62 minute read

Functional changes as compared with JAGUAR 20/25 km/h from serial no. 492 00133 - 492 01613 see 1.1

from CLAAS Combines JAGUAR 900 - 830 900 - 830 PROFISTAR 900 - 830 Hydraulic Technical Systems Manual

Chapter

Index................................................................................. index-1

1 Overall hydraulic system

1.1 Hydraulic circuit diagrams......................................... 1-4 1.1.1 JAGUAR 20/25km/h from serial no. 492 01614........ 1-4 1.1.2 JAGUAR 20/25km/h from serial no. 492 00133 ñ 492 01613.................. 1-10 1.1.3 JAGUAR 20/25km/h km/h from serial no. 492 00011 ñ 492 00132.................. 1-16 1.1.4 JAGUAR SPEEDSTAR/PROFISTAR with electro-hydraulic ground drive (EFA)...................... 1-22

1.2 Valve inserts............................................................ 1-26

1.2.1 Overview of valve inserts........................................ 1-26 1.2.2 Function of valve inserts......................................... 1-27

1.1

Hydraulic circuit diagrams

1.1.1

JAGUAR 20/25 km/h

- from serial no. 492 01614

1.1 Hydraulic circuit diagrams 1.1.1 JAGUAR 20/25km/h from serial no. 492 01614

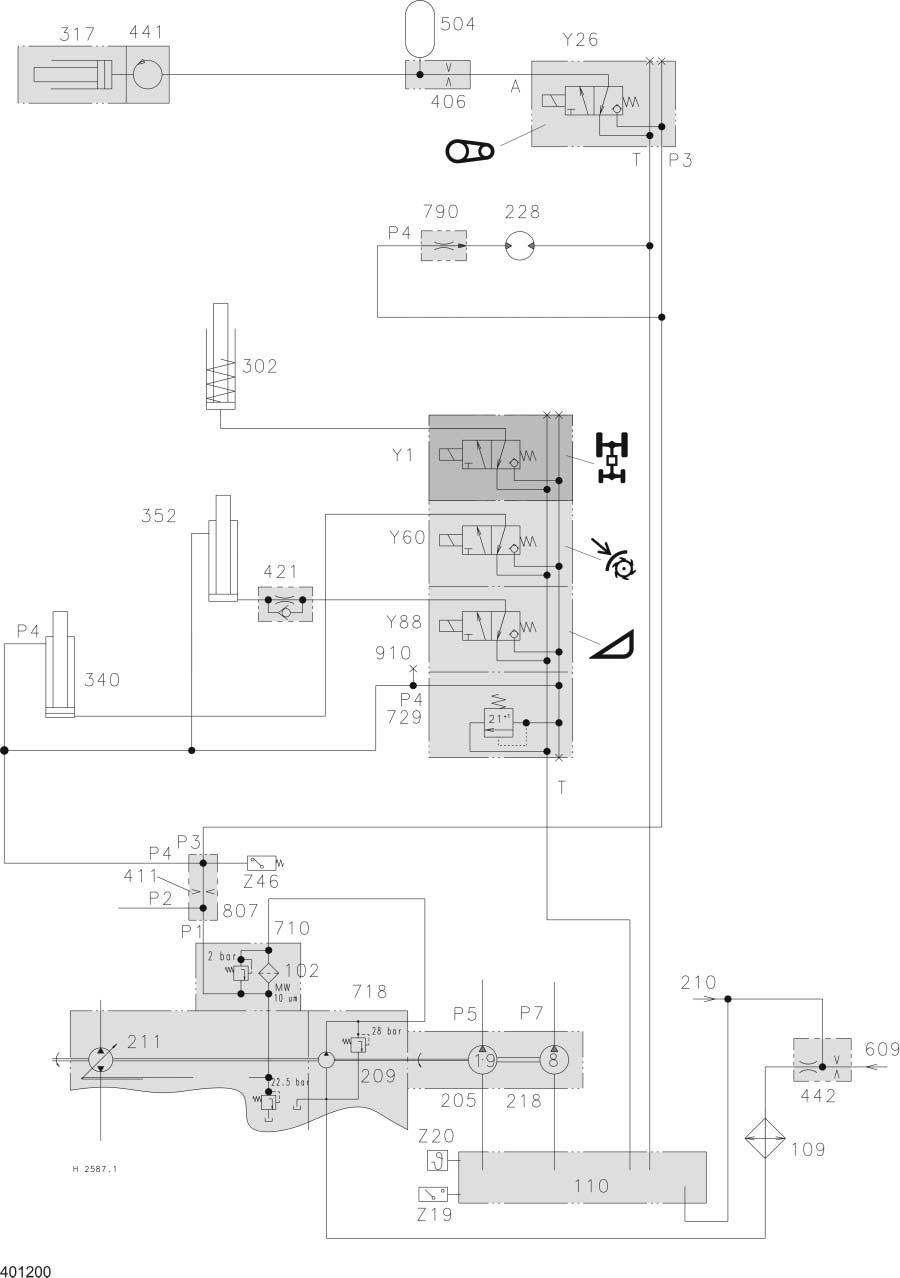

Functional changes as compared with JAGUAR 20/25 km/h from serial no. 492 00133 - 492 01613 (see 1.1.2): - the suction arm drive motor (228) runs permanently because it is supplied with oil directly from the line header (807). - the line header (807) has been added. - the front attachment clutch hydraulic cylinder (352) has been modified as from serial no. 1820, this eliminates the optional one-way restrictor valve 422 for RU.

Item Designation

Remark B2 Ground pressure oil pressure sensor Sensor B5 Working hydraulics oil pressure sensor Sensor Y1 4-Trac (all-wheel drive) solenoid coil 3/2 way solenoid valve Y2 Discharge door close solenoid coil 3/2 way solenoid valve Y3 Discharge door far solenoid coil 3/2 way solenoid valve Y4 Upper discharge chute slow/fast rotation solenoid coil 2-step restrictor Y5 Upper discharge chute left rotation solenoid coil 3/2 way solenoid valve Y6 Upper discharge chute right rotation solenoid coil 3/2 way solenoid valve Y7 Upper discharge chute raise solenoid coil 3/2 way solenoid valve Y8 Upper discharge chute lower solenoid coil 3/2 way solenoid valve Y9 AUTOPILOT left solenoid coil 3/2 way solenoid valve Y10 AUTOPILOT right solenoid coil 3/2 way solenoid valve Y26 Main drive solenoid coil 3/2 way solenoid valve Y29 Raise hitch solenoid coil 3/2 way solenoid valve Y30 Lower hitch solenoid coil 3/2 way solenoid valve Y60 Cover solenoid coil 3/2 way solenoid valve Y61 Sharpening stone left movement solenoid coil 3/2 way solenoid valve Y62 Sharpening stone right movement solenoid coil 3/2 way solenoid valve Y72 Additional control valve 1 ñ A solenoid coil 3/2 way solenoid valve Y73 Additional control valve 1 ñ B solenoid coil 3/2 way solenoid valve Y77 Working hydraulics circulation shut-off valve solenoid coil 2/2 way solenoid valve Y85 Raise front attachment solenoid coil 2/3 way solenoid valve (PWM) Y86 Reverse front attachment solenoid coil 3/2 way solenoid valve Y87 Lower front attachment solenoid coil 3/3 way solenoid valve (PWM) Y88 Front attachment clutch solenoid coil 3/2 way solenoid valve Y93 Additional control valve 2 ñ A solenoid coil 3/2 way solenoid valve Y94 Additional control valve 2 ñ B solenoid coil 3/2 way solenoid valve Z19 Hydraulic oil level switch (min.) Oil level OK, switch open Z20 Hydraulic oil temperature Normally open contact Z46 Low-pressure hydraulics/ground drive oil pressure actual value function switch Oil level OK, switch open Z47 Reverser drive end position actual value function switch Normally open contact Z52 Sharpening stone left movement oil pressure actual value function switch Sharpening stone in parking position, switch open Z53 Sharpening stone right movement oil pressure actual value function switch Sharpening stone in parking position, switch closed 102 Pressure filter 10 µm 104 Control pressure vent plug 107 Oil drain 109 Hydraulic system oil cooler 110 Oil tank 112 Return flow filter Sieve filter 205 Working hydraulics pump 19 cm /rev. at n = 2890 rpm 206 Upper discharge chute rotation drive motor 160 cm /rev. 209 Ground drive feed pump 22.5 cm /rev. at n = 2890 rpm 210 Ground drive variable displacement motor See ESIS

Item Designation Remark 211 Ground drive variable displacement pump See ESIS 218 Steering hydraulics pump 8 cm /rev. at n = 2890 rpm 11 cm /rev. for JAGUAR with electronic ground drive 226 Front attachment reverser drive motor 470 cm /rev. 228 Suction arm drive motor 50 cm /rev. 233 Silage additive pump 302 All-wheel drive clutch hydraulic cylinder actuated by oil pressure 303 Discharge door hydraulic cylinder 304 Upper discharge chute hydraulic cylinder 313 Ground drive servo control pump hydraulic cylinder 317 Main drive clutch hydraulic cylinder actuated by oil pressure 323-1 Steering hydraulics cylinder 323-3 Steering hydraulics cylinder (all-wheel drive) 332 Pick-up crop guard lift hydraulic cylinder 333 Pick-up auger lift hydraulic cylinder 340 Cover hydraulic cylinder 341 Sharpening stone movement hydraulic cylinder 351 Front attachment raise/lower hydraulic cylinder 352 Front attachment clutch hydraulic cylinder new cylinder as from serial no. 1820 353 Front attachment reverse hydraulic cylinder 355 Ground drive servo control motor hydraulic cylinder 405 Orifice plate ∅ 0.6 mm 406 Orifice plate ∅ 0.8 mm 411 Orifice plate ∅ 1.8 mm 421 Front attachment engage one-way restrictor valve 422 Front attachment engage one-way restrictor valve option for RU, is dropped as from serial no. 1820 441 Rotary coupling 442 Venturi meter 501 Working hydraulics pre-pressurization accumulator 0.75 l, pre-pressurized to 80 bar 504 Main drive clutch accumulator 0.075 l, pre-pressurized to 6 bar 511 Front attachment relief accumulator pre-pressurized to 40 bar 609 Orbitrol steering unit rotary disc valve OSPC 200 612 Front attachment load switch-over valve mechanically actuated 614 Front attachment lower flow control valve mechanically actuated 615 Ground drive direction control pressure valve mechanically actuated 616 Ground drive speed control pressure valve mechanically actuated 617 Working hydraulics pre-pressurization relief screw valve mechanically actuated 703 Working hydraulics pressure relief valve 175+15 bar, hydraulically actuated 707 Pressure holding valve (non-return valve) hydraulically actuated 708 Ground drive pressure cut-off valve hydraulically actuated 710 Ground drive filter bypass valve ∆p = 2 bar, hydraulically actuated 713 Ground drive multifunction valve backward valve 420 bar, hydraulically actuated 714 Ground drive multifunction valve forward valve 420 bar, hydraulically actuated 716 Ground drive feed pressure relief valve hydraulically actuated 718 Ground drive feed circuit cold weather starting valve hydraulically actuated 719 Ground drive tap pressure control valve hydraulically actuated 721 Ground drive oil tapping shuttle valve hydraulically actuated 725 Steering double shock valve hydraulically actuated 726 Steering pressure relief valve hydraulically actuated 728 Anti-cavitation valve (non-return valve) hydraulically actuated 729 Low-pressure hydraulics pressure relief valve hydraulically actuated 732 Non-return valve hydraulically actuated 734 Lock-up valve unit (non-return valve) hydraulically actuated 737 Ground drive servo control motor speed valve hydraulically actuated

Item Designation Remark 738 Ground drive servo control forward/backward valve hydraulically actuated 742 Steering safety valve hydraulically actuated 743 Pilot-controlled one way valve 2/2 way, hydraulically actuated 790 Suction arm drive flow control valve Q = 2 l/min, hydraulically actuated 804 Whole crop harvesting cutterbar quick release coupling 807 Line header 901 Working hydraulics measuring point 902 Ground drive hydraulics high pressure backward measuring point 903 Ground drive hydraulics high pressure forward measuring point 908 Ground drive hydraulics control pressure forward measuring point 909 Steering hydraulics measuring point 910 Low-pressure hydraulics measuring point Minimess port

1.1.2

JAGUAR 20/25 km/h

- from serial no 492 00133 ñ 492 01613

Functional changes as compared with JAGUAR 20/25 km/h from serial no. 492 00011-492 00132 (see 1.1.3): - The ground drive control pressure shuttle valve (739) has been dropped.

The line installation in this area was modified accordingly.

Item Designation

Remark B2 Ground pressure oil pressure sensor Sensor B5 Working hydraulics oil pressure sensor Sensor Y1 4-Trac (all-wheel drive) solenoid coil 3/2 way solenoid valve Y2 Discharge door close solenoid coil 3/2 way solenoid valve Y3 Discharge door far solenoid coil 3/2 way solenoid valve Y4 Upper discharge chute slow/fast rotation solenoid coil 2-step restrictor Y5 Upper discharge chute left rotation solenoid coil 3/2 way solenoid valve Y6 Upper discharge chute right rotation solenoid coil 3/2 way solenoid valve Y7 Upper discharge chute raise solenoid coil 3/2 way solenoid valve Y8 Upper discharge chute lower solenoid coil 3/2 way solenoid valve Y9 AUTOPILOT left solenoid coil 3/2 way solenoid valve Y10 AUTOPILOT right solenoid coil 3/2 way solenoid valve Y26 Main drive solenoid coil 3/2 way solenoid valve Y29 Raise hitch solenoid coil 3/2 way solenoid valve Y30 Lower hitch solenoid coil 3/2 way solenoid valve Y60 Cover solenoid coil 3/2 way solenoid valve Y61 Sharpening stone left movement solenoid coil 3/2 way solenoid valve Y62 Sharpening stone right movement solenoid coil 3/2 way solenoid valve Y72 Additional control valve 1 ñ A solenoid coil 3/2 way solenoid valve Y73 Additional control valve 1 ñ B solenoid coil 3/2 way solenoid valve Y77 Working hydraulics circulation shut-off valve solenoid coil 2/2 way solenoid valve Y85 Raise front attachment solenoid coil 2/3 way solenoid valve (PWM) Y86 Reverse front attachment solenoid coil 3/2 way solenoid valve Y87 Lower front attachment solenoid coil 3/3 way solenoid valve (PWM) Y88 Front attachment clutch solenoid coil 3/2 way solenoid valve Y93 Additional control valve 2 ñ A solenoid coil 3/2 way solenoid valve Y94 Additional control valve 2 ñ B solenoid coil 3/2 way solenoid valve Z19 Hydraulic oil level switch (min.) Oil level OK, switch open Z20 Hydraulic oil temperature Normally open contact Z46 Low-pressure hydraulics/ground drive oil pressure actual value function switch Oil level OK, switch open Z47 Reverser drive end position actual value function switch Normally open contact Z52 Sharpening stone left movement oil pressure actual value function switch Sharpening stone in parking position, switch open Z53 Sharpening stone right movement oil pressure actual value function switch Sharpening stone in parking position, switch closed 102 Pressure filter 10 µm 104 Control pressure vent plug 107 Oil drain 109 Hydraulic system oil cooler 110 Oil tank 112 Return flow filter Sieve filter 205 Working hydraulics pump 19 cm /rev. at n = 2890 rpm 206 Upper discharge chute rotation drive motor 160 cm /rev. 209 Ground drive feed pump 22.5 cm /rev. at n = 2890 rpm 210 Ground drive variable displacement motor See ESIS

Item Designation Remark 211 Ground drive variable displacement pump See ESIS 218 Steering hydraulics pump 8 cm /rev. at n = 2890 rpm 11 cm /rev. for JAGUAR with electronic ground drive 226 Front attachment reverser drive motor 470 cm /rev. 228 Suction arm drive motor 50 cm /rev. 233 Silage additive pump 302 All-wheel drive clutch hydraulic cylinder actuated by oil pressure 303 Discharge door hydraulic cylinder 304 Upper discharge chute hydraulic cylinder 313 Ground drive servo control pump hydraulic cylinder 317 Main drive clutch hydraulic cylinder actuated by oil pressure 323-1 Steering hydraulics cylinder 323-2 Steering hydraulics cylinder (all-wheel drive) Up to serial no. 492 01019 323-3 Steering hydraulics cylinder (all-wheel drive) From serial no. 492 01020 332 Pick-up crop guard lift hydraulic cylinder 333 Pick-up auger lift hydraulic cylinder 340 Cover hydraulic cylinder 341 Sharpening stone movement hydraulic cylinder 351 Front attachment raise/lower hydraulic cylinder 352 Front attachment clutch hydraulic cylinder 353 Front attachment reverse hydraulic cylinder 355 Ground drive servo control motor hydraulic cylinder 405 Orifice plate ∅ 0.6 mm 406 Orifice plate ∅ 0.8 mm 411 Orifice plate ∅ 1.8 mm 421 Front attachment engage one-way restrictor valve 422 Front attachment engage one-way restrictor valve optional RU 441 Rotary coupling 442 Venturi meter 501 Working hydraulics pre-pressurization accumulator 0.75 l, pre-pressurized to 80 bar 504 Main drive clutch accumulator 0.075 l, pre-pressurized to 6 bar 511 Front attachment relief accumulator pre-pressurized to 40 bar 609 Orbitrol steering unit rotary disc valve OSPC 250 up to 492 01019 OSPC 200 from 492 01020 OSPC 200 from 492 00133 USA 612 Front attachment load switch-over valve mechanically actuated 614 Front attachment lower flow control valve mechanically actuated 615 Ground drive control pressure direction valve mechanically actuated 616 Ground drive control pressure speed valve mechanically actuated 617 Working hydraulics pre-pressurization relief screw valve mechanically actuated 703 Working hydraulics pressure relief valve 175+15 bar, hydraulically actuated 707 Pressure holding valve (non-return valve) hydraulically actuated 708 Ground drive pressure cut-off valve hydraulically actuated 710 Ground drive filter bypass valve ∆p = 2 bar, hydraulically actuated 713 Ground drive multifunction valve backward valve 420 bar, hydraulically actuated 714 Ground drive multifunction valve forward valve 420 bar, hydraulically actuated 716 Ground drive feed pressure relief valve hydraulically actuated 718 Ground drive feed circuit cold weather starting valve hydraulically actuated 719 Ground drive tap pressure control valve hydraulically actuated 721 Ground drive oil tapping shuttle valve hydraulically actuated 725 Steering double shock valve hydraulically actuated 726 Steering pressure relief valve hydraulically actuated 728 Anti-cavitation valve (non-return valve) hydraulically actuated 729 Low-pressure hydraulics pressure relief valve hydraulically actuated 732 Non-return valve hydraulically actuated 734 Lock-up valve unit (non-return valve) hydraulically actuated 737 Ground drive servo control motor speed valve hydraulically actuated

Item Designation Remark 738 Ground drive servo control forward/backward valve hydraulically actuated 742 Steering safety valve hydraulically actuated 743 Pilot-controlled one way valve 2/2 way, hydraulically actuated 790 Suction arm drive flow control valve Q = 2 l/min, hydraulically actuated 804 Whole crop harvesting cutterbar quick release coupling 901 Working hydraulics measuring point 902 Ground drive hydraulics high pressure backward measuring point 903 Ground drive hydraulics high pressure forward measuring point 908 Ground drive hydraulics control pressure forward measuring point 909 Steering hydraulics measuring point 910 Low-pressure hydraulics measuring point Minimess port

1.1.3

JAGUAR 20/25 km/h

- from serial no. 492 00011 ñ 492 00132

Item Designation

Remark B2 Ground pressure oil pressure sensor Sensor B5 Working hydraulics oil pressure sensor Sensor Y1 4-Trac (all-wheel drive) solenoid coil 3/2 way solenoid valve Y2 Discharge door close solenoid coil 3/2 way solenoid valve Y3 Discharge door far solenoid coil 3/2 way solenoid valve Y4 Upper discharge chute slow/fast rotation solenoid coil 2-step restrictor Y5 Upper discharge chute left rotation solenoid coil 3/2 way solenoid valve Y6 Upper discharge chute right rotation solenoid coil 3/2 way solenoid valve Y7 Upper discharge chute raise solenoid coil 3/2 way solenoid valve Y8 Upper discharge chute lower solenoid coil 3/2 way solenoid valve Y9 AUTOPILOT left solenoid coil 3/2 way solenoid valve Y10 AUTOPILOT right solenoid coil 3/2 way solenoid valve Y26 Main drive solenoid coil 3/2 way solenoid valve Y29 Raise hitch solenoid coil 3/2 way solenoid valve Y30 Lower hitch solenoid coil 3/2 way solenoid valve Y60 Cover solenoid coil 3/2 way solenoid valve Y61 Sharpening stone left movement solenoid coil 3/2 way solenoid valve Y62 Sharpening stone right movement solenoid coil 3/2 way solenoid valve Y72 Additional control valve 1 ñ A solenoid coil 3/2 way solenoid valve Y73 Additional control valve 1 ñ B solenoid coil 3/2 way solenoid valve Y77 Working hydraulics circulation shut-off valve solenoid coil 2/2 way solenoid valve Y85 Raise front attachment solenoid coil 2/3 way solenoid valve (PWM) Y86 Reverse front attachment solenoid coil 3/2 way solenoid valve Y87 Lower front attachment solenoid coil 3/3 way solenoid valve (PWM) Y88 Front attachment clutch solenoid coil 3/2 way solenoid valve Y93 Additional control valve 2 ñ A solenoid coil 3/2 way solenoid valve Y94 Additional control valve 2 ñ B solenoid coil 3/2 way solenoid valve Z19 Hydraulic oil level switch (min.) Oil level OK, switch open Z20 Hydraulic oil temperature Normally open contact Z46 Low-pressure hydraulics/ground drive oil pressure actual value function switch Oil level OK, switch open Z47 Reverser drive end position actual value function switch Normally open contact Z52 Sharpening stone left movement oil pressure actual value function switch Sharpening stone in parking position, switch open Z53 Sharpening stone right movement oil pressure actual value function switch Sharpening stone in parking position, switch closed 102 Pressure filter 10 µm 104 Control pressure vent plug 107 Oil drain 109 Hydraulic system oil cooler 110 Oil tank 112 Return flow filter Sieve filter 205 Working hydraulics pump 19 cm /rev. at n = 2890 rpm 206 Upper discharge chute rotation drive motor 160 cm /rev. 209 Ground drive feed pump 22.5 cm /rev. at n = 2890 rpm 210 Ground drive variable displacement motor See ESIS

Item Designation Remark 211 Ground drive variable displacement pump See ESIS 218 Steering hydraulics pump 8 cm /rev. at n = 2890 rpm 226 Front attachment reverser drive motor 470 cm /rev. 228 Suction arm drive motor 50 cm /rev. 233 Silage additive pump 302 All-wheel drive clutch hydraulic cylinder actuated by oil pressure 303 Discharge door hydraulic cylinder 304 Upper discharge chute hydraulic cylinder 313 Ground drive servo control pump hydraulic cylinder 317 Main drive clutch hydraulic cylinder actuated by oil pressure 323-1 Steering hydraulics cylinder 323-2 Steering hydraulics cylinder (all-wheel drive) 332 Pick-up crop guard lift hydraulic cylinder 333 Pick-up auger lift hydraulic cylinder 340 Cover hydraulic cylinder 341 Sharpening stone movement hydraulic cylinder 351 Front attachment raise/lower hydraulic cylinder 352 Front attachment clutch hydraulic cylinder 353 Front attachment reverse hydraulic cylinder 355 Ground drive servo control motor hydraulic cylinder 405 Orifice plate ∅ 0.6 mm 406 Orifice plate ∅ 0.8 mm 411 Orifice plate ∅ 1.8 mm 421 Front attachment engage one-way restrictor valve 422 One-way restrictor valve optional RU 441 Rotary coupling 442 Venturi meter 501 Working hydraulics pre-pressurization accumulator 0.75 l, pre-pressurized to 80 bar 504 Main drive clutch accumulator 0.075 l, pre-pressurized to 6 bar 511 Front attachment relief accumulator pre-pressurized to 40 bar 609 Orbitrol steering unit rotary disc valve OSPC 250 612 Front attachment load switch-over valve mechanically actuated 614 Front attachment lower flow control valve mechanically actuated 615 Ground drive control pressure direction valve mechanically actuated 616 Ground drive control pressure speed valve mechanically actuated 617 Working hydraulics pre-pressurization relief screw valve mechanically actuated 703 Working hydraulics pressure relief valve 175+15 bar, hydraulically actuated 707 Pressure holding valve (non-return valve) hydraulically actuated 708 Ground drive pressure cut-off valve hydraulically actuated 710 Ground drive filter bypass valve ∆p = 2 bar, hydraulically actuated 713 Ground drive multifunction valve backward valve 420 bar, hydraulically actuated 714 Ground drive multifunction valve forward valve 420 bar, hydraulically actuated 716 Ground drive feed pressure relief valve hydraulically actuated 718 Ground drive feed circuit cold weather starting valve hydraulically actuated 719 Ground drive tap pressure control valve hydraulically actuated 721 Ground drive oil tapping shuttle valve hydraulically actuated 725 Steering double shock valve hydraulically actuated 726 Steering pressure relief valve hydraulically actuated 728 Anti-cavitation valve (non-return valve) hydraulically actuated 729 Low-pressure hydraulics pressure relief valve 21+1 bar 732 Non-return valve hydraulically actuated 734 Lock-up valve unit (non-return valve) hydraulically actuated 737 Ground drive servo control motor speed valve hydraulically actuated

Item Designation Remark 738 Ground drive servo control forward/backward valve hydraulically actuated 739 Ground drive control pressure shuttle valve 742 Steering safety valve hydraulically actuated 743 Pilot-controlled one way valve 2/2 way, hydraulically actuated 790 Suction arm drive flow control valve Q = 2 l/min, hydraulically actuated 804 Whole crop harvesting cutterbar quick release coupling 901 Working hydraulics measuring point 902 Ground drive hydraulics high pressure backward measuring point 903 Ground drive hydraulics high pressure forward measuring point 908 Ground drive hydraulics control pressure forward measuring point 909 Steering hydraulics measuring point 910 Low-pressure hydraulics measuring point Minimess port

1.1.4

JAGUAR

1.1.4 JAGUAR SPEEDSTAR/PROFISTAR with electro-hydraulic ground drive (EFA)

Item Designation

Remark B2 Ground pressure oil pressure sensor Sensor B5 Working hydraulics oil pressure sensor Sensor B97 Drive hydraulics forward high-pressure sensor B98 Drive hydraulics backward high-pressure sensor Y1 4-Trac (all-wheel drive) solenoid coil 3/2 way solenoid valve Y2 Discharge door close solenoid coil 3/2 way solenoid valve Y3 Discharge door far solenoid coil 3/2 way solenoid valve Y4 Upper discharge chute slow/fast rotation solenoid coil 2-step restrictor Y5 Upper discharge chute left rotation solenoid coil 3/2 way solenoid valve Y6 Upper discharge chute right rotation solenoid coil 3/2 way solenoid valve Y7 Upper discharge chute raise solenoid coil 3/2 way solenoid valve Y8 Upper discharge chute lower solenoid coil 3/2 way solenoid valve Y9 AUTOPILOT left solenoid coil 3/2 way solenoid valve Y10 AUTOPILOT right solenoid coil 3/2 way solenoid valve Y26 Main drive solenoid coil 3/2 way solenoid valve Y29 Raise hitch solenoid coil 3/2 way solenoid valve Y30 Lower hitch solenoid coil 3/2 way solenoid valve Y59 Servo circuit solenoid coil 3/2 way solenoid valve Y60 Cover solenoid coil 3/2 way solenoid valve Y61 Sharpening stone left movement solenoid coil 3/2 way solenoid valve Y62 Sharpening stone right movement solenoid coil 3/2 way solenoid valve Y72 Additional control valve 1 ñ A solenoid coil 3/2 way solenoid valve Y73 Additional control valve 1 ñ B solenoid coil 3/2 way solenoid valve Y77 Working hydraulics circulation shut-off valve solenoid coil 2/2 way solenoid valve Y85 Raise front attachment solenoid coil 2/3 way solenoid valve (PWM) Y86 Reverse front attachment solenoid coil 3/2 way solenoid valve Y87 Lower front attachment solenoid coil 3/3 way solenoid valve (PWM) Y88 Front attachment clutch solenoid coil 3/2 way solenoid valve Y93 Additional control valve 2 ñ A solenoid coil 3/2 way solenoid valve Y94 Additional control valve 2 ñ B solenoid coil 3/2 way solenoid valve Y141 Ground drive forward solenoid coil Y142 Ground drive backward solenoid coil Y143 Ground drive/cut off valve solenoid coil Y144 Ground drive variable displacement motor solenoid coil Z19 Hydraulic oil level switch (min.) Oil level OK, switch open Z20 Hydraulic oil temperature Normally open contact Z46 Low-pressure hydraulics/ground drive oil pressure actual value function switch Oil level OK, switch open Z47 Reverser drive end position actual value function switch Normally open contact Z52 Sharpening stone left movement oil pressure actual value function switch Sharpening stone in parking position, switch open Z53 Sharpening stone right movement oil pressure actual value function switch Sharpening stone in parking position, switch closed 102 Pressure filter 10 µm 107 Oil drain 109 Hydraulic system oil cooler 110 Oil tank 112 Return flow filter Sieve filter 205 Working hydraulics pump 19 cm /rev. at n = 2890 rpm 206 Upper discharge chute rotation drive motor 160 cm /rev. 209 Ground drive feed pump 22.5 cm /rev. at n = 2890 rpm 210 Ground drive variable displacement motor See ESIS

Item Designation Remark 211 Ground drive variable displacement pump See ESIS 218 Steering hydraulics pump 8 cm /rev. at n = 2890 rpm 11 cm /rev. for JAGUAR with electronic ground drive 226 Front attachment reverser drive motor 470 cm /rev. 228 Suction arm drive motor 50 cm /rev. 233 Silage additive pump 302 All-wheel drive clutch hydraulic cylinder actuated by oil pressure 303 Discharge door hydraulic cylinder 304 Upper discharge chute hydraulic cylinder 313 Ground drive servo control pump hydraulic cylinder 317 Main drive clutch hydraulic cylinder actuated by oil pressure 323-1 Steering hydraulics cylinder 323-3 Steering hydraulics cylinder (all-wheel drive) 332 Pick-up crop guard lift hydraulic cylinder 333 Pick-up auger lift hydraulic cylinder 340 Cover hydraulic cylinder 341 Sharpening stone movement hydraulic cylinder 351 Front attachment raise/lower hydraulic cylinder 352 Front attachment clutch hydraulic cylinder 353 Front attachment reverse hydraulic cylinder 355 Ground drive servo control motor hydraulic cylinder 359 Shifter rail locking 405 Orifice plate ∅ 0.6 mm 406 Orifice plate ∅ 0.8 mm 413 Orifice plate ∅ 2.2 mm 421 Front attachment engage one-way restrictor valve 441 Rotary coupling 442 Venturi meter 501 Working hydraulics pre-pressurization accumulator 0.75 l, pre-pressurized to 80 bar 504 Main drive clutch accumulator 0.075 l, pre-pressurized to 6 bar 511 Front attachment relief accumulator pre-pressurized to 40 bar 609 Orbitrol steering unit rotary disc valve OSPC 200, mechanically actuated 612 Front attachment load switch-over valve mechanically actuated 614 Front attachment lower flow control valve mechanically actuated 617 Working hydraulics pre-pressurization relief screw valve mechanically actuated 703 Working hydraulics pressure relief valve 175+15 bar, hydraulically actuated 707 Pressure holding valve (non-return valve) hydraulically actuated 710 Ground drive filter bypass valve ∆p = 2 bar, hydraulically actuated 713 Ground drive multifunction valve backward valve 420 bar, hydraulically actuated 714 Ground drive multifunction valve forward valve 420 bar, hydraulically actuated 716 Ground drive feed pressure relief valve hydraulically actuated 718 Ground drive feed circuit cold weather starting valve hydraulically actuated 719 Ground drive tap pressure control valve hydraulically actuated 721 Ground drive oil tapping shuttle valve hydraulically actuated 725 Steering double shock valve hydraulically actuated 726 Steering pressure relief valve hydraulically actuated 728 Anti-cavitation valve (non-return valve) hydraulically actuated 729 Low-pressure hydraulics pressure relief valve hydraulically actuated 734 Lock-up valve unit (non-return valve) hydraulically actuated

Item Designation Remark 738 Ground drive servo control forward/backward valve hydraulically actuated 742 Steering safety valve hydraulically actuated 743 Pilot-controlled one way valve 2/2 way, hydraulically actuated 757 Ground drive additional feed valve 758 Ground drive restrictor valve 790 Suction arm drive flow control valve Q = 2 l/min, hydraulically actuated 804 Whole crop harvesting cutterbar quick release coupling 807 Line header 901 Working hydraulics measuring point 909 Steering hydraulics measuring point 910 Low-pressure hydraulics measuring point Minimess port 916 Working hydraulics pump measuring point

1.2 Valve inserts 1.2.1 Overview of valve inserts

Valve inserts in the directional control valves

Fig. Item Designation Remark Marking at top Marking at bottom Order no.

A None None 2 631 442.0 B Y2 Discharge door close solenoid coil 3/2 way solenoid valve None None 631 444.0 Y3 Discharge door far solenoid coil 3/2 way solenoid valve None None 631 444.0

Y4 Upper discharge chute slow/fast rotation solenoid coil Y5 Upper discharge chute left rotation solenoid coil Y6 Upper discharge chute right rotation solenoid coil Y7 Upper discharge chute raise solenoid coil Y8 Upper discharge chute lower solenoid coil Y72 Additional control valve 1 ñ A solenoid coil Y73 Additional control valve 1 ñ B solenoid coil Y93 Additional control valve 2 ñ A solenoid coil Y94 Additional control valve 2 ñ B solenoid coil 2-step restrictor 3/2 way solenoid valve 3/2 way solenoid valve 3/2 way solenoid valve 3/2 way solenoid valve 3/2 way solenoid valve 3/2 way solenoid valve 3/2 way solenoid valve 3/2 way solenoid valve None None 631 444.0

None None 631 444.0

None None 631 444.0

None None 631 444.0

None None 631 444.0

None None 631 444.0

None None 631 444.0

None None 631 444.0

None None 631 444.0

C Y61 Sharpening stone left movement solenoid coil Y62 Sharpening stone right movement solenoid coil 3/2 way solenoid valve 3/2 way solenoid valve 2 3 631 482.0

2 3 631 482.0

D 1 3 631 483.0

E 4 2 631 500.0

F 3 3 631 421.1

G without shoulder None 631 525.0

H None None 631 524.0

K ñ Ball V ñ pilot spool Note: When disassembling or replacing a valve insert, the copper ring 094 001.0 must be replaced.

Some of the solenoid valve coil cores are equipped with a return spring in which case they are marked with an "F" on the face end. When performing repairs, these coil cores with return spring 213 030.1 may also be used for functions without return spring.

Description of function Some of the valve inserts used are listed below in order to make the differences between these inserts regarding their function on the machine clear.

631 444.0

Spherical seat 2.5 mm Spool 2.8 mm This valve insert is designed as a spool-type seated valve and therefore closes the return line to the tank before the spherical seat is opened. A positive overlap avoids both oil losses during the switch-over process and pressure peaks in the tank line which is important when operating accumulators. In this valve, the stroke is limited by the solenoid which has the biggest force in its end position, thus delaying the switch-off time due to the residual magnetism.

631 482.0

Spherical seat 1.8 mm Conical seat 3.7 mm This conical seat valve has a mechanical stop provided by the cone, preventing the solenoid from reaching its end position and ensuring that the valve cuts off very fast as compared to the spool-type seated valves. In addition, the large conical seat in this valve has a pressure-limiting function. The small spherical seat here acts as a restrictor and allows the valve to switch against relatively high pressure levels with a small current intensity.

Pressure limitation The pressure limitation for this conical seat valve (631482.0) is set to approx. 120 bar. Setting is carried out by using a valve insert with a relatively large cross-section at the conical seat. The hydraulic force acts on the valve insert and consequently also on the electromagnetic force. Starting at a pressure of 120 bar, the conical seat in the valve insert opens because the electromagnetic force is not sufficient any more and the oil pressure is relieved to the tank.

2 Steering hydraulics

2.1 Hydraulic circuit diagram..........................................................2-2

2.2 Function diagram of steering hydraulics..................................2-4

2.2.1 Neutral.....................................................................................2-4 2.2.2 Steering actuation....................................................................2-6

2.3 Checking the steering..............................................................2-8

2.4 Autopilot solenoid valve.........................................................2-10

2.5 Testing and measurements...................................................2-12

2.1 Hydraulic circuit diagram

Item Designation Remark Y9 AUTOPILOT left solenoid coil 3/2 way solenoid valve Y10 AUTOPILOT right solenoid coil 3/2 way solenoid valve Y77 Working hydraulics circulation shut-off valve solenoid coil 2/2 way solenoid valve Y85 Raise front attachment solenoid coil 2/3 way solenoid valve (PWM) Y86 Reverse front attachment solenoid coil 3/2 way solenoid valve Y87 Lower front attachment solenoid coil 3/3 way solenoid valve (PWM) Z19 Hydraulic oil level switch (min.) Oil level OK, switch open Z20 Hydraulic oil temperature switch Normally open contact 102 Pressure filter 10 µm 109 Hydraulic system oil cooler 110 Oil tank 112 Return flow filter Sieve filter 205 Working hydraulics pump 19 cm /rev. at n = 2890 rpm 209 Ground drive feed pump 22.5 cm /rev. at n = 2890 rpm 211 Ground drive variable displacement pump 105 cm /rev. 218 Steering hydraulics pump 8 cm /rev. at n = 2890 rpm 11 cm /rev. for JAGUAR with electronic ground drive 323-1 Steering hydraulics cylinder 323-2 Steering hydraulics cylinder (all-wheel drive) Up to serial no. 492 01019 323-3 Steering hydraulics cylinder (all-wheel drive) From serial no. 492 01020 442 Venturi meter 609 Orbitrol steering unit rotary disc valve OSPC 250 up to 492 01019 OSPC 200 from 492 01020 OSPC 200 from 492 00133 USA 614 Front attachment lower flow control valve mechanically actuated 703 Working hydraulics pressure relief valve 175 +15 bar, hydraulically actuated 707 Pressure holding valve (non-return valve) hydraulically actuated 710 Ground drive filter bypass valve ∆p = 2 bar, hydraulically actuated 718 Ground drive feed circuit cold weather starting valve hydraulically actuated 725 Steering double shock valve hydraulically actuated 726 Steering pressure relief valve hydraulically actuated 728 Anti-cavitation valve (non-return valve) hydraulically actuated 742 Steering safety valve hydraulically actuated 743 Pilot-controlled one way valve 2/2 way, hydraulically actuated 901 Working hydraulics measuring point 909 Steering hydraulics measuring point Remark: In drawing H 2593.0, component 757 Ground drive additional feed valve is missing for JAGUAR SPEEDSTAR/PROFISTAR with electronic ground drive.

2.2 Function diagram of steering hydraulics 2.2.1 Neutral

Item Designation Remark 112 Return flow filter Sieve filter 218 Steering hydraulics pump 8 cm /rev. at n = 2890 rpm 229 Steering hydraulics proportioning pump 323-1 Steering hydraulics cylinder 323-2 Steering hydraulics cylinder (all-wheel drive) Up to serial no. 492 01019 323-3 Steering hydraulics cylinder (all-wheel drive) From serial no. 492 01020 609 Orbitrol steering unit rotary disc valve OSPC 250 up to 492 01019 OSPC 200 from 492 01020 OSPC 200 from 492 00133 USA 725 Steering double shock valve hydraulically actuated 726 Steering pressure relief valve hydraulically actuated 728 Anti-cavitation valve (non-return valve) hydraulically actuated 742 Steering safety valve hydraulically actuated Steering system Open center = when the steering is in neutral position, there is a connection between pump and tank. Non reaction = when the steering is in neutral position, a force acting on the steered wheels does not cause any reaction on the steering wheel.

Designations: O ñ Orbit (Orbitrol) S ñ Steering P ñ Pump C ñ Version 250 ñ Oil displacement in cm /rev. 200 ñ Oil displacement in cm /rev. V ñ Valve block 20 ñ Pressure setting of shock valves x10

Pressure measurement: Circulation pressure = 17+8 bar System pressure = 150+15 bar Shock valve = 200±15 bar

Measuring preconditions: Steering hydraulics: Pressure measurements are carried out at: - maximum volume flow (maximum motor speed), - an oil temperature of 45 ñ 50 C.

Design of valve unit: The steering valve consists of a rotor set (proportioning pump) (229) and a rotating distributor with inner and outer rotary disc (609).

The steering gear shaft actuates the rotary disc (609), the continued rotary movement driving the rotor (229) by means of a socket-type shaft.

Neutral function: In neutral position, the oil is directed back to the tank through the nonreturn valve (742) and the rotary disc (609) (open center). The circulation pressure must not exceed 20 bar.

Both sides of the steering cylinder (323) are shut off by the rotary disc (609). Pressure peaks due to external forces on the steered axle are relieved to the tank via the shock valves (725) (non reaction).

2.2.2 Steering actuation

Emergency steering function When actuating the steering in one direction, the inner rotary disc (609) is twisted against the outer rotary disc (609) by up to 8 . During this process, the return line from the pump (218) to the tank is closed and the connection to the proportioning pump (229) is released.

Via the rotor (229) and the rotary disc (609), the volume flow is released as a function of sense of rotation, path and speed to the piston or the piston rod side of the steering cylinder (323). Here, the displacing surface of the steering cylinder (323) is connected with the return line to the tank via the rotary disc (609).

As soon as there is no more steering motion, leaf springs bring the inner and outer rotary discs (609) back to neutral position. Now both sides of the steering cylinder are shut off again and the connection from the pump (218) to the tank is re-established.

When the steering system is not supplied any more externally by pump (218), the non-return valve (742) closes and thus ensures that no oil will escape from the steering system.

When actuating the steering in one direction, the inner and outer rotary disc (609) are twisted against each other correspondingly. Now the oil can be conveyed from one side of the steering cylinder (323) via nonreturn valve (728) to the other side through human power by driving the rotor (229).

2.3 Checking the steering

Steering gear shaft Height play = 0.1 to 0.3 mm

Clearance from bottom inside rotary valve = 3 mm

Return When the steering wheel is actuated with the diesel engine shut off, the leaf springs in the rotary disc must bring the steering wheel back to its neutral position.

Reaction If steering reaction is insufficient, internal leaks in the steering system must be checked. To do this, disconnect the lines from the steering cylinder and plug them tightly with plugs. With the oil at operating temperature and at max. no-load speed of the diesel engine, the steering wheel must not allow more than 4 turns in both directions when using a force of approx. 25 Nm.

When the actual number of turns is more than 4, check the steering valve for leaks. When the actual number of turns is less than 4, check the steering cylinder and the optional autopilot valve for leaks.

Power In case of insufficient power in the steering, check tyre size, tyre pressure and machine ballast, condition of the connecting rod and smooth action of stub axles.

A pressure test at the steering hydraulics measuring port must show the value 150+15 bar. Adjusting the pressure relief valve on the machine in built-in condition is not possible.

Caution: Any installation work on the steering hydraulics must be followed by venting the system on both hydraulic lines of the steering cylinder with the diesel engine running.

2.4 Autopilot solenoid valve

Item Designation Remark A Port Autopilot left B Port Autopilot right P5 Port Pressure supply T Port Return line Y9 AUTOPILOT left solenoid coil Is activated to make Autopilot steer to the left Y10 AUTOPILOT left solenoid coil Is activated to make Autopilot steer to the right K Piston Opens non-return valve mechanically 734 Lock-up valve unit (non-return valve)

Autopilot ñ steering to the left

Autopilot ñ steering to the right The working hydraulics circulation shut-off valve (Y 77) and the solenoid coil (Y 9) are actuated and open the ball via the pilot spool. Oil flows from P5 to the lock-up valve unit via the ball. The non-return valve (port A) is opened by the oil flow against the spring force and oil flows to the steering cylinder. Before this, the pressure built up pushes the piston (K) towards port (B) and opens the non-return valve (port B). The oil coming from the cylinder return side flows via the open right non-return valve. The return flow lifts the pilot spool of the solenoid coil (Y 10) and thus returns to the tank.

The working hydraulics circulation shut-off valve (Y 77) and the solenoid coil (Y 10) are actuated and open the ball via the pilot spool. Oil flows from P5 to the lock-up valve unit via the ball. The non-return valve (port B) is opened by the oil flow against the spring force and oil flows to the steering cylinder. Before this, the pressure built up pushes the piston (S) towards port (A) and opens the non-return valve (port A). The oil coming from the cylinder return side flows via the open left nonreturn valve. The return flow lifts the pilot spool of the solenoid coil (Y 9) and thus returns to the tank.

Note: The copper ring beneath the valve inserts must be replaced upon each assembly as otherwise leaks may occur.

Dimensions of copper ring: 14 x 8 x 1 mm.

2.5 Testing and measurements

909 Steering hydraulics measuring point 442 Venturi meter

Measuring pre-conditions: Steering hydraulics:

Set values: Pressure measurements are carried out at: - maximum volume flow (maximum motor speed), - an oil temperature of 45 ñ 50 C.

Circulation pressure = 15+8 bar. Maximum pressure = 167+15 bar.

3 Working hydraulics

3.1 Hydraulic circuit diagram..........................................................3-4

3.2 Main valve: Circulation shut-off valve, front attachment raise/lower solenoid valve............................3-8

3.3 Valve combination with accumulator.....................................3-12

3.4 Hitch solenoid valve...............................................................3-14

3.5 Grinding, additional control unit 1, additional control unit 2 solenoid valve.................................3-16

3.6 Corn cracker adjustment........................................................3-18

3.7 Front attachment reverse solenoid valve (Y 86)....................3-22

3.8 Front attachment reverser drive motor (226).........................3-24

3.9 Upper discharge chute rotation drive motor (206).................3-26

3.10 Front attachment load switch-over valve (612)......................3-28

3.11 Pressure accumulator volume switch-over valve (Direct Disc option)................................................................3-30

3.12 Testing and measurements ...................................................3-32

3.1

Hydraulic circuit diagram

3.1 Hydraulic circuit diagram

Item Designation

Remark B2 Ground pressure oil pressure sensor Sensor B5 Working hydraulics oil pressure sensor Sensor Y2 Discharge door close solenoid coil 3/2 way solenoid valve Y3 Discharge door far solenoid coil 3/2 way solenoid valve Y4 Upper discharge chute slow/fast rotation solenoid coil 2-step restrictor Y5 Upper discharge chute left rotation solenoid coil 3/2 way solenoid valve Y6 Upper discharge chute right rotation solenoid coil 3/2 way solenoid valve Y7 Upper discharge chute raise solenoid coil 3/2 way solenoid valve Y8 Upper discharge chute lower solenoid coil 3/2 way solenoid valve Y9 AUTOPILOT left solenoid coil 3/2 way solenoid valve Y10 AUTOPILOT right solenoid coil 3/2 way solenoid valve Y29 Raise hitch solenoid coil 3/2 way solenoid valve Y30 Lower hitch solenoid coil 3/2 way solenoid valve Y61 Sharpening stone left movement solenoid coil 3/2 way solenoid valve Y62 Sharpening stone right movement solenoid coil 3/2 way solenoid valve Y72 Additional control valve 1 ñ A solenoid coil 3/2 way solenoid valve Y73 Additional control valve 1 ñ B solenoid coil 3/2 way solenoid valve Y77 Working hydraulics circulation shut-off valve solenoid coil 2/2 way solenoid valve Y85 Raise front attachment solenoid coil 2/3 way solenoid valve (PWM) Y86 Reverse front attachment solenoid coil 3/2 way solenoid valve Y87 Lower front attachment solenoid coil 3/3 way solenoid valve (PWM) Y93 Additional control valve 2 ñ A solenoid coil 3/2 way solenoid valve Y94 Additional control valve 2 ñ B solenoid coil 3/2 way solenoid valve Z19 Hydraulic oil level switch (min.) Oil level OK, switch open Z20 Hydraulic oil temperature Normally open contact Z47 Reverser drive end position actual value function switch Normally open contact Z52 Sharpening stone left movement oil pressure actual value function switch Sharpening stone in parking position, switch open Z53 Sharpening stone right movement oil pressure actual value function switch Sharpening stone in parking position, switch closed 107 Oil drain 110 Oil tank 112 Return flow filter Sieve filter 205 Working hydraulics pump 19 cm /rev. 206 Upper discharge chute rotation drive motor 160 cm /rev. 209 Ground drive feed pump 22.5 cm /rev. 211 Ground drive variable displacement pump See ESIS 218 Steering hydraulics pump JAGUAR 20/25 km/h = 8 cm /rev. JAGUAR 40 km/h = 11 cm /rev. 226 Front attachment reverser drive motor 470 cm /rev. 233 Silage additive pump 303 Discharge door hydraulic cylinder 304 Upper discharge chute hydraulic cylinder 323 Steering hydraulics cylinder 332 Pick-up crop guard lift hydraulic cylinder 333 Pick-up auger lift hydraulic cylinder 341 Sharpening stone movement hydraulic cylinder 351 Front attachment raise/lower hydraulic cylinder 353 Front attachment reverse hydraulic cylinder 405 Orifice plate ∅ 0.6 mm 406 Orifice plate ∅ 0.8 mm 501 Working hydraulics pre-pressurization accumulator 0.75 l. pre-pressurized to 80 bar 511 Front attachment relief accumulator pre-pressurized to 40 bar 612 Front attachment load switch-over valve mechanically actuated 614 Front attachment lower flow control valve mechanically actuated 617 Working hydraulics pre-pressurization relief screw valve mechanically actuated

Item Designation Remark 703 Working hydraulics pressure relief valve 175+15 bar, hydraulically actuated 707 Pressure holding valve (non-return valve) hydraulically actuated 734 Lock-up valve unit (non-return valve) hydraulically actuated 743 Pilot-controlled one way valve 2/2 way, hydraulically actuated 804 Whole crop harvesting cutterbar quick release coupling 901 Working hydraulics measuring point

3.2 Main valve: Circulation shut-off valve, front attachment raise/lower solenoid valve

Designations A Output to front attachment load switch-over valve (612) T Tank port P5a Pump port P5b Parallel port to other directional control valves G Non-return valve (inlet valve) E Pilot spool F Compressed spring H Front attachment raise spool K Piston R Control spool .......................................................5 ñ 50 l/min U Circulation shut-off valve control spool V Pilot valve

Y 77 Circulation shut-off valve solenoid coil Y 85 Raise front attachment solenoid coil Y 87 Lower front attachment solenoid coil

614 Front attachment lower flow control valve .......................................................5 ñ 50 l/min

703 Pressure relief valve............................................180+15 bar 901 Working hydraulics measuring port 743 Front attachment lower valve 707 Pressure holding valve (non-return valve)

Function description: 1/3

Pressure relief valve The spring in the pressure relief valve (703) is pre-stressed for a system pressure of 180±15 bar. The pressure setting may be modified by removing or adding shims.

A 0.5 mm shim corresponds to approx. 10 bar A 1.2 mm shim corresponds to approx. 23 bar

The above values refer to a rated pressure of 180 bar and may deviate, depending on the actual system. Each time the setting has been modified, the system pressure must be checked.

Note:

Basic setting To ensure the position of spool (H) for the function "Raise front attachment - slow", the dimension from the top edge of the spool (H) to the body must be 4.3 mm with the coil core (Y 85) removed. The position may be corrected by removing or adding shims above the compressed spring in the spool pot (H).

A weaker compressed spring ñ as compared to the spool (H) - is located below the spool of the circulation shut-off valve (U).

The drop rate of the front attachment is set to a drop time of 5-6 seconds over the entire stroke range on the Front attachment lower flow control valve (614) (depending on the corresponding setting of the front attachment load switch-over valve (612)).

Function description:: 2/3

Function of circulation shut-off valve The circulation shut-off valve (Y 77) blocks the circulating volume flow from

P5a to T of the open hydraulic system when a function has been actuated.

Single-acting functions are an exception to this when the consumer is relieved to the tank or when oil pressure is taken from a possibly existing working hydraulics pre-pressurization accumulator (501).

In neutral position, the circulation shut-off valve (Y 77) is not actuated, making the oil flow back to the tank via the ring channels on the spool (U). Due to the large channel cross-section, the circulation pressure is very low.

When pressure must be built up for a consumer or if the working hydraulics pre-pressurization is not sufficient (on machines with accumulator 501), the circulation shut-off valve (Y 77) is actuated using the directional control valve of the corresponding function. Now spool (U) closes the connection from P5a to T, and the top ring channel is closed first in order to achieve smooth switching-over.

The pressure relief valve (703) opens at a maximum system pressure of 180+15 bar and relieves the pressure to the tank.

Function "Raise front attachment - slow" When the "Raise - slow" function is used, the directional control valve (Y 85) is actuated with a pulsed voltage of 80 Hz and approx. 50% PWM (pulse width modulation). At the same time, the circulation shut-off valve (Y 77) is actuated with 12 V DC.

This pulse circuit makes the spool (H) move only to such an extent that the oil must flow via the restrictor pocket inside the spool and the bottom ring channel. The volume flow thus restricted is directed to the consumer port (A) via the non-return valve (G) and slowly raises the front attachment. The residual oil flows back to the tank via the pressure relief valve (703).

Function "Raise front attachment - fast"

Pulse width modulation When the "Raise - fast" function is used, the directional control valve (Y 85) and the circulation shut-off valve (Y 77) are actuated with 12 V DC.

The spool (H) is moved to its end position, making oil flow via both ring channels on the spool (H). The full volume flow is directed to the consumer port (A) via the non-return valve (G) and quickly raises the front attachment.

12V 50%

6VEffektiv

0V

Lex-034 50% 80Hz

Function description: 3/3

Function "Lower front attachment - slow"

Function "Lower front attachment - fast"

Flow control valve When the "Lower - slow" function is used, only the directional control valve (Y 87) is actuated with a pulsed voltage of 80 Hz and approx. 40% PWM (pulse width modulation) by the Contour module A11.

This pulsed circuit is sufficient to open the spherical seat in the pilot valve (V), however, the force is too low to overcome the spring force (F). Spool (E) therefore cannot close the ring channel to the return line. The load caused by the front attachment displaces the oil via the spherical seat and the bores of spool (E) into the return channel to the tank. The small cross-section at the spherical seat now restricts the volume flow, making the front attachment lower slowly.

When the "Lower - fast" function is used, only the directional control valve (Y 87) is actuated with 12 V DC.

The spherical seat in pilot valve (V) is opened and the spring force (F) is overcome through the force of the solenoid. The spool (E) closes the ring channel to the return line, making the load pressure of the front attachment act on the piston plates (K); the load pressure now opens outlet valve (743) due to the surface difference. The oil is now displaced by the front attachment via the outlet valve (743) and the control spool (R) into the return line to the tank. The drop rate of the front attachment here mainly depends on the setting of the flow control valve (614).

When the "Lower front attachment ñ fast" function is used, the oil displaced via port A flows to the tank through the restrictor in the control spool of the flow control valve (614). This creates a ram pressure ahead of the control spool, making the latter move against the control spring and restrict the return channel to the tank as a function of the load pressure. When the load pressure at port A changes, both the oil flow through the restrictor and the load pressure against the control spool change, too, and consequently also the return channel cross-section. This control function keeps the effective oil flow through the restrictor in the control spool and through the cross-section in the return channel constant, regardless of the load pressure.

The front attachment drop rate is adjusted merely by the pre-stress of the control spring at the handwheel. This reduces the effective oil flow by relieving the control spring, since even a low load pressure will restrict the return channel cross-section.

Item Designation Remark A1 Port Rotate upper discharge chute to the right A2 Port Rotate upper discharge chute to the left B1 Port Discharge door close B2 Port Discharge door far B5 Working hydraulics oil pressure Sensor C1 Port Lower upper discharge chute C2 Port Raise upper discharge chute P5 Port Pressure supply under pressure by non-return valve (707) T Port Return line to tank Y2 Discharge door close solenoid coil 3/2 way solenoid valve Y3 Discharge door far solenoid coil 3/2 way solenoid valve Y4 Upper discharge chute slow/fast rotation solenoid coil 2-step restrictor Y5 Upper discharge chute left rotation solenoid coil 3/2 way solenoid valve Y6 Upper discharge chute right rotation solenoid coil 3/2 way solenoid valve Y7 Upper discharge chute raise solenoid coil 3/2 way solenoid valve Y8 Upper discharge chute lower solenoid coil 3/2 way solenoid valve 405 Orifice plate ÿ 0.6 mm 406 Orifice plate ÿ 0.8 mm 501 Working hydraulics pre-pressurization accumulator 0.75 l. pre-pressurized to 80 bar 617 Working hydraulics pre-pressurization relief screw valve mechanically actuated

Function

Caution ñ Danger of accident The pressurized oil from port P5 is under pressure due to non-return valve (707) (see overall circuit diagram). Machines with Autopilot are equipped with the accumulator (501). This accumulator prevents the circulation shut-off valve (Y 77) from being activated too frequently for small oil consumptions in rapid sequence from the pre-pressurized hydraulic circuit P5b (see Main valve) and avoids the resulting oil heat-up. The applied oil pressure is monitored by the working hydraulics sensor (B 5) and reported to the module A9 "Autopilot". If the oil pressure falls below 135 bar, module A9 activates the circulation shut-off valve Y 77 and deactivates it at 165 bar. This pressurized oil is available at all working hydraulics solenoid valves except the front attachment raise and lower solenoid valves.

Prior to performing service work on the working hydraulics, the oil under pressure must be drained by unscrewing the relief screw (617). For function and tasks of the solenoid coils please refer to the table.

Designations Y29 Raise hitch solenoid coil Y30 Lower hitch solenoid coil 734 Lock-up valve unit (non-return valve)

T Tank port P5 Pump via circulation shut-off valve port A Consumer port (see overall circuit diagram) B Consumer port (see overall circuit diagram) K Piston

Neutral function Solenoid coils are not energized. Both sides of the hydraulic cylinder are blocked tightly by the non-return valves (137) in the consumer ports A and B.

Funktion Arbeitsstellung Solenoid coils are energized. According to the required direction of motion, one of the solenoid valves and the working hydraulics circulation shut-off valve (Y 77) are actuated. The corresponding pilot spool opens the ball in the valve insert and closes the return line to the tank. The pressure which consequently rises builds up against piston (K) and opens the non-return valve (137) at port A or B.

The return line of the hydraulic cylinder is thus released to the tank via the valve insert of the unactuated solenoid valve. The pressure rising further now opens the non-return valve (137) at the opposite port and the hydraulic cylinders are retracted or extended.

Note: The copper ring beneath the valve inserts must be replaced upon each assembly as otherwise leaks may occur.

Dimensions of copper ring: 14 x 8 x 1 mm.

3.5 Grinding, additional control unit 1, additional control unit 2 solenoid valve

Designations Y61 Sharpening stone left movement solenoid coil Y62 Sharpening stone right movement solenoid coil Y72 Additional control valve 1 ñ A solenoid coil Y73 Additional control valve 1 ñ B solenoid coil Y93 Additional control valve 2 ñ A solenoid coil Y94 Additional control valve 2 ñ B solenoid coil

T Tank port P5 Pump via circulation shut-off valve port A Consumer port (see overall circuit diagram) B Consumer port (see overall circuit diagram)

Explanation of function, using grinding as an example

0 position None of the solenoid coils (Y 61 / Y 62) is energized. Ports (A) and (B) are connected to the tank (T).

Sharpening stone to the left

(see also overall circuit diagram) The circulation shut-off valve (Y 77) and the solenoid coil (Y 61) are actuated. The pilot spool of the solenoid coil (Y 61) opens the ball against the pressure in port (P5). Volume flow flows from port (P5) via the ball to port (A) and continues to the left-hand connecting rod end of the sharpening stone movement hydraulic cylinder (341). The volume flow displaced during this process from the right-hand connecting rod end of the sharpening stone movement hydraulic cylinder (341) lifts the pilot spool of the solenoid coil (Y62) and thus returns to the tank.

Sharpening stone to the right

(see also overall circuit diagram) The circulation shut-off valve (Y 77) and the solenoid coil (Y 62) are actuated and open the ball via the pilot spool. Oil flows from P5 via the ball to port B, continues to oil pressure switch Z 53 and to the right-hand connecting rod end of the sharpening stone cylinder (341). The return flow coming from the left-hand connecting rod end of the sharpening stone cylinder (341) lifts the pilot spool of the solenoid valve (Y61) and thus returns to the tank.

Pressure limitation The pressure limitation for sharpening is set to approx. 120 bar. Setting is carried out by using a valve insert with a relatively large cross-section at the conical seat. The hydraulic force acts on the valve insert and consequently also on the electromagnetic force. Starting at a pressure of 120 bar, the conical seat in the valve insert opens because the electromagnetic force is not sufficient any more and the oil pressure is relieved to the tank.

Note: The copper ring beneath the valve inserts must be replaced upon each assembly as otherwise leaks may occur.

3.6 Corn cracker adjustment

Item Designation

Remark A Figure Cracker adjusting range (26 mm piston stroke) B Figure Venting range (piston on double pump overall length 231 mm) a Port to left adjusting cylinder b Port to right adjusting cylinder c Port Filling port d Piston is turned in or out for cracker gap adjustment e Port for venting the cracker gap adjustment 356 R Cylinder Cracker gap adjustment, right 356 L Cylinder Cracker gap adjustment, left 230 Corn cracker adjustment pump Serves as a proportioning pump for cracker adjusting cylinder

Adjusting and venting Adjust minimum corn cracker gap at the corn cracker adjustment (double pump 230). Check the gap between the corn cracker rollers at the biggest diameter (with worn rollers), set value 0.5 mm. Adjustment to be carried out at the stop bolts (S). - Remove adjusting device at the corn cracker adjustment pump (230) so that the hexagon socket of piston (d) can be accessed. - Connect minimess hose to the low-pressure hydraulics measuring point (910) and to filling port (c). - Place vent hoses on vent ports (e) of both adjusting cylinders (356) on the right-hand and left-hand side. Direct the vent hoses into a collecting container. - Adjust the corn cracker adjustment pump (230) to 231 mm, see item B. - Start the engine. - Vent cylinders (356 L) and (356 R) until the oil comes out without bubbles. - Stop the engine and remove the minimess hose first from the filling port (c) and then from the low-pressure hydraulics measuring point (910). - Turn in the piston (d) up to the dimension 222 mm, see figure A. - Slightly open the vent ports (e) on the right-hand and left-hand side and relieve the oil pressure, thus re-establishing the mechanical basic position. - Close the vent ports (e) again.

Turn in the piston (d) until the roller gap is 2 mm. Check if the clearance of the cracker rollers is parallel. A tolerance of 0.3 mm is allowed. If the clearance is not parallel, repeat the venting process. Remove vent hoses. Re-fit adjusting device to the corn cracker adjustment pump (230).

In case of mechanical cracker adjustment, adjust the scale value (2 mm) on the scale. In case of electrical cracker adjustment, program the gap clearance of 2 mm in the CIS. (See Operator's Manual)

Caution! During operation, the clearance of the cracker rollers must absolutely not fall below the minimum clearance of 1 mm, i.e. the corn cracker clearance must not be set to less than 1 mm (manual and/or electrical). Otherwise, the bolts (S) might get in contact and cause damage to the corn cracker.

3.7 Front attachment reverse solenoid valve (Y 86)

Designations Y86 Reverse front attachment solenoid coil Z47 Reverser drive end position 226 Front attachment reverser drive motor 353 Front attachment reverse hydraulic cylinder

T Tank port P5 Pump via circulation shut-off valve port A Front attachment reverse hydraulic cylinder port

Neutral function The spring force displaces the oil from the reverser cylinder (353) via the connection from A to T in the solenoid valve (Y 86) to the tank. Port (P5) is shut off.

Reversing function Just before it reaches its end position is the volume flow totally released to the front attachment reverser drive motor (226) by the front attachment reverse hydraulic cylinder (353).

3.8 Front attachment reverser drive motor (226)

Designations: 226 Front attachment reverser drive motor....................470 cm /rev.

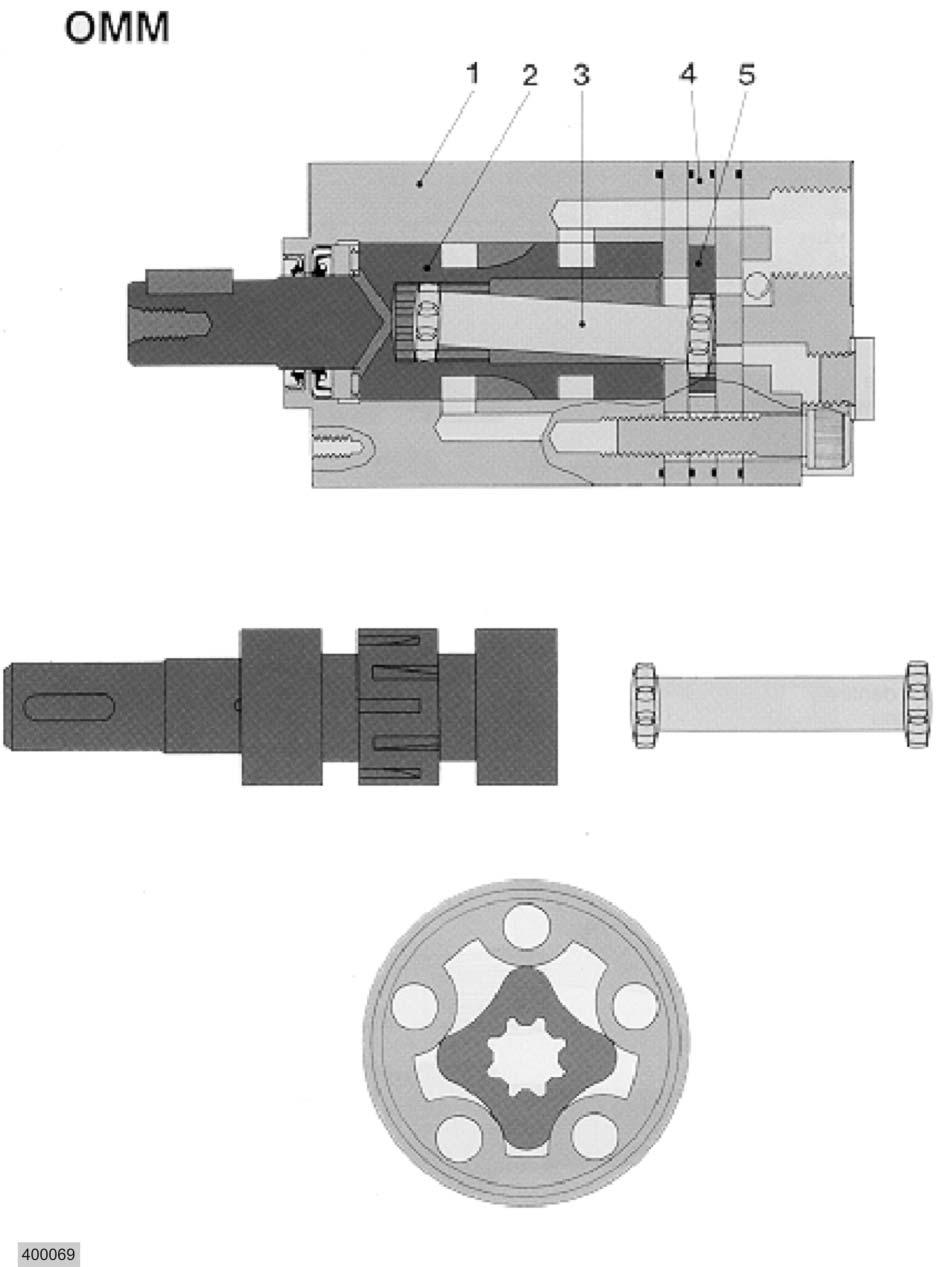

3.9 Upper discharge chute rotation drive motor (206)

Key to diagram: 1 Housing 2 Output shaft / distributor valve 3 Cardan shaft 4 Ring gear 5 Gear

206 Upper discharge chute rotation drive motor ...........160 cm /rev.

3.10 Front attachment load switch-over valve (612)

Task: When lifting lightweight and heavy front attachments, the hydraulic pressure in the Front attachment raise/lower cylinders (351) is kept at the same level.

Benefit: Improved response of Contour system and of ground pressure control with an accumulator. This is made possible by the Front attachment load switch-over valve (612) switching over to different pressure surfaces in the hydraulic cylinders (351).

Designations K Face end of cylinders ÿ 75 mm R Rod end of cylinders = (face end ÿ 75 mm ñ cylinder rod surface ÿ 50 mm) P6 Pressurized oil from Front attachment raise/lower main valve. T Tank port return line X Safety pin to avoid switching over under load, resulting in unwanted lowering of the front attachment.

Figure A This position is selected for lightweight front attachments such as pick-up and 4-row maize header.

Effective hydraulic pressure surface in the Front attachment raise/lower hydraulic cylinders (351): Face end minus rod end = cylinder rod surface ÿ 50 mm.

Figure B Switching position to allow actuating the Front attachment load switchover valve (612). To do this, the front attachment must be lowered and the hydraulic pressure at port P6 must be completely relieved. (pressure display in CIS shows no pressure.) The spring (see X) pushes the safety pin in and the change-over lever of the Front attachment load switch-over valve (612) can be set to the other position.

Figure C This position is used for heavy front attachments such as maize headers, 6-row and 8-row RU maize headers and cutterbars. The rod end of the hydraulic cylinders is connected with the tank. The effective hydraulic pressure surface in the Front attachment raise/lower hydraulic cylinders (351) is the face end ÿ 75 mm.

3.11 Pressure accumulator volume switch-over valve (Direct Disc option)

Key to diagram: 351 Raise/lower front attachment hydraulic cylinder 511 Front attachment relief accumulator 612 Front attachment load switch-over valve 655 Pressure accumulator volume switch-over valve

B2 Downward force oil pressure sensor P Pressurized oil P6 Pressurized oil from Front attachment raise/lower main valve T Tank port

Function The switch-over valve (655) allows increasing the volume of accumulator (511). This is required for better adaptation of the ground pressure control (Contour) when using front attachments of different weights (alternative to Direct Disc mower, as an option).

Operation of accumulator circuit

To operate the accumulator volume switching-over (655), the front attachment must be lowered and the hydraulic pressure at port P6 must be completely relieved. (pressure display in CIS shows no pressure.) The spring (see X) pushes the safety pin in and the lever of the accumulator volume switch-over valve (655) can be set to the other position.

3.12 Testing and measurements

901 Working hydraulics measuring point

Measuring pre-conditions: Working hydraulics: Pressure measurements are carried out at: - maximum volume flow (maximum motor speed), - an oil temperature of 45 ñ 50 C

Set values: Circulation pressure 2.5+6 bar. Maximum pressure 185+15 bar.

4 Low-pressure hydraulics

4.1 Hydraulic circuit diagram......................................................... 4-2

4.1.1 JAGUAR 20/25 km/h from serial no. 492 01614.................... 4-2 4.1.2 JAGUAR 20/25 km/h from serial no. 492 00011 ñ 492 01613................................. 4-4 4.1.3 JAGUAR SPEEDSTAR/PROFISTAR with electro-hydraulic ground drive (EFA)...................................... 4-6

4.2 Position of components.......................................................... 4-8

4.3 Solenoid valve (3/2 way)....................................................... 4-12

4.4 Pressure relief valve............................................................. 4-14

4.5 Front attachment clutch hydraulic cylinder........................... 4-16

4.6 Shifter rail locking hydraulic cylinder..................................... 4-18

4.7 Suction arm drive flow control valve..................................... 4-20

4.8 Suction arm drive motor........................................................ 4-22

4.9 Line header........................................................................... 4-24

4.10 Knife support valve cylinder.................................................. 4-26

4.11 Testing and measurements .................................................. 4-28

4.1 Hydraulic circuit diagram 4.1.1 JAGUAR 20/25 km/h from serial no. 492 01614

Functional changes as compared with JAGUAR 20/25 km/h from serial no. 492 00011-492 01613 (see 5.1.2): - the suction arm drive motor (228) runs permanently because it is supplied with oil directly from the line header (807). - the line header (807) has been added.

Item Designation

Remark Y1 4-Trac (all-wheel drive) solenoid coil 3/2 way solenoid valve Y26 Main drive solenoid coil 3/2 way solenoid valve Y60 Cover solenoid coil 3/2 way solenoid valve Y88 Front attachment clutch solenoid coil 3/2 way solenoid valve Z19 Hydraulic oil level switch (min.) Oil level OK, switch open Z20 Hydraulic oil temperature Normally open contact Z46 Low-pressure hydraulics/ground drive oil pressure actual value function switch Oil level OK, switch open 102 Pressure filter 109 Hydraulic system oil cooler 110 Oil tank 205 Working hydraulics pump 19 cm /rev. at n = 2890 rpm 209 Ground drive feed pump 22.5 cm /rev. at n = 2890 rpm 210 Ground drive variable displacement motor 211 Ground drive variable displacement pump See ESIS 218 Steering hydraulics pump 8 cm /rev. at n = 2890 rpm 228 Suction arm drive motor 50 cm /rev. 302 All-wheel drive clutch hydraulic cylinder actuated by oil pressure 317 Main drive clutch hydraulic cylinder actuated by oil pressure 340 Cover hydraulic cylinder 352 Front attachment clutch hydraulic cylinder new cylinder as from serial no. 1820

406 Orifice plate ∅ 0.8 mm 411 Orifice plate ∅ 1.8 mm 421 Front attachment engage one-way restrictor valve 441 Rotary coupling 442 Venturi meter 504 Main drive clutch accumulator 0.075 l, pre-pressurized to 6 bar 609 Orbitrol steering unit rotary disc valve OSPC 200, mechanically actuated 710 Ground drive filter bypass valve ∆p = 2 bar, hydraulically actuated 718 Ground drive feed circuit cold weather starting valve hydraulically actuated 729 Low-pressure hydraulics pressure relief valve hydraulically actuated 790 Suction arm drive flow control valve Q = 2 l/min, hydraulically actuated 807 Line header 910 Low-pressure hydraulics measuring point Minimess port

Item Designation

Remark Y1 4-Trac (all-wheel drive) solenoid coil 3/2 way solenoid valve Y26 Main drive solenoid coil 3/2 way solenoid valve Y60 Cover solenoid coil 3/2 way solenoid valve Y88 Front attachment clutch solenoid coil 3/2 way solenoid valve Z19 Hydraulic oil level switch (min.) Oil level OK, switch open Z20 Hydraulic oil temperature Normally open contact Z46 Low-pressure hydraulics/ground drive oil pressure actual value function switch Oil level OK, switch open 102 Pressure filter 109 Hydraulic system oil cooler 110 Oil tank 205 Working hydraulics pump 19 cm /rev. at n = 2890 rpm 209 Ground drive feed pump 22.5 cm /rev. at n = 2890 rpm 210 Ground drive variable displacement motor 211 Ground drive variable displacement pump See ESIS 218 Steering hydraulics pump 8 cm /rev. at n = 2890 rpm 228 Suction arm drive motor 50 cm /rev. 302 All-wheel drive clutch hydraulic cylinder actuated by oil pressure 317 Main drive clutch hydraulic cylinder actuated by oil pressure 340 Cover hydraulic cylinder 352 Front attachment clutch hydraulic cylinder 406 Orifice plate ∅ 0.8 mm 411 Orifice plate ∅ 1.8 mm 421 Front attachment engage one-way restrictor valve 422 Front attachment engage one-way restrictor valve option for RU, is dropped as from serial no. 1820 441 Rotary coupling 442 Venturi meter 504 Main drive clutch accumulator 0,075l. pre-pressurized to 6 bar 609 Orbitrol steering unit rotary disc valve OSPC 250 up to 492 01019 OSPC 200 from 492 01020 OSPC 200 from 492 00133 USA 710 Ground drive filter bypass valve ∆p = 2 bar, hydraulically actuated 718 Ground drive feed circuit cold weather starting valve hydraulically actuated 729 Low-pressure hydraulics pressure relief valve hydraulically actuated 790 Suction arm drive flow control valve Q = 2 l/min, hydraulically actuated 910 Low-pressure hydraulics measuring point Minimess port

4.1.3 JAGUAR SPEEDSTAR/PROFISTAR with electro-hydraulic ground drive (EFA)

Item Designation

Remark Y1 4-Trac (all-wheel drive) solenoid coil 3/2 way solenoid valve Y26 Main drive solenoid coil 3/2 way solenoid valve Y59 Servo circuit solenoid coil 3/2 way solenoid valve Y60 Cover solenoid coil 3/2 way solenoid valve Y88 Front attachment clutch solenoid coil 3/2 way solenoid valve Z19 Hydraulic oil level switch (min.) Oil level OK, switch open Z20 Hydraulic oil temperature Normally open contact Z46 Low-pressure hydraulics/ground drive oil pressure actual value function switch Oil level OK, switch open 102 Pressure filter 109 Hydraulic system oil cooler 110 Oil tank 205 Working hydraulics pump 19 cm /rev. at n = 2890 rpm 209 Ground drive feed pump 22.5 cm /rev. at n = 2890 rpm 210 Ground drive variable displacement motor 211 Ground drive variable displacement pump See ESIS 218 Steering hydraulics pump 8 cm /rev. at n = 2890 rpm 228 Suction arm drive motor 50 cm /rev. 302 All-wheel drive clutch hydraulic cylinder actuated by oil pressure 317 Main drive clutch hydraulic cylinder actuated by oil pressure 340 Cover hydraulic cylinder 352 Front attachment clutch hydraulic cylinder 359 Shifter rail locking 406 Orifice plate ∅ 0.8 mm 413 Orifice plate ∅ 2.2 mm 421 Front attachment engage one-way restrictor valve 441 Rotary coupling 442 Venturi meter 504 Main drive clutch accumulator 0.075 l, pre-pressurized to 6 bar 609 Orbitrol steering unit rotary disc valve OSPC 200, mechanically actuated 710 Ground drive filter bypass valve ∆p = 2 bar, hydraulically actuated 718 Ground drive feed circuit cold weather starting valve hydraulically actuated 729 Low-pressure hydraulics pressure relief valve hydraulically actuated 790 Suction arm drive flow control valve Q = 2 l/min, hydraulically actuated 807 Line header 910 Low-pressure hydraulics measuring point Minimess port

4.2 Position of components

Tailgate area

Y59 Servo circuit solenoid coil Y26 Main drive solenoid coil 504 Main drive clutch accumulator

Inside, centre

228 Suction arm drive motor 790 Suction arm drive flow control valve

Front, under right-hand front attachment channel cover

421 Actuate front attachment one-way restrictor valve 352 Front attachment clutch hydraulic cylinder

Centre right

441 Rotary coupling 317 Main drive clutch hydraulic cylinder

Inside, right

Y1 4-Trac (all-wheel drive) solenoid coil Y60 Cover solenoid coil Y88 Front attachment clutch solenoid coil 729 Low-pressure hydraulics pressure relief valve 910 Low-pressure hydraulics measuring point

4.3 Solenoid valve (3/2 way)

Key to diagram: A Consumer port P4 Low-pressure port S Emergency operation screw T Tank port V Valve insert

Description of function:

With the solenoid coil de-energised, a connection is provided from the consumer port (A) to the return line into the tank (T) via the conical seat in the valve insert (V). Here the low pressure (P4) applied is blocked by the spherical seat in the valve insert (V).

When the corresponding solenoid coil for a given function is actuated, the plunger opens the ball in the valve insert (V) and closes the conical seat to the return line (T). The low pressure (P4) is thus applied to the hydraulic cylinder via the consumer port (A).

Note: In case of emergency operation, screw (S) must be screwed in up to the stop to make the conical seat in the valve insert (V) close the return line to the tank (T) tightly.

Key to diagram: 729 Low-pressure hydraulics pressure relief valve............21+4 bar

4.5 Front attachment clutch hydraulic cylinder (352)

Key to diagram::: 352 Front attachment clutch hydraulic cylinder (Figure A: from serial no. 1820 Figure B: up to serial no. 1819)

421 Front attachment engage one-way restrictor valve

422 Front attachment engage one-way restrictor valve (option for RU, is dropped as from serial no. 1820)

4.6 Shifter rail locking hydraulic cylinder

Keys to diagram: 359 Shifter rail locking hydraulic cylinder 624 Venting valve

a Shifter rail b Ball c Compressed spring d Piston e Compressed spring f Port

Function: Shifter rail is locked No pressurized oil is applied at port (f). The compressed spring (e) pushes the piston (d) on the ball (b) which locks the shifter rail (a).

Shifter rail is unlocked The solenoid valve (Y104) has been actuated, making pressurized oil flow beneath the piston (d) via port (f). The piston (d) is actuated to the top against the compressed spring (e). Now the ball (b) is loaded only by the compressed spring (c). The shifter rail (a) can be actuated against this spring force.

Venting procedure

The actuation circuit must be vented:

- when the actuation circuit has been opened, - when shifting gears is possible only after extended actuation of button (K) on the gear shift lever.

1. Set ground speed control lever to N position. 2. Block the machine by actuating the service braking system and the parking brake. 3. Start diesel engine and let it run at idle speed. 4. Press button (K) on the ground speed control lever. 5. Another person opens the vent valve (624). 6. Continue venting until oil comes out without bubbles. Collect any escaping oil. 7. Close vent valve (624).

Note: Check oil level in hydraulic oil tank and add some oil if necessary.

Bezeichnungen: 790 Suction arm drive flow control valve

A Low pressure B To suction arm drive hydraulic motor C Insert D Measuring orifice E Spool F Spring

Function: - Ensuring constant speed of suction arm - Avoiding an oil pressure drop in the low-pressure hydraulics, especially on the main drive clutch.

2 way flow controller: The measuring orifice (D) whose diameter determines the volume flow is part of the movable piston. When the feed flow increases, the piston moves towards the spring (F) and restricts the drain cross-section, keeping the pressure difference at the measuring orifice constant.

4.8 Suction arm drive motor (228)

Designations: 228 Suction arm drive motor..........................................50 cm /rev.

1 Body 2 Drive shaft 3 Cardan shaft 4 Ring gear 5 Gear

Item Designation Remark 102 Pressure filter 413 Orifice plate ∅ 2.2 mm 807 Line header Z46 Pressure switch 12 bar NC contact. Monitors the pressure in the low-pressure hydraulics. P1 Volume flow input from pressure filter (102) P2 Output to the ground drive variable displacement motor (210), input (E). P3 Output to suction arm drive motor (228) P4 Output to low-pressure hydraulics