12 minute read

II. ATTACHING AND DETACHING MOWER DECK

from Iseki Diesel Riding Lawn Mower SXG216 Mower Deck SCMA40 Collector SBC402X Operator's Manual - PDF

WARNING: When attaching or detaching the mower deck to the machine:

• Place the machine on level, hard ground.

• Apply the parking brake securely.

• Shift the PTO lever to the STOP ( ) position.

1. ATTACHING THE MOWER DECK

Attach the mower deck first to the machine and then connect the drive shaft.

■ INSTALLATION OF MOWER DECK a. • Remove the joint cover, (12). The lift lever (1) to raise the mower link in the highest position. b. Set the gauge wheels (3) of the mower deck in the lowest position (Refer to page 70). c. Before installing the mower deck, set the rear gauge wheels (3) sideways.

•Set the height adjust dial, (9) to the most lowest position.

(1) Lift lever(4) Rear link(7) Ring clip(10) Chute

(2) Mower discharge cover(5) Front link(8) Front wheel(11) Drive shaft

(3) Gauge wheel(6) Lock nut(9) Height adjust dial(12) Joint cover (13) Joint cover/mower d. Place the mower deck underneath the machine. e. Insert the discharge cover (2) of mower deck into the chute (10) of machine. f. Install the rear link (4) into the mower deck with pin. g. Install drive shaft (11) into the machine. h. Install the front link (5) into the machine and the mower deck. i. Pull the lift lever (1) to raise the mower deck. j. Set the gauge wheels (3) of the mower deck straightly.

Attach the joint cover, (12) (13).

IMPORTANT: •When installing and removing the mower deck, turn forward the height adjust dial (9) fully to lower the mower deck.

• After installing the mower deck, be sure that the ground clearance of the bottom surface of the mower deck is 135mm.

• When the mower deck is leaning to forward or backward, adjust length of the front link (5).

In case of leaning to forward: Make length of the front link (5) shorter In case of leaning to backward : Make length of the front link (5) longer

2. DETACHING THE MOWER DECK

Detach the mower deck in reverse order of attaching: Remove the drive shaft first and then the mower deck.

CAUTION: Be sure to disconnect the universal joint on the PTO shaft of the machine.

IMPORTANT: Be sure to keep the removed parts.

III. MOWER OPERATION

1. BEFORE OPERATION

CAUTION:

• Before starting mowing operation, be sure to equip ISEKI standard grass collector. Never mow the grass without the collector or the lawn mower scatters grass, stone and other flying debris, which is very dangerous.

• Become familiar with how to operate the lawn mower and understand safety instructions by reading this manual carefully.

• Make sure that all safety covers and guards are installed in position.

• Make sure that the blade bolts are tightened securely.

• Before moving the lawn mower into the working site, check the whole area and get rid of all obstacles such as stones, wood, empty tins, bottles, wires, etc in older to assure safe operation.

• Make sure that the mower operation will not cause any injury to children, animals, bystanders, or damage to trees, buildings, etc.

• Check the place to mow for bumps, ditches, mounds, steps, slopes, inclination, softness, water pools, etc. ahead of time to avoid accidents such as turnover, fall, side-sliding of the lawn mower.

2. CUTTING HEIGHT ADJUSTMENT

b.Select one of the setting holes to get the required cutting height, insert the pin, and retain it with the spring clip pin. The label showing the relationships between the setting holes and cutting heights is stuck on the mower deck.

c. Also set the cutting height of the gauge wheels by re-setting the setting hole for the setting pin with the spring clip pin removed.

d.The right and left gauge wheels should be set to the same cutting height.

e.Lower the mower deck by the lift lever.

CAUTION: Before operating the lift lever, be seated in the operator’s seat and make sure of the safety conditions when lowering the mower deck.

3. STARTING MOWING OPERATION

a.Start the engine and turn the throttle lever to the intermediate position between the low speed (t) and high speed (r) positions.

IMPORTANT: When engaging the PTO clutch, slow down the engine speed sufficiently for safety.

IMPORTANT: When the lawn mower moves backward with engaging PTO, reverse speed limits to 0.3 m/s.

CAUTION: Whenever you encounter any trouble with the mower, ask your dealer for repair immediately.

WARNING: b.Pull the lift lever to raise the mower deck. h.Turn the throttle lever to the high speed (r) position to raise engine speed. i. As the HST forward travel pedal is depressed gradually, the lawn mower starts to travel. c. Release the parking brake. d.Push down the HST forward travel pedal gradually to drive the machine into the working site. e.Release the HST pedal gradually to stop the lawn mower. f. Lower the mower deck by the lift lever. g.Shift the PTO lever to the ON ( ) position.

• As soon as the PTO lever is shifted to the ON ( ) position, the mower blades start rotating and eject cut grass or stones through the discharge opening. Consequently, before operating the PTO lever make sure that there is no people, animals, or physical properties like buildings, cars, etc. within a range where ejected grass or stones may reach.

• The mower blades should be turned only on turf or grassland with the mower deck lowered.

CAUTION: Be sure to start mowing at sufficiently low speeds and increase travelling speed gradually.

NOTE: Before starting the operation, be sure to set the rear gauge wheels to forward and lock it by inserting pin, to prevent from damaging the grass.

IMPORTANT: The screens of the air-intake openings provided under the steering wheel, and the radiator screen should be kept clean. Never keep on operating with clogged screens, or the engine may be overheated, which may result in engine seizure.

4. CLEANING A MOWER DECK AND CHUTE CLOGGED WITH GRASS

When mowed grass is not ejected from the mower deck or the mower chute is clogged, stop operating immediately and remove clogged grass.

When the discharge opening inside chute (3) is clogged: a.Shift the PTO lever to the OFF ( ) position and move the lift lever upper to raise the mower deck in the highest position. b.Move the dump lever (6) downward or push the dump switch (LAE-type) to dump the collector. c. Stop the engine and remove the key. d.Pull up the cleaning lever (4) and remove the clogged grass (8) in the chute (3). e.Depress the Bottom plate, (9) downward and remove the clogged grass in the front portion of chute. f. Scrape out the staying grass with the cleaning stick,(7).

DANGER: Stop the engine and remove the key before removing the clogged grass in chute and mower deck.

5. EMERGENCY STOP

• When any of the following abnormalities is encountered, stop the machine and mower deck immediately.

- Abnormal noise

- Abnormal vibration

- Abnormal smell

- Blade hitting an obstacle

- The machine hitting an obstacle

• The cause of trouble should be located and corrected immediately. If not, consult your dealer. Never attempt to keep on operating the machine without locating and correcting the cause of trouble. After striking a foreign object, inspect the mower for damage and make repairs before restarting and operating mower.

• When the operator leaves the seat, the safety system automatically stops the engine. When leaving the machine to remove obstacles such as twigs, pebbles, etc., the PTO lever must be shifted to the OFF position and the parking brake applied.

(1) Mower deck under plate(4) Cleaning lever(7) Cleaning stick

(2) Mower discharge cover(5) Cleaning plate(8) Clogged grass

(3) Chute(6) Collector dump lever(9) Bottom plate

6. STOPPING MOWING OPERATION

a.Release the HST pedal.

b.Turn the throttle lever to the low speed position (t) to reduce the engine speed.

c. Lock the brake pedal.

CAUTION: Park the machine on level, hard ground and make sure that the locking of brake pedal is applied securely.

d.Shift the PTO lever to the STOP ( ) position.

e.Turn the key switch to the STOP ( ) position to stop the engine.

IMPORTANT: •Never attempt to stop the engine abruptly when it is running at high speeds.

•Be sure to let the engine idle for about 5 minutes after long operation and then stop the engine. Abrupt engine stopping may lead to overheating causing seizure.

f. Remove the starter key without fail.

7. EFFICIENT MOWING

IMPORTANT: a. For mowing tall grass i. Mow grass twice. ii. When trying to finish in one pass, select a sufficiently slow travelling speed. It may also be required to set the cutting width to half or one-third of that for normal operation. b. For mowing highly moist grass or on wet ground i. If the turf damage by the tyres could result, wait until the grass and land have dried sufficiently. ii. Wet grass requires a higher grass cutting height setting than when mowing dry grass, as the cutting height is often lower than expected during operation. iii.Select a sufficiently slow travelling speed and avoid sudden starts, turns, and stops. If not, the turf may be damaged. c. For mowing low moisture content grass or when there is a lot of dead grass i. Advance should be in a direction where the dust does not hit the operator by taking into consideration the direction of the wind. ii. When the air-intake screens are clogged, clean them at once.

•Be sure to mow at full throttle (r).

•Choose an adequate traveling speed in accordance with the height or other conditions of grass to be cut.

•When the screens for the air-intake openings and radiator are clogged with dust, clean them at once. Never go on operating with clogged screens.

•Mowing is desirable when the grass is dew-free: in the afternoon or late afternoon, thus preventing the mower from heavy clogging.

•Always keep the mower deck clean.

•Check the blade ends for damage. (Refer to page 75 and 76.)

•Repeated mowing is recommended before the grass grows to high.

•Cutting grass too closely may damage the grass. To maintain a green lawn, never mow more than one-third off the height of the grass in a mowing.

•A slower travelling speed will result in improved mowing. Avoid selecting such a travelling speed that causes the machine to bounce.

•Short, fast turns will damage the turf. Slow down sufficiently when turning.

•Frequent sharpening of the mower blades results in beautiful finish and less load on equipment, which leads to economical operation.

First, mow the grass to a height low enough for the next finishing pass. Then finish to the desired grass height.

The second travelling pass should be shifted sideways by 20 cm (8 in.) or so, or travel perpendicular to the first passes, which will result in a beautiful even finish.

IMPORTANT: •When operating the machine in dusty circumstances, keep on paying attention to the coolant temperature warning lamp.

•Never continue operating when screens are clogged, or engine breakdown may result.

IV. INSPECTION AND MAINTENANCE OF MAJOR PARTS

CAUTION:

• When servicing the machine, place it on level, hard ground.

• Stop the engine and remove the starter key.

• Apply the parking brake securely.

• Push down (d) the lift lever to lower the mower to the ground.

• Shift the PTO lever to the STOP position ( ).

• Service the machine after the engine has cooled down sufficiently.

With these items in mind, confirm the safety conditions for maintenance operation without fail ahead of time.

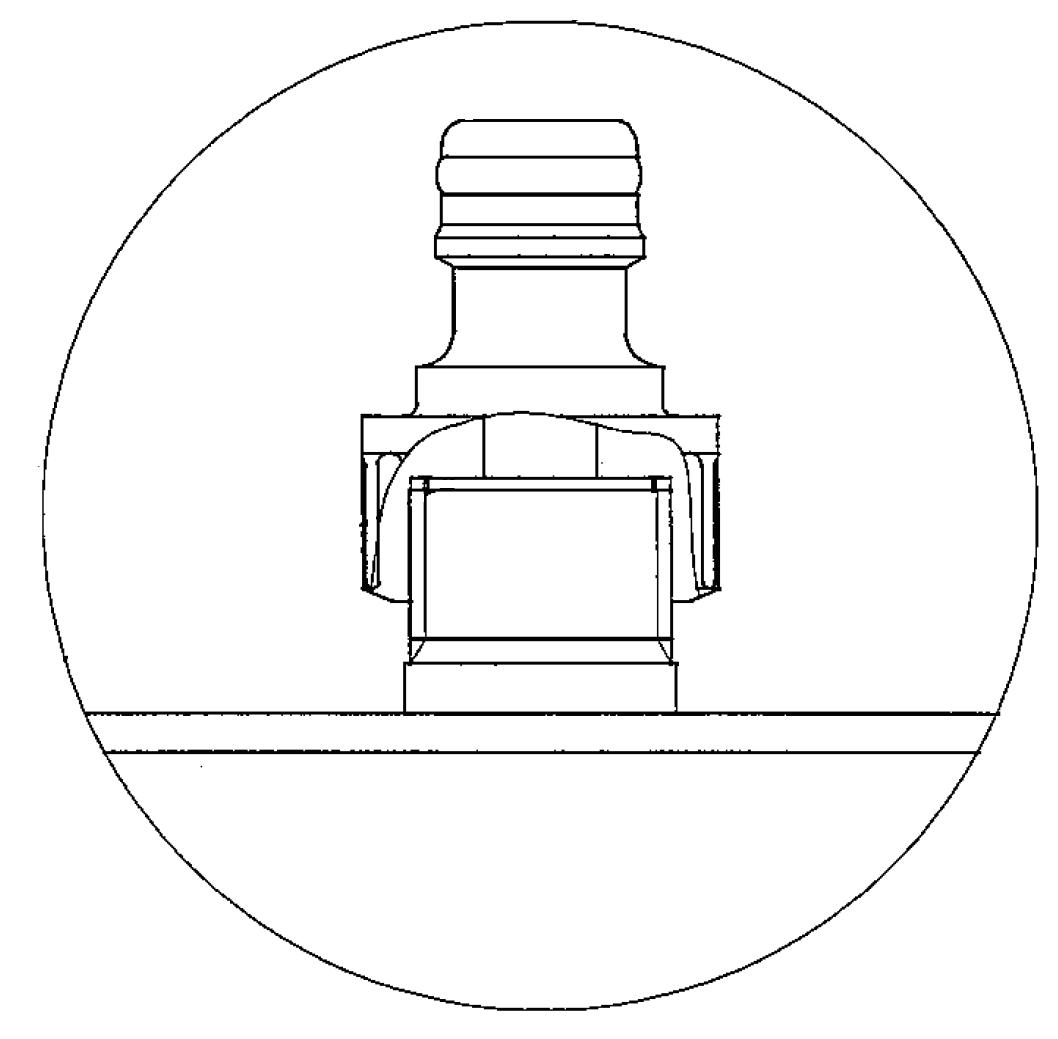

1. INSPECTION AND REPLACEMENT OF BEVEL GEAR CASE

• Inspection of oil level in the bevel gear case a.Bevel gear case (Left-hand side) and (Right-hand side) : Remove the level plug located on the side of the bevel gear case.

IMPORTANT: Check the oil level after every 50 hours of operation.

(Left-hand side) b.Check to see if a small amount of oil overflows through the level plug hole. If so, the level is normal. If not, replenish with gear oil SAE80 through the plug hole using an oil pitcher or the like.

OilGear oil SAE 80

Capacity Each bevel gear case 0.3 liter (0.07 imp.gal.)

IMPORTANT: Before replacing the level plug, be sure to wrap the threads with sealing tape without fail, or oil may leak through the plug.

• Replacement of oil a.Remove the level plug and filler plug. Then drain all oil by tilting the gear case. b.Supply a gear oil through the oil filler plug. c. Wrap the threads of the plugs with sealing tape and re-install them.

IMPORTANT: Replace oil after the initial 50 hours of operation and then after every 300 hours of operation.

IMPORTANT: All oil spilt on the gear case mount should be wiped off completely with cloth.

(1) Bevel gear case (LH) (3) Oil filler plug (2) Level plug

(Right-hand side)

(1) Bevel gear case (RH) (3) Oil filler plug (2) Level plug

2. INSPECTION & REPLACEMENT OF BLADES

• Inspection of blades for phase position Left-hand side & Right-hand side.

DANGER: Don’t touch the blade. Before handling the blade, put on the glove.

• Inspection for height of blades a.Remove the bolts(1) from left-hand side blade and righthand side blade(5), and then remove washer(2), plate(3), blade(5) and sims(4). b.Change the position of shims(4) to adjust the height of blade by putting shims(4) on the top or under the blade. c.Make sure that the height for head of both blade is same.

(1) Blade (Left-hand side)

(2) Blade (Right-hand side) a.Confirm that blade (Left-hand side) (1) and blade (Right-hand side) (2) are at right angles to each other. b.“When these blades are not at right angles to each other, straighten them by following ways.”

CAUTION: 3 shims are equipped with each blade. Make sure that the number of shims for each blade is 3. If 3 shims is not equipped with each blade, it may result in break-down of blade and bevel gear case.

• Inspection of blades a. Turn the mower deck upside down.

CAUTION: When turning the mower deck upside down, take care not to allow it to hit your feet.

(1) Bolt (M10)(3) Plate(5) Blade

(2) Washer(4) Shims (1.2)(6) Collar (blade)

1.Remove one of the bolts (1) of blades (5).

2.Remove the collar (6) assembly.

3.Install the collar (6) assembly so that blade (Left -hand side) (1) and blade (Right-hand side) (2) are at right angles to each other.

4.Fix the blade with mower deck by a piece of wood to tighten the bolt (1)

Tightening torque: 590 kgf•cm (43 ft. lbf)

5.“After installing the blade, be sure to confirm that it has no trouble by turning the blade with hand.” b. Check the mower blades for deformation and damage. a.New Blade b.Blade with rounded edge c.Excessively worn blades are very dangerous. So replace such blades with new ones at once.

IMPORTANT: •If the blade ends have become round due to wear, enlarged clearance between blades leave uncut grass behind. The blade should be checked timely and worn ones should be replaced immediately.

•Low cutting height or the operation just after soil has been applied will wear blades rapidly. The blades should be checked more frequently.

4. INSPECTION OF ROLLERS

Make sure that the roller turns smoothly.

c. The blade bolts should be tightened to the specified torque with the blades chocked respectively.

Tightening torque: 590 kg•cm (43 ft. lb)

(1) Front roller (2) Gauge wheel (3) Water hose plug (4) Plate

IMPORTANT: •When the wheels and rollers are hard to turn, disassemble them and clean them.

•After re-assembly, be sure to grease them sufficiently:

5. CLEANING OF MOWER DECK

(1) Blade (2) Bolts (M10) (3) Wood d.There are two kinds of blades for respective mower decks. Be sure to install the blades in the proper positions.

DANGER: Be sure to use new bolts when changing blades.

IMPORTANT: Make sure that the blades are not in contact with the mower deck by turning them by hand.

Parts code Punched ID

Left8670-306-001-20 I 8670 A a.Remove shaft cover, and clear the grass and dust accumulated under the cover before operation, or damage to bearings and oil seals will be caused. b.Before the use of water hose plugs (3), remove plates (4) from water hose plugs. Pour the water into mower deck from water hose plugs and turn the blade.

CAUTION: Be sure to replace the removed cover after cleaning.

SCMA 40

Right8670-306-002-20 I 8670 B e.Connect the mower deck to the machine properly, referring to the paragraph “attaching and detaching the mower deck” at page 68.

3. INSPECTION OF GAUGE WHEELS c. After mowing, clear the underside of the mower deck and blades of accumulated grass and dirt. Especially after operation in wet grass, wash them without fail, or accumulated wet grass and dirt will cause performance deterioration.

As the gauge wheels are installed on the rear ends of the mower, they are more vulnerable to being hit and deformed by obstacles than any other part. When a wheel does not turn smoothly or is deformed, replace it with a new gauge wheel immediately.

IMPORTANT: After the use of water hose plugs (3), return plates (4) to water hose plugs.

CAUTION: When pouring the water into mower deck to clean, be sure to lower the engine speed.

6. FILLING DIAGRAM

All the shafts mentioned below have a grease fitting on their end. Grease them up periodically. The gear case should also be serviced periodically for oil replenishment and replacement.

Ref.

pointsLubricants Quantity : litres (lmp. gal.)

1Bevel gear case (Left-hand side)Gear oil SAE 800.3 (0.07)

2Bevel gear case (Right-hand side)Gear oil SAE 800.3 (0.07)

3Drive shaft Grease

Inject until grease overflows

4Gauge wheel As required

5Front roller As required

6Drive shaft

Bolls

Pins and clips

There should be no loose ones. -

There should be no lost or deformed ones. -

IMPORTANT: • Above mentioned service intervals are for normal usage. If working conditions are harder, earlier service is recommended.

• If special skill or special tool are required or you feel difficulty in maintenance, consult your dealer.