4 minute read

Maserati Granturismo S

Refilling

Gearbox 3.1 litres SAE 75W90 which exceeds API GL4-GL5C API MT1-PG2 specifications Oil type Shell Transaxle 75W90.

Brake circuit Synthetic fluid NHTSA n.116 DOT4, ISO 4925, SAE J1703 –J1704, CUNA NC 956-01. SAE J1703, FMVSS No. 116 DOT 4 and ISO 4925 Shell Donax UB (DOT 4 Ultra) oil.

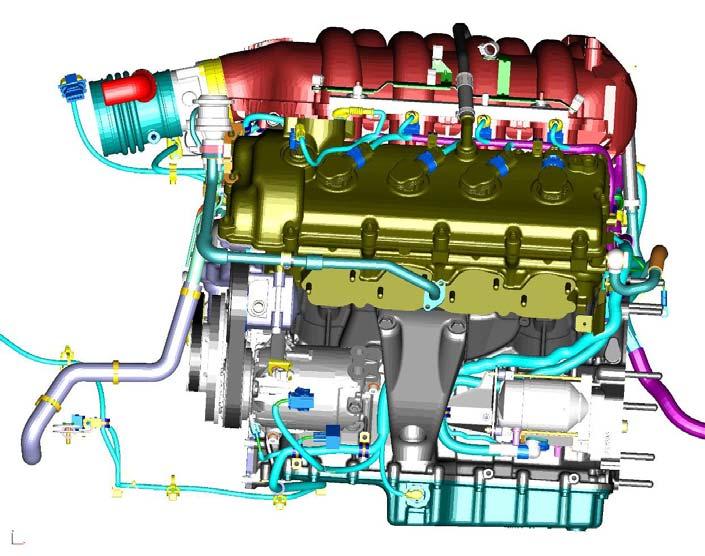

Engine

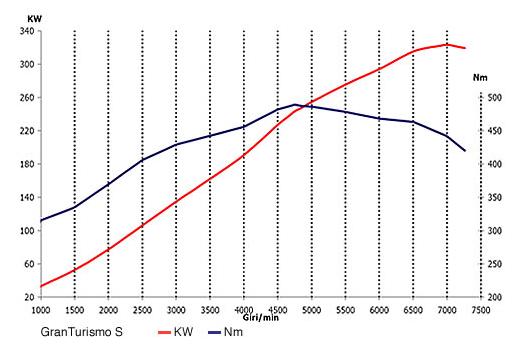

The maintechnicalinnovationon the Maserati GranTurismoS livesunder the bonnet, wherethe latestversionofthe newfamily of wet-sumppowerunitsisfitted; the new and more powerful4.7 litreV8 engineiscapableofdevelopingpoweroutput of440 HP at 7,000 rpmand peaktorqueof490 Nmat 4,750 rpm.

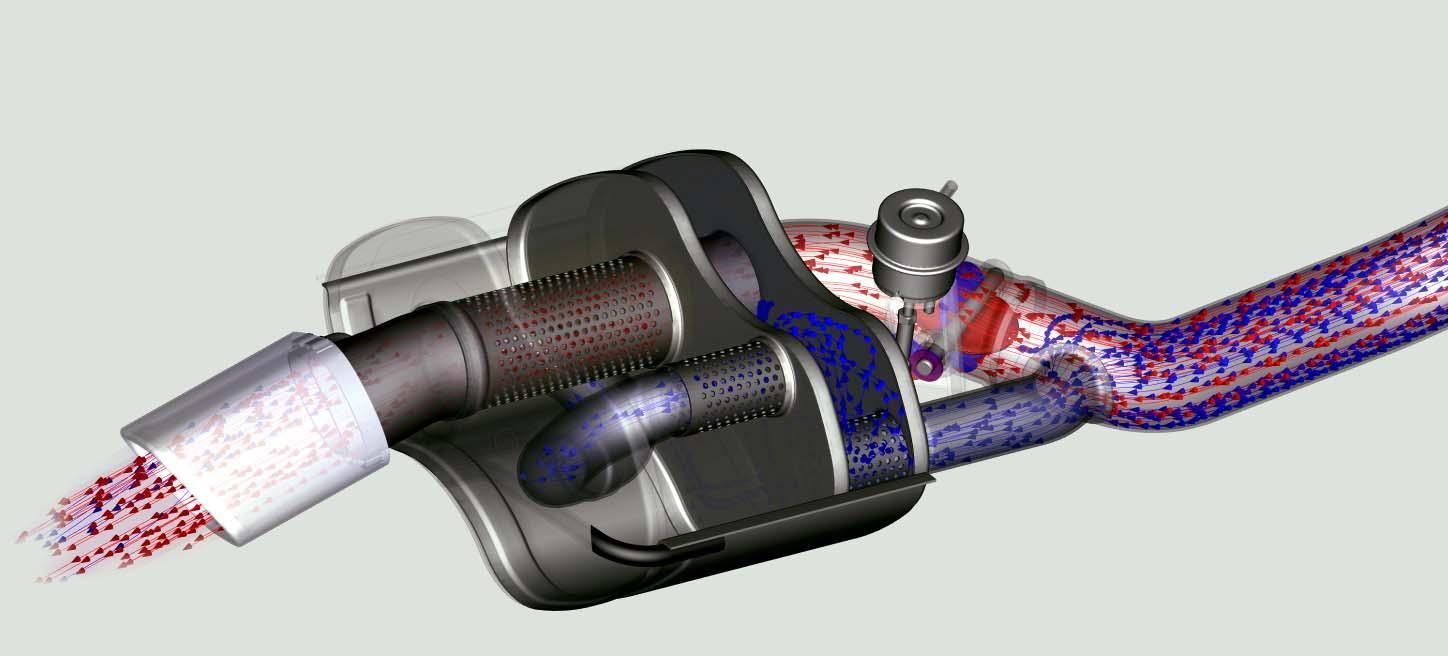

In keepingwiththe philosophyofthe mostrecentMaserati engines, the 4.7 litrepower unitadoptsa lubricationsystem withwetpaperelements, first introducedwiththe launchofthe Quattroporte Automatica, and alsoadoptedon the GranTurismowith automatictransmissionand nowappliedforthe first timeon a modelfittedwithan electro-actuatedgearbox.

Comparedwiththe previousdry sumpsolution, the wetsumpusesfewerpumpsto recoverthe oil and reducesoperatingnoiseconsiderably, tothe benefit ofdriving comfort and improvedbalancebetweencomfort and performance.

Recognisableon the outsidebythe redcylinderhead covers, the new4.7 L engine wasdevelopedspecificallytoincreasethe car's performance and providethe driver of the Maserati GranTurismoS withanevenmore exhilaratingdrivingexperience.

The newengineisreadytocomplywithfuture Euro-5 regulationsforEuropeand LEV2 regulationsforthe USA.

The engineon the Maserati GranTurismoS isaneight-cylinderV enginewitha 90° angle betweenthe banks; the displacementis4,691 cc. The timing hasfourchaindrivenoverheadcamshafts(two per bank), withfourvalvesper cylindercontrolledby hydraulictappets. The camshaftson the intakeside are fittedwitha low-pressure continuoustiming variator, withcomplete actuationtimesoflessthan0.15 seconds. The increasein displacementfrom4,244 cc to4,691 cc hasbeenobtainedby increasingthe bore and strokevalues. The mechanicalpart ofthe F136YE engineis derivedfromthe F136UC engine.

Crankcasein hardenedaluminium/siliconalloywithnewNikasil-steelcylinderliners. Bore increasedby2 mm to94 mm, strokeincreasedby4.7 mm to84.5 mm. New single-cast crankshaftin hardenedsteel, individuallybalanced, restingon fivemain bearings.

New auxiliary drive belt crankshaft pulley with reduced diameter(same as F136S engine) to match higher engine speed.

Also the following components have been redesigned: pistons, piston sealings, piston cooling oil jets, connecting rods, connecting rod bearings, lower crankcase part, sump, flywheel, engine timing cover.

Cylinder heads in hardened aluminium/silicon alloy with high volumetric and thermodynamic efficiency combustion chambers.

Four overhead camshafts (two per bank) and four valves per cylinder.

Intake valves Ø37.8 mm, lift 10.5 mm (without clearance).

Exhaust valves Ø31 mm, lift 9.3 mm (without clearance).

TIMING:

Timing controlled by chains whose tension is guaranteed by two hydraulic tensioners. Intake valves open at 15°ATDC / close at 68.6°ABDC(corresponding to 0.6 mm valve lift, VVT-actuator in rest position).

Exhaust valves open at 44°BBDC / close at TDC, cam lift 9.3 mm (corresponding to 0.6 mm valve lift).

Valves driven by Ø35 mm hydraulic tappets

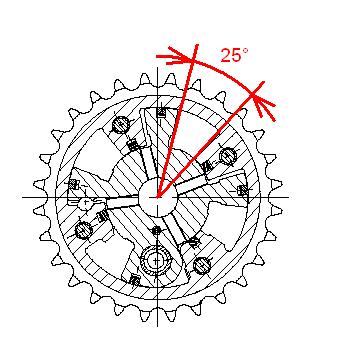

Intake Timing Adjustment F136ye

Rotate the crankshaftby 15° aftertop dead centre; thiscorrespondstoa strokeof 1.86mm ofthe pistonaftertop dead centre.

Checkthatthe downstrokeofthe tappet(whichbeganbeforethe TDC), consequently the opening ofthe intakevalve, is 0.60 ±0.08 mm.

Exhaust Timing Adjustment F136ye

Rotate the enginein a clockwisedirection and position the first pistonat TDC withthe camshaftsin a balancedsituation (exhaustclosedand intakeopen). Makesurethat the relative dialgaugeisset tozero.

Placethe tipofthe dialgaugeon the tappetofanexhaustvalve. The dialgaugestem mustbeplacedin a position whichisasperpendicularaspossiblewithrespecttothe tappetsurface.

Reset the dialgaugemeasuringthe shiftofthe exhausttappet.

Rotate the crankshaftin a clockwisedirection untiloneexhaustvalve isclosed.

Checkthatthe downstrokeofthe tappet, consequentlythe opening ofthe exhaust valve, is 060 ±0.08 mm.

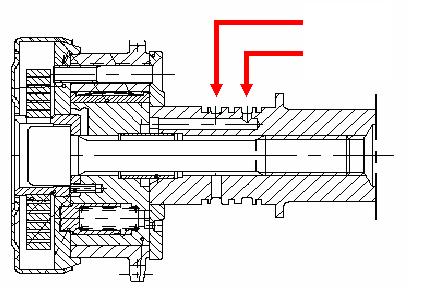

Variable Timing

Stepless, low-pressurevariablevalve timing system on intakecamshafts

The timing ofthe intakecamshaftscan be modifiedcontinuouslybetweenmaximum retardedand maximumadvancedposition. The VVT-actuatorhasanoperatingrange of25 degrees, correspondingto50 crankshaftdegrees.

Engine idling: intake timing is retarded. Late opening of the intake valves minimises valve overlap. This guarantees stable combustion and smooth idling.

Low and middle revs, medium to high load: intake timing is advanced. Early opening of the intake valves creates high valve overlap. Exhaustgases are partially reburned, which lowers combustion temperature and reduces emissions of NOx. Early closing of the intake valves at low revs improves volumetric efficiency.

High revs, full load: intake timing is retarded. Late closing of the intake valves improves volumetric efficiency as a result of the high inertia of the incoming air.

Note: when switching off the engine, the solenoid valve is brought back to the retarded position, this to make sure the VVT-actuator returns to its rest position, against the force of the internal spring.

Advancing channel Retarding channel

Locking pin

The harmonisation of the intake and exhaust geometry together with the use of continuous-action timing variators on the intake camshafts, optimisation ofthe combustion chambers and the engine calibration itself means that82% of torque can be obtained from 2500 rpm. This translates into exceptional pick-up capacity even with long gears, allowing comfortable driving on motorway journeys and, in general, the engine's full potential can be exploited over the entire operating range.

The cylinderheadsare alsomadeofaluminiumalloyand integrate the system carrying secondaryair intothe exhaustmanifoldstoobtainlow emissionlevels. Allthe conduits (water, oil, secondaryair) are madedirectlyin the enginecastingstocreate a highly rigid, space-savingsystem and providea strong guaranteeofqualityduringassembly, and hencehigh reliability.

Incorporatingthe ancillarysystems(water pumps) withthe engine's maincastingsand the highlyrigiddesign ofallthe wide-wallelementsresultsin low enginenoiselevels and high componentreliability.

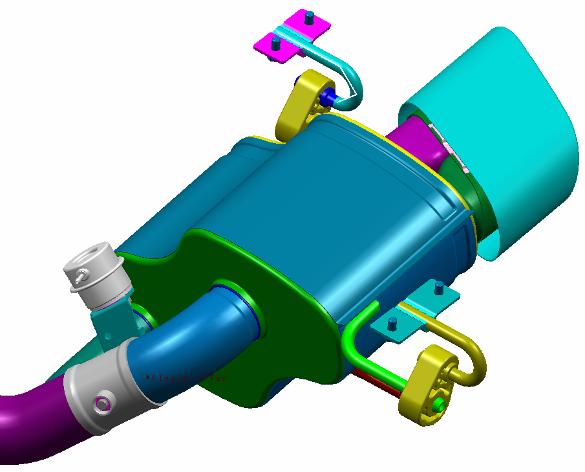

Lubrication

Lubricationisperformedbythe wet-sump system bymeansofanoil pumpintegrated intothe enginecrankcaseand relative strainer.

Total amountofengineoil (at ‘Max’referenceon dipstick): 9 L DifferencebetweenMIN and Max referenceon dipstick: 1.5 L

Cooling

The oil-water heatexchangerisintegratedintothe engineblock.

Coolantcirculationisactivatedbya centrifugalpump, whichisdrivenbythe camshaft bymeansofa poly-Vdrive belt.

Pump

Centrifugalwater pumpwithby-pass incorporatingthe thermostaticvalve.

Radiator

The water radiatorislocatedin the frontofthe enginecompartment. The electricextractionfansare locatedon the extractionhoodand are common tothe water radiator, AC condenserand hydraulicsteeringcoil.

Expansiontank

Locatedon the right-handside, the expansiontank isa modifiedversionofthe one foundon the Quattroporte.

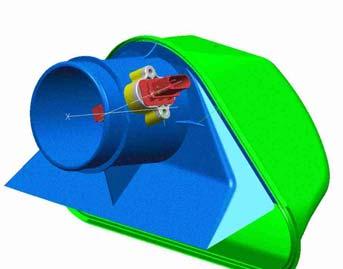

Externalair intakein raisedposition

The air isfedthroughtwoholes.

Air resonators

Locatedbetweenair flow meterand motor-driventhrottle

Intakemanifold

Madeofplastic.

Control

The controlconsistsofthe motor-driventhrottlebody and the acceleratorpedalwith sensor.

Linesbetweenexternalair intakesand filterbox

Sleeveswithminimum hydraulicdiameterof80 mm.

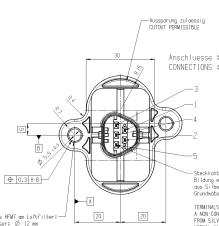

Air flow meter

New air flow measuringdevicewithoutgridforlaminar flow and differentconnection.

Exhaust

The Maserati GranTurismo S gives a voice to its 440 HP with a special sporty exhaust system, designed to emphasise the deep throaty growl of the new V8 engine, but also provide the level of on-board comfort expected from a GranTurismo. The steel exhaust system consists of two exhaust lines, one for each bank of cylinders, compensated with a central silencer. Two pneumatic valves, controlled electronically by the engine control unit and operated by the driver through the "Sport" button on the centre dashboard, are fitted close to the two rear silencers.

In aesthetic terms, the modified design of the two exhausts with dual oval chrome tailpipes make the new system instantly recognisable.

As on all Maserati models, the Maserati GranTurismo S adopts an exhaust system with metallic rather than ceramic catalytic converters. This solution reduces the density of the cells inside the catalytic converters and as a result lessens the section resistant to exhaust gas flow.