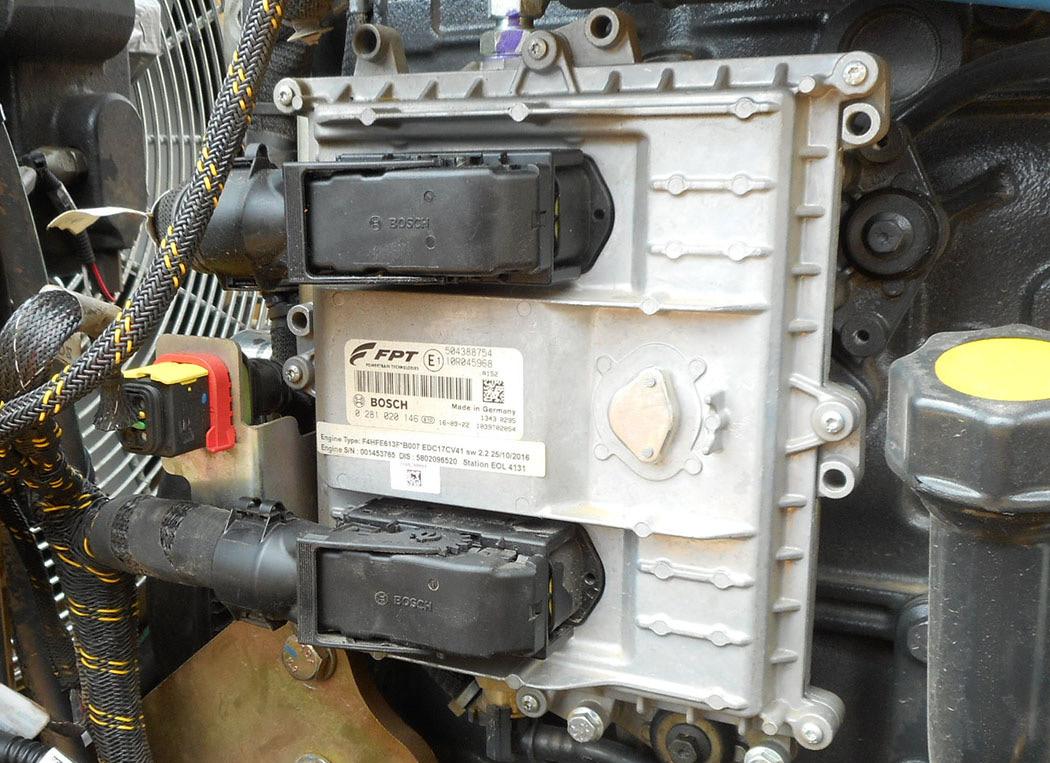

A B

A Exhaust Flap Connector B Engine ECU Connectors

9. Disconnect the exhaust flap connector. 10. Disconnect the two connectors from the engine ECU (electronic control unit).

The ECU is located on the right side of the engine.