1 minute read

Removal and Installation of Take-up Roller

Warning ・ When loosening the grease cylinder check valve, loosen it a little at a time. ・ The pressure inside the cylinder is very high, so there is a danger of grease being expelled and the plug flying off. The check valve adjustment procedure should not be done in front of the check valve. ・ Do not get under the machine when the main unit is jacked up. ・ Make sure to place the main unit on wood planks or the like to prevent falling. ・ Align the shoe assembly feed location and stop the engine except when working.

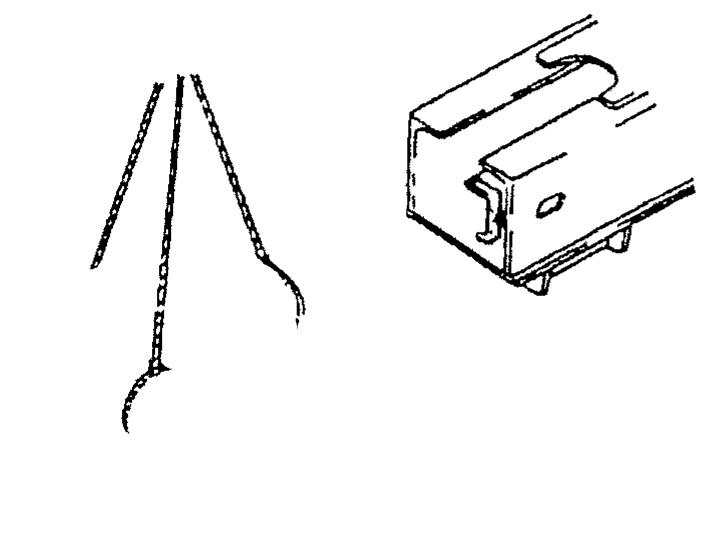

Items to prepare •Wrench (30 mm) •Hammer •Lifting equipment •Loctite #262 •Striking jig •Liftcrane •Crowbar •Wood planks, etc. •Rag 1.Removal of take-up roller [1] Remove the shoe assembly. See the "Removal and Installation of Shoe Assembly". [2] Use a crowbar (3) to pull off the take-up roller (1) from the side frame (2).

[3] Install the lifting equipment (4) on the take-up roller (1) and hang it from the side frame (2) with the liftcrane.

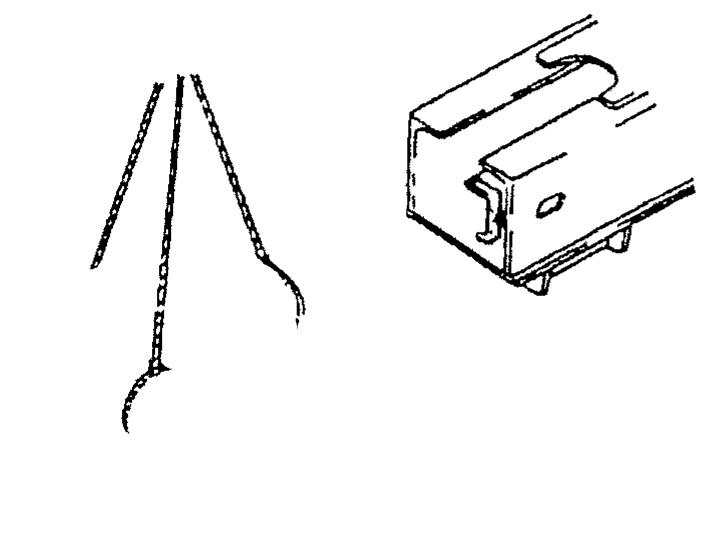

[4] Place the take-up roller (1) onto wood planks (6) as in the diagram. Use a wrench (30 mm) to remove the 4 bolts (5) of the take-up roller (1) and separate the take-up roller (1) and the grease cylinder (7).

2.Installation of take-up roller [1] Use a wrench (30 mm) to fasten the take-up roller (1) and grease cylinder (2) with the bolt (3). At this time, be sure to coat the bolt with Loctite #262. Tightening torque: 580 - 620 N•m

[2] Install the lifting equipment (6) on the take-up roller (1) as in the diagram, lift it up with the liftcrane, and insert it into the side frame (5).

Push in with the crowbar until the grease cylinder (2) contacts the recoil spring assembly.

[3] Install the shoe assembly.

For details on installation, see the "Removal and Installation of Shoe Assembly" procedure.

4 Wood plank