3 minute read

5th Wheel Adaptor Materials Pod………………………………………………341

5TH WHEEL ADAPTOR

The roof support trailer tow point is specifically designed to attach the machine to a heavy load trailer such as one for transporting longwall roof supports.

The RAS attach plate is fitted with a 5th wheel mechanism for minimising component strain when hauling heavy loads.

The tow point is rated for a 65000 kg roof support trailer with a maximum vertical load of 15000 kg.

Specification

Unladen Mass: 1500 kg Width: 1180 mm Height: 1500 mm Length: 1100 mm Operating Grade (side to side): 1:8

Servicing

Every time the RAS tow point is used a visual inspection should be carried out to ensure that the locking and retention components are in good condition.

1. Check the tow point RAS attach hooks for damage. 2. Check the RAS lock tongue slot and 5th wheel centre for damage or excessive wear. 3. Check that the 5th wheel assembly fasteners are secure and check the 5th wheel assembly for signs of cracking or damage. 4. Check that the RAS lock tongue is fully engaged in the RAS plate lock tongue slot. 5. Check that 5th wheel assembly are free to rotate and release and lock function need to be tested.

Grease 5th wheel assembly every 125 service hours.

It is recommended that non destructive structural integrity testing be carried out annually on the RAS lock tongue slot, the RAS attach hooks and 5th wheel assembly. Three step part dye penetrate testing is recommended.

1. Thoroughly clean and degrease the lock tongue slot plate, RAS attach hooks, and 5th wheel assembly. Allow to dry. 2. Apply the three step non-destructive test as per the manufacturer’s recommendations. 3. Record or mark any suspect areas and have the repair carried out promptly.

Do not use 5th wheel attachment if defects found with the structure or towing components. Losing the trailer when operation could cause serious damage and personal injure. Report the faults immediately to a supervisor and have the fault repaired and verified before use.

Grease Nipper

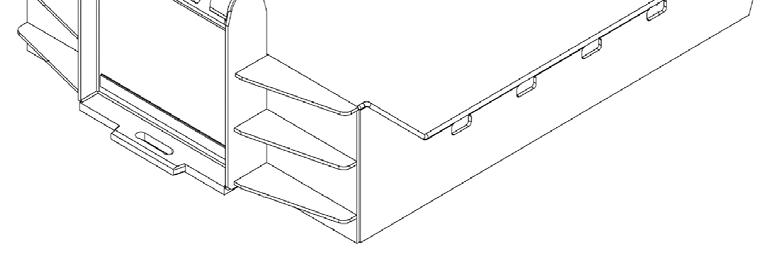

MATERIALS POD

The materials pod attachment is used to carry supplies and equipment within the mine’s structure.

Specifications

Unladen mass: 3320 kg Length: 3477 mm Width: 2505 mm Height: 1410 mm Capacity (Distributed evenly over four pallets): 6700 kg Operating Grade (side to side): 1:8

Servicing

Every time the materials pod is attached to the machine a visual inspection should be carried out to ensure that the components are in good condition.

1. Check the attachment RAS attach hooks for damage and wear. 2. Check the RAS lock tongue slot for damage or excessive wear. 3. Check the materials pod back plate and arm welds for signs of cracking or stress. 4. Check all components for damage, DO NOT use if damaged or faulty. 5. Check that the RAS lock tongue is fully engaged in the RAS plate lock tongue slot. 6. Slew the jib and check for free operation and hydraulic system leaks.

It is recommended that non-destructive structural integrity testing be carried out annually on the RAS lock tongue slot, the RAS attach hooks, jib arm welds and lifting components. Three step part dye penetrate testing is recommended.

1. Thoroughly clean and degrease the lock tongue slot plate, RAS attach hooks, jib arm welds, lifting hook and clevis and associated welds and allow to dry. 2. Apply the three step non-destructive test as per the manufacturer’s recommendations. 3. Record or mark any suspect areas and have the repair carried out promptly.

Tie Downs

RAS Attach Hooks

RAS Lock Tongue Slot

This lifting device shall:

Only be used by trained and authorised operators. Not lift more than the rated laden safe working load. Not be operated on grades more than 1:8 (side to side). Not to exceed the maximum laden tramming speed of one kph. Carry the loads as close as possible to the ground at all times.