1 minute read

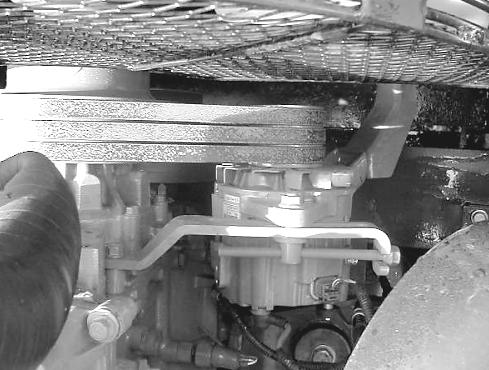

FAN AND ALTERNATOR DRIVE BELT

Service specifications

Visual check................................................................Every 10 hours or every day Check belt tension.........................................................................Every 250 hours

BD01E075 IMPORTANT: If the engine runs with the belt slack, the belt can slip in its housing and cause the engine to overheat or the battery to receive insufficient charge.

Tension adjustment

1 2

Tension check

1

CS98M560 Press the center of the belt, exerting a pressure of about 20 lbs (10 kg). The belt deflection should be about 1/4 to 1/2 inch (8 to 12 mm). NOTE: Check if there are any signs of wear damage to the pulleys or the belt. Check carefully to ensure that the belt is correctly positioned in the pulley grooves. If the belt is stretched, cracked or frayed, it must be replaced.

CS99A852 Loosen the mounting bolts (1). Use the adjustment screws (2) to move the alternator outwards until belt tension is correct. Tighten the alternator mounting bolts (1).

Replacing the drive belt

1 2

1

CS99A852 Remove the mounting bolts (1). Use the adjustment screws (2) to push the alternator inwards. Remove the worn belt. Install a new belt. Adjust the belt tension. Tighten the mounting bolts (1). Run the engine for about an hour and then check the belt tension again.