2 minute read

Hydraulic Isolation

PNEUMATIC ISOLATION

To isolate the pneumatic system perform the following procedure:

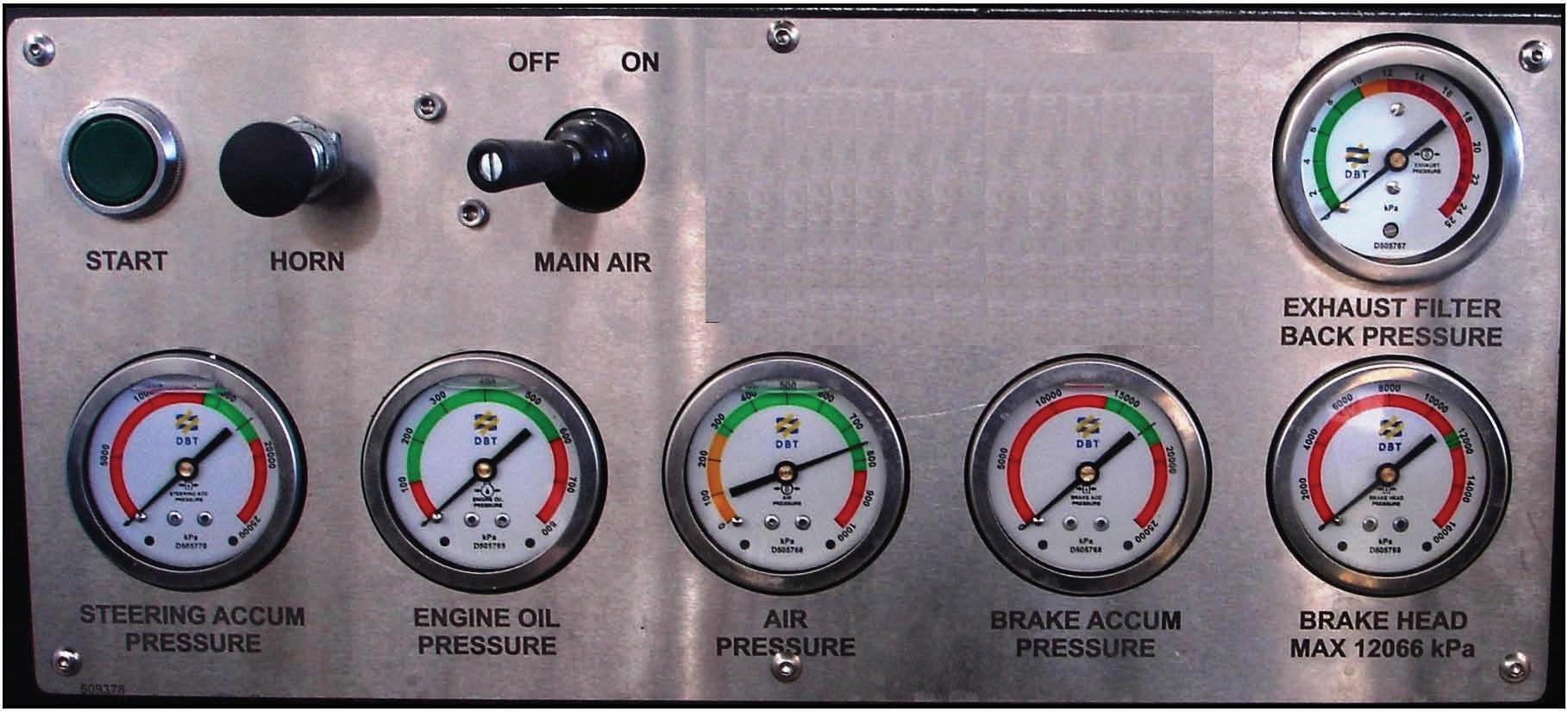

1. Ensure the area is clear of any obstruction and area is fit for carrying out safe operation and maintenance. 2. Lower the lift arms or any attachment to the ground, shutdown the engine, fit a danger tag to the on/off toggle switch, connect the articulation lock and chock the wheels. 3. Locate the main air isolation valve located in the engine compartment and rotate to the off position. 4. Relieve air pressure in the system lines by successively switching the on/off toggle switch until the air pressure gauge reads zero when the on/off toggle switch is in the on position.

If work is required on the air receiver it will be necessary to remove air pressure from the receiver by actuating the main air drain valve located next to the fill point. Stored air pressure will be safely released to the atmosphere. Ensure that the three-way ball valve is not connected to an external pressure source.

Compressed air can be hazardous. Wear suitable personal protective equipment such as safety glasses and hearing protection.

Main Air Isolation Valve Main Air Drain Valve Main Air Charge Valve

MAIN AIR MANIFOLD

HYDRAULIC ISOLATION

To isolate the hydraulic system perform the following procedure:

1. Ensure the area is clear of any obstruction and area is fit for carrying out safe operation and maintenance. 2. Lower the lift arms or any attachment to the ground, shutdown the engine, fit a danger tag to the on/off toggle switch, connect the articulation lock and chock the wheels. 3. Depress the attachment quick connects button located in the operator's compartment. This will remove any residual pressure stored in the PTO lines. 4. Observe both steering and brake pressure gauges located in the operator's compartment. The hydraulic system features a steering and brake accumulator automatic dump off which removes hydraulic pressure from both accumulators once the engine and main air has been stopped. This is immediate. This is done by an air pilot from the air circuit. 5. Remove hydraulic tank pre-charge pressure (50 kPa) by cracking hydraulic tank filler cap.

Ensure all loads are mechanically supported before removal of any hydraulic lines. Hydraulic fluid may be hot. Wear personal protective equipment such as safety glasses, long sleeve shirt and gloves.

Always assume there is hydraulic pressure in hydraulic lines or components unless it has been isolated by yourself.

Crack hose end fitting (if pressure is present in line tighten fitting and remove pressure as above) but do not remove till any residual pressure is removed.

Steering Accumulator Pressure Gauge Brake Accumulator Pressure Gauge