1 minute read

Electronic Shut down system

ELECTRONIC SHUTDOWN SYSTEM

GENERAL DESCRIPTION

The electronic shutdown system is an electronic methane and engine monitoring shutdown system for the use on diesel engine powered machinery used for underground coal mining. If the methane in the atmosphere reaches a predetermined low (but still safe) level, the electronic shutdown system will alert the operator to the likely danger with an indicator light. If the methane level in the atmosphere reaches a predetermined high (and dangerous) level, the electronic shutdown system will shutdown the machine’s engine and indicate with a light the reason for the shutdown. The electronic shutdown system, also checks for several alarm conditions on the machine. If any hazard is detected, it will shutdown the machine and light up the appropriate display LEDs on the display panel.

The shutting down of the machine is effected via a solenoid valve that controls the pilot air pressure for the shut off valve on the machine. Should there be a malfunction in the solenoid circuit, the operator is also alerted with another display LED.

POWER SUPPLY

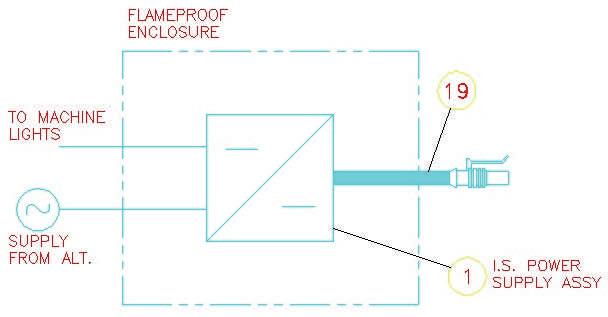

A small standby battery that is charged by the 12 V alternator driven by the machine's engine powers the electronic shutdown system. The supply from the alternator first passes through safety circuits that are housed in a flameproof enclosure. The supply leaves the flameproof enclosure as an intrinsically safe supply, which is fed to the 12 volt battery pack. The battery pack itself is intrinsically safe. It contains a 2.6 Ah, 12 V dry, vented lead acid battery. When fully charged, the battery can run electronic shutdown system for about six hours. Being intrinsically safe, the battery pack is not mounted in a flameproof enclosure and can be changed in the hazardous zone of an underground coal mine.

Flameproof Enclosure Converting Alternator Supply to Intrinsically Safe Supply to Battery

To replace IS battery:

1. Shutdown machine as per shutdown procedure. 2. Unplug battery supply plug. 3. Unplug battery charge plug. 4. Unbolt battery from IS Control Box and replace battery.