1 minute read

LUBRICATION

Greasing

There are numerous grease fittings on the Manure Spreader. Lubricated properly and often with a high-quality grease, will prolong the life of the Manure Spreader. Replace any missing or plugged grease fittings.

Wipe dirt from the fittings before greasing to prevent the dirt from being forced into the bearing or pivot. Grease should come out around the shaft on sleeve type bearings. To minimize dirt build-up, avoid excessive greasing. After greasing, wipe off the excess grease from around the outside of the bearings to prevent the accumulation of chaff and grit.

NOTE:Grease all fittings at the intervals of operation listed, before and after storing the Manure Spreader. Use a good grade of Lithium-base grease.

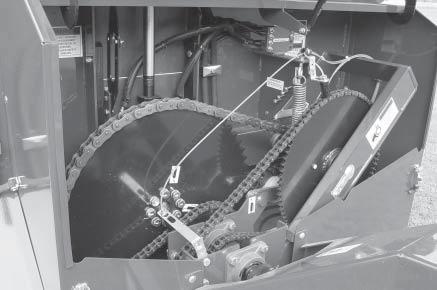

Grease Fitting Locations - Grease Every 10 Hours (or Daily)

1.Main Auger Thrust Washer

2.Main Auger Front Bearing

3.Front auger Slide Plate (4 Remote Zerks)

4.Auger Jackshaft (Behind Sprocket)

5.Idler Arm

6.Input Shaft Bearings (2 Remote Zerks)

7.Over-Running Clutch (2 Places)