3 minute read

Control and operation

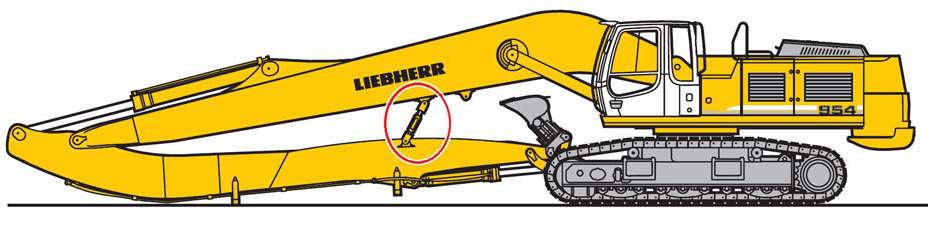

Hydraulic removable counterweight

Notice!

When an additional counterweight 8 is installed, the screws 12 are no longer accessible.

2 Main counterweight 12 Mounting bolts for counterweight

3 Counterweight shell 13 Mounting bolts for counterweight shell

8 Additional counterweight 18 Mounting bolts for additional counterweight 11 counterw. carrier frame 21 Mounting bolts for counterw.carrier frame

The mounting bolts 18 of the optionally mounted additional counterweight 8 must be torqued to::

Machine

Bolts 18: Number / Size - Quality4 X / M42 - 10,9

Tightening torque: N.m / (ft . lbs)4900 / (3640)

The mounting bolts 13 of the counterweight shell 3 must be torqued to

Machine modelR974C

Bolts 13: Number / Size - Quality4 X / M36 - 10,9

Tightening torque: N.m / (ft . lbs)3300 / (2430)

Note!

These screws must not be loosened when removing the counterweight. Their tightening torque must be checked at each reinstallation of the counterweight 2, and in any case every 1000 working hours.

The

Machine modelR974C

Bolts 21: Number / Size - Quality6 X / M42 - 10,9

Tightening torque: N.m / (ft . lbs)4900 / (3640)

Hinweis!

This screws are not accessible when the counterweight 2 is installed on the machine. They must not be loosened when removing the counterweight. Their tightening torque must be checked before each reinstallation of the counterweight 2

3.12Transport

Investigate the travel route.

Danger!

Drive with increased caution under obstacles, particularly electrical lines.

Respect the safety instructions and local circulation legislation.

If required, adapt the machine, its vehicle, the lifting gears and lashing materials to the restrictions about the load, the height, the length and the width of the convoy.

Make sure that the whole machine can be transported by checking the maximal authorized load of the vehicle.

When restarting the machine, proceed according to the operating manual instructions.

3.12.1Driving the machine onto the trailer

Have a signaller providing the necessary signs during the operations. Align the machine with the trailer.

Slightly raise the attachment and swing the uppercarrige to place the attachment on the opposite side of the truck tractor.

Fig. 3-151 Trailer under the machine

Lower the trailer and drive it between both undercarriage side frames.

Danger!

Avoid contact metal on metal.

Place sufficiently dimensionned wooden chocks between the trailer pan and the central part of the undercarriage.

Slightly raise the trailer pan up to the transport position. Check that the wooden chocks are correctly positionned. Lower the attachment on the trailer pan.

For the machines fiitted out with a Multi-User attachment:

–Retract the attachment and lower it on the pan trailer. The stick cylinder must not be extended at the stop.

–Attach the stick to the boom with the adjustable connecting rod. Secure with the beta pin.

Switch off the engine (or motor).

Turn the ignition key to the contact position (and in case of an electric machine, switch the machine on).

Relieve pressure lines by moving carefully the joystick several times in all directions.

Remove the ignition key (and in case of an electric machine, switch the machine off). Push the safety lever up.

Close and lock all doors, covers and panels on the machine.

3.12.2Lifting the machine with a crane

Danger!

The machine could slip or fall!

Employ only experienced personnel with the attachment of the load and the guiding of the crane operator.

Always wear work gloves when working with cables. Have another person guide and signal the operator during the operations. Never stand under the lifted machine!

Make sure suitable lifting equipment is available. The table below shows the forces that must be considered when choosing lifting gear for a standard machine, without counterweight nor attachment:

ModelF1

R 964 C600002000038504300

R 974 C79500180004117 4327 * 4600 min

P 974 C19700960040004120

* industrial attachment

Hin Note

Distance L aims that the lifting cables are vertical when seen from the machine side. Length H1 ensure an horizontal lifting position of the machine.

Preparatory removals

Lower the boom, retract the stick and bucket as far as they will go. Remove the working tool and the stick (see "Attaching and dismounting attachment parts").

Support the end of the boom on the ground.

Switch off the engine. Turn the ignition key to the position 0 (and in case of an electric machine, switch the machine on).

Relieve pressure lines by moving carefully the joystick several times in all directions.

Remove the ignition key (and in case of an electric machine, switch the machine off). Push the safety lever up.

Close and lock all doors, covers and panels on the machine. Remove the machine boom.

Remove the counterweight (with the additionnal counterweight if installed). See "Installing and removing the counterweight" or "Installing and removing the hydraulic counterweight".

Warning!

During lifting, loading on the trailer and transport of the counterweight shell take care that the telescopic cylinders don’t knock, push or support the weight of other components.