15 minute read

VOLTS 20 VOLTS 26 VOLTS

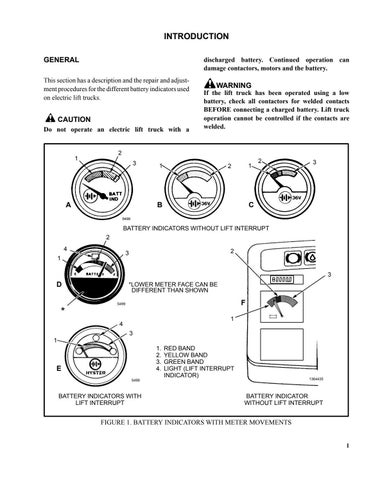

INTRODUCTION

GENERAL

This section has the description and repairs for the brake system. These parts include the park brake, service brake and master cylinder, the disassembly and assembly of the service brakes and the park brakes. The electrically released park brake is also described in this section. Checks and Adjustments are described at the end of this section.

DESCRIPTION

The J30XMT, J35XMT, J40XMT, J1.60XMT, J1.80XMT and J2.00XMT lift trucks feature dual hydraulically operated service disc brakes and mechanically operated park disc brakes. Both brake systems operate independently of each other although they both use a single disc mounted on the bevel gear shaft of the transaxle for braking. The location provides a mechanical advantage for effective braking. The service brake master cylinder and separate reservoir are sealed. The reservoir has a level sensor connected to a warning light in the instrument panel, which displays when the brake fluid is low. The service brake is actuated by the large pedal located in the operator’s compartment. The pedal can be operated with either the left or right foot. The park brake is set by a pedal operated by the operator’s left foot. The park brake is released by operating the release lever located on the left side of the instrument panel. Both a warning buzzer and indicator light are used to remind the operator to set and release the park brake.

The lift truck may also be furnished with an optional electrically operated park brake. When furnished, the park brake applies when the operator leaves the seat of the lift truck. The park brake mechanism is attached to the park brake linkage at the front of the lift truck and replaces the standard park brake linkage.

REPAIRS

SERVICE BRAKE PADS (See FIGURE 1 and FIGURE 2)

Removal

To access the brakes, the mast and carriage must be raised and a safety chain installed. Follow the instructions in section PERIODIC MAINTENANCE, 8000 SRM 528or 8000 SRM 584, SAFETY PROCEDURES WHEN WORKING NEAR THE MAST.

1.Move the lift truck to a safe, level area. Block the tires. Raise the carriage high enough to chain the carriage so that it does not move. Disconnect the battery.

2.Remove the capscrews retaining the disc brake shield and remove the disc brake shield.

3.Remove the spring clips retaining the pins on both ends of the service brake caliper. 4.Remove the pins and the brake pads.

NOTE: The original brake pad installed in the carrier side of the service brake is affixed to the carrier side with hot glue. Use a screwdriver to pry the pad from the carrier side. Clean the carrier side before installing a replacement pad.

Installation

1.Install the brake pads in both the carrier side and the cam side of the caliper.

2.Install the pins to retain the pads.

3.Install the spring clips to retain the pins.

4.Install the disc brake shield.

5.Remove the air from the brake system. See REMOVE AIR FROM BRAKE SYSTEM.

6.Connect the battery. Remove the safety chain and lower the mast. Remove the blocks from the tires.

5

10

11 12 13

9 11

7

1.BRAKE SHIELD 2.CAPSCREWS 3.WASHERS 4.BRACKET 5.SCREW 6.SERVICE BRAKE CALIPER 7.NUT 8.RETAINER PIN 9.SPRING CLIP 10.BUSHING 11.WASHER 12.PARKING BRAKE CALIPER 13.BRACKET 5

4

1 6

3

2 10

8

7

FIGURE 1 – SERVICE BRAKE ARRANGEMENT

SERVICE BRAKE CALIPER

Removal

To access the brakes, the mast and carriage must be raised and a safety chain installed. Follow the instructions in section PERIODIC MAINTE-

NANCE, 8000 SRM 528 or 8000 SRM 584, SAFETY

PROCEDURES WHEN WORKING NEAR THE MAST.

1.Move the lift truck to a safe, level area. Block the tires. Raise the carriage high enough to chain the carriage so that it does not move. Disconnect the battery.

2.Remove the capscrews and lockwashers retaining the disc brake shield and remove the disc brake shield. 3.Disconnect and cap the hydraulic brake lines to the service brakes. Cap the ports of the service brake to prevent dirt from entering the system.

4.Remove the last two capscrews and lockwashers retaining the service brake bracket to the transaxle. Remove the bracket containing the service brake assembly from the brake disc.

Installation

1.Align the service brake assembly with the brake disc and align the service brake bracket with the transaxle housing.

2.Install the service brake housing and the disk brake shield to the transaxle housing using the three capscrews and lockwashers. Tighten the capscrews to 41 N m (30 lbf ft).

1

5 4 3 2

13

6

1.INSERT 2.PISTON 3.DUST COVER 4.PISTON SEAL 5 7 8

5.BLEEDER SCREW 6.RETAINER PIN 7.BUSHING 8.SPRING CLIP 9

FIGURE 2 – SERVICE BRAKE CALIPER

3.Check to see that the service brake assembly slides freely within the mounting bracket. If the brake does not move freely, loosen the two nuts that hold the brake assembly together. Tighten the nuts to 19 N m (14 lbf ft) and check again for free movement. The service brake must be free to float.

4.Remove the caps from the service brake assembly and the hydraulic brake lines and connect the lines to the brake assembly. It may be necessary to bleed the air from the system.

5.Bleed the air from the brake system.

6.Install the disc brake shield between the transaxles, using the four capscrews and lockwashers.

7.Remove the safety chain and lower the carriage to the floor. Remove the blocks from the tires and connect the battery. Check the level of brake fluid. Check the operation of the service brake before returning the lift truck to service.

10 12 11

9.DISC PAD 10.CARRIER 11.CAPSCREW 12.WASHER 13.LOCKNUT

Disassembly

1.After the service brakes have been removed from the lift truck, remove the two nuts retaining the brake caliper halves together. 2.Remove the spring clips retaining pins on both ends of the brake caliper and remove the discs. Separate the brake halves, by removing the capscrews and spacers.

3.Remove the dust cover, piston and piston seal from the caliper.

Cleaning solvents can be flammable and toxic, and can cause skin irritation. When using cleaning solvents, always follow the recommendations of the manufacturer. Wear eye protection.

DO NOT use an oil solvent to clean the brake caliper. Use a solvent approved for cleaning of brake parts. Do not permit oil or grease in the brake fluid or on the brake components or the brake pads.

4.Clean and inspect the piston and the caliper bore for scores, erosion, or pitting. Replace the piston if any of these conditions are noted. The caliper should not be honed. Replace the complete assembly if these conditions are noted.

5.Measure the brake disc pads. The minimum measurement for the pads is – 0.76 mm (0.03 in). Replace the pads if necessary.

Assembly

1.Lubricate a new piston seal with clean brake fluid and install the seal onto the piston. Assemble the piston into the brake caliper bore. Install a new dust cover.

2.Install the capscrews, spacers and nut to hold the caliper halves together. Do not tighten the capscrews and nut completely until the brake assembly is installed. See INSTALLATION–SERVICE BRAKES.

3.Align and install the pins and the brake discs in the brake assembly. Install the spring clips to retain the pins.

PARK BRAKE CALIPER (See FIGURE 3)

Removal

To access the brakes, the mast and carriage must be raised and a safety chain installed. Follow the instructions in PERIODIC MAINTENANCE, 8000 SRM 528 or 8000 SRM 584, SAFETY PROCEDURES WHEN WORKING NEAR THE MAST.

1.Park the lift truck in a level area, block the wheels. Disconnect the battery. Release the park brake. Raise the carriage high enough to chain the carriage so that it does not move.

2.Remove the capscrews retaining the disc brake shield and remove the disc brake shield.

3.Remove the cotter pin and the clevis pin retaining the rod ends to the brake lever.

4.The park brake assembly may be removed from the transaxle by removing the last capscrew and lockwasher retaining the bracket and brake assembly to the transaxle. Disassemble the brake assembly by removing the two capscrews, spacers and nuts. Separate the caliper halves. Retain the spacers removed from between the caliper halves for use at assembly.

Installation

1.Align the carrier and cam sides of the brake in the park brake bracket. Align the spacers between both sides. Install a spacer under the head of the capscrews and install the capscrews through the caliper halves and the spacer. Install another spacer on the opposite side of the capscrew and install the nut. Tighten the nut to 29 N m (21 lbf ft) torque, then turn the nut an additional one half turn.

2.Install the bracket and brake assembly on the transaxle using the top capscrew and washer. Tighten the capscrews to 41 N m (30 lbf ft). Install the bottom capscrew when installing the disc brake shield.

3.Align the brake lever and the rod end. Install the clevis pin through the lever and rod end. Install a new cotter pin to retain the clevis pin.

4.Check to make certain that the park brake assembly can float within the brake bracket.

5.Install the disc brake shield using the four capscrews removed at assembly.

6.Remove the safety chain and lower the carriage to the floor. Remove the blocks from the tires and connect the battery. Check the operation of the park brake before returning the lift truck to service.

Disassembly

1.After the park calipers have been removed from the lift truck, remove the two nuts retaining the brake caliper halves (carrier side and cam side) together. Remove the capscrews, bushings, spacers and both the disc pads.

2.Remove the cotter pin, nut, washer, push pin, spring and back-up plate from the cam side of the park brake caliper.

Cleaning solvents can be flammable and toxic, and can cause skin irritation. When using cleaning solvents, always follow the recommendations of the manufacturer. Wear eye protection.

DO NOT use an oil solvent to clean the brake caliper. Use a solvent approved for cleaning of brake parts. Do not permit oil or grease in the brake fluid or on the brake components or the brake pads.

1.CARRIER SIDE 2.DISC PAD 3.CAM SIDE 4.DISC PAD 5.BACK-UP PLATE 6.PUSH PIN 7.SPRING 8.COTTER PIN 9.NUT 15

12 13

8 9 10 11

7 6 3 5 4 2 1

FIGURE 3 – PARKING BRAKE CALIPER

13 14

10.WASHER 11.LEVER 12.CAPSCREW 13.BUSHING 14.NUT 15.SPACER

FL1043

3.Clean and inspect the bushings and spacers for wear or elongated holes. Inspect the spring for damage. Replace any damage parts if these conditions are noted.

4.Measure the disc pads. The minimum thickness of cam side park brake disc pad is 6.60 mm (0.26 in). Replace the disc pads if the cam side pad is less than the specified thickness. The brake disc pads must be replaced in pairs.

Assembly

1.Install the disc pad in the carrier side. Install the back-up plate and the disc pad in the cam side.

2.Install the park brake in the park brake bracket. See INSTALLATION–PARK BRAKES.

MASTER CYLINDER

Removal

To access the brakes, the mast and carriage must be raised and a safety chain installed. Follow the instructions in PERIODIC MAINTENANCE, 8000 SRM 528 or 8000 SRM 584, SAFETY PROCEDURES WHEN WORKING NEAR THE MAST.

1.Move the lift truck to a safe, level area. Block the tires. Raise the carriage high enough to chain the carriage so that it does not move. Disconnect the battery.

2.Remove the floor plates.

3.Loosen one of the hydraulic brake lines to the service brakes and drain the brake fluid from the reservoir into a suitable container. Plug the brake line and the fitting on the service brake.

4.Remove and discard the cotter pin retaining the master cylinder to the brake pedal. Remove the washer and clevis pin and remove the master cylinder from the pedal.

5.Remove the capscrew and washers retaining the master cylinder to the block.

6.Remove the clamp retaining the hose to the master cylinder from the reservoir and disconnect the hose.

7.Wipe the exterior of the master cylinder to remove any surface dirt.

1.Align the master cylinder with the block and install the washers and the capscrew. Note that one washer should be positioned on each side of the block.

2.Align the fork end of the master cylinder with the pedal and install the clevis pin, washer and a new cotter pin.

3.Install the hose from the reservoir on the master cylinder. Install the clamp to retain the hose.

4.Remove the plugs from the brake line and the service brake. Attach the brake line to the service brake.

5.Fill the brake reservoir with brake fluid. The brake fluid used for the service brakes shall meet the requirements of SAE J1703 and Federal Motor Vehicle Safety Standard–FMVSS 116 (DOT 3). The capacity of the reservoir is 1.1 litre (37 oz).

6.Remove the air from the brake system. See REMOVE AIR FROM BRAKE SYSTEM.

7.Install the floor plates.

8.Connect the battery. Remove the safety chains and lower the carriage. Remove the blocks from the tires.

Disassembly (See FIGURE 4)

Be careful when removing or installing snap rings. These snap rings can come loose during removal or installation with enough force to cause an injury. Always use the correct snap ring pliers and wear eye and face protection during removal and installation.

1.Pull back on the rubber boot and using snap ring pliers, remove the snap ring from the cylinder body. Remove the push rod and fork end.

2.Remove the secondary cup, piston, washer, main cup, spring retainer, spring and valve from the cylinder body.

3.Discard the valve, main cup, washer, secondary cup and boot.

Cleaning solvents can be flammable and toxic, and can cause skin irritation. When using cleaning solvents, always follow the recommendations of the manufacturer. Wear eye protection.

DO NOT use an oil solvent to clean the brake caliper. Use a solvent approved for cleaning of brake parts. Do not permit oil or grease in the brake fluid or on the brake components or the brake pads.

4.Wash all metal components in clean brake fluid and dry using a clean, regulated compressed air supply.

5.Inspect the cylinder body bore for scoring or pitting. Replace the complete assembly if the body is defective.

6.Inspect the fork end for damage or elongated holes. Replace the fork end if damaged or holes are elongated.

7.Check that the spring is not cracked or distorted. Replace the spring if it is cracked or distorted.

2

3 1

4

5 6

7

8

1.CYLINDER BODY 2.VALVE 3.SPRING 4.RETAINER 5.MAIN CUP 6.WASHER 7.PISTON 8.SECONDARY CUP 9

10

11

9.SNAP RING 10.RUBBER BOOT 11.FORK END

FIGURE 4 – MASTER CYLINDER

Assembly

1.Coat all the parts using clean brake fluid prior to assembly.

2.Install the valve, spring, spring retainer, main cup, washer, secondary cup, piston and secondary cup into the piston.

Be careful when removing or installing snap rings. These snap rings can come loose during removal or installation with enough force to cause an injury. Always use the correct snap ring pliers and wear eye and face protection during removal and installation.

3.Install the rubber boot on the fork end. Align the fork end and rubber boot with the secondary cup. Install the snap ring.

4.Install the master cylinder. See MASTER CYLINDER–INSTALLATION.

FOOT OPERATED PARK BRAKE LEVER ASSEMBLY (See FIGURE 5)

Removal

To access the service brakes, the mast and carriage must be raised and a safety chain installed. Follow the instructions in PERIODIC MAINTENANCE, 8000 SRM 528 or 8000 SRM 584, SAFETY PROCEDURES WHEN WORKING NEAR THE MAST.

1.Move the lift truck to a safe, level area. Block the wheels. Raise the carriage high enough to safety chain the carriage so that it does not move. Disconnect the battery.

2.Remove the brake release lever by removing the cotter pin and washer retaining the lever to the park brake assembly. Remove the top overhead guard mounting capscrew, lockwasher and nut and remove the lever and bracket.

3.Remove the nut retaining the ball stud to the bellcrank. Loosen the jam nut on the ball stud and remove the ball stud from the brake cable. Remove the brake cable return spring. Remove the cotter pin and washer retaining the brake cable and cam block to the park brake lever assembly. Remove the clevis pin and remove the cam block and brake cable from the park brake assembly.

4.Identify the wires to the park brake switch and remove nuts from the wires. Remove the nuts and washers retaining the switch and insulator to the plate assembly.

5.To remove the park brake lever assembly, remove the two capscrews, lockwashers, washers and nuts from the park brake mounting bracket welded to the cowl.

NOTE: The three plain washers are used on the lower mounting bolt as a spacer. Remove the park brake assembly from the lift truck.

6.If necessary, remove the switch mounting plate assembly by removing the nuts and washers.

Be careful when removing or installing snap rings. These snap rings can come loose during removal or installation with enough force to cause an injury. Always use the correct snap ring pliers and wear eye and face protection during removal and installation.

7.To remove the bellcrank, remove the nuts and washers retaining the brake rods to the bellcrank. Use a pair of snap ring pliers to remove the snap ring and washer retaining the bellcrank to the mounting bracket on the early production models. On the later production models remove the capscrew, washer, shims and the self lubed washer.

Installation

Be careful when removing or installing snap rings. These snap rings can come loose during removal or installation with enough force to cause an injury. Always use the correct snap ring pliers and wear eye and face protection during removal and installation.

1.On the early production models, install the bellcrank on the mounting bracket using the washer and snap ring. On the later production models install the self lubed washer, shims (as required) washer and capscrew. Install the brake rods in the bellcrank and install the washers and nuts.

2.Install the switch plate assembly to the park brake lever assembly.

3.Align the park brake lever assembly with the mounting bracket on the cowl. Install the capscrews, lockwashers, plain washers and nuts to retain the brake assembly to the mounting bracket.