4 minute read

PROPEL PROCEDURE

PROPEL PROCEDURE

Before beginning the propel operation, the operator should first inspect the travel route for large rocks, deep ruts, or uneven contours. When working on a grade, verify the slope and compare to the allowable maneuvering slope limits (see APPENDIX 5).

CAUTION: Do not attempt to maneuver or steer the machine on grades which exceed the allowable maneuvering slopes without consulting the special propel LIMITATIONS CHARTS AT THE END OF THIS SECTION. Failure to follow these instructions could result in a machine tip-over, damaging the equipment and resulting in possible serious injury or death.

The operator’s display terminal leveling/propel screen should be monitored during propel to make sure the allowable machine stability limits are not exceeded.

Once it has been verified that the travel route is in good condition, the machine is now ready to propel.

NOTE: The drill should only be propelled with the mast fully lowered, fully raised and locked, or locked at an ANGLE HOLE setting.

For long propels of 1,000 feet (304.8 meters) or more, or if the machine is to be propelled over grades which approach the allowable stability limits, the tool string should be disassembled, the rotary drive unit lowered, and the mast lowered. This achieves the most STABLE condition for a machine against tipping and also reduces stresses in the mast structure.

If while propelling with the MAST-DOWN and the HEAD-DOWN the drill starts to list, it will continue to list until the upper works contacts the pivotal axle. The machine will reach equilibrium when the upper works contacts the pivotal axle and WILL NOT TIP OVER. With the mast-down and the head-down, full listing will NOT cause the machine to tip over. The operator should attempt to propel toward a more level area on the bench to correct this condition.

All of the stability values shown are based on a fully loaded machine (i.e. full water tank, cable on cable reel, full compliment of specified pipe, all oils and operating fluids) as originally specified by the Customer and shipped by Bucyrus International, Inc.

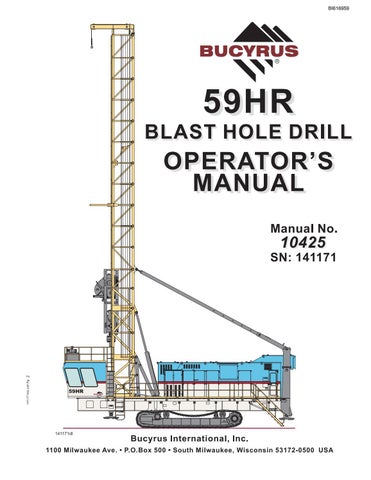

The 59HR is propelled using the controls on the operator’s console in the operator’s cab or radio controlled from the remote propel station outside the machine.

Operator Controls - Propel

1. Verify that the hoist brake is set. Verify that the tool string is clamped with the tool wrenches to prevent the tools from moving during the propel operation. Also, verify that the tool string is hoisted to a position to avoid striking the ground when the machine is propelled. Verify that the leveling jacks are fully retracted and that the dust curtains are fully raised. Verify that the boarding stair is raised.

2. Move the operating mode selector switch to PRIMARY PROPEL, SECONDARY PROPEL, or to REMOTE PROPEL. The remote propel is radio controlled.

3. Press the drill/propel control ON pushbutton. The automatic leveling/propel screen will appear on the operator’s display terminal. If the propelling is being done from the remote propel station, turn the enabling key switch to the ENABLE position.

4. At the control console or remote propel station, turn the propel selector switch to the SLOW SPEED position.

NOTE: There are two propel speeds available to the operator, slow speed and normal. For the inexperienced operator or for maneuvering in tight spots and in drill patterns, the SLOW SPEED setting allows for a more relaxed control operation.

When the operator becomes more proficient or when moving from one site to another, the increased speed of normal propel is used.

5. To propel straight forward lift up on both joysticks to unlatch them and release the propel brakes, then move both joysticks slowly forward. Speed is increased as the levers are moved forward. To propel straight in reverse pull both joysticks slowly to the rear. Speed is increased as the levers are pulled.

Propel - Forward or Reverse

6. To make a gradual forward right turn, leave the right joystick in neutral and operate the left joystick forward.

Propel - Gradual Right Hand Turn

Propel - Gradual Left Hand Turn

7. To make a gradual forward left turn, leave the left joystick in neutral and operate the right joystick forward.

8. Gradual turns should be done in steps of 15 degrees each. After turning the machine a maximum of 15 degrees, the machine should be propelled straight for about one-half of the length of the machine to clear the crawler belts of dirt and rocks. Turning the drill in more than 15 degree increments will subject the crawler belts to severe strain.

Propel - Counter-Rotation Left Hand Turn

9. To make a sharp right (counter-rotation) turn, push the left joystick forward and pull the right joystick to the rear. To make a sharp left turn, push the right joystick forward and pull the left joystick to the rear.

Gradual Turns - 15° Increments

CAUTION: ENSURE THAT THE TURN IS STOPPED EVERY 15 DEGREES AND THAT THE MACHINE IS PROPELLED FORWARD, OR REARWARD, AT LEAST TEN FEET PRIOR TO RESUMING THE TURN. MAKING GRADUAL TURNS WILL GREATLY EXTEND THE SERVICE LIFE OF THE TRACKS.

NOTE: When using the counter-rotation method for turning, have a helper available who can watch that the trail cable does not get fouled and/or torn from the main junction box or cable reel.

NOTE: The ability of the machine to turn sharply is dependent on the surface on which the machine is setting. A soft surface will cause the crawlers to dig in and machine to bog down.

NOTE: The propel brakes are released whenever either joystick is lifted from its mechanical neutral detent. The propel brakes are set when both joysticks are returned to their neutral detent and released.