8 minute read

1.5 Inspection & maintenance safety

1.5INSPECTION & MAINTENANCE SAFETY

A.READ CAREFULLY OPERATING / MAINTENANCE PROCEDURES

Incorrect maintenance may cause not only damages on the machine, but also injury. Make sure to read and fully understand the maintenance procedures and safety precautions described in the Instruction and Maintenance manual before performing any maintenance in this machine.

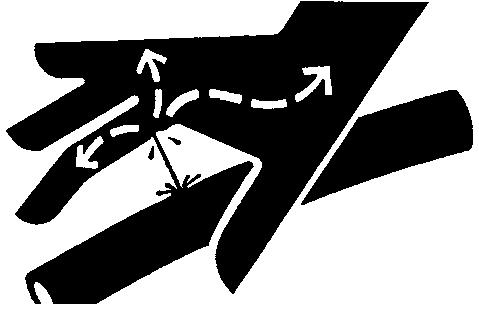

B.MEETING PRIOR TO WORK

Toprevent any accidents or injury due to errors, have a meeting before start working. When a flagman is provided, make sure that all signals are understood accordingly.

READ OPERATING PROCEDURES

C.ORGANIZE AND CLEAN UP WORKING AREA

Organize and clean up the working area.

Remove any obstacles and also remove any grease, oil, paint, broken pieces, etc., from the working area to avoid injury.

MEETING PRIOR TO WORK

F1458

CLEANING UP WORKING AREA

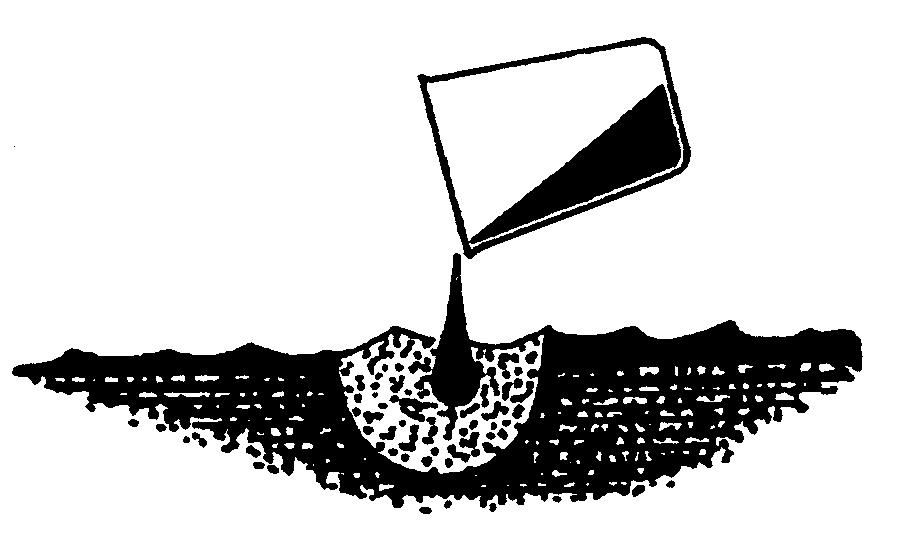

D."TAG-OUT" MACHINE

Before performing any inspection or maintenance procedures to the machine, fill out and post to the operator’s controls a "DO NOT

OPERATE" tag to warn persons not to start the machine. Also inform the supervisor and all operators that the machine is under inspection or maintenance and they will be informed when the machine is ready for normal operation.

O P E RA T E D O N O T

E.TOOLS & EQUIPMENT

Use the proper tools and equipment for the task at hand. Know the proper use of the tools and equipment before starting any inspection or maintenance procedures.

"TAG-OUT" MACHINE

F.SET THE ATTACHMENT

Always set the machine in the hydraulic oil check position on firm level ground before attempting any inspection or maintenance procedures to the machine. If it is not possible to put the machine in this position, secure the boom, arm and attachment to help prevent sudden movement. ALWAYS PLACE ATTACHMENTS

ON THE GROUND AND RAISE THE SAFETY

LOCK LEVER BEFORE LEAVING THE CAB.

G.CLEAN THE MACHINE

Keep the machine clean and free of debris, excess or spilled lubricants, fuel and fluids. Use approved solvents, detergents and water to clean the machine and its components on a regular basis. Be careful not to allow water to reach electrical components. Serious damage can occur to the electrical system by allowing water to reach the electrical components. Never clean inside of cab, or electrical components with pressurized water or steam.

USE PROPER TOOLS

F1479

BUCKET DOZER BLADE

HYDRAULIC OIL LEVEL CHECK POSITION

KEEP MACHINE CLEAN

F1462

H.STOP THE ENGINE

BE CERTAIN TO TURN ENGINE OFF AND

PLACE THE SAFETY LOCK LEVER IN THE

“LOCKED” (UP) POSITION before attempting any inspection or maintenance procedures to the machine. Failure to stop engine could result in serious bodily injury or death.

I. REFUELING

Move the machine to a well ventilated area for refueling. Use only specified fuel as described in the MAINTENANCE section of this MANUAL.

Immediately clean up all spilled fuel and dispose of properly. After refueling is complete, securely tighten fuel cap.

Never use the fuel for cleaning.

J.SUPPORT THE MACHINE

If it becomes necessary to raise the machine for inspection or maintenance, always support the machine by positioning the machine as shown in the illustration and use safety supports or blocks, with a sufficient capacity rating to support the machine, under the crawler/frame.

NEVER INSPECT OR PERFORM

MAINTENANCE PROCEDURES UNDER A

RAISED MACHINE THAT IS NOT

SUFFICIENTLY SUPPORTED.

K.HYDRAULIC PRESSURE

Under normal conditions, all circuits of the hydraulic system are under extreme pressure.

When inspecting for leaks, use a small piece of cardboard, wood or metal to locate leaks.

SMALL (PINHOLE) LEAKS CAN BE

DANGEROUS IF CONTACT WITH SKIN OR

EYES IS MADE. Wear approved safety glasses or face shield, gloves, hard hat, safety shoes and work clothes during all inspection and maintenance procedures.

Seek for immediate medical assistance if injury occurs.

F14407 F14406

STOP ENGINE / ENGAGE SAFETY LOCK LEVER

REFUELING

F1475

SUPPORT

BLOCK

SUPPORT THE MACHINE

F1471

F3636

CHECKING FOR HIGH PRESSURE LEAKS

L.PRESSURIZED FLUIDS & LUBRICANTS

Always release pressure from hydraulic reservoir, engine coolant, fuel system and all systems containing pressure before removing any caps or components. BE CAUTIOUS OF

HOT FLUIDS AND GASSES FROM SYSTEMS

ON MACHINES THAT HAVE JUST BEEN

STOPPED. ALLOW SUFFICIENT TIME FOR

SYSTEMS TO COOL BEFORE PERFORMING

ANY INSPECTION OR MAINTENANCE

PROCEDURES.

M.PAY ATTENTION TO EXHAUST GAS

Maintenance for the machine indoor or in the place with poor ventilation may cause poisonning by gas.

Pay special attention to ventilate any exhaust gas, fuel, cleaning oil, paint or similar articles.

Ensure proper ventilation to the working area when the machine is operated indoors. Provide a ventilating fan, if required.

N.PREVENTIVE MEASURE AGAINST FIRE

It is unavoidable to handle flammable materials such as battery, fuel, lubricating oil, etc. in a maintenance area; therefore, follow the general guidelines to prevent fire: • Use a nonflammable cleaning oil to clean the parts, etc. • Extinguish any bare fire possible to inflame. • Provide an appropiate fire fighting equipment such as fire extinguisher. • Refrain from smoking during maintenance work. • Put away any flammable materials when grinding work or welding work.

O.USE APPROVED WORK LIGHTS

Use only approved work lights when performing inspection and maintenance procedures to prevent possible fire or explosion. Certain types of work lights should not be used due to the possibility of ignition of certain flammable gasses and fluids from the machine.

F14397

RELEASE HYDRAULIC TANK PRESSURE

F1446

PAY ATTENTION TO EXHAUST GAS

PREVENTIVE MEASURE AGAINST FIRE

F1480

USE APPROVED WORK LIGHTS

P.DO NOT HEAT HYDRAULIC EQUIPMENT

OR PIPING

Never apply heat to hydraulic equipment or piping, such as welding, soldering, heating with torch, etc.

Heating of hydraulic components or piping will cause gas expansion, which can easily catch fire and/or explode.

Q.WORKING ABOVE GROUND

There exists danger of falling when working on areas above ground. Be careful not to approach edges. *Make sure to use the appropiate equipment, such as ladders or a manlift when working above ground. In addition, strap yourself to the proper equipment accordingly. • Avoid spillage of any oil or grease. • Do not leave any tools around the working area. • Use extreme caution to avoid slipping while walking. *Never jump into or from climbing equipment.

Use a step-ladder or handrail and securely maintain a three point contact while mounting or dismounting at all times. *Make sure to read the manlift equipment operator’s manual before using. *Comply with climbing equipment weight ratings.

R.DO NOT DROP TOOLS AND PARTS

Dropping of any tools and parts in the working area may cause injury or faulty machine operation.

Do not leave any tools or articles in the working area or component compartment. Make sure to store all tools properly when the work is completed.

DO NOT HEAT HYDRAULIC PIPING

F21544

TAKE CARE AT ELEVATED SPOT

S.ELECTRICAL SYSTEM

Before performing any inspection or maintenance to the electrical system, or performing any welding procedures, disconnect the negative (–) cables from the battery terminals. Not disconnecting the negative (–) cable could cause extensive damage to the excavator’s electrical system.

DO NOT DROP OFF TOOLS AND PARTS

WHEN REMOVING, REMOVE THE NEGATIVE TERMINAL FIRST

ELECTRICAL SYSTEM PRECAUTION

T.CAUTION TO MODIFICATION

The Manufacturer will not be liable for any injury or damages due to equipment modification without approval.

When any modification is intended, consult with your Dealer in advance.

U.AFTER COMPLETION OF MAINTENANCE

WORK

Always, make sure to check machine for proper functioning when any maintenance is completed: •After any maintenance work is completed, operate the engine at low idle, and check for leakages and abnormalities. •Slowly operate each machine function to confirm proper operation. •Increase the engine speed gradually, and again check for leakages and abnormalities. •Operate each operating lever normally to confirm smooth operation.

V.DISPOSE OF WASTE PROPERLY

Dispose of oils, fuel, coolant, solvents, filters, batteries etc. according to federal, state and local codes and regulations regarding hazardous waste disposal. Contact Local authorities for proper disposal methods of such materials.

CAUTION TO MODIFICATION

CONFIRM SMOOTH OPERATION

F1478

DISPOSE OF WASTE PROPERLY

W.GENERAL GUIDELINES FOR WELDING

Welding work must be performed by a certified welder with sufficient experience. In addition, safety practices must be followed by any personnel involved in such work. Identify all cracks to be repaired or areas to be welded by thoroughly cleaning the suspected surface, remove paint, and check with dye penetrant or magnetic particle testing. The life expectancy of the welded area depends on the work quality and the attention given to details during welding. •Avoid welding structures with surface temperature below 16 ºC (60 ºF). If needed, preheat surface to hand-touch. In cases where the machine components are extremely cold, it is recommended that the components be brought inside and allow them to warm to 16 ºC ~ 20 ºC (60 ºF ~ 70 ºF) for at least 12 hours prior to welding. •Remove paint from any surface to be heated or welded. Painted surfaces give off unhealthy gasses when heated or welded. Use mask and proper skin protection when removing paint from any surface. When removing paint sanding, do not breath the generated dust.

Make sure to use plenty soup and water to rinse the surface to be welded, since chemicals will generate unhealthy gasses when heated and/or welded.

WARNING

•Provide a fire extinguisher reachable at all times while performing grinding, heating, or welding. •Make sure to clean oil and/or flammable materials from any surface to be cut. •Protect all flammable parts and surfaces from sparks and/or flames. •Make sure to perform work in a well ventilated area. •Keep sparks and flames away from paint and/or solvent. •Keep sparks and flames from cylinder rods, seals, electrical wires, and/or hydraulic hoses.

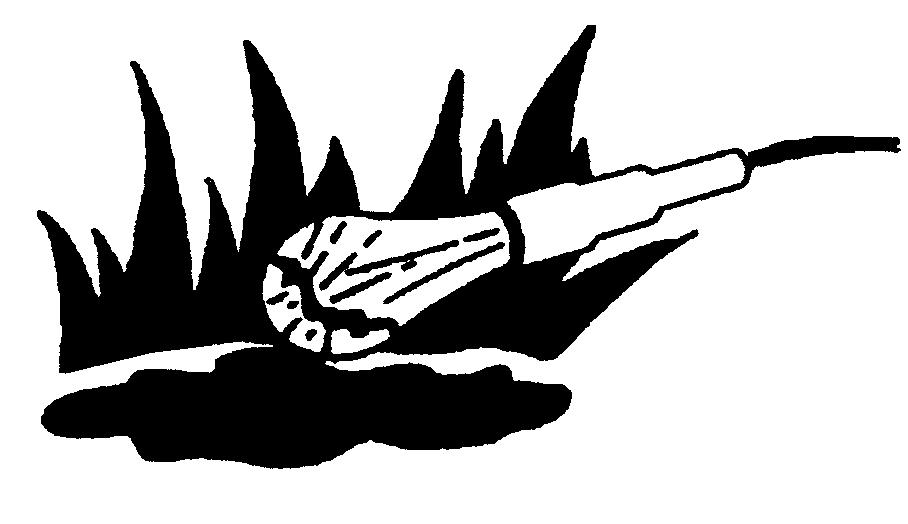

X.CRAWLER SHOE TENSION

The grease used to adjust the crawler shoe tension is under extreme pressure in the cylinder. Use extreme caution when adjusting crawler shoe tension. KEEP FACE, HANDS AND LEGS AWAY

FROM THE GREASE NIPPLE AREA. Carefully and slowly loosen the grease nipple when lessening crawler shoe tension. Never loosen grease nipple more than one complete turn.

Refer to Section “MAINTENANCE” for the procedures to adjust the tension on the crawler shoe.

F14399

USE CAUTION WHEN ADJUSTING CRAWLER

Y.PAYING ATTENTION TO BROKEN PIECES

WHEN HAMMERING

Flying particles may cause injury when hammering tempered parts, such as pin, edge, tooth, bearing, etc..

Wear protective clothes such as protective glasses, safety hat, etc. during maintenance.