3 minute read

Safety instructions

Safety information for electrical system

Danger!

High voltage is still present on the excavator up to the main breaker 6kV when the machine is in standby by pushing button 6kV OFF from the cab. ALL ELECTRIC WIRES AND BOXES mounted on upper/undercarriage must be considered under voltage.

To disconnect totally the excavator, proceed with a lock and tag out procedure at the power station as follows: Locate power station supply and distribution. Stop excavator, disconnect excavator from the network at field switch. Check voltage presence on excavator supply line. Earth and short-cut the supply line. Lockout and tag out at field switch.

Open the connection box of the supply cable installation and use the lever on the inside to earth the uppercarriage. Close the connection box and keep the key in a safe place.

Always use adapted tools suitable for the voltage.

Workplaces should have a written lockout procedure for each machine, depending on your country, outlining:

A Safe Work Procedure has been developed by Liebherr-Mining Equipment Colmar SAS for its electrician personnel working on electric plant of an electric machine. This document is available in the Service Manual for information and must be adapted to your local electric regulations and procedures.

Some electric components (such as high voltage supply cable, transformers, motor windings...) store some residual electric power. Before working on electric circuit including such components, you must discharge these components to the earth.

Concerning work with voltage on electric system, Liebherr-Mining Equipment Colmar SAS recommends to lock and tag out (power OFF) at the supply station or at the field switch in case of any maintenance or work on electric risks areas. People must be trained and certified from their employer according to the electrical local regulations.

Safety instructions

Safety guidelines to connect and start-up this electric machine

Danger!

Never cross the extern limit distance of Danger Area with any tools or any body parts. The approach area can only be considered as the working area, in order to measure the voltage or check voltage presence. The area must be roped and tagged. Parts under voltage should be protected to avoid any electrifying.

The following figure illustrates the danger area A and the approach area B around aries DL and DV). Always observe local regulations concerning these areas according to the country you are working in.

Any job/maintenance at proximity of voltage must be done with all safety requirements presented in this ma

THERE ARE NO SHORT CUTS IN SAFETY!

2.6Safety guidelines to connect and start-up this electric machine

When connecting this machine to an electrical power source, as well as during the initial start-up, the following instructions and safety guidelines must be adhered to : all pertaining local, state and national standards, safety guideline, rules and regulations (such as ANSI, CIMA, DIN, IEC, INRS, ISO, NEC, NEMA, NF, OSHA, SAE, UL, VBG, VDE, EN, UTE, etc...) must be adhered to at all times. stallation, particularly connecting the machine to an outside power source and the start-up procedure must be performed by a qualified and certified personnel. operly protected against over-voltage and excessive current draw, short circuits and faulty ground. be switched off at the first fault (insulation, overcurrent, overload or ground fault) and this fault must be solved. m or component damage, the supply voltage of all three phase conductors must be nearly the same (equal). re must be of sufficient gauge (cross

Signs on the machine section). red and all fasteners and contacts must be clean and properly connected. ape and in good condition. Under voltage, they have to be carried with insulated gloves 6kV. moved. Immediately replace illegible, damaged or missing safety signs and decals.

These signs warn of electrical hazards. Proper precautions, attention and procedures are required to prevent accidental injury or death.

DANGER HIGH VOLTAGE

DANGER SUPPLY LINES FROM BELLOW ARE UNDER VOLTAGE

Never touch any electrical component under voltage. Always disconnect the main power source (circuit) before commencing with repairs.

Never touch any electrical component under voltage. Always disconnect the main power source (circuit) before commencing with repairs.

2.7Signs on the machine

2.7.1Introduction

The excavator comprises several types of signs: the safety plates provide warnings relating to dangers of accidents which could result in serious injury or death. the information plates indicate specific points relating to the operation, maintenance and characteristics of the machine. the nameplates are attached to components for which the machine serial number must be provided when ordering spare parts.

Danger!

Non-observance of safety plates can result in serious injury or death. Check warning plates regularly to ensure that they are complete and clearly legible.

Replace missing or illegible safety and information plates immediately. You will find the ordering numbers of these plates in the spare parts book of the excavator.

2.7.2Arrangement of signs

2.7.3Explanation of signs

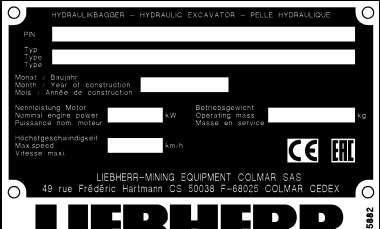

This typeplate gives the following information:

Plate 3: Typeplate LEC (Liebherr-Mining Equipment Colmar SAS)

This typeplate gives the following information:

Plate 4: Typeplate LAM (Liebherr America)

This typeplate gives the following information:

Plate 5: Typeplate LBR (Liebherr Brazil) "CE" / "EAC"

This typeplate gives the following information:

Plate 6: Typeplate LBR (Liebherr Brazil)

This typeplate gives the following information:

* Estimated mass of the machine in its standard version (without optional equipment) according to its configuration: Diesel, electric, backhoe, shovel or pontoon.

Plate 20: Danger signal label

Indicates to stay out of the surrounding operating area in order to avoid severe injury.

© Liebherr-Mining Equipment Colmar SAS 2020