5 minute read

Removal and Installation of Engine Inter Cooler

from Sumitomo SH250-5 SH250-5LR Hydraulic Excavator Service Repair Manual WLSM2105-00W - PDF DOWNLOAD

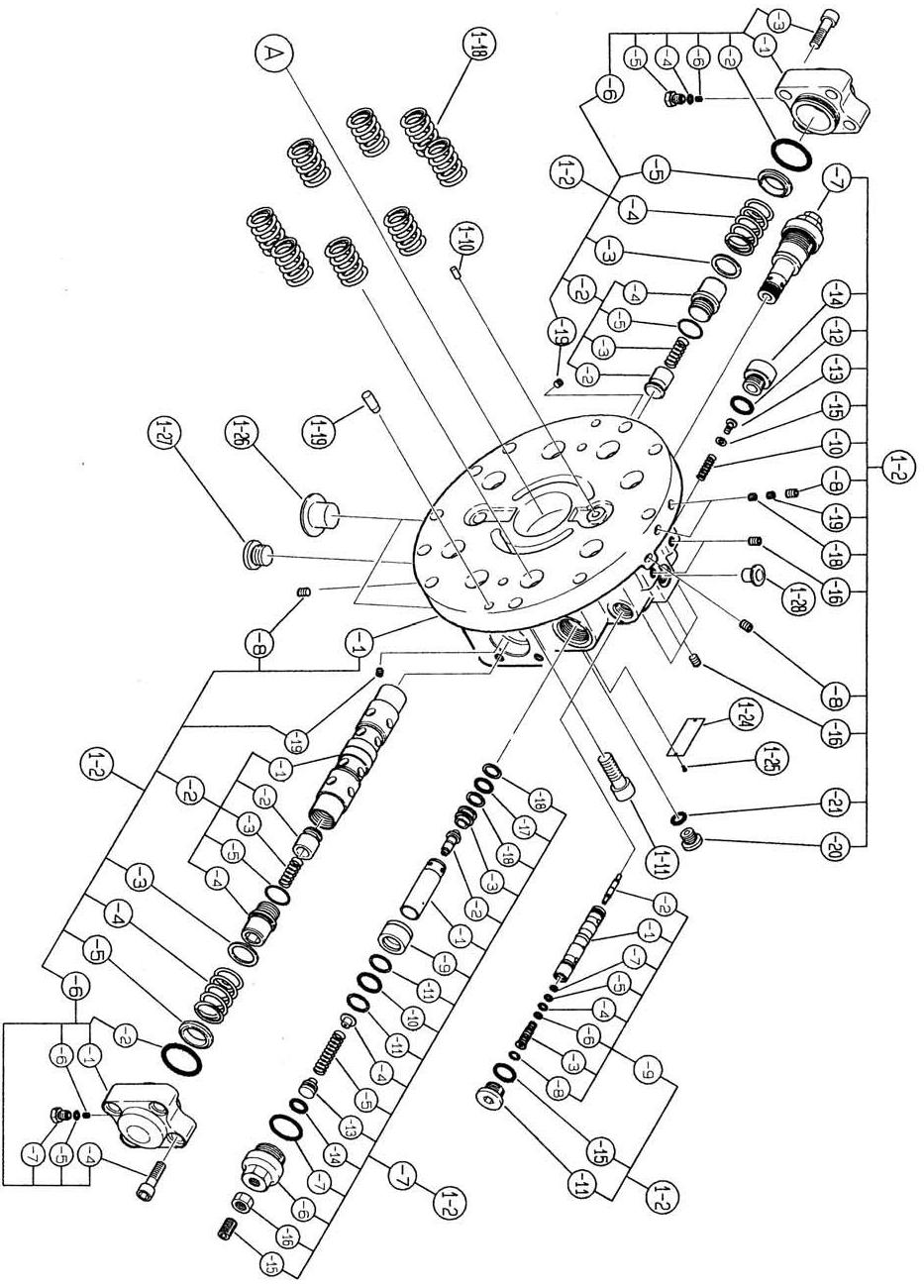

[5] 2-speed control function section troubleshooting

Problem

Will not switch to high-speed rotation Possible cause

Pilot pressure oil is not reaching the Ps port.

There is foreign matter caught between the spool and base plate, and the spool will not switch.

Switching to high-speed rotation occurs, but switching to low-speed rotation occurs if the hydraulic oil temperature increases.

Will not switch to low-speed rotation There is abnormal wear in the sliding sections of the 2-speed control piston section, and pressurized oil is leaking into the case.

The 2-speed control piston is not fit in place. Foreign matter is clogging the orifice in the 2-speed oil path, and pressurized oil is not reaching the 2-speed control piston. There is abnormal wear in the sliding sections of the 2-speed control piston section, and pressurized oil is leaking into the case.

Even if the speed control switch is set to low speed, the Ps port pressure does not decrease.

The 2-speed control valve spring is damaged. The 2-speed control valve spring is not fit in place. There is foreign matter caught between the spool and base plate, and the spool will not return.

Switching to lowspeed rotation occurs, but switching to highspeed rotation occurs during operation. Foreign matter is clogging the orifice in the 2-speed oil path, and pressure cannot escape from inside the 2-speed control piston chamber. The 2-speed control valve spring is worn and the switching pressure is reduced. Foreign matter is clogging the pilot line, and the pilot pressure increases up to switchover pressure due to leaking from the 2-speed control valve. Countermeasure and solution

After investigating whether pilot pressure oil is reaching the Ps port, investigate the causes of problems and countermeasures for each piece of equipment and perform inspection and repair. After performing disassembly and removing foreign matter, investigate the degree of damage according to the Maintenance Procedures and perform reassembly if reusing is possible. If reusing is impossible, perform replacement with the base plate kit. Perform disassembly and replace using the flange holder kit.

Attach the 2-speed pistons in the correct position. Perform disassembly and reassemble after removing foreign matter.

Perform disassembly and replace using the flange holder kit.

Investigate whether the Ps port pressure is 0.5 MPa or lower and recheck the line system. Perform disassembly and replace the spring after removing foreign matter. Attach the spring in the correct position.

After performing disassembly and removing foreign matter, investigate the degree of damage according to the Maintenance Procedures. Perform reassembly if reusing is possible. If reusing is impossible, perform replacement with the base plate kit. Perform disassembly and reassemble after removing foreign matter.

Perform disassembly and replace the spring. Clean the inside of the line and remove foreign matter. Also, recheck the line system.

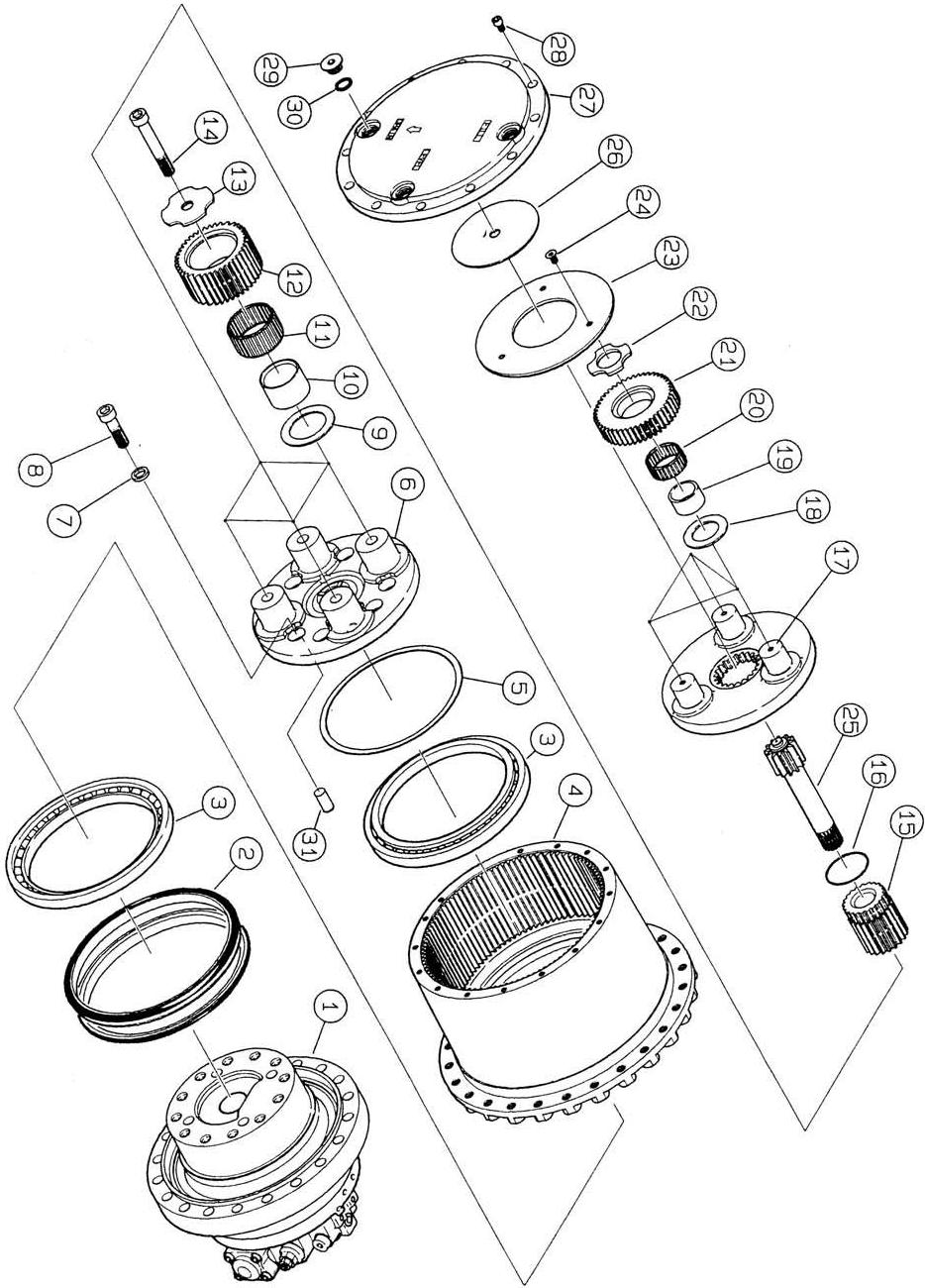

[6] Reduction gear troubleshooting

Problem

Rotation does not occur

Abnormal noise is coming from the reduction gear during driving.

The reduction gear section is heating up to an abnormal degree. Possible cause Countermeasure and solution

There is an operation problem in a piece of equipment other than the piston motor or reduction gear.

There is an operation problem in the motor aside from the reduction gear. A load exceeding the motor output torque is operating. The reduction gear angular bearing is damaged and will not rotate. After investigating whether pressure is reaching the motor inlet side, investigate the causes of problems and countermeasures for each piece of equipment and perform inspection and repair. See [1] - [5] in Troubleshooting.

After investigating the load, remove the load acting on the motor. Replace the reduction gear. Investigate whether an excessive external load is acting on the motor. If the external load is excessive, remove this load.

The gear inside the reduction gear is damaged and it will not rotate. The bearing inside the reduction gear is damaged and it will not rotate. The spline inside the reduction gear is damaged and it will not rotate. Replace the reduction gear.

The gear inside the reduction gear is damaged. Replace the reduction gear.

The bearing inside the reduction gear is damaged. There is abnormal wear on the sliding sections of the reduction gear and interference between parts is occurring.

Perform disassembly and check the status of damage. If damage is discovered, replace the reduction gear. In there are no parts that are especially damaged, replace worn parts and reassemble after cleaning. Reduction gear lubricating oil is insufficient. Check that there are no locations from which oil is leaking. Perform disassembly and check the status of damage within the reduction gear. If damage is discovered, replace the reduction gear. Fill with lubricating oil to the stipulated volume.

There is too much reduction gear lubricating oil. The bearing inside the reduction gear is damaged. An abnormal thrust load is occurring in the reduction gear due to inappropriate thrust plate selection. Adjust the lubricating oil amount to the stipulated volume. Replace the reduction gear.

Perform disassembly and check the status of internal damage. If damage is discovered, replace the reduction gear. If no especially notable amount of damage is discovered, replace the thrust plate with another one of the correct thickness.

Problem

Oil leaking is occurring Possible cause

There is looseness in fastening bolts on the reduction gear cover, and oil leaking is occurring.

Plugs for the oil fill, oil drain and oil check ports on the reduction gear cover are loose, and oil leaking is occurring. O-rings for oil fill, oil drain and oil check ports on the reduction gear cover are deteriorating, and oil leaking is occurring.

There is cracking in the housing and oil leaking is occurring. There is foreign matter caught on the sliding surface of the floating seal and oil leaking is occurring. Oil leaking is occurring due to corrosion on the sliding surface of the floating seal. The O-ring of the floating seal is deteriorated or damaged and oil leaking is occurring. The seal collar of the floating seal is split and oil leaking is occurring. Countermeasure and solution

Remove the cover, reapply liquid packing, and tighten the cover to the specified torque. Fill with lubricating oil to the stipulated volume.

Retighten the plugs to the specified torque. After tightening, fill with lubricating oil to the stipulated volume. Replace the O-rings for the plugs. After replacement, tighten the plugs to the specified torque and fill with lubricating oil to the stipulated volume. Replace the reduction gear.

Disassemble the reduction gear, remove foreign matter from the floating seal and perform reassembly. Disassemble the reduction gear and replace the floating seal.

10.Motor Repair Kit

See the attached Parts List for the contents of the repair kit.