30 minute read

1.Foreword .................................................................5

2.2. Clothing and personal protection items

Avoid loose clothing, jewellery and loose long hair which may catch on controls or in moving parts and cause serious injury or death. Also, do not wear oily clothing because it is hazardous to your health and is fl ammable.

2.3. Unauthorised modifi cation

• Any modifi cation made without authorisation from Moxy Engineering AS can create hazards. • Before making a modifi cation, consult your local Moxy Dealer. Moxy Engineering AS will not be responsible for any injury or damage caused by any unauthorised modifi cation.

2.4. Getting on and off the dump truck

• Always use handles and steps when entering and getting off the dump truck. • Ensure safety, maintaining at least three-point contact of hands and feet with handles and steps. • NEVER jump on or off the dump truck. NEVER get on or off a moving dump truck. • Always clean off grease, oil, ice, snow and dirt to avoid slippery truck surfaces.

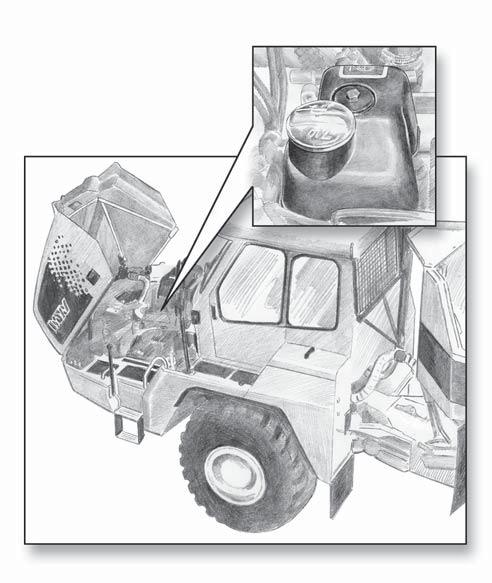

2.5. Fire prevention for fuel and oil

Fuel, oil and antifreeze can be ignited by a fl ame. Fuel is particularly FLAMMABLE and can be HAZARDOUS. • Keep fl ames away from fl ammable fl uids. • Stop the engine and do not smoke when refuelling. • Tighten all fuel and oil caps securely. • Refuelling and oiling should be carried out in well ventilated areas.

• Spilt fuel and oil must always be cleaned up immedi- ately. • Keep oil and fuel in a secure place and do not allow unauthorised persons to enter.

2.6. Precautions when handling at high temperatures

Immediately after operations are stopped, the engine coolant, engine oil and hydraulic oil are at high temperatures, and are still under pressure. Attempting to remove the cap, drain the oil or coolant, or replace the fi lters may lead to serious burns. Always wait for the temperature to fall, and follow the specifi ed procedure when carrying out these operations. • To prevent hot coolant from spurting out: 1. Turn engine off 2. Allow coolant to cool down. 3. Slowly loosen cap to relieve pressure before remov- ing. • To prevent hot oil from spurting out: 1. Turn engine off 2. Allow oil to cool down. 3. Slowly loosen cap to relieve pressure before removing.

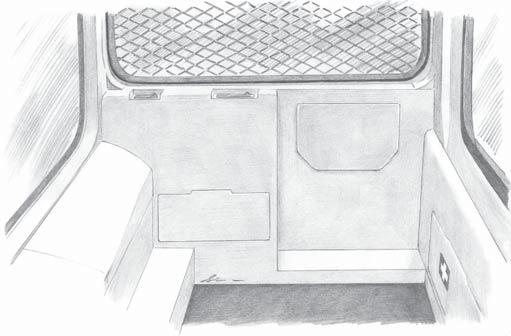

2.7. Fire extinguisher, fi rst aid kit and warning triangle

(optional equipment) • Know how to use the fi re extinguisher (Distributor/ Dealer fi tted). If the fi re extinguisher is missing, contact your local Moxy Dealer. Location: Left hand side in the cab.

• If the fi rst aid kit is present in the cab, keep it in its storage place. Location: Left hand side in the cab, below the rear side window.

• If the warning triangle is present, keep it in its storage place. Location: Toolbox in the right hand side fender. • See also Safety equipment in chapter 3. • Know what to do in case of fi re.

• Be sure you know the phone numbers of persons you should contact in case of an emergency.

2.8. Precautions for optional accessories

• When installing and using optional accessories, read the information related to the equipment in this manual. • Do not use equipment or parts that are not authorised by Moxy Engineering AS. Use of unauthorised equipment or parts could create a safety problem and adversely aff ect the proper operation and useful life of the dump truck. • Any injury, accidents, product failure resulting from the use of unauthorised attachments will not be the respon sibility of Moxy Engineering AS.

A

The cab on this dump truck is tested and approved to current ROPS (Roll-Over Protective Structure) and FOPS (Falling Object Protective Structure) standards. ISO 3471 ROPS ISO 3449 FOPS

• This cab meets the requirements for objects falling onto the cab roof, and will protect the operator while he is remaining in the cab. • This cab meets the requirements for roll-over protection. A precondition for protection is that the operator USES THE SEAT BELT and remains in the cab. Therefore, hold onto the steering wheel if the dump truck should roll over. DO NOT ATTEMPT TO JUMP CLEAR!

• The approval sign for ROPS/FOPS is located on the fi re wall underneath the bonnet.

• Structural damage, an overturn, modifi cation, alteration or not permitted repair can aff ect the cab strength and there by void the certifi cation • Consult Moxy Engineering AS or your Moxy Dealer to determine this structure’s limitations without voiding its certifi cation.

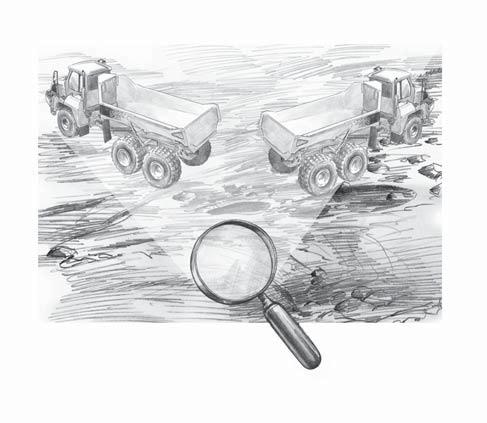

2.10. Emergency exit

• This dump truck is fi tted with two emergency exits. • Left door and front side window on right hand side. • If door is blocked, you can get out through the front side window.

• Remove hammer (A) from storage location and break front side window.

3.1. Safety at the work site

• Before starting the engine, make sure that the bonnet is closed and thoroughly check the area for any unusual conditions that could be potentially dangerous. • Before starting the engine, examine the terrain and soil conditions of work site. Determine the best and safest method of operation.

3.2. Fire prevention

• Thoroughly remove wood chips, leaves, paper and other fl ammable material accumulated in the engine compartment, or other places on the dump truck. THEY COULD CAUSE FIRE!.

• Marsh land, when dry, is highly fl ammable. Marsh land can self ignite even in low temperatures. Always keep the engine and engine compartment clean!

• Check fuel, lubrication and hydraulic system for leaks. Have any leaks repaired. Clean up any excess oil, fuel or other fl ammable fl uids. (Check points - see daily mainte- nance "Walk around check") • Be sure that the fi re extinguisher is present and working. The fi re extinguisher shall be located on left hand side in the cab.

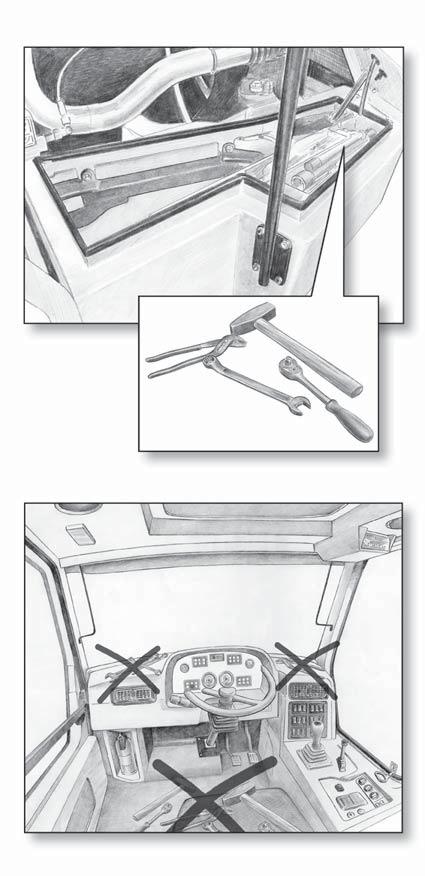

3.3. In operator's cab

• Do not leave tools or spare parts laying around in the operator's cab. They may damage or break the control levers or switches. They could also hit the operator and cause serious injury. Always keep the tools in the tool box (in right hand side fender). • Keep the cab fl oor, controls, steps and handrails free of oil, grease, ice, snow and dirt.

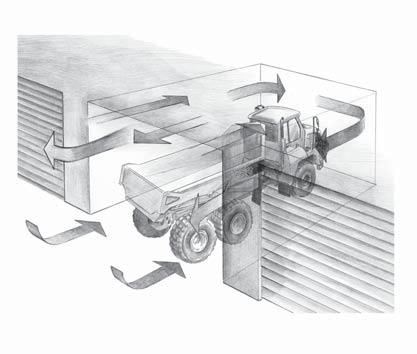

3.4. Ventilation for enclosed areas

If it is necessary to start the engine within an enclosed area, provide adequate ventilation. Exhaust fumes from the engine can KILL.

3.5. Precautions for mirrors, windows and lights

• Remove all dirt from the surface of the windows and lights to ensure that you can see well. • Adjust the rear view mirrors so that you can see clearly from the operator's seat, and always keep the surface of the mirrors clean. If any glass is broken, replace it with a new part. • Check that the head lights, working lights and all other lights are installed to match the operating conditions. Check also that they light up properly.

4. When starting the engine

• Walk around the dump truck just before you enter it, to check for people and objects that might be in the way. • When starting the engine, sound the horn as alert. • Fasten the seat belt and remain seated while in motion. Standing up is dangerous! Concentrate on and evaluate surroundings. Stop the dump truck if you are uncertain of how to operate safely. • Slow driving is required to ensure hazard-free operation, especially on curves, narrow roads, hills/cliff s, bumpy or slippery ground. If the visibility is restricted and/or obstructed, designate a person to check and direct the work site traffi c. • Ensure that you keep a safe distance from other vehicles and nearby people. Be sure that no persons or objects are situated in the articulation area or the overturn area (left and right hand side of the dump truck) before turning or driving. Also make sure that no persons or objects are situated behind the dump truck before reversing or when tipping the load.

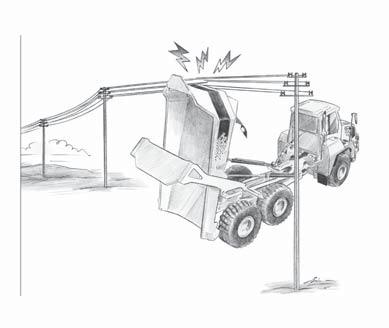

5. Do not go close to high-voltage cables

• Going close to high-voltage cables can cause electric shock. Do not raise the body near high-voltage cables.

The following actions are eff ective in preventing accidents: • Wear shoes with rubber or leather soles.

• Use a signalman to give warning if the dump truck approaches too close to the electric cable. • If the body should touch the electric cable, the operator should not leave the operator's cab. The operator should remain in the cab until it has been confi rmed that the electricity has been shut off . • When carrying out operation near high-voltage cables, do not let anyone come close to the dump truck. • Check with the electricity company about the safety zone and voltage of the cables before starting operations.

1

2

Battery main switch (OFF) 3

6. Battery hazard prevention

• Battery electrolyte contains sulphuric acid and can quickly burn the skin and eat holes in clothing. If you spill acid on yourself, immediately fl ush the area with water. • Battery acid could cause blindness if splashed into the eyes. If acid gets into the eyes, fl ush them immediately with large quantities of water and see a doctor at once. • If you accidentally drink acid, drink a large quantity of water or milk, beaten egg or vegetable oil. Call a doctor or hospital immediately. • When working with batteries ALWAYS wear safety glasses or goggles. • Batteries generate hydrogen gas. Hydrogen gas is very EXPLOSIVE, and is easily ignited with a small spark or fl ame. • Before working with batteries, turn the starter switch to the OFF position, and the battery main switch must be turned OFF.

• Avoid short-circuiting the battery terminals through accidental contact with metallic objects, such as tools, across the termi- nals.

• When removing or installing, check which is the positive (+) and negative (-) terminal. Removing the batteries (see fi gure): 1. Disconnect (-) terminal connected to the earth point. 2. Disconnect the battery cable between the batteries. 3. Disconnect (+) terminal connected to the starter. When installing the batteries, carry out the procedure in the opposite order, 3 - 2 - 1. • Tighten the battery caps securely. • When removing any battery cap, wear rubber gloves to prevent electrolyte contact with the skin. • Tighten the battery terminals securely, check that the terminals are not loose by trying to move the battery cables by hand. Loosened terminals can generate sparks and lead to an explo- sion.

7. Air conditioning system hazard prevention

• The air conditioning system is fi lled with refrigerant (R134a). • Always use safety glasses or goggles, gloves, boiler suit and protective footwear when inspecting, servicing and repairing the air conditioning system. • Refrigerant R134a has a property that can cause frostbite if it comes into contact with bare skin or eyes. • Always work on the air conditioning system in well-ventilated places. • High concentration of the refrigerant in gaseous form can cause drowsiness, headache, dizziness and at worst uncon- sciousness. Very high concentration of the gas can even cause cardiac insuffi ciency. Do not smoke when servicing the air conditioning system!

Worker protection rules, refrigerant

The following worker protection actions must be taken if there is any contact with escaping refrigerant: • Refrigerant in gaseous form can cause drowsiness, headache, dizziness and at worst unconsciousness. Very high concentration of the gas can even cause cardiac insuffi ciency. In all cases, get into fresh air and move the aff ected person from the risk zone. Contact a doctor.

• If larger quantities of fl uid refrigerant come into contact with skin (frostbite), the injured area should be carefully warmed with luke warm running water and covered with a sterile com press. Contact a doctor. • If fl uid refrigerant comes into contact with a person's eyes (frostbite), rinse the eyes with lukewarm running water, min. 10 min. Contact a doctor.

• If fl uid refrigerant is accidentally swallowed, there can be serious frostbite in the mouth and gullet. Rinse the mouth with water. DO NOT INDUCE VOMITING. Contact a doctor.

8. Rules to follow when fi lling fuel or oil

• Spilt fuel and oil may cause you to slip, so always clean up immediately. • Slowly loosen the caps to relieve pressure before removing the caps. • Always check fuel/oil specifi cations (chapter 6, lubricants) before refi lling. • Always refi ll fuel and oil in a well-ventilated place. • Always tighten the cap of fuel and oil fi llers securely. • Never use fuel for washing any parts.

9. Expansion tank coolant level

1. If it is necessary to refi ll coolant to the expansion tank, stop the engine and allow the engine and the expansion tank to cool down before refi lling coolant. 2. Slowly loosen the caps to relieve pressure before removing the caps. 3. Always refi ll using pre-mixed coolant. (See chapter 7, maintenance)

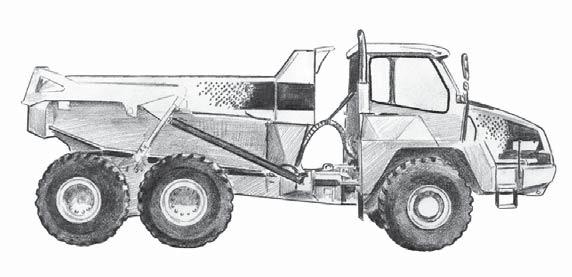

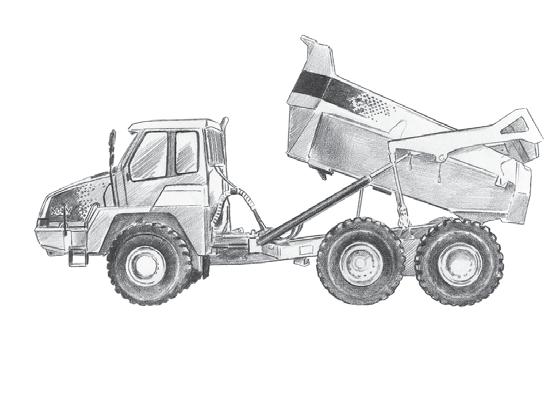

10. Machine turning

This articulated dump truck has two frames and the design allows unrestricted turning between front and rear chassis. Overturn of one frame while the other remains level is possible.

It is possible that the operator will not receive warning signs of an overturn, therefore: • Avoid high speed turning and hard braking in curves. • Reduce speed, avoid sudden turning if travelling across slopes. • The rear chassis stability decreases when tipping. Be alert when body is raised. Do not under any circumstances drive with raised body!

11. Emergency steering

The emergency steering pump will be activated if the engine stops. It is possible to steer the dump truck when it is in motion, but the steering speed will be slower.

If the emergency steering light illuminates at truck speeds above approx.. 5 km/h: • Stop as soon as possible and park in a safe place! Continued driving may result in uncontrollable steering. • Correct the fault before operating the dump truck again. If necessary, contact your Moxy Dealer.

12. Travelling on slopes

• Travelling on hills, banks or slopes that are steep, can result in the dump truck starting to slide/slip or roll over. • Always check ground conditions before travelling on slopes. • Always travel straight up or down on slopes. • Do not turn on slopes or travel across slopes. Always go down to a fl at place to perform these operations. • Keep travel speed very low.

WARNING

Ground conditions, gradients, friction, available traction and type of load is of vital importance for safe operation and stability on slopes.

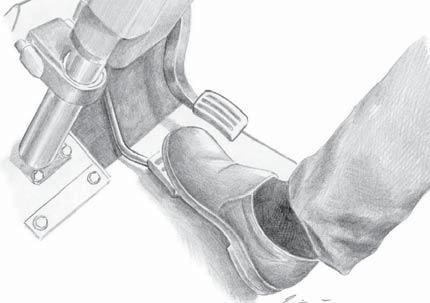

13. Operation of brakes

The service brakes must never be applied for long periods due to danger of fading (loss of braking eff ect due to overheating).

To avoid fading, depress the pedal firmly and release it after the speed is reduced.

Select a gear and adjust the speed in a downhill slope so that the speed can be controlled with the engine brake or engine and retarder brake, without the use of the service brake to hold the speed. Never use the service brake for long periods. Avoid racing the engine. See also Operating Instructions.

14. Engine over speed ( Emergency retarder)

When the operator releases there foot off the accelerator, the exhaust brake is automatically engaged. Driving downhill with the accelerator pedal released, the engine rpm’s will increase, when the engine rpm's reach 2,200 the transmission retarder is activated, this will disengage when rpm’s drop to 1,800, the exhaust brake will continue to operate.

It’s called emergency retarder because the cooling capacity is not designed for continuous operation.

If the truck is on a downhill slope and the operator does not release there foot off the accelerator pedal, the exhaust brake is activated at 2,450 rpm’s to override the operator error. The transmission emergency retarder brake will be activated at 2,500 rpm.

To prevent engine damage due to the over-speed situation, the transmission control unit (TCU) will perform an automatic up-shift to the next gear, if engine reach's 2,700 rpm’s.

15. Wading

Never drive into water (river beds, ponds, fl ooded pits, ditches etc.) without knowing the ground surface and depth. The bottom can be slippery, obstacles such as rocks/holes and other dangerous areas can be diffi cult to determine, and the force of a river current can be substantial. If it is found to be safe, drive slowly to avoid splashing. Do not stop unless absolutely necessary.

Be aware of reduced braking eff ect when brakes are wet.

The brake linings must be checked/replaced more often when driving in wet and swampy areas, because wear of the linings will increase (see 500 hours service for procedure).

The maximum wading depth is:

MT31 - 1100mm, i.e. up to the front fenders

MT41 - 1250mm, i.e. up to the front fenders

NOTE

Under no circumstances let water fl ow through the grill!

16. Dangerous loads

If the body is exhaust heated, dangerous loads such as explosives or infl ammable materials like petrol's, oils etc. must not be transported.

In some countries there may be special national regulations for transportation of dangerous loads.

To blank off the exhaust heating, do as follows: • Always allow the dump truck to cool down before changing exhaust direction.

1. Remove the clamps on both the vertical exhaust pipe and the pipe which goes to the body. 2. Remove the plate which gives heating to the body (in the vertical exhaust pipe). 3. Remove the ring from the pipe which goes to the body and install it into the vertical exhaust pipe. 4. Install the plate which will blank the exhaust to the body (in the pipe which goes to the body) 5. Refi t the clamps.

17. Welding on the dump truck

The transmission and the engine are equipped with electronic control units. Before welding on the dump truck: 1. Disconnect batteries.

2. Unplug the connectors on the electronic control units for the engine and the transmission. The units are located behind the cover on the back wall (behind the instructor seat back rest, if that is fi tted). 3. Earth point should be less than 1 m from welding point. 4. There should not be sealings and bearings between the welding point and the earth point.

OFF

18. Top tailgate

For safe tipping: See Operating Instructions.

If top hinged tailgate is fi tted to this dump truck, particular attention should be paid to the material handled in the interest of both safety and effi ciency.

The top tailgate is suitable for materials which are both well fragmented and free fl oating, such as dry earth, gravel, sand, coal, etc. In such instances, discharge should be continuous during the whole cycle of tipping.

However, if the material is poorly fragmented or adhesive, such as clay, bulky boulders etc., it is imperative that a top tailgate is NOT fi tted. Such materials do not have an even discharge and problems could arise during the tipping cycle when the material comes in contact with the top tailgate. Cases have been reported where the tailgate restriction has caused the front wheels of the dump truck to leave the ground. Such a situation creates instability of the front of the dump truck, and results in reduction of operator safety.

WARNING

Moxy Engineering AS cannot be held responsible for any damage that may occur through improper use of the top hinged tailgate.

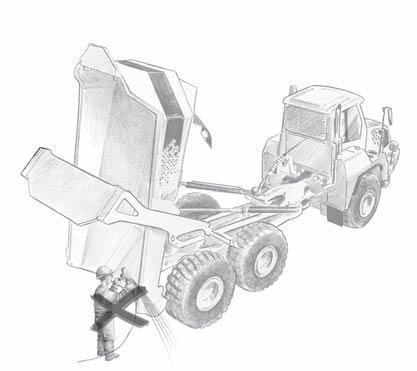

DANGER

It is hazardous to work/stand underneath the tailgate while the body is raised! The tailgate must be removed if any work is to be done inside the body while the body is raised.

Removal of the top tailgate: 1. Attach wire or chain to the lifting points. The tailgate shall be disassembled in three parts, tailgate arms (left and right) and the rear tailgate plate. Be sure that wire or chain are attached to all three tailgate parts before disassembling. 2. Remove all screws (see arrows) on the tailgate (both sides) and lift off the tailgate parts. Approx. weight: 1500 kg.

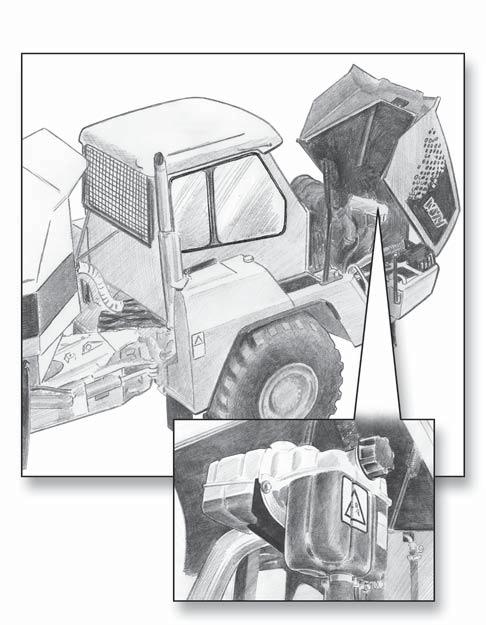

19. Engine bonnet

Do not open the bonnet when the engine is running. The bonnet is fi tted with lockable bonnet opener on left hand side. The bonnet must always be closed and secured with the lock when operating the dump truck.

When the bonnet is open, make sure that the bonnet catcher for open position (on left hand side) secures the bonnet from falling down.

• To open the bonnet: 1. Depress the button on the handle grip on left hand side. 2. Lift the bonnet catcher. 3. Push up the bonnet. 4. Check that the bonnet catcher engages. • To close the bonnet: 1. Push the bonnet forward. 2. Lift the bonnet catcher. 3. Push down the bonnet and see to that the lock engages.

DANGER

It is hazardous to work/stand underneath the bonnet without applying the bonnet catcher! Do not operate the dump truck

20. Tiltable cab

Always secure the tilted cab with the support before service/inspection and other work/stand underneath the cab. The cab must always be closed and secured with the locks when operating the dump truck. Before tilting the cab, check that there are no loose objects in the cab.

When the cab is tilted, make sure that the support secures the cab from falling down. To tilt the cab. • To tilt the cab:

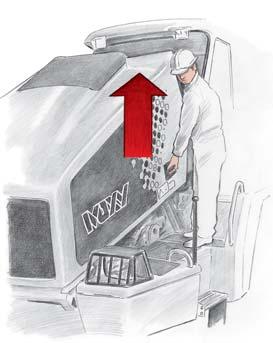

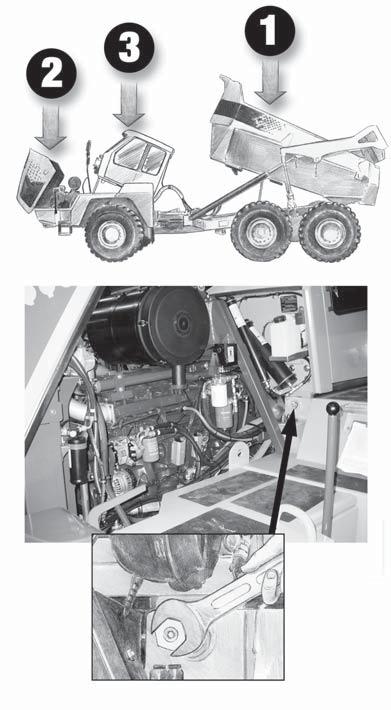

1. Lift the body and secure it with the body support (see item 21). 2. Stop the engine. 3 Open the bonnet and apply the bonnet catcher (see item 19). 4. Put a plastic bag or similar around the brake fl uid reservoirs before the cab is tilted. To prevent brake fl uid spillage. 5. The cab has two tilted positions: • Service position - Must be secured with the safety support, see below (item 8) • Top position - The cover behind the hydraulic tank has to be removed before tilting the cab to top position.

a

b - If exhaust heating is fi tted, this must also be removed. - The cab must be fastened to a crane or similar when tilted for safety reason. 6. Remove one bolt on each side of the cab. Spanner: 46 mm 7. Push up the cab by using the hydraulic pump (a) on left hand side. If hydraulic pump is not installed, crane has to be used. • Make sure that the handle for up-and down pushing (b) is in the up-position (the illustration shows the down-posi tion). 8. In service position: Fasten the safety support (c) to the anchorage point at the cab and front frame, by using the bolts removed in item 6. The safety support is to be found in the toolbox.

• To lower the cab:

1. Unscrew the safety support (c). Put it back to its storage place in the tool box. 2. Lower the cab by using the hydraulic pump (a) on left hand side. If hydraulic pump is not installed, crane has to be used. • Make sure that the handle for up-and down pushing (b) is in the down-position (the illustration shows the down- position). 3. Refi t the bolt on each side of the cab.

4. Remove the plastic bags on the brake fl uid reservoirs. 5. Close the bonnet.

6. Lower the body. 7. Refi t the cover behind the hydraulic tank and the exhaust heating, if this was removed.

DANGER

It is hazardous to work/stand underneath the cab without applying the safety support! Do not enter the cab while it is tilted! Do not operate the dump truck with a tilted and secured cab!

c

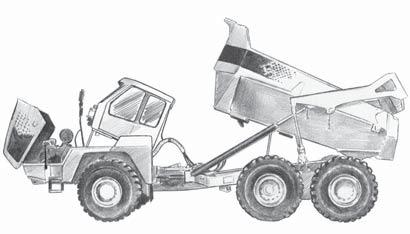

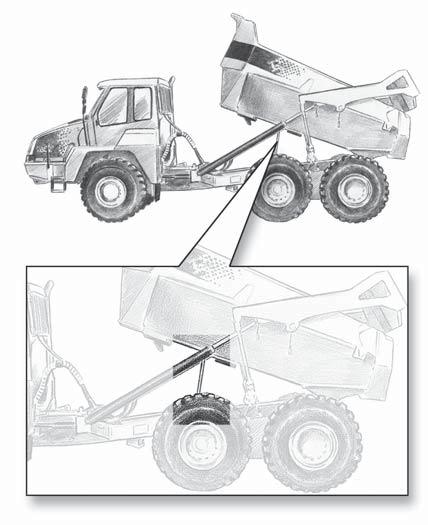

21. Body support

Always secure the raised body with the body support before service/inspection and other work underneath the body. The body support device is intended for empty body only! • Engagement of the support device: 1. Raise the body. 2. Make sure that the parking brake is on (locked) before leaving the cab. 3. Lift the body support in top position. 4. Slowly lower the body towards the support device until fi rmly positioned. 5. Return the tip control lever to hold position. 6. Stop the engine and remove the starter switch key. • Disengagement of the support device: 1. Start the engine. 2. Lift the body slightly. 3. Return the tip control lever to hold position when the body is off the body support. 4. Make sure that the parking brake is on (locked) before leaving the cab. 5. Lower the body support. 6. Lower the body.

DANGER

It is hazardous to work/stand underneath the body without applying the body support device! Do not operate the dump truck with a raised and secured

22. Service position

Prepare the dump truck before service, maintenance and other work on the dump truck. Take every precaution for safe work. If more than one person shall perform work, one person should supervise to maintain the safety. 1. Park on a level ground and apply the parking brake. 2. Apply the articulation lock (see item 24). Block the wheels (see item 23). 3. Stop the engine and remove starter switch key if not necessary for the work. Disconnect the main switch on the front fender (left hand side). 4. Secure the dump truck from being operated by accident or by persons unauthorised by attaching a warning label to the steering wheel. Do not allow persons to approach the area unnecessar- ily. 5. Be aware of hot fl uids and components. 6. Block up all lifted components to prevent them from falling during work/stand underneath.

Before starting up after work, make sure the dump truck is in good operating condition.

23. Wheel chocks

Always place wheel chocks under the wheels to avoid spontaneous rolling: • when parking • during maintenance and other work • during transportation of dump truck.

The lock prevents the dump truck turning when applied. • Apply the lock: 1. Take out the spring cotter, lift the pin and swing the linkage forward into the hinge ear. 2. Insert the pin through linkage and ear and refi t the spring cotter.

• Release the lock:

1. Take out the spring cotter, and remove the pin through the linkage and ear. 2. Swing the linkage backwards, insert the pin through the link age and ear, and refi t the spring cotter.

The lock must always be applied: • During maintenance, greasing and other work. • When lifting or hoisting the truck, see item 25. • During dump truck transportation, see item 26.

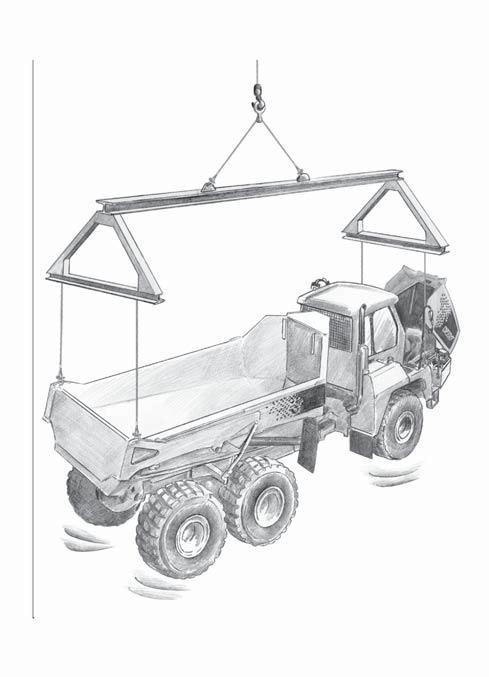

25. Lifting / hoisting

1. Apply the articulation lock (see item 24). 2. Open and secure (see item 19) the bonnet. 3. Fit suitable lifting wires or chains to the hoisting points at both sides of the body and engine, and use a suitable lifting beam as shown.

Machine net weight: MT25: approx. 22,500 kg MT26 : approx. 23,500 kg MT31: approx. 25,150 kg MT36: approx. 28,800 kg MT41: approx. 29,200 kg incl. tailgate

WARNING

Never lift or hoist a loaded truck, the points are intended for an empty dump truck only!

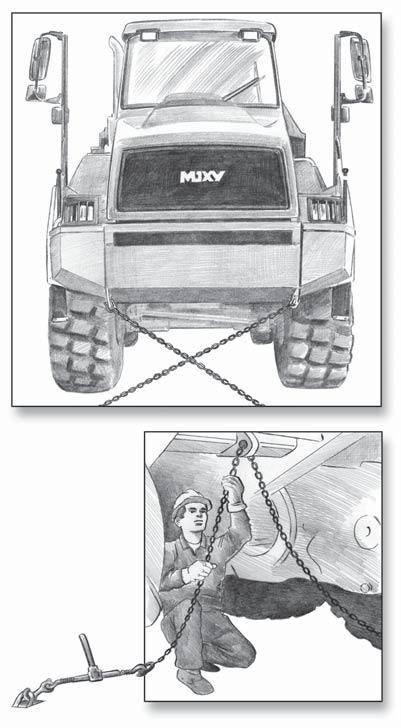

26. Dump truck transportation

1. Apply the parking brake. 2. Apply the articulation lock. 3. Apply wheel chocks.

Fit suitable wires or chains to the tie down points as shown and tighten them up.

CAUTION

Always transport the truck without load in the body!

27. High pressure

Be aware of high pressure in the hydraulic system (with running engine and operated service brakes) and tyres. Do not strike or bend pressure hoses or tubes. Do not use bare hands for checking leaks, use shield as protection to avoid personal injury. Even a pin-hole size leak can penetrate the skin. Always release pressure before maintenance or servicing:

Procedure: • Stop the engine. • Operate the brake pedal repeatedly until the accumulators are empty.

Accumulators can also be emptied through the accumulator test connectors.

Be aware that the accumulators will be recharged with oil when the engine is re-started. Tyres: Release the pressure through the rim nipple before attempting to remove any embedded objects or removing tyre/rim assembly from the machine. The pressure inside the tyres is substantial and an explosion can cause damage and serious personal injury. Never heat or weld on rims or surrounding areas when the tyre is infl ated. Stand behind the tread when infl ating a tyre.

28. Safety labels

The following labels are related to safety and should always be present and easy to read. Do not cover labels with paint or similar:

Cab certifi cation.

The cab has been approved to current ROPS/FOPS standards. Structural damage, an overturn, modifi cation, alteration or not permitted repair can aff ect the cab strength and thereby void the certifi cation. Consult your Moxy Dealer to determine this structure’s limitations without voiding its certifi cation.

Warning - use of top tailgate • Top tailgate is fi tted on this dump truck.

• Pay particular attention to the material handled by dump truck with top tailgate. • Wrong material and improper use of top tailgate can cause a DANGEROUS situation and reduce the operator's safety. • Read the operating manual (safety instructions, item 18) before operation. Warning - never coast in neutral • Never coast with the gear selector in the neutral position. • The braking eff ect and the operator's safety will be reduced. Warning - dangerous loads • Explosive or infl ammable loads must not be transport if the body is exhaust heated.

Emergency exit • The emergency exit can be used by removing the hammer from the storage location and break front side window.

• Read the operating manual (safety instructions, item 2.10) before operation. Warning - operation, inspection and maintenance

• Improper operation and maintenance can cause serious injury or death. • Read the manual and labels before operation and maintenance. Follow instructions and warnings in the manual and on labels on the dump truck. • Always keep the manual in the cab. If this manual is lost, please contact your Moxy Dealer for a replacement.

Warning - air conditioner • Refrigerant R 134a under high pressure. • Read the operating manual (safety instructions, item 7 and chapter 7, maintenance) before servicing Fire extinguisher • The fi re extinguisher is located on the left hand side in the cab.

Warning - welding precaution • Disconnect the batteries and unplug the connectors on the electronic control units before welding. • Read the operation manual (safety instructions, item 17) before welding.

First aid kit

• The fi rst aid kit (if fi tted) is located on the left hand side in the cab, below the rear side window. • Read the operating manual (safety instructions, item 2.7).

Warning - limited visibility • Keep out of this area when the engine is running, the operator has limited visibility. • To prevent serious injury or death carry out the following before moving the dump truck: • Be sure no one is on or near the dump truck. • Sound horn to alert people nearby. Warning - engine is running • Never open the bonnet with the engine running. • To prevent serious injury stop the engine before opening the engine bonnet. • Wait until all engine parts have completely stopped before touching them. • Do not touch hot surfaces! Fingers or hands can be burnt.

Note - sling and/or tie down point • Read the operating manual (safety instruction, item 25 and 26)for correct use of the sling and/or tie down point. Warning - pinch danger • Keep clear, pinch danger in the articulation area.

• To prevent serious injury or death carry out the following before moving/turning the dump truck: • Be sure no one is on or near the dump truck. • Sound horn to alert people nearby. • Always use the articulation lock when servicing! • Read the operating manual (safety instructions, item 24).

Warning - body support • Do not stand underneath the body without applying the body support device.

• Always use the body support when working underneath the body. • Empty body before body support is used.

MT25/MT26/MT31/MT36/MT41

Note - sling and/or tie down point • Read the operating manual (safety instruction, item 25 and 26) for correct use of the sling and/ or tie down point. ROPS/FOPS approval cab • Read the operating manual (safety instructions, item 2.9).

Note - check oil specifi cation • Always check oil specifi cations before refi lling. • Read the operating manual (chapter 6, lubricants) before refi lling.

Note - use correct type of grease • Always check grease specifi cations before refi lling. • Read the operating manual (chapter 6, lubricants) before refi lling.

Warning - hot area!

• The exhaust pipes and nearby area may be hot. Fingers and hands can be burnt!

• Use gloves when checking the transmission oil level or fi lling oil. Warning - hot coolant can spurt out

• If it is necessary to refi ll coolant to the expansion tank, stop the engine and allow the engine and the expansion tank to cool down.

• Slowly loosen the cap to relieve pressure before removing the cap.