1 minute read

Remove engine oil pressure gauge manifold �racket.

GROUP 00

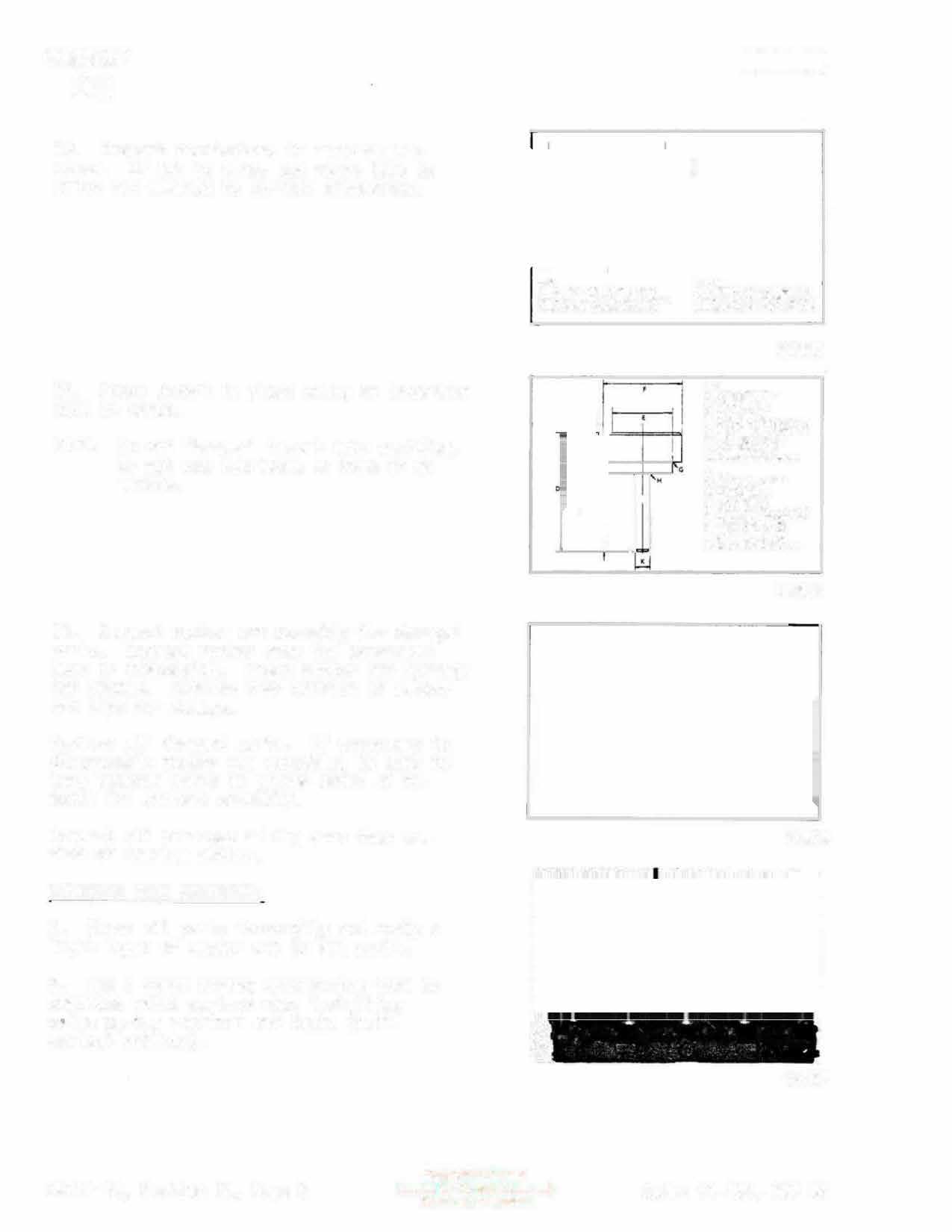

13. Inspect counterbore to measurements shown. If not to size, use valve bore as pilot and machine to correct dimensions.

14. Press insert in place using an insertion tool as shown. NOTE: Do not "hammer" insert into position. Do not use lubricant on bore or on insert.

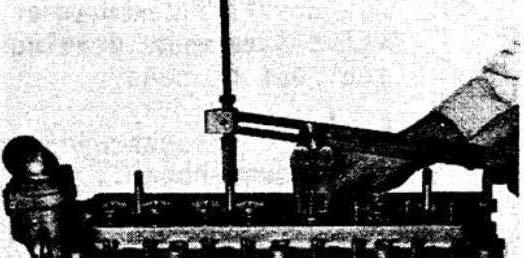

16. Inspect rocker arm assembly for damaged parts. Inspect rocker arms for excessive wear or distortion. Check rocker arm springs for damage. Examine wear surface of rocker arm tips for damage. Replace all damaged parts. If necessary to disassemble rocker arm assembly, be sure to keep removed parts in proper order of removal for correct assembly. Inspect oil passages making sure they are free of foreign matter. C Y L I N D E R HEAD ASSEMBLY: 1. Clean all parts thoroughly and apply a light layer of engine oil to all parts. 2. Use a valve spring compression tool to compress valve springs when installing valve spring retainer and locks (ha1fconical collets).

A.....02&3/0.291,n (7,1tfl.31 mml 8-2 016S/2.011'S � (51.22/51,24 mmt C-flaOKit O 01 S 1n 10,311 rnml ma.1 b.l'lallSI � 375/0 310 in (9 S219 U mmJ 8-1 671/1 679 tn !•2.f.2/412 &4 mm, C-R•o1uso01s1n tO31mm1 m11.

L.

25828

A.-r't 11'1 11,H ftWII Mu• ...... 11'1111,Gll'MII C,-4 ZXI � Cl.»-1 D--3 "' (71.a -· E-1 ,a/1 Y3 _,. (A0.11/40.11 _, ,-1oa1,ao1t .. 1s1.w11,2t '"'"'' 0-11» • 10..n-1 '"°'"" ,,._n •� ".,. _, ,.-w

�•,111(1,M-1 .. .e.s· lt-0 SWO l1l 11'1 ft Ult•1 -1 .,_,

"-"''"" ,,.s-...... 1 .. -s•

9-f Ill Clt,05 ,.,., C-0.)12 tt'1 (1.ft _, o-JO 11'1 Ht,0-1 (-1 h1JU4 .,_ flt,1'0/1',72 �""l 111--1 f701f -.,. IU.W4l.t1 _, 0-11».., to..n-1,.,..,.._ ,._,,,,'" 11.se-, �-... ,;.....1/IIMIIM-J•US" IC-0 J1V0 11'),. 11,tVI 47 11¥11

2 5 8 2 6

25819

25767