3 minute read

FLANGE NUT

Removal of Operator Compartment (See FIGURE 12. and FIGURE 13.)

NOTE: If the lift truck needs to be moved under low overhead clearances, the normal position of the operator compartment can be moved temporarily to the low mount position.

NORMAL POSITION

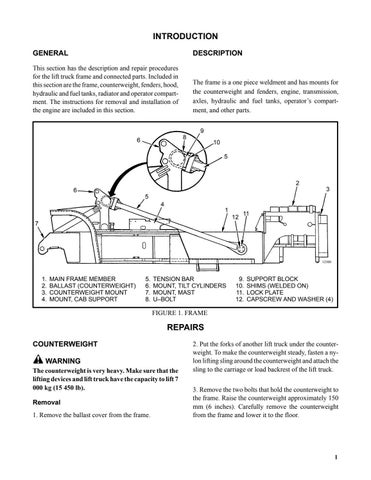

1. If the operator compartment assembly needs repair or replacement, remove it as follows: a.Remove the stairways from the running boards and operator platform at each side of the lift truck. b.Remove the long tension bars from both sides of the lift truck. Disconnect the U–bolts that fasten the end of the tension bars to the tilt cylinder mount directly beneath the front of the operator compartment. The opposite end of each tension bar is mounted to a large pin on the frame and fastened by a lock plate. Remove the capscrews from the lock plates and remove the tension bars from the lift truck.

c.Remove the metal covers that are between the main frame and the bottom of the operator platform. First remove the LH and RH brackets at the top corners of the covers near where the stairways attached to the platform.

NOTE: If the operator compartment is to be lowered to the low–mount position and not actually removed, the hydraulic lines, brake lines and electrical wiring need not be disconnected.

2. If the operator compartment and platform will be removed from the lift truck proceed with the following steps. Make sure the hydraulic lines have identification tags, then disconnect the lines at the operator compartment. Put caps on the open lines. a.Put tags for identification on the brake lines and brake pedal valves. Disconnect the air lines and wires at the valves. Disconnect the throttle cable at the throttle pedal. b.Disconnect the hoses at the heater. Disconnect the wiring harness at the heater. Disconnect the cable at the heater valve.

c.Disconnect the wiring harnesses between the lift truck and the operator compartment.

WARNING Make sure that the lifting device has the capacity to lift a minimum of 454 kg (1000 lb).

d.Connect a lifting device to a spreader bar that is through the door openings at the top of the operator compartment (under the overhead guard structure). Put material that will be a cushion at the top of the door openings to prevent damage.

Carefully lift the cab away from the lift truck. Set the cab assembly in a suitable storage area and put blocks under the unit to make it secure and stable.

CAUTION Make sure all hydraulic lines, brake lines, electrical wires and other hoses and attachments are not damaged.

LOW–MOUNT POSITION

If the operator compartment and platform will be lowered (and not removed) proceed with the following steps. 1. Connect a lifting device to a spreader bar that is through the door openings at the top of the operator compartment (under the overhead guard tubes). Put material that will be a cushion at the top of the door openings to prevent damage. Operate the lifting device just enough to support the weight of the operator’s compartment.

WARNING Make sure that the lifting device has the capacity to lift a minimum of 454 kg (1000 lb).

2. Disassemble and remove the side channel plates and cross–member assembly that is between the frame and the bottom of the operator platform. Remove the capscrews, nuts and washers that fasten. Raise the operator compartment slightly and remove the side plates and cross–member as they are disassembled from each other.