1 minute read

Remove throttle linkage at the car buretor.

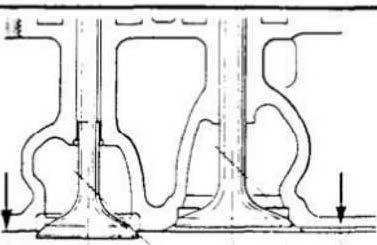

10. Check the fit of valve stems in bore. if worn, replace with new valves having oversized stems available as (0,08, 0,38, and 0,76 mm) 0.003, 0.015, and 0.030 in. oversize. NOTE: If oversize stems are used, pilot bores in head must be reamed with piloted reamer to give (0,10 rrrn) 0.004 in. clearance. NOTE: If oversized stems are used, be sure to also use correct size oversized seals.

11. Inspect valve seats for damage (burnt or eroded areas) or for corrosion or carbon build-up on surfaces. If damaged, valve seat faces must be refaced. Reface seat to dimensions and limits shown in tables.

1 2 . The exhaust valve has a removable seat. The preferred method of seat removal is by use of a valve seat insert puller. If one is not available, seat can be removed by following method: a). Grind a scrap valve to fit inside of seat. b). Weld a scrap valve to seat in three places. Use old head gasket to protect head surface when welding. Be careful not to weld on head. c). Use a soft-faced.hammer to strike valve stem end, driving valve and seat out of head. d). Remove all burrs and foreign matter from counterbore. !-

44' " 0•081 HI 12.0& .... ) MAX. ' 4e• I 0-04S,n (1.14 • .,.JMU.

25765

85Ml71

j l -

85Ml73