1 minute read

SERVICE LUBRICATION

from Frontier Rotary Tillers RT 1173 RT 1273 RT 2293 RT 1181 RT 2283 Operator's Manual(F07011069) - PDF

• Firmly block tiller on horizontal surface.

• Always keep oils and greases well away from children’s reach.

• Always thoroughly read the warnings and precautions indicated on the containers. Avoid contact with the skin.

• Always thoroughly and fully wash after use. The utilized oils should be treated in compliance with the current anti-pollution laws.

Every 8 work hours

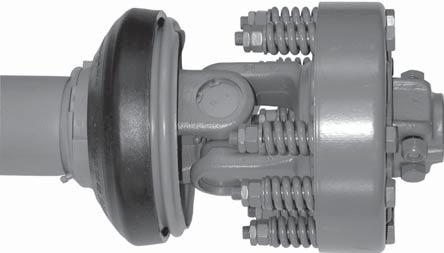

• Grease the cardan shaft cross journals (A) and (B).

• Check that the bolts fixing the hoe blades (I) are well tightened.

• Grease the rotor spindles (D).

Every 50 work hours (see page 23 for E, F, G, I and H)

• Check the level of the oil in the gearbox or in the reduction unit (E) and top off to the level mark on the rod as necessary.

• Side transmission gears : check the level of the oil in the side casing of the transmission unit, unscrewing the level plug (G) and checking that oil flows out. Add oil through the fill plug (F) if necessary. It should flow from the level plug.

Every 400 work hours

• Change the oil in the reduction unit and transmission casing by completely draining off the old oil through the drain plug under the reduction unit and through the transmission drain plug.(H)

• When this operation is carried out, it is also advisable to demount and clean the clutch disks (C) (if the cardan shaft has a clutch). Check the tightening of the clutch springs.

Service Lubrication - Page 22