6 minute read

IV. INSPECTION AND MAINTENANCE OF MAJOR PARTS

from Iseki Mower SXG323 326 Mower Decks SCMA54 SCMB48 SCMC48 Collectors SBC550X & 600X Operator's Manual

CAUTION:

• When servicing the lawn mower, place it on level, hard ground.

• Stop the engine and remove key from the starter switch.

• Apply the parking brake securely. (GE TYPE)

• Apply the parking lock securely. (E TYPE)

• Move the lift lever forward ( ) to lower the mower to the ground.

• Move the PTO lever to the STOP position ( ).

• Service the lawn mower after the engine has cooled down sufficiently.

With these items in mind, confirm the safety conditions for maintenance operation without fail beforehand.

1. INSPECTION AND REPLACEMENT OF BEVEL GEAR CASE

• Inspection of oil level in the bevel gear case a. Bevel gear case (Left-hand side) and (Right-hand side) : Remove the level plugs (2) located on the back side of the bevel gear case.

IMPORTANT: Check the oil level after every 50 hours of operation.

(Left-hand side)

(1) Bevel Gear case (Left-hand side) (3) Oil filler plug

(2) Level plug

(Right-hand side)

(1) Bevel Gear case (Right-hand side) (3) Oil filler plug

(2) Level plug b. Check to see if a small amount of oil overflows through the plug hole. If so, the level is normal. If not, replenish with gear oil SAE80 through the plug hole using an oil pitcher or the like.

Oil Gear oil SAE 80

Capacity Both bevel gear cases 300 cc (0.07 imp.gal.)

IMPORTANT: Before installing the level plug, be sure to wrap the threads with sealing tape without fail, or oil may leak through the plug.

• Replacement of oil a. Remove the level plug (2) and oil filler plug (3). Then drain all oil by tilting the gear case. b. Wrap the threads of the oil filler plug (3) with sealing tape and screw it in and supply with fresh oil through the level plug hole using an oil pitcher. c. Wrap the threads of the level plug with sealing tape and re-install it. d. Re-install the belt covers.

IMPORTANT: Replace oil after the initial 50 hours of operation and then after every 300 hours of operation.

IMPORTANT: All oil split on the gear case mount should be wiped off completely with cloth. If it is not, the belt may be smeared with oil and become slippery.

2. INSPECTION AND REPLACEMENT OF FRONT BELT

• Inspection of the front belt tension a. Remove the pulley cover (1) installed on the mower deck.

CAUTION: Never forget to replace all the removed covers.

• Replacement of the front belt a. Remove the pulley cover (1) installed on the mower deck. b. Loosen the nuts (8) of the tension rod and loosen the tension rod (7). c. Remove the front belt (4) and install a new belt.

IMPORTANT: • Be sure to install the belt as illustrated.

• An improperly installed belt will not work as expected but also may result in the belt breaking right away.

• Be sure to use the following ISEKI’s genuine belts:

SCMA54 8665-203-700-00 BELT/VCOGB038

SCMB48 8674-203-200-00 BELT/VCOGB035

(1) Pulley cover b. Inspect the front belt tension. Check if the front belt (4) is tensioned properly. When its tension is correct, the clearances between coils of the tension spring (6) should be 1.1 to 1.2 mm (0.04 ~ 0.05 inch)

SCMC48 8663-203-700-00 BELT/VCOGB036 d. Make sure that the belt is seated properly on the groove of each pulley and apply tension to it by expanding the tension, referring to the paragraph for “Inspection of belt tension.” e. Re-install the pulley cover (1).

CAUTION: Never forget to replace the removed pulley cover.

3. INSPECTION & REPLACEMENT OF BLADES

• Inspection of blades a phase position (Left-hand side) & (Right-hand side) a. Make sure that blade (Left-hand side)(1) and blade (Right-hand side)(2) are at right angles to each other.

(2) Input pulley (5) Output pulley (8) Nuts (3) Tension arm (6) Tension spring (4) Front belt (7) Tension rod

IMPORTANT: Stretch front belt (4) on a specified value with the tension rod (7) when the tension power of front belt (4) is insufficient because the down of the performance of the lawn mower.

• Inspection of front belt a. Remove the pulley cover (1) installed on the mower deck. b. Check the belt for damage and dirt. If it is smeared with oil or dirt, or wet with water, wipe it clean with a dry cloth. When damaged, install a new belt. b. When these blades are not at right angles to each other, straighten them by following ways.

• Inspection of blades a. Turn the mower deck upside down. b. Check the mower blades for deformation and damage.

CAUTION: When turning the mower deck upside down, take care not to hit or damage your feet by the mower deck.

(3) Bolt (M12) (6) Plate (8) Blade

(4) Spring washer (7) Shims (1.2) (9) Collar (blade)

(5) Washer (13X26X03)

1. Remove one of the bolt (3) of blade (8).

2. Remove the collar (9) assembly.

3. Install the collar (9) assembly so that blade (Left-hand side)(1) and blade (Right-hand side)(2) are at right angles to each other.

4. Fix wood between blade and mower deck to tighten the bolt (3)

Tightening torque: 1000 kg•fcm (72ft.lb)

5. After installing the blade, be sure to confirm that it has no trouble by turning the blade with hand.

DANGER: Do not touch the blade. Before handling the blade, put on the glove.

• Inspection for height of blades

a. Remove the bolts (3) from left-hand side blade and right-hand side blade (8), and then remove washer (4) (5), plate (6), blade (8), and shims (7).

b. Change the position of shims (7) to adjust the height of blades by putting shims (7) on the top or under the blades.

c. Make sure that the height for head of both blades is same.

CAUTION: 3 shims are equipped with each blade. Make sure that the number of shims for each blade is 3. If 3 shims is not equipped with each blade, it may result in break-down of blade and bevel gear case.

IMPORTANT: • If the blade ends have become round due to wear, enlarged clearance between blades leave uncut grass behind. The blade should be checked timely and worn ones should be replaced immediately. • Low cutting height or the operation just after soil has been applied will wear blades rapidly. The blades should be checked more frequently.

a. New Blade b. Blade with rounded edge c. Excessively worm blades are very dangerous. So replace such blades with new ones at once. c. The blade bolt should be tightened to the specified torque with the blades chocked respectively.

Tightening torque: 1000kg•cm (72 ft•lb) d. There are two kinds of blades for respective mower decks. Be sure to install blades in the proper positions. e. Connect the mower deck to the lawn mower properly, referring to the paragraph for “attaching and detaching the mower deck” at page 76 and 77.

DANGER: Be sure to use new bolts when replacing blade with new one.

IMPORTANT: Make sure that the blades are not in contact with the mower deck by turning them by hand.

4. INSPECTION OF GAUGE WHEELS

As the gauge wheels are installed on the rear ends of the mower deck, they are more vulnerable to being hit and deformed by obstacles than any other part. When a gauge wheel (1) does not turn smoothly or is deformed, replace it with a new gauge wheel immediately.

6. CLEANING OF MOWER DECK

a. Remove belt cover, and clear the grass and dust accumulated under the cover before operation, or shorter service life of the belts and damage to bearings and oil seals will be caused.

CAUTION: Be sure to replace the removed cover after cleaning.

(1) Gauge wheel

5. INSPECTION OF ROLLERS

Make sure that the rollers (1) turn smoothly.

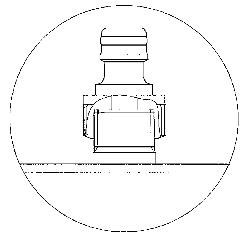

(1) Water hose plug (2) Plate

b. Before the use of water hose plugs (1), remove plates (2) from water hose plugs. Pour the water into mower deck from water hose plugs and turn the blade.

c. After mowing, clear the underside of the mower deck and blades of accumulated grass and dirt. Especially after operation in wet grass, wash them without fail, or accumulated wet grass and dirt will cause performance deterioration.

IMPORTANT: After the use of water hose plugs (1), return plates (2) to water hose plugs.

CAUTION: When pouring the water into mower deck to clean, be sure to lower the engine speed.

(1) Roller

IMPORTANT: • When the gauge wheels and rollers are hard to turn, disassemble them and clean them.

• After re-assembly, be sure to grease them sufficiently:

7. FILLING DIAGRAM

All the shafts mentioned below have a grease fitting on their end. Grease them up periodically. The gear case should also be serviced periodically for oil replenishment and replacement.

:Inspection, replenishment, and adjustment : Cleaning and washing : Replacement

IMPORTANT: • Above mentioned service intervals should be used as reference creteria. If working conditions are harder, earlier service is recommended.

• If special skill or special tool are required or you feel difficulty in maintenance, consult your dealer