5 minute read

Preface

This operator's manual has been written for the operator and maintenance personnel of the diesel engine.

It contains descriptions for:

– Technical data

– Safety regulations

– Handling and operation

–Maintenance

The operator's manual is to be carefully read and applied before commissioning and later at regular time intervals by each person who is assigned to work with/on the diesel engine.

Work with or on the diesel engine is e.g.: Handling, Servicing, including maintenance, inspection. This facilitates familiarization with the diesel engine for the operator and prevents malfunctions due to improper handling.

You will understand that we cannot recognize warranty claims that arise due to

Liebherr will cancel all possible obligations undertaken by Liebherr and/or its dealers, such as guarantee commitments, service agreements etc., without prior notice if parts other than original Liebherr parts or spare parts purchased from Liebherr are used for maintenance and repair.

Under extreme conditions, more frequent maintenance than scheduled in the inspection plan can be required.

Changes, conditions, copyright:

– We reserve the right to make changes to technical details of the diesel engine

–Warranty and liability conditions of the general terms and conditions of Liebherr are not extended through the preceding information.

–Information and images in this manual may not be duplicated or distributed, nor used for competition purposes. All rights according to the copyright law are expressly reserved.

D9508A7 SCR with exhaust aftertreatment system SCR (selective catalytic reduction) / 2013140001

1.1 Technical description

1.1.1 Design

This section contains an overview of the diesel engine with names of the parts shown

1.1.2 Explanation of the type designation

Description

D9508A7SCREngine type designation

DEngine type: D = diesel engine

95Hole: 128 mm / stroke: 157 mm

08Number of cylinders

A7Injection system:A7 = Common Rail

SCRExhaust aftertreatment system: SCR Tab.

D9508A7 SCR with exhaust aftertreatment system SCR (selective catalytic reduction) / 2013140001

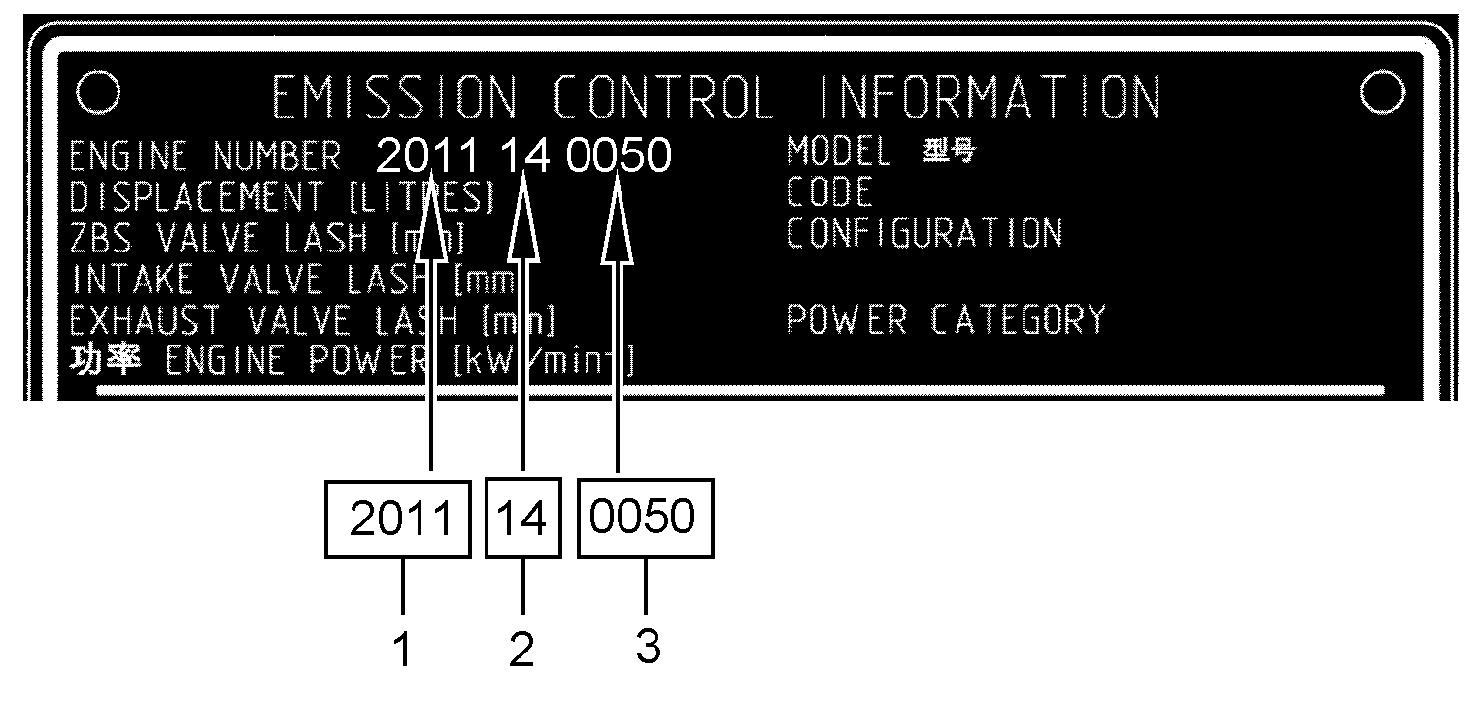

Diesel engine type plate

The diesel engine type plate is attached on the left crankcase side viewed from the the diesel engine).

Diesel engine number

1 Year

2 Number

3 Sequential number

D9508A7 SCR with exhaust aftertreatment system SCR (selective catalytic reduction) / 2013140001

D9508A7 with exhaust aftertreatment system (selective catalytic reduction) / 2013140001

D9508A7 SCR with exhaust aftertreatment system SCR (selective catalytic reduction) / 2013140001

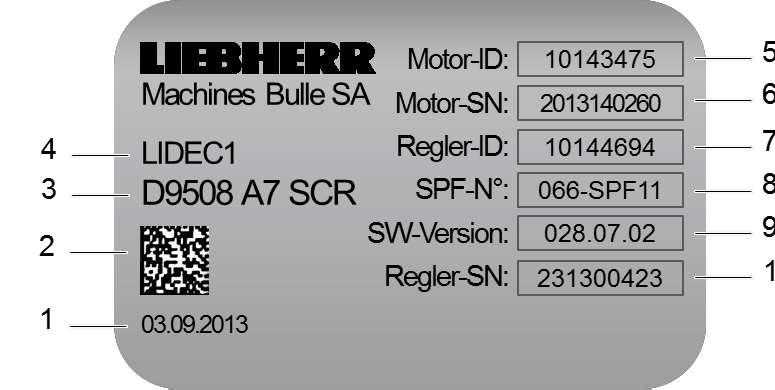

Enginecontrol unit type plate

Note The information on the motor control unit type plate corresponds to the delivery condition (ex works Liebherr Machines Bulle). Depending on may no longer be current. The actual information can be called up on the device display or read out by means of the Liebherr Sculi diagnostics and service tool.

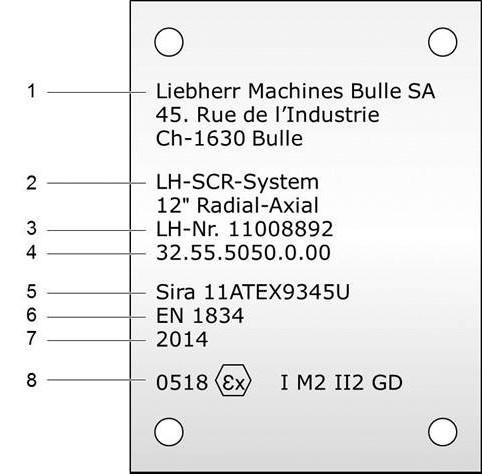

ATEX type plate

1.1.3 Design features

Diesel engine construction

Water-cooled, 8 cylinder V-diesel engine with common rail (CR) direct injection, exhaust gas turbocharging and charge air cooling.

D9508A7 SCR with exhaust aftertreatment system SCR (selective catalytic reduction) / 2013140001

D9508A7 with exhaust aftertreatment system (selective catalytic reduction) / 2013140001

D9508A7 SCR with exhaust aftertreatment system SCR (selective catalytic reduction) / 2013140001

Diesel engine characteristics

Arobust basic construction and generous dimensions form the basis for high operational safety and a long life. Minimal fuel consumption, low noise and exhaust emissions through a combustion process especially aligned to high demands. Minimal maintenance cost on easily accessible parts and a multitude of mounting diesel engine.

Driving gear

The 8 cylinder V-diesel engine has a 5-fold mounted, forged steel crankshaft with inductively hardened running surfaces and 6 bolted counterweights.Atorsional vibration damper is attached on the fan side to the crankshaft. Precisely forged cracked connecting rod, driving gear mounting system in leaded bronze, three-layer friction bearings or sputter bearings. Steel Monotherm piston with stage support and cooling channel. Replaceable, wet cylinder liners.

Crankcase

vermicular cast iron and a bedplate out of spheroidal graphite iron as the crankcase bottom. 4-valve single cylinder heads with a swirl duct and replaceable valve seat rings and valve guides. Flywheel housing, front ancillary support housing and oil pan on the bottom close the diesel engine.

Drive control

Two inlet and outlet valves per cylinder hanging in the cylinder head.Actuated through 5-fold mounted steel camshaft via roller tappet, push rod and rocker arm. Drive from camshaft, high pressure pump, fuel feed pump, air compressor and auxiliary hydraulic pumps from the crankshaft via case-hardened gear wheels on housing side.

Cooling

Thermostaticallycontrolledliquidcoolingwithcoolantpump.Individualsupplyofeach cylinderunitviadistributionchannelsmoldedinthecrankcase.Pistoncoolingthrough the cooling channel from the lubricating oil circuit of the diesel engine.

Lubrication

Pressure lubrication with two lubricating oil pumps for crankshaft, connecting rod and camshaft bearings as well as piston pin bushings, roller tappet and rocker connected to the diesel engine lubricating oil circuit.

D9508A7 SCR with exhaust aftertreatment system SCR (selective catalytic reduction) / 2013140001

Injection system

Electronic diesel engine control

The electronic diesel engine controller (EDC) is used for speed, spray start and torque regulation on the diesel engine.The EDC consists primarily of sensors and the control unit. Equipment on the diesel engine side and vehicle side is connected via cable harnesses to the EDC control unit.

Electronic sensors on the engine side

Charge air pressure sensor, fuel pressure sensor, rail pressure sensors, oil pressure sensor, temperature sensor for coolant and speed sensors are interfaces for external monitoring and control functions.The individual functions and error messages are described in the respective user documentation.

Mounting options for pumps

Mounting hydraulic pumps is possible on two auxiliary outputs.

1.1.4 Diesel engine special equipment

Diesel engine brake and auxiliary brake system

Air compressor

lubrication of the air compressor is connected to the corresponding circuits of the diesel engine.

Air conditioning compressor

The air conditioning compressor can be directly mounted to the diesel engine and can be driven via a magnetic coupling with a V-ribbed belt. When the air conditioning system is turned on, the magnetic coupling is active and the compressor works.

Cold package

are already integrated.

D9508A7 SCR with exhaust aftertreatment system SCR (selective catalytic reduction) / 2013140001

D9508A7 with exhaust aftertreatment system (selective catalytic reduction) / 2013140001

D9508A7 SCR with exhaust aftertreatment system SCR (selective catalytic reduction) / 2013140001

1.2 Technical data

1.2.1 Diesel engine

NameUnitValue

ConstructionV-diesel engine

Number of cylinders8

Firing order1-5-7-2-6-3-4-8

Holemm128

Strokemm157

DisplacementI16.16

Compression ratio21:1

Direction of rotation of the diesel engine left

Power groupLG1 to LG5

Power rating according tosee type plate

Rated powersee type plate

Rated speedsee type plate

Emission limitssee type plate

Diesel engine weight, drykg1530

1.2.2 Standard cylinder head

NameUnitValue

Valve clearance, inlet, coldmm

Valve clearance, outlet, coldmm

1.2.3 Cylinderheadwithengineauxiliarybrakesystem(ABS)

NameUnitValue

Valve clearance, inlet, cold

Valve clearance, outlet valve bridge / rocker arm, cold

Valve clearance, outlet valve bridge / counterholder, cold

D9508A7 SCR with exhaust aftertreatment system SCR (selective catalytic reduction) / 2013140001

NameUnitValue

Output (at rated speed of 1900 rpmand counter-pressure of 0.6 bar)

NameUnitValue

Start of opening°C82

Completely opened°C92 NameUnitValue

Current type 1A100

Current type 2A110

Current type 3A140 NameUnitValue

NameUnitValue

ConnectionSAE 1

3

NameUnitValue

Output at rated speed of 1900 rpm and 8 barl/min410

NameUnitValue

Transmission ratio1 : 1.303

Water-cooledyes

D9508A7 SCR with exhaust aftertreatment system SCR (selective catalytic reduction) / 2013140001

D9508A7 with exhaust aftertreatment system (selective catalytic reduction) / 2013140001

D9508A7 SCR with exhaust aftertreatment system SCR (selective catalytic reduction) / 2013140001

1.2.10 Knorr air compressor 720 cm3

NameUnitValue

Output at rated speed of 1900 rpmand 8 barl/min1040

NameUnitValue

Transmission ratio1 : 1.229

Water-cooledyes

D9508A7 SCR with exhaust aftertreatment system SCR (selective catalytic reduction) / 2013140001