2 minute read

LEVELING

2. To spool the trail cable onto the reel, turn the cable reel switch to the REEL IN position.

3. To spool the trail cable off of the reel, turn the cable reel switch to the REEL OUT position.

LEVELING

To level the drill, proceed as follows:

1. Place the machine in the proper location to drill the required hole. Verify that the leveling jack pads will rest on solid footing. Cut or fill or reposition as necessary to achieve solid footing. Maximum angle for jack pad is 17°.

2. The operating mode selector switch must be in the DRILL position and the main air compressor motor must be energized.

NOTE: Normally the machine will be leveled using the automatic leveling switch, Step 3. For manual leveling use Step 4 through 7.

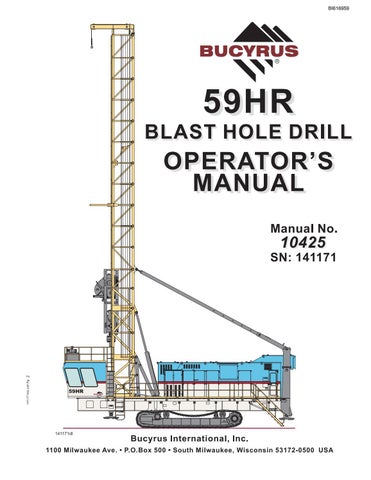

Machine Orientation

3. To level the machine automatically verify that the operating mode selector switch is in the drill mode, then turn the automatic leveling switch to the EXTEND position and hold the switch in that position. The Automatic Leveling/Propel screen will come on automatically on the operator’s

display terminal. Use the screen to monitor the drill as it is being leveled. The jack cylinders will extend and raise and level the machine. When the machine is raised and leveled, release the switch and it will spring return to the CENTER or OFF position. This procedure can be performed by the operator while he is seated at the main operator’s console.

4. To level the machine manually, use the four joysticks and the automatic leveling screen on the operator’s display terminal. The operator is seated at the control console as he operates the joystick controls and at the same time observes the operator’s display terminal screen.

5. Lower all four leveling jacks until they are resting on the ground. Then, starting with the low side (left or right) of the drill, slowly lower the jacks until the weight of the machine is resting on them. The leveling jack controls should be operated in pairs while doing this operation. This reduces the twisting of the drill frame. Once the weight of the machine is resting on the downhill side leveling jacks, slowly lower the uphill side levelling jacks until the machine weight is resting on them. The machine need not be raised a great deal during this operation, since the purpose is only to get the weight of the machine resting on the leveling jacks.

CAUTION: During this and subsequent leveling procedures, it is important that the drill stays as close to level as possible. Care should be taken especially when working on steep grades.

6. Once the machines weight is resting on the leveling jacks, the machine may be leveled. Starting with the downhill side of the machine, lower the two side leveling jacks to bring the machine into side-to-side level as observed on the operator’s display terminal screen. Then, once the machine is level from side-to-side, operate the leveling jack controls for the downhill end of the machine to bring the machine into level end-to-end as observed on the operator’s display terminal screen.

7. Once the machine is level, make sure that the weight of the machine is off of the crawlers. The preferred method of doing this is to raise the machine until the closest point of the lower rollers to the crawler belts is 2" to 7" (5.1 to 17.8 cm). This assures that the machine is resting on the leveling jacks while maintaining a low center of gravity.