2 minute read

ELECTRICAL AND COMPUTERS

MACHINE IDENTIFICATION AND SERIAL NUMBERS

Please record all serial numbers related to this machine below and have them ready before calling for assistance.

The machine serial number plate is located inside the cab behind the operator's seat.

The machine serial number is also stamped on the top side of the upper frame in the front right corner.

Machine Model Number: _________________________

Machine Serial Number: _________________________

Model Year: ___________________________________

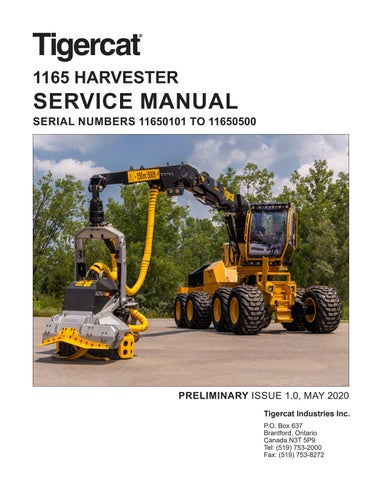

Tigercat 1165 Harvester

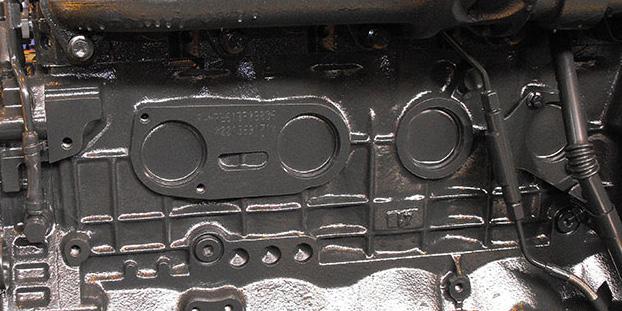

Engine Serial Number Location

The engine serial number is also stamped on the side of the engine, below the exhaust manifold.

Engine Serial Number: __________________________

Engine Identification Label Location

The engine identification label is located on top of the engine beside the oil fill cap.

Engine Date of Manufacture: ______________________

Tigercat 1165 Harvester Introduction

SAE STANDARDS FOR MACHINE OPERATOR PROTECTIVE STRUCTURES

The operator enclosure for this machine meets the following standards:

• ISO 8082-2:2011 ROLL OVER PROTECTION STRUCTURES (ROPS) • OREGON OSHA 437-007-0775:14A TIP-OVER PROTECTION STRUCTURES (TOPS) • ISO 8083:1989 11 600J FALLING OBJECTS PROTECTION STRUCTURES (FOPS) • ISO 8084:1993 OPERATOR PROTECTION STRUCTURES (OPS) • ISO 2867:1994

• SAE J1356: FEB 1988

• OREGON OSHA 437-007-0775:14B,C • AS 4988 2002

MODIFICATIONS AND REPAIRS

The integrity of the ROPS, TOPS, FOPS, OPS structure and its continued ability to provide the level of protection it was designed for could be seriously affected by any modifications to the structure, its mounting or to the chassis to which it is attached.

Tigercat emphasizes that the certification of approval of the ROPS, TOPS, FOPS, OPS structure will become void if any such modifications take place.

Tigercat may officially grant approval for modifications only by:

• Written approval of repairs or modifications signed by the Tigercat Engineering

Manager; or • Approved modifications officially released by Tigercat.

Both of the above are provided that the work is carried out in the factory approved manner. Unauthorized modifications and/or repairs made or contributed to by a customer or a Tigercat distributor may result in creating a dangerous situation and therefore the customer or Tigercat distributor will be considered to have assumed the risk involved or be negligent in creating this situation. Tigercat will not be held responsible for situations arising from having created unauthorized modifications/changes to the structure.

Operator cabs are designed to ROPS, TOPS, FOPS, OPS standards so that they will withstand force and absorb energy during a roll over (ROPS), tip-over (TOPS), when resisting the impact of a falling object (FOPS) and minimize the possibility of operator injury from penetrating objects (OPS). When a permanent deflection of the structure occurs, the structure can no longer provide the original designed level of protection and should be replaced. Attempts to straighten the structure, particularly by the application of heat, can reduce still further the structures remaining capability to protect. The mounting and the frame or chassis to which the cab is attached is considered an integral part of the ROPS, TOPS, FOPS, OPS and is included in the design, test and certification of the product.

Contact the Tigercat Service department before attempting any modifications or repair to tip-over protective structures.