2 minute read

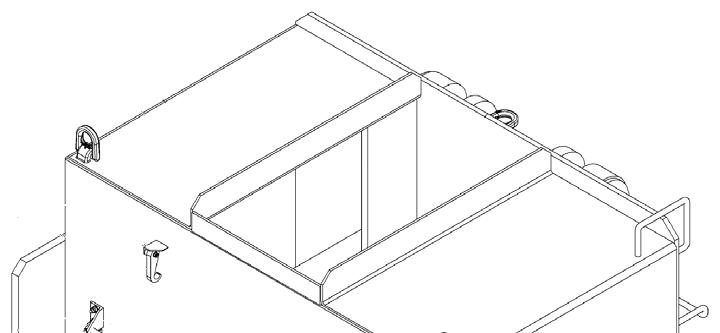

Elevated Work Platform

ELEVATED WORK PLATFORM

The elevating work platform is designed to be carried by the machine’s RAS attach system. The primary purpose for the platform design is for personnel to access the mine roof or elevated services and provide a safe working area for performing tasks when elevated above ground level.

The platform is fitted with operator controls for engine emergency stop.

Specifications

Maximum number of persons to be elevated: Tare mass of platform (approximate): Maximum load of platform: Platform length: Platform width: Total height: Maximum vehicular inclination (front to rear): Maximum vehicular inclination (side to side): 2 1900 kg 1500 kg 2820 mm 2300 mm 1260 mm 1:4 1:8

Platform Raise/Lower and Tilt Adjustment

All raising, lowering and tilt adjustment are carried out from the operator’s compartment using the lift and tilt controls. An inclinometer is mounted on the platform chassis to enable the platform to be positioned horizontally.

The platform is not intended for personnel riding. Do not transport personnel in the platform as serious injury may result. Always allow personnel to exit the platform from ground level before tramming the machine.

Emergency Stop

The emergency stop valve located on the platforms plate closest to the RAS attach hooks. Once activated it stops the machine’s diesel engine. Once the engine has stopped hydraulic power is also isolated to the raise/lower and tilt functions.

Servicing

Daily:

1. Check the RAS attach hooks for damage. 2. Check the RAS lock tongue slot for damage or excessive wear. 3. Check that the platform access door latches are functional and the door swings freely. 4. Check that the RAS lock tongue is fully engaged in the RAS plate lock tongue slot. 5. Check that the platform deck and guard rails are free of damage and slip, trip and fall hazards. 6. Before introducing into service with attachment connected to the machine test the emergency stop valve. 7. Ensure all accessories are not damaged and in good working order.

Weekly:

1. Lubricate the access door hinges and return spring slides. 2. Ensure all accessories are not damaged and in good working order.

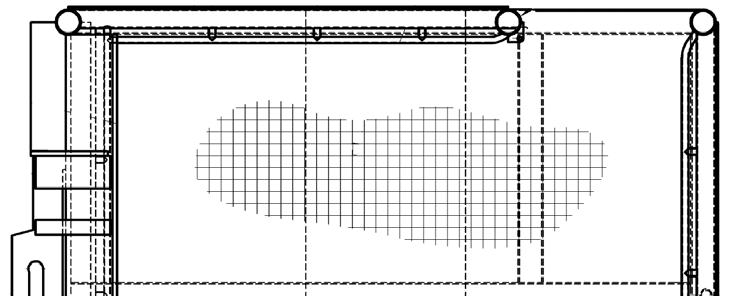

Plan View of Work Platform

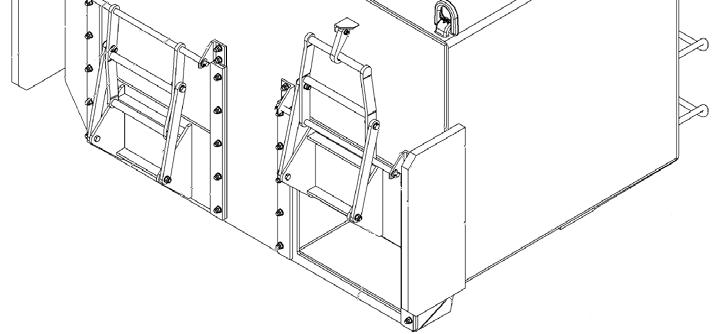

Spring Return Gate and Self Latching Catch

The work platform has a number of various attachments available for use, these attachments are to be fully maintained and kept in good working to the OEM’s specifications.

Corner Post Accessory Adjustments Cable and Pipe Handlers

Pipe Handler with Vice assembly

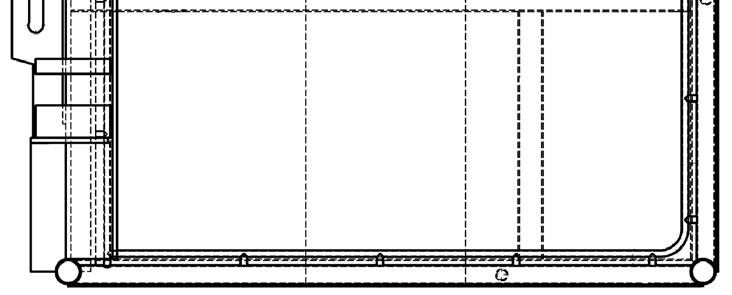

CONCRETE HOPPER

The hopper is designed to be carried by the machine’s RAS attach system. The primary purpose is to transport concrete to various parts of the mine.

The concrete hopper is fitted with one access/fill section at the top and two delivery Shute's fitted with manually operated gates.

Specifications

Tare mass of hopper (approximate): 4300 kg Maximum load (concrete): 9651 kg (4 M³) Hopper length: 2094 mm Hopper width: 2430 mm Total height: 1700 mm Maximum vehicular inclination (front to rear): 1:4 Maximum vehicular inclination (side to side): 1:8

Platform Raise/Lower and Tilt Adjustment

All raising, lowering and tilt adjustment are carried out from the operator’s compartment using the lift and tilt controls.