397 minute read

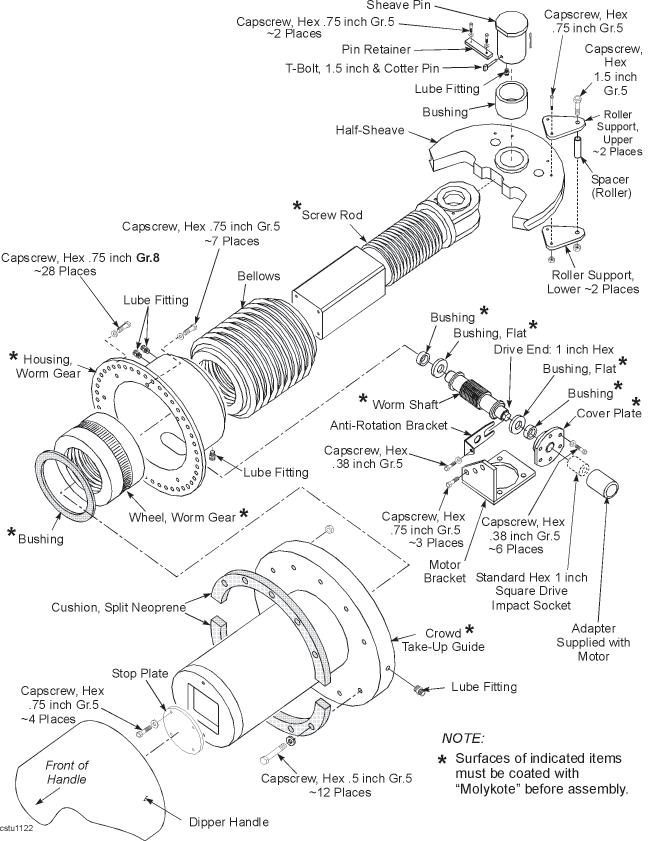

Dipper Trip - General Arrangement

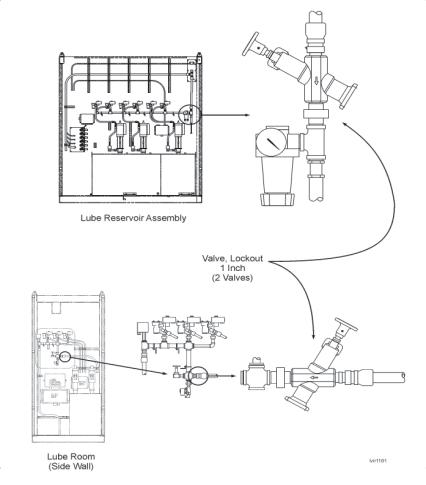

A single-line automatic lubrication system applies open gear lubricant (OGL) and grease via a programmable logic controller (PLC). The system has six lube pumps (four for OGL and two for grease), each feeding individual PLC controlled circuits. Lincoln Powermaster Four 75:1 air powered pumps are mounted on two reservoirs. High pressure hoses with reusable fittings are utilized.

Lubrication Room

The six separately controlled lube circuits provide selective distribution frequency and quantity resulting in reduced lubricant usage and cost.

FRONT END EQUIPMENT

The front end equipment consists of the boom, the boom point sheaves, padlock, saddle block, dipper handle, dipper, dipper trip mechanisms, running ropes and boom suspension strands.

SUSPENSION STRANDS

The suspension strands are designed to maintain the proper boom angle. These are fixed-length strands that support the entire weight of the boom and the load.

BOOM

The boom is a welded steel structure consisting of twin box girders integrally connected at the boom point and in the lower section between the shipper shaft and boom feet. Impact resistant steel is utilized, coupled with 100% penetration and UT quality welds on all main splice joints. Design optimization has resulted in heavier outside skin plates, minimizing the need for internal diaphragms. This reduction in weld related stress concentrations further enhances structural life. Open manholes have been incorporated in the boom as a standard feature permitting periodic structural inspection. Integral “ladders” within the upper boom sections permit internal access without lowering the boom.

Boom Assembly

The boom is supported by four pre-stressed suspension (structural) strands attached to equalizer links on the A-frame. These inherent long life structural strands carry the working loads of the front end equipment. A boom limit switch with soft setdown prevents boom jacking shock loads.

RUNNING ROPES

Hoist, crowd, retract and dipper trip ropes are all plastic impregnated for increased life and for sheave and drum grooving life enhancement. The double twin hoist ropes are attached to the center of the hoist drum using ferrule-becket anchoring for faster rope change out. Each rope passes over a boom point sheave through the padlock and back over the boom point sheave to the hoist drum. The dual twin hoist rope configuration stabilizes the dipper while digging by attachment to the outer edges of the dipper body.

Ropes - General Arrangement

Crowd and retract ropes are attached to the crowd drum and work as an integral system. As the crowd rope is wound on to the drum, the retract rope is reeled off.

SADDLE BLOCK

The saddle block is positioned between the boom side girders in the mid-section of the boom. It pivots on manganese-bronze bushings about the shipper shaft. It acts as a guide for the longitudinal movement of the dipper handle. The free-floating design of the handle in the saddle block eliminates handle torsion.

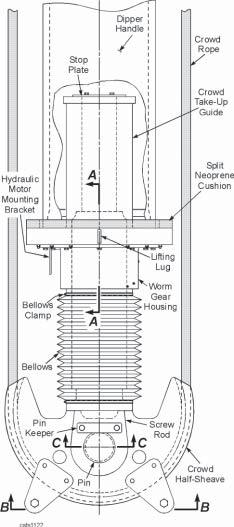

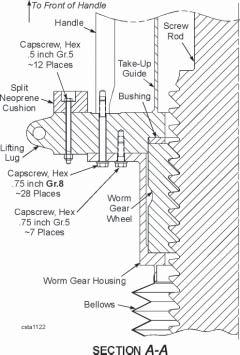

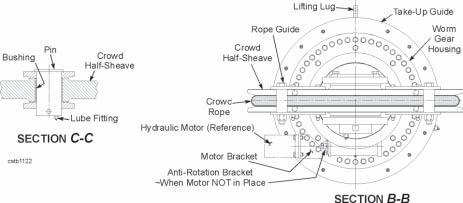

DIPPER HANDLE

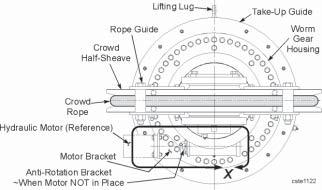

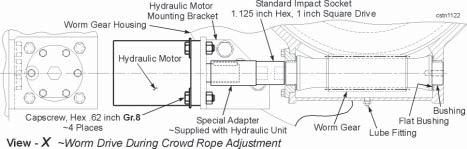

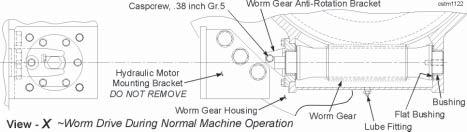

The dipper is attached to one end of the large diameter handle. The crowd rope half-sheave is attached to the other end. A hydraulic rope take-up mechanism at the dipper end, and the crowd rope adjusting mechanism are used to remove slack from the crowd/retract rope system. The dipper handle crowds out and retracts within the saddle block.

An electrical rate reduction circuit, along with the crowd ropes, absorb digging shock loads encountered when the dipper is crowded into the bank.

DIPPER

A general purpose dipper is usually constructed as a casting and plate weldment. The dipper lip and lower front are alloy heat treated castings. The dipper body, back, upper sides and door are made of steel plate. Removable tooth adapters and replaceable tooth points are attached to the lip casting to penetrate the bank material.

The door is hinged and latched to the dipper body. A dipper trip mechanism controls the release of the latch bar, allowing the door to swing open. The latch bar holds the door shut during digging. Spring loaded snubbers dampen the door’s swinging action.

Dipper Assembly

PADLOCK

Padlocks connect the hoist ropes to the outer edges of the dipper while still permitting fore and aft and sideways movement.

DIPPER TRIP

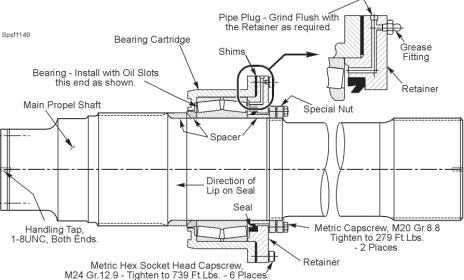

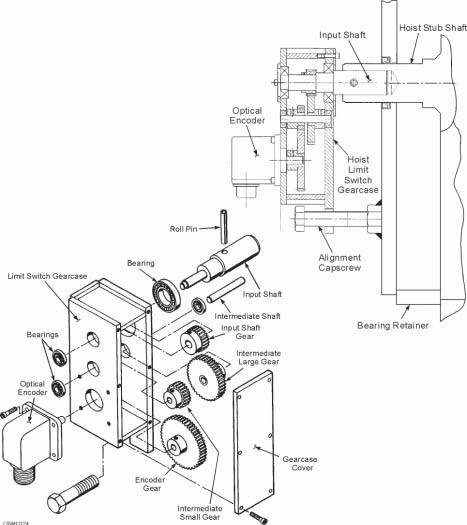

The dipper trip is a wire rope activated dipper door trip mechanism driven by an electric motor through gear reduction mounted on the boom near the boom foot.

Dipper Trip - General Arrangement

TYPICAL MACHINE SPECIFICATIONS

This specification describes the principal mechanical features of a standard Bucyrus International, Inc. 495HR IGBT Acutrol controlled machine. The machine is fully revolving, crawler mounted and equipped to operate from an alternating current power source.

NOTE: These are typical machine specifications.

Working Weight (w/Dipper) Dipper (60 yd3, 46 m3) Ballast Net Weight, minus Ballast and Dipper

Weights

(pounds) (kilograms)

2,877,000 1,305,000 145,000 65,800 700,000 318,200 1,928,000 874,500

Front End Equipment

Boom

Welded, Impact Resistant Steel Boom Point Sheaves Twin Grooved, Flame Hardened Boom Point Sheave Diameter 96" 243.84cm Shipper Shaft Sheaves Twin Grooved, Flame Hardened Shipper Shaft Sheave Diameter 72" 182.88cm Dipper Handle Diameter 34" 86.36cm Dipper Handle Wall Thickness 3" (nominal) 7.62 cm

Rope Data

Hoist

# Ropes Diameter

Type Constr.

2 2 3/4"69.88mm Twin Dual 6X37

Crowd 1 2 1/2" 63.5mm Single Dual 6X37

Retract

1 2 1/2" 63.5mm Single Dual 6X37 Dipper Trip 1 3/4" 19.1mm Single 6X37 Boom Suspension 4 3 1/4" 82.6mm Equalized Structural Strand

Typical Dimensions and Working Ranges

US

Metric

Dipper Capacity (nominal) .............................................60 yd3 ..................... 46 m3 Dipper Capacities (range) ......................................... 40-80 yd3 .......... 30.6-61.2 m3 Length of Boom ..................................................................67'....................20.4 m Boom Angle.......................................................................43º.........................43º Effective Length of Dipper Handle .................................35’-10"....................10.9 m Overall Length of Dipper Handle......................................47’-0”....................14.3 m A:Dumping Height........................................................33’-0".................. 10.05 m A1:Dumping Height at Maximum Radius .......................28’-3"....................8.61 m B:Dumping Radius - Maximum ....................................71’-0".................. 21.64 m C:Cutting Height - Maximum........................................60’-3".................. 18.02 m D:Cutting Radius - Maximum .......................................82’-0".................. 25.00 m E:Radius of Level Floor .............................................. 52’-11”.................. 16.11 m G:Clearance Height @ Boom Point Sheaves................68’-0".................. 20.72 m H:Clearance Radius @ Boom Point Sheaves ...............64’-9”.................. 19.74 m I: Clearance Radius @ Revolving Frame .................... 29’-11"....................9.12 m J:Clearance - Revolving Frame to Ground ..................11’-11"....................3.63 m K:Height of A-Frame....................................................45’-7".................. 13.89 m N:Operator’s Cab Eye Level .........................................30’-0"....................9.14 m

H D

BUCYRUS

K

J

I

495HR

N

E

B

A1 A C G

COMPONENT WEIGHTS

Quantity Weight Each

(U.S. Pounds)

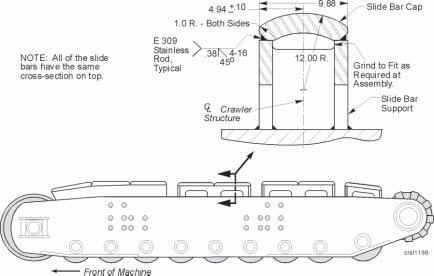

Lower Works

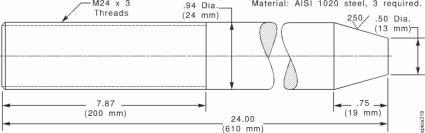

Truck Frame................................................1...........191,430 Pintle Bushing .............................................1..................280 Lower Rail...................................................9..................570 Thrust Rail...................................................9..................170 Propel Brake Adapter.................................2..................370 Propel Brake..............................................2..................650 Propel Brake Hub.......................................2....................60 Propel Motor ...............................................2...............4,500 Propel Motor Blower...................................2..................210 Propel Motor Guard ....................................2....................60 Crawler Belt (47 shoes)...............................2...........123,280 Crawler Link (78.75”) .................................47..............2,480 Crawler Assembly~Shipping .......................2...........129,730 Crawler Assembly~Mechanical ...................2...........129,530 Crawler Structure ........................................2.............77,650 Propel Gearcase........................................2.............15,850 Front Idler....................................................2...............5,800 Shaft, Front Idler..........................................2...............1,150 Adjusting Block ...........................................4..................370 Load Roller .................................................8...............2,020 Shaft, Load Roller .......................................8..................550 Rear Idler ....................................................2...............3,800 Shaft, Rear Idler ..........................................2..................700 Tumbler,Drive..............................................2...............7,120 Shaft, Drive Assy.........................................2...............4,330 Shaft, Drive .................................................1...............3,370 Sleeve, Center Pintle ..................................1...............9,100 Collar, Center Pintle, Upper.........................1..................380 Nut, Lock, Assy, Center Pintle.....................1...............1,480

Quantity Weight Each

(U.S. Pounds)

Upper Works

A-Frame Front Leg.....................................1..............23,000 A-Frame Rear Leg......................................2................6,650 Auxiliary Winch Assembly............................2................2,350 Boom Foot Pin............................................2...................550 Upper Rail...................................................10.................500 Swing Planetary Gearcase..........................2..............10,600 Swing Pinion Shaft Assembly......................4................1,990 Swing Pinion Shaft......................................4................1,460 Swing Bearing Carrier ................................4...................230 Swing Shaft Bearing...................................4...................100 Swing Brake Adapter..................................2...................270 Swing Brake...............................................2...................490 Swing Motor (w/o Tach) ...............................1................4,500 Swing Motor (w/ Tach) .................................1................3,600 Crowd 2nd Intermediate Shaft .....................1................2,000 Crowd 2nd Intermediate Gear .....................1................2,640 Crowd Motor Shaft Coupling .......................1...................150 Crowd Frame..............................................1..............11,500 Crowd Pinion Guard....................................1...................280 Crowd Gearcase Cover ..............................1................2,700 Crowd Upper Gear Guard ...........................1...................170 Crowd Gear Guard - Lower .........................1...................340 Crowd Drum ...............................................1..............12,800 Crowd Drum Spur Gear...............................1................4,970 Crowd 1st Intermediate Shaft ......................1...................130 Crowd 1st Intermediate Gear ......................1................1,080 Crowd Brake..............................................1...................500 Crowd Brake Adapter.................................1...................270 Crowd Motor ...............................................1................4,000 Air Swivel....................................................1...................150 Collector Ring Assembly .............................1...................230 Housing, Front ............................................1...................150 Housing, Rear .............................................1...................150 Hoist Planetary Gearcase ...........................1..............35,500 Hoist Pinion ................................................2................1,650 Hoist Pinion Bearing Carrier .......................2...................460

Quantity Weight Each

(U.S. Pounds)

Upper Works (Cont.) Hoist Machinery Guard - Bottom..................1................2,000 Hoist Machinery Guard - Rear .....................1...................940 Hoist Machinery Guard - Front.....................1................1,300 Hoist Bearing Housing ................................2................3,200 Hoist Drum..................................................1..............30,700 Hoist Spider................................................1..............16,000 Hoist Drum Gear.........................................1..............11,000 Hoist Frame - R. H. .....................................1................8,400 Hoist Oil Cooler ..........................................1................2,650 Hoist Motor .................................................1..............15,000 Hoist Brake.................................................1................1,350 Hoist Brake Adapter....................................1...................500 Hoist Brake Hub..........................................1...................210 Hoist Motor Coupling Shaft Assembly..........1................1,440 Coupling Shaft, Gearcase.......................1...................940 Coupling, Motor.......................................1...................600 Hoist Motor Coupling Guard - Gearcase......1...................150 Hoist Motor Coupling Guard - Motor............1...................100 Boarding Stairs...........................................1................4,100 Machinery House Filter Assembly................2................1,330 Control Room Filter Assembly - Tenkay .......1................7,500 Revolving Frame.........................................1............166,750

Front End

Boom (Bare)...............................................1............138,500 Boom Bumper Assembly.............................8.....................30 Boom Point Sheave Assembly ....................1................6,800 Boom Point Shaft........................................2................1,050 Boom Point Sheave ....................................2................4,230 Saddle Block & Liner Assembly..................1..............25,010 Liner, Saddle Block.....................................2................1,300 Bushing, Saddle Block/Shipper Shaft..........2...................100 Collar, Shipper Shaft...................................2...................120 Shipper Shaft..............................................2................4,880 Shipper Shaft Assembly ..............................1................5,110 Crowd / Retract Rope .................................2................2,100

Quantity Weight Each

(U.S. Pounds)

Front End (Cont.) Hoist Rope..................................................1 pair.......10,400 Suspension Rope .......................................4................2,750 Pendant Equalizer - R.H. .............................1................2,400 Pendant Equalizer - L.H. .............................1................2,400 Handle Weldment........................................1.............48,700 Crowd Take-Up Shop Assy .........................1.............10,300 Crowd Take-Up Guide .............................1...............2,200 Crowd Take-Up Worm Gear....................1..................610 Crowd Take-Up Gear Housing.................1..................440 Crowd Take-Up Screw Rod.....................1...............4,520 Crowd Half-Sheave.................................1...............1,920 Retract Take-Up Cylinder ............................2..................150 Retract Take-Up Guide................................1..................500 Retract Spreader and Stop..........................1...............2,100 Crowd Sheave ............................................2...............2,600

Dipper Assembly:

Complete Dipper w/ Liners.........................1...........164,550 Includes:.......................................................................... Dipper Body with Liners..........................1...........109,810 Latch Bar................................................1...............1,180 Latch Lever.............................................1..................500 Snubbers................................................2...............1,750 Pitch Brace.............................................2...............3,340 Center Shroud.........................................8..................500 Corner Shroud.........................................4..................300

Section 2 Operation

Always refer to the safety information in Section 1 of this manual before starting any maintenance procedure on this machine.

Table of Contents

GENERAL INFORMATION ............................................................................................................5 OPERATION NEAR ELECTRICAL LINES...............................................................................5 OPERATOR’S CONTROLS .........................................................................................................7 PRIMARY OPERATING CONTROLS.....................................................................................7 CONTROLS ON THE LEFT CONSOLE...........................................................................8 LEFT MASTER SWITCH.............................................................................................8 DIPPER TRIP..............................................................................................................8 SIGNAL HORN.............................................................................................................8 Left Control Console ...................................................................................................................9 START PUSHBUTTON.............................................................................................10 PLC POWER ON......................................................................................................10 DRIVE CABINET TEMPERATURE............................................................................10 INCOMPLETE SEQUENCE......................................................................................10 SYSTEM READY.......................................................................................................10 PHASE SEQUENCE.................................................................................................10 AUXILIARY GROUND FAULT ....................................................................................10 HOIST BRAKE..........................................................................................................11 CROWD BRAKE ......................................................................................................11 SWING BRAKE.........................................................................................................11 PROPEL BRAKE......................................................................................................11 HVAC UNIT SELECTOR...........................................................................................11 TEMPERATURE........................................................................................................11 HVAC SYSTEM CONTROL.......................................................................................11 HVAC FAN SPEED....................................................................................................11 AUXILIARY HEATER..................................................................................................11 CONTROLS ON THE RIGHT CONSOLE.......................................................................12 RIGHT MASTER SWITCH.........................................................................................12 Right Control Console ................................................................................................................13 EMERGENCY STOP PUSHBUTTON.......................................................................14 WINDSHIELD WIPER SWITCHES...........................................................................14 CONTROL STOP PUSHBUTTON............................................................................14 CONTROL RESET PUSHBUTTON..........................................................................14 AIR COMPRESSOR.................................................................................................15

DIG/PROPEL TRANSFER SWITCH...............................................................................15 HEATED MIRRORS..................................................................................................15 MAIN POWER OFF PUSHBUTTON.........................................................................15 MAN ON GROUND....................................................................................................16 EARTH CONTINUITY LOCKOUT PUSHBUTTON....................................................16 SEAT POSITION.......................................................................................................16 RADIO/CASSETTE/CD.............................................................................................16 OPERATOR’S DISPLAY.............................................................................................................17 DISPLAY AREA AND INDICATORS .......................................................................................17 DISPLAY SCREENS.............................................................................................................18 Title Screen ...............................................................................................................................18 Main Menu .................................................................................................................................19 Main Menu - Info ........................................................................................................................19 Active Alarm ..............................................................................................................................20 New Alarm .................................................................................................................................20 Alarms Help ...............................................................................................................................21 Rope Reeving/Pintle Tightening..................................................................................................22 Rope Reeving/Pintle Tightening Help..........................................................................................23 Calibration Help.........................................................................................................................24 Fault Counters/Operating Hours .................................................................................................25 PLC Menu Screen ......................................................................................................................25 Typical Bearing Temperature Screen ..........................................................................................26 Operator’s Screen ......................................................................................................................26 BRAKE INDICATORS.....................................................................................................27 TIME/DATE WINDOW.....................................................................................................27 CONTROL STATUS INDICATORS..................................................................................28 LIMIT SLOWDOWN INDICATORS..................................................................................28 DIG/PROPEL INDICATOR..............................................................................................28 INFORMATIONAL ICONS ................................................................................................29 DELAYED SHUTDOWN INDICATOR.............................................................................29 ACTIVE ALARMS INDICATOR.........................................................................................29 AIR PRESSURE..............................................................................................................29 LUBRICATION CONTROL PANEL........................................................................................30 FIRE SUPPRESSION SYSTEM............................................................................................30 CABLE REEL OPERATION........................................................................................................31 PRE-START CHECKS................................................................................................................32 WALK-AROUND GROUND LEVEL INSPECTION................................................................32

ON-BOARD INSPECTION....................................................................................................34 START-UP, OPERATION AND SHUTDOWN.............................................................................35 MACHINE START-UP ............................................................................................................35 RESTARTING AFTER AN ELECTRICAL FAULT ...................................................................36 MACHINE OPERATION.........................................................................................................37 MACHINERY MOTIONS ........................................................................................................38 HOIST MOTION...............................................................................................................38 CROWD MOTION...........................................................................................................39 PROPEL MOTION...........................................................................................................40 Propel - Straight Forward/Reverse .............................................................................................40 SWING MOTION .............................................................................................................41 PROPER SWING MOTION.......................................................................................42 STEERING ......................................................................................................................43 COUNTER-ROTATION TURNS................................................................................45 POSITIONING THE MACHINE.........................................................................................46 BACK-UP METHOD..................................................................................................46 DRIVE-BY METHOD .................................................................................................47 START OF THE DIG CYCLE..........................................................................................48 Force the Dipper Lip into the Bank.............................................................................................48 Variations on Dipper Penetration ................................................................................................49 Dig with the Dipper Beneath the Boom Point ..............................................................................50 ENGAGING THE BANK ...................................................................................................50 SLOPE LIMITATIONS ......................................................................................................52 Slope vs. Degrees ......................................................................................................................52 Rollover and Operation Limits.....................................................................................................53 EXCAVATED MATERIAL ........................................................................................................53 OPERATION CHECKS.........................................................................................................54 OPERATING HINTS ..............................................................................................................55 STOPPING THE MACHINE ...................................................................................................56 SHUTDOWN.........................................................................................................................56

Section 2 Operation

GENERAL INFORMATION

This section of the manual will assist in the operation of this machine. It provides the operator with the location and explanation of the controls, instructions for machine operation and certain maneuvering techniques. Throughout this section and the remainder of the manual, the use of the terms “LEFT, RIGHT, FRONT and REAR” refer to machine locations as viewed by the operator sitting in the operator’s seat in the cab.

Safe operation of the machine minimizes production delays and costly damage to equipment. Carefully study and follow all recommended procedures in this manual. Safety guidelines are intended to prevent accidents from occurring and are provided in the interest of all mine personnel. Overall safety depends upon the use of good judgment and the alertness of the entire mining crew. Refer to Section 1 in this manual for specific safety precautions.

OPERATION NEAR ELECTRICAL LINES

DANGER: HIGH VOLTAGE! The following precautions shall be complied with whenever operating around or near electrical distribution and transmission lines.

Working in the vicinity of electrical power lines presents a very serious hazard and special precautions must be taken. For purposes of this manual we are considering the entire machine or its load, in any position, that can reach to within the minimum distance specified by local, state and federal regulations.

Safe operating practices require that you maintain the maximum possible distance from the lines and never violate the minimum clearances.

Before working in the vicinity of power lines, always take the following precautions:

• Always contact the owners of the power lines or the nearest electric utility before beginning work.

• You and the electrical utility representative must jointly determine what specific precautions must be taken to insure safety. • It is the responsibility of the user and the electric utility to see that necessary precautions are taken.

• Consider all lines to be power lines and treat all power lines as energized even though it is known that the power is shut off and the line is visibly grounded. • Slow down the operating cycle. Reaction time may be too slow and distances may be misjudged. • Caution all ground personnel to stand clear of the machine at all times. • Use a signal person to guide the machine into close quarters. The sole responsibility of the signal person is to observe the approach of the machine to the power line. The signal person must be in direct communication with the operator and the operator must pay close attention to the signals.

DANGER: HIGH VOLTAGE! Death or injury could result should any part of the machine approach the minimum distance of an energized power line specified by local, state and federal regulations.

OPERATOR’S CONTROLS

The operator must become familiar with the machine and its operating controls before operating the machine.

The operating controls will be grouped as primary and secondary controls, depending upon their location. The primary controls are the controls located in the operator’s cab and the secondary controls are the controls located in the machinery house.

The descriptions listed should familiarize the operator with each control’s location and functional use. The terms left, right, forward and reverse indicate directions with the operator seated in the cab and facing forward, and with the boom extending over the front of the crawlers.

PRIMARY OPERATING CONTROLS

CONTROLS ON THE LEFT CONSOLE

LEFT MASTER SWITCH

The Left Joystick functions as the crowd/horn/dipper trip/propel master switch. It is the vertical handle mounted on the left console of the operator’s seat. The switch will spring return to neutral when released.

During normal operation, pushing the joystick forward will extend the dipper handle and dipper into the bank. Pulling the joystick rearward will retract the dipper handle and dipper toward the machine. The neutral position between the crowd and retract functions is defined by a detent that is easily felt. The rate of motion is controlled by varying the distance the joystick is moved from the neutral (center) position. Full forward or full rearward position provides maximum speed to the handle. Moving the joystick to neutral will cause a braking action slowing the crowding or retracting handle. Reversing the joystick will cause the motion to stop and if the joystick is held in this position, it will change the direction of the motion.

With the propel transfer switch in the PROPEL position, pushing the joystick forward will cause the left crawler to move forward. Pulling the joystick to the rear will cause the left crawler to move in the reverse direction. The crowd/retract motion is locked out electrically when the machine is in the propel mode.

DIPPER TRIP

The dipper trip is part of the crowd joystick function. Moving the joystick to the right will activate the dipper trip mechanism which releases the dipper door latch. The dipper trip is operational throughout the entire range of the crowd motion.

SIGNAL HORN

Moving the joystick to the left will activate the signal horn. The signal horn is operational throughout the entire movement range of the crowd motion.

Left Control Console

START PUSHBUTTON

A pushbutton that, when pressed, will power up the drive system. The system ready light will go out.

PLC POWER ON

A green light that indicates the status of the PLC.

DRIVE CABINET TEMPERATURE

A green light that indicates temperature in the drive cabinet is neither too low nor too high.

INCOMPLETE SEQUENCE

A red light that indicates an incomplete sequence of startup events.

SYSTEM READY

A green light that indicates that the drive system is ready to start, but not yet started.

PHASE SEQUENCE

A green light that indicates that the phase sequence is okay in the incoming power.

AUXILIARY GROUND FAULT

A green light that when lit, indicates that no auxiliary power ground fault exists. If the light is off, alert an electrician as soon as possible.

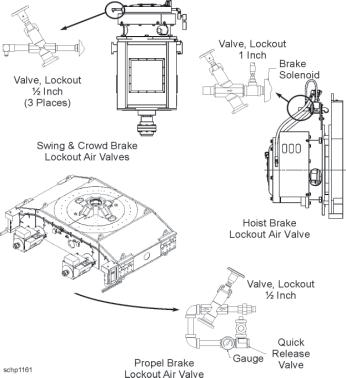

HOIST BRAKE

A selector switch used to set or release the Hoist Brake.

CROWD BRAKE

A selector switch used to set or release the Crowd Brake.

SWING BRAKE

A selector switch used to set or release the Swing Brake.

PROPEL BRAKE

A selector switch used to set or release the Propel Brake.

HVAC UNIT SELECTOR

A 3-position selector switch used to select air conditioner unit No.1, No. 2, or off.

TEMPERATURE

A rheostat used to control the temperature in the operator’s cab relative to the selected mode of operation.

HVAC SYSTEM CONTROL

A 4-position selector switch used to select the HVAC system mode of operation.

HVAC FAN SPEED

A 3-position selector switch used to control the volume of air moved by the system.

AUXILIARY HEATER

A 3-position selector switch used to control the auxiliary heater.

CONTROLS ON THE RIGHT CONSOLE

RIGHT MASTER SWITCH

The Right Joystick functions as the hoist/swing/propel master switch. It is a joystick mounted on the right console of the operator’s seat. The joystick is used to control the hoist, swing and right crawler motions of the machine. The position of the propel transfer switch will determine whether this switch controls the hoist motion or the crawler motion.

With the propel transfer switch in the dig position, pushing the joystick forward will lower the dipper. Pulling the joystick to the rear will hoist the dipper. The neutral position between the hoist and lower functions is defined by a detent that is easily felt. The speed of moving the dipper is controlled by varying the distance the joystick is moved from the neutral (center) position. The full forward, or full rearward position provides maximum speed to the dipper. Moving the joystick to neutral will cause a braking action slowing the hoisting or lowering motion. Reversing the joystick will cause the motion to stop and if the joystick is held in this position, it will change the direction of the motion.

NOTE: When the hoist/swing master switch is used in the hoist/ lower mode the switch is a spring returned switch. That is, it will return to the neutral position when it is released. Moving the joystick to the left from the neutral position will cause the machine to swing to the left. Moving the joystick to the right will cause the machine to rotate to the right. The swing motion is operational throughout the entire movement range of hoisting or lowering the dipper. The swing rate of acceleration is controlled by varying the distance the joystick is moved from the neutral position. Moving the joystick to the neutral position will not stop the swing motion but will allow the machine to coast. To stop or change direction the control joystick is moved past the neutral point in the opposite direction. The rate of deceleration is controlled by varying the distance the joystick is moved from the neutral position in the opposite direction.

With the propel transfer switch in the propel position, pushing the lever forward will cause the right crawler to move forward. Pulling the lever to the rear will cause the right crawler to move in the reverse direction. The hoist motion is locked out electrically when the machine is in the propel mode.

NOTE: When the JOYSTICK is used in the swing mode the switch is a spring returned switch. That is, it will return to the neutral position when it is released.

Right Control Console

EMERGENCY STOP PUSHBUTTON

The machine stop/emergency stop pushbutton is located on the right operator’s console. It is used to remove power from the machine motions after the motions have been stopped in the normal manner. A second purpose of the pushbutton is to stop the machine under operational emergency conditions. Pushing this button will provide electrical and immediate mechanical braking simultaneously. Therefore, this button should only be used if the operator intends the harshest braking of all motions. If the machine is in motion, power will remain on the motions in order to provide electrical braking for a few seconds. If the machine is in motion or stopped, this button will power the DC bus to approximately zero voltage quickly after the time delay.

CAUTION: PRESSING THIS BUTTON WHEN ANY DRIVE IS IN MOTION MAY RESULT IN COMPONENT DAMAGE.

WINDSHIELD WIPER SWITCHES

The windshield wiper switches control the starting and stopping as well as the speed of the windshield wipers.

CONTROL STOP PUSHBUTTON

The control stop pushbutton is a pushbutton located on the right operator’s console. Normally it is used to de-energize controls after the machine has been safely stopped by placing motion controls in neutral.

CONTROL RESET PUSHBUTTON

CAUTION: This is not an automatic reset system. All controls must be returned to neutral before the control reset button is pushed.

The control reset pushbutton is a pushbutton located on the right operator’s console. The reset pushbutton restores control to all motions if no additional faults exist. This pushbutton is inoperative until the main power start control has been actuated.

If a control fault occurs that shuts down a motion, all motions will automatically be shut down together. At this time the operator should set all brakes. If the fault clears, the motion may be reset by pressing this pushbutton. If the fault does not clear, the unfaulted motions can be restarted by pressing this pushbutton to enable these motions to reposition themselves.

AIR COMPRESSOR

A 3-position selector switch use to select either compressor No.1, No.2 or off.

DIG/PROPEL TRANSFER SWITCH

The Dig/Propel Transfer Switch is used to switch between the two primary operating modes of the machine. The current mode of operation will be indicated on the Operator’s screen on the Operator’s Display.

IMPORTANT: •WHILE IN THE DIG MODE, THE PROPEL CONTROLS ARE DISABLED. •WHILE IN THE PROPEL MODE, THE DIG CONTROLS ARE DISABLED.

The recommended procedure to transfer from hoist to propel is to bring all motions to a controlled stop by the operator. Turn the hoist brake switch to the SET position and then press the control stop pushbutton. Turn the transfer switch from DIG to PROPEL.When the indicator on the Operator Display screen indicates that the transfer has been completed, turn the propel brake switch to release.

HEATED MIRRORS

The heated mirrors switch is a 2-position switch located on the right control console. It is used to activate the heating mechanism in the operator’s cab outside mirrors.

MAIN POWER OFF PUSHBUTTON

The main power off pushbutton is located on the right operator’s console. It is used only to immediately remove power from the drives in case of an electrical emergency involving component failure or fire.

CAUTION: PUSHING THE “POWER OFF” PUSHBUTTON WHILE IN MOTION WILL IMMEDIATELY SET THE MECHANICAL BRAKES AND REMOVE INCOMING HIGH VOLTAGE FROM THE DRIVES. THIS ACTION MAY RESULT IN COMPONENT DAMAGE. It will also result in the inability to power the DC bus voltage down to a low value. This voltage will decay slowly, taking several minutes.

MAN ON GROUND

A 2-position switch that when set to ON will illuminate a light on the roof of the operator’s cab. Use this switch to alert other equipment in the area that a person is on the ground in the vicinity of the machine.

EARTH CONTINUITY LOCKOUT PUSHBUTTON

The earth continuity lockout pushbutton is used to trip the breaker that supplies power to the machine. When the machine is operating, this pushbutton should be used to shutdown the machine only when removal of power to the machine is required.

Actuation of this pushbutton when motions are running will cause all motions to automatically electrically brake to a stop and, when the motion speed has reached less than 5% speed, set all mechanical brakes. If the motions are already stopped, the brakes will be set and power is removed immediately. A similar switch is located on the front panel of the PLC control cabinet that can be used during testing of the machine.

DANGER:THE OPERATOR SHOULD NEVER LEAVE THE OPERATOR’S SEAT BEFORE PRESSING THE CONTROL STOP PUSHBUTTON. Setting only the mechanical brakes with individual switches in not a sufficient safeguard to prevent machine damage and/or personnel hazards.

SEAT POSITION

A selector switch used to move the operator’s seat and consoles forward or back. The seat will continue to move as long as the switch is held, or until the end of the seat’s travel is reached.

RADIO/CASSETTE/CD

A quality AM/FM Radio with cassette and CD player for the operator’s use and connected to speakers in the operator’s cab.

OPERATOR’S DISPLAY

The Operator’s Display is a CTR panel used to provide the operator with an interface to the machine and it’s functional areas. From this informational display the operator can make inputs that effect machine operation, monitor systems and make system adjustments. Through this display terminal the operator will receive pertinent fault data to identify potential problems and prevent machine damage.

The display panel is mounted on a tilt-swivel bracket on the left side of the operator. Individual operators can position the screen in any desired position.

DISPLAY AREA AND INDICATORS

The display area of the monitor screen is the large area in the center of the screen. This area is “touch sensitive.” All information will be displayed on this area in either a text format or in the form of visual icons. The buttons and icons that appear on the screen will respond to touching the screen in the appropriate area of the icon.

These icons and buttons will react by activating the screen, switch activation or display information relevant to the icon. The switches and buttons will be covered in the following pages under the screen topic in which they appear.

The indicators on the lower portion of the screen area are indicators and sensors which indicate functionality of the operator display and it’s interface with the machine’s PLC controller. They have no effect on machine operational use.

All the machine controls can be found on the Operator’s Display Panel touch sensitive screen or the left and right Control Consoles of the operator’s seat.

DISPLAY SCREENS

The Title Screen display appears when the machine is initially started.

Title Screen

The information provided in the central area of the screen is machine specific and lists the machine serial number, the customer name and a listing of important documents and drawings associated with the machine.

The 2 buttons available, if touched, will cause the display to refresh with the information of the desired screen.

Main Menu

The Main Menu screen will provide the operator with a choice of 16 buttons to select. Touching the screen in any of these button areas will cause the display to change to the requested option. Many of these screens will be displayed in the following pages. Several screens have an INFO button which will provide more detailed information concerning the functionality of listed buttons and switches.

Main Menu - Info

The Main Menu Information screen provides information about the various display screen options available through the Main Menu screen.

Active Alarm

The Active Alarm screen will provide a list of all active alarms and faults that have been initiated on the machine and have not been RESET. Once an alarm or fault has been sensed, these messages will remain visible and WILL NOT be removed from this screen until it is RESET.

New Alarm

The New Alarm screen appears automatically any time a machine sensor detects a newly occurring fault or warning message. This screen has the ability to list up to 10 of the new fault messages that

have occurred. If more than 10 new fault messages are present a message will appear below the white text box indicating that more messages are present.

NOTE: It is important to remember that messages will appear in this screen that are no longer active alarm messages. All messages will appear since the time of the last reset.

Alarms Help

The Alarms Help screen can be reached from any of the alarm message screens at any time. This screen will provide clarifying information related to the alarm system on your machine.

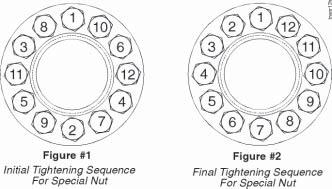

Rope Reeving/Pintle Tightening

The Rope Reeving/Pintle tightening screen is selected in order to make adjustments to the center pintle or change any of the main machine wire ropes. This screen will become active in the pintle tightening mode. If rope reeving is the desired intent, a selection must be made at the buttons in the lower left of the display area.

NOTE: Before switching between different modes of operation the Disable Selected Mode button should be pressed.

Switches for the activation/release of the hoist, crowd and swing brakes are provided, along with condition indicators displayed below the brake switches. This screen assists in the correct wrapping of the ropes on drums and allows full control of drum movements.

Rope Reeving/Pintle Tightening Help

This screen will provide clarifying information on the reeving of ropes and pintle tightening.

Calibration

The Calibration screen is used to set the various limits required to control the movements of the machine.

On this screen can be found switches for the hoist, crowd and swing brakes along with status indicators for each.

The limit settings can be found on the left side of the display area.

The white text box near the bottom of the display area displays the current positions of the components.

Calibration Help

This screen will provide clarifying information on the calibration process.

Fault Counters/Operating Hours

The Fault Counter/Operating Hours screen provides the operator with information on the number of faults that have occurred since last RESET. It also provides the total operating hours.

PLC Menu Screen

This screen will active further screens which are used to monitor various racks within the PLC cabinets.

Typical Bearing Temperature Screen

Operator’s Screen

The Operator’s Screen is the primary operational information tool to be visible to the machine operator during daily use of this machine. The controls available on this screen will provide the operator with the information needed to view “at a glance” the status of items required for digging and make changes in control settings.

BRAKE INDICATORS

The 4 rectangular areas in the upper left portion of the operator’s screen provide DISPLAY ONLY information on the motion brakes. The HOIST, CROWD, SWING and the PROPEL brakes are separately identified at this location.

NOTE: The hoist, CROWD AND SWING brakes ARE not to be used as a braking device, except as a holding brake or with an electrical fault or in an emergency. The primary function of the brake is to prevent motor rotation while the particular function is not in use.

1. SET - This will indicate a condition where the brake for that system is fully set and functional as a braking device to prevent movement of that system.

2. SETTING - This message indicates that the brake is in a transition period between the RELEASED and the SET positions. During this period the brake is not functional and care should be exercised to not rely on the brake at this time.

3. RELEASED - This message is an indication that the brake is fully released for the system in question.

4. RELEASING - This is an indication that the brake is in a transition phase from the Set position and has not yet achieved the fully RELEASED position.

NOTE: While in transition from one setting to another (ie: during the RELEASING and SETTING periods, the button will be displayed in yellow. While fully SET or fully RELEASED the button will be displayed in grey.

NOTE: Unlike the other brakes on the machine, the propel brakes are intended as operational brakes and are used in the operation of the machine

TIME/DATE WINDOW

The Time/Date window, locate in the lower left corner of the screen will provide the current local time and date information to the operator at all times. In addition, the total operating hours on the machine will also be displayed.

CONTROL STATUS INDICATORS

The Control Status indicator buttons provide an immediate visual notification of which control systems are functional at that moment. When a control system is active it will be illuminated in green. If a control indicator is grey the system control for that function is currently disabled.

The Dig/Propel switch will have an effect on the status indicators and controls by automatically disabling the propel controls when the machine is in the Dig Mode of operation. Likewise the Hoist, Crowd and Swing controls are automatically disabled when the machine is in the Propel Mode.

It is important to remember that when a brake system is SET the controls for that motion will be disabled.

LIMIT SLOWDOWN INDICATORS

The Limit Slowdown indicators are provided on the operator’s screen to provide the operator with an indication that he is reaching the limits of either the Hoist or the Crowd ropes. These indicators, normally grey, will illuminate yellow as the motion extends into the limit area and the machine has signaled a slowdown condition.

The operator will notice that the reaction of the machine will actually slow down in an effort to prevent damage to the machine by exceeding limits.

The actual settings for these limits is made on the Calibration screen.

DIG/PROPEL INDICATOR

This icon will indicate the current operating mode of the machine by an illumination of the active control in red. To activate the other operating mode, use the Dig-Propel Transfer switch on the operator’s console.

INFORMATIONAL ICONS

The below listed icons are for informational display during the operational use of the machine. These icons will normally be displayed in grey unless the message within the icon is active, and the icon will illuminate yellow.

POWER OFF - Get information from ELECTRICAL.

SYSTEM ON - Get information from ELECTRICAL.

MASTER SWITCH NEUTRAL - Get information from ELECTRICAL.

BOOM JACK LIMIT - This message indicates that the boom is being jacked upward by the crowd motion into the bank. Power is removed from the crowd controls during this event. Pressure must be relieved from the crowd system for controls to return to normal.

FANS OFF - Get information from ELECTRICAL.

LADDER DOWN - This icon displays a message indicating that the boarding ladder is NOT currently stowed in it’s topmost position.

DELAYED SHUTDOWN INDICATOR

The Delayed Shutdown indicator will normally appear as a grey button near the right side of the screen. This indicator will illuminate red when a delayed shutdown fault has occurred and the machine is now in the delay process.

This is a direct indication to the operator that the machine is about to automatically shut down and he must make preparations.

When this illuminates the operator should stop any swing motion and safely place the dipper on the ground in preparation to lose control in one or more machine systems.

ACTIVE ALARMS INDICATOR

The Active Alarms indicator will illuminate red, from grey, whenever there exists a condition in which an active alarm is being signalled from a machine sensor. This indicator will remain red at any time that any active alarm condition exists.

AIR PRESSURE

The air pressure gauge is located on the right portion of the Operator Display. It indicates the regulated air pressure available in the air system.

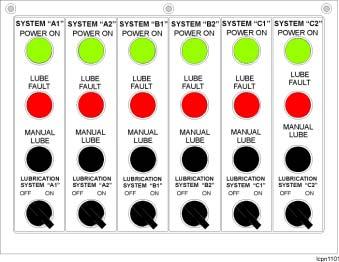

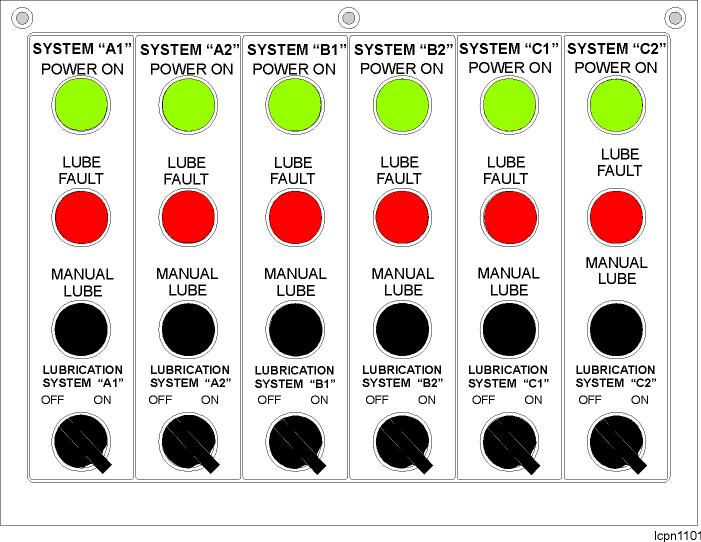

LUBRICATION CONTROL PANEL

The top row on this panel consists of a group of indicating lights. A red light indicating that the system has a fault and a green light indicating that power for the system is provided for each independent lubricating system (A, B & C). Isolating switches are used to provide power to each system and a means of isolating each system from electrical power. They are also used to reset lubrication faults. These switches are normally on. Manual lube buttons are also provided.

FIRE SUPPRESSION SYSTEM

Fires on surface mining equipment typically involve faults in electrical equipment, or the combustion of flammable fluids. The time between the onset of the fire and its detection is critical. Early detection and suppression of a fire minimizes hazards to personnel, equipment damage, downtime and loss of production. The optional fire suppression system on this machine is supplied and installed by an outside source. Please refer to the system’s manufacturer for maintenance and parts information.

CABLE REEL OPERATION

The cable reel is designed to pick up trail cable as the machine moves toward its power source. It is not designed to drag the trail cable over the ground. The “line pull” of the cable is proportional to operating pressure. The correct line pull is when there is sufficient pull on the cable to wind it on the reel but not too great to put unnecessary strain on the trail cable.

The “line speed” is dependent on the volume of hydraulic oil flowing through the system. The correct line speed is slightly faster than the travel speed of the machine. NOTE: Swing the Control Valve Boom to its fully extended position to allow the cable reel operator to remian in visual contact with the machine operator. To operate the cable reel proceed as follows: 1. If the machine is so equipped, verify that the cable reel “On/Off” switch in the operator’s cab is in the “On” position. 2. Jog the start/stop pushbutton at the cable reel to check for proper rotation of the pump. 3. Start the pump and allow oil to circulate for five minutes. 4. The cable reel, if properly adjusted, will then automatically wind or unwind the trail cable as the machine is propelled.

DANGER: For maximum safety when manually operating the cable reel, the cable reel operator must be in view of the machine operator at all times. The boom mounted to the right side of the cable reel is used for this purpose.

5. To operate the cable reel manually, close the needle valve mounted on the right end of the reel frame. When the valve is closed, the hydraulic system can be operated without the propel clutch air being applied. 6. Manual control of the cable reel is then controlled by the 4-way valve mounted to the swing out boom of the cable reel.

PRE-START CHECKS

Before starting, inspect the machine to ensure it is ready to be put into operation. Failure to make such a routine check could result in unnecessary downtime. For example: an undetected oil leak could result in a dry gearcase, eventually leading to excessive gear wear or destruction, seized bearings or other mechanical problems. Broken strands in the hoist ropes, crowd rope, retract rope or structural strands could, if undetected, result in serious injury or damage to the machine or haulage unit. A few minutes spent inspecting the machine often results in considerable savings in time and machine efficiency. Section 4 of this manual contains reproducible checklists to assist in record keeping and ensure that adequate inspection standards are met.

WALK-AROUND GROUND LEVEL INSPECTION

Check the following areas daily during a general walk-around inspection:

1. Check the areas under and around the crawlers for signs of oil leaks. If single droplets are noticed, leakage is minimal. Determine the point of leakage and make a note of it on the log sheet. If pooling of oil is noticed, determine the source and take corrective action immediately. Determine if loose hardware, a defective gasket, a combination of both, or a similar problem is responsible. Tighten hardware or replace defective gaskets.

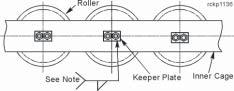

2. Inspect the crawler belts for missing links or lock pins, excessive belt sag, cracked shoes or other deterioration. Check the oil level in the propel planetary gearcase. Add oil as required.

3. Check the swing rack and pinion guards for rocks, dirt and other debris that will interfere with the operation of the machine. Inspect the swing rack gear and rollers for the proper lubricant film.

DANGER: HIGH VOLTAGE! THE MACHINE TRAIL CABLE CARRIES A LETHAL VOLTAGE. Handle the cable in an approved manner with appropriate rubber gloves and insulated hooks or tongs.

4. Visually inspect the trail cable for cuts, abrasions and other damage.

5. Visually inspect exterior of machinery house for damage or evidence of internal leakage.

6. Inspect the dipper trip mechanism, rope, latch bar and associated hardware for damage, adjustment and wear.

7. Inspect the dipper door, hardware and bumpers for damage and excessive wear.

8. Inspect fulcrum attachment points, take up cylinders and spacers and dipper handle for damage, excessive wear and evidence of adequate lubrication.

9. Inspect boom bumper for security and damage.

10. Inspect the dipper and tooth adapters for tightness and excessive wear.

11. Inspect padlocks for damage, wear and evidence of adequate lubrication.

12. Check both the running ropes and the boom structural strands for broken strands and loose sockets.

ON-BOARD INSPECTION

Check the following areas daily on board the machine:

1. Visually inspect the swing, crowd and hoist gearcases for oil levels and leaks. Repair or service as required.

2. Visually inspect all machinery for loose bolts, nuts, clamps or unusual deterioration. Repair as required.

3. Visually inspect the open gears of the swing, crowd and hoist machinery for proper lubricant film and evidence of adequate lubrication from the automatic lubricant dispensing system.

4. Visually inspect hoist and crowd ropes for wear, lubrication and evidence of birdcaging near the drum attachment beckets.

5. Check the oil level in the air compressor. Add oil if required.

6. Check lubricant supply level in the air system lubricator and lube system lubricators.

7. Inspect the automatic lubrication central pumping stations for any signs of malfunctioning. Check the lubricant supply and refill tanks if required.

8. Visually inspect swing, crowd and hoist brake assemblies for damage, wear and evidence of an overheated condition.

9. Check the operator’s cab for cleanliness and visual condition of controls and location of special equipment that may be required by the mine site. Check all operating controls for freedom of movement. Controls should move freely without binding.

10. Clean windows of operator’s cab.

11. Inspect all walkways and stairways to ensure there are no obstructions or fluids creating a safety hazard.

12. Ensure all external stairways and/or ladder(s) are raised and properly stowed.

13. Perform the following manual lubrication points: Crowd Cushion Sheave..............OGL - 1 Fitting Padlock Pins...............................OGL - 6 Fittings Dipper Pins.................................OGL - 2 Fittings Dipper Trip Rope Guide Roller...OGL - 1 Fitting Latch Lever Sleeve.....................OGL - 1 Fitting Structural Strand Pins.................OGL - 4 Fittings Hoist Rope Roller Bushings.......MPG - 4 Fittings

NOTE: Detailed information on the proper servicing of these components can be found in Sections 3 and 4 of this manual.

MACHINE START-UP START-UP, OPERATION AND SHUTDOWN

Whether starting the machine for the first time, or starting after the machine has been in service for some time, the procedures are essentially the same.

1. Perform all pre-start checks listed earlier in this section of the manual.

2. Insure that all boarding stairs and/or ladders are in their raised and latched position.

3. At the AC control cabinet (part of the MCC) verify that the uninterruptable breaker is in the on position. At the motor control cabinet, verify that all breakers are in the on position.

4. In the operator’s cab check that all brake switches are in the set position and that the control joysticks are in the neutral position. Then go to the electrical room at the rear of the machinery house.

5. In the operator’s cab and use the following sequence to start the machine.

a. Verify that the auxiliary ground fault light, which is a green light, is lit.

CAUTION: If the light is off, alert an electrician as soon as possible. The machine may be operated with one such fault but a second fault could cause damage to the machine and/or become a safety hazard. The fault should be cleared as soon as possible.

b. Verify that the phase sequence light, which is a green light, is lit. This indicates that the incoming power sequence is correct. If it is not correct, the light will be out and the machine will not start. The electrical maintenance personnel must correct the sequence.

NOTE: This light also indicates auxiliary power phase unbalance, phase loss or under voltage. If any of these faults occurs, when the machine is running, an alarm will also sound. In event of such an alarm, the electrician should be notified but machine may be operated.

c. Verify that the PLC and drive cabinets temperature lights, which are green lights, are lit. If the cabinet temperature is too low or too high, the machine cannot be started.

d. Verify that the PLC power on light, which is a green light, is lit.

e. Turn the air compressor switch to the run position, if so equipped, or select one of multiple compressors. (For machines with pushbuttons instead of a switch to control the air compressor, press the start pushbutton)

f. Verify that the system ready light, which is a green light, is lit.

g. Press the system START pushbutton. When this button is pressed, the system ready light will go out and the drive system will automatically power up.

h. Verify that the incomplete sequence light, which is a red light, is out. If the light is lit, call the electrician to troubleshoot the sequence.

6. Check the air pressure gauge for correct air pressure. The machine cannot be operated until the air pressure is at the specified rating.

7. Again verify that the brake switches are in the set position, the joysticks are in the neutral position, and the air pressure is at the correct pressure. Sound the signal horn and be sure all personnel are clear of machine.

8. Turn the propel transfer switch to the dig position. When the display lights indicate that the process is complete, press the control reset pushbutton to activate the controls.

9. Turn the hoist, crowd and swing brake switches to the released position.

10. Briefly actuate the swing, crowd and hoist controls to make sure each motion is operational.

RESTARTING AFTER AN ELECTRICAL FAULT

To restart the machine after the electrical control system has gone into a fault condition, proceed as follows:

NOTE: Before any or all motions can be reset, the following conditions must be met:

a. No operator’s monitor special screens are activated.

b. For hoist/propel motion the hoist/propel transfer switch is in the position called for by the operator’s mode selector switch.

c. The master switch for the motion being reset must be in the NEUTRAL position.

d. The motion mechanical brake selector switch must be in the SET position.

1. For hoist or crowd travel limit faults, the motion will first slow down and then will stop, but the controls will remain active. Reversing the master switch will remove the fault and allow continued operation.

2. For a boom jacking fault, ALL motions will stop but the controls will remain active. Reversing the crowd master switch will remove the fault and allow continued operation.

3. If the boarding ladder and/or stairs are pulled down while the machine is in operation, an alarm message will be sent to the operator, and swing and propel motions will be shut down. The hoist and crowd motions will remain active.

Once the ladder and/or stairs are back in position, the motions may be restarted by pressing the control reset pushbutton.

4. For most other faults, the machine will be shut down and brakes set. In these situations, the controls cannot be reset until the fault has been corrected by an electrician.

MACHINE OPERATION

Efficient operation is essentially the result of understanding and applying the basic techniques related to each machine motion, to achieve fast, smooth and safe load cycles. The interrelated coordination of the hoist, swing and crowd motions results in efficient machine operation.

Each motion is described in the following paragraphs. The operator should thoroughly learn each motion, its purpose and how this knowledge can be applied in becoming a better operator.

When learning to handle the controls, be sure that all personnel are clear of the machine and that there is ample clearance with no danger spots around the machine, such as culverts, ditches, embankments, and that the machine is not too close to the digging face or overhanging ledge and large rocks.

Use the operator’s display in the operator’s cab to assist in the operation of the machine. The monitor allows a large number of messages to be sent to the operator from all portions of the control system. These messages fit into four basic categories:

1. Normal routine operational messages. 2. Alarm only. 3. Delayed shutdown messages. 4. Immediate faults and shutdowns.

This display also allows the setting of certain operating parameters for the machine. Refer to separate manual for the operation of the display as the proper use of the monitor messages is essential for the operation of the machine.

HOIST MOTION MACHINERY MOTIONS

Hoist motion is controlled by the operator’s right joystick. Set the propel transfer switch in the DIG mode. The crawlers should be positioned so that the digging is done over the front of the crawlers. Move the joystick between the hoist and lower until a “feel” is developed for the height, depth range and speed at which the dipper moves. Practice the hoist function until movement can be stopped smoothly.

CAUTION: This joystick also controls the swing motion through left and right motions.

CROWD MOTION

Crowd motion is controlled by the operator’s left joystick. Move the joystick to crowd and retract the dipper handle until a “feel” is developed for the limits and speed of the motion.

CAUTION: This joystick also controls the signal horn and dipper trip.

Practice the crowd and retract functions until the movement can be stopped smoothly. Combine the crowd and hoist functions and practice until smooth coordinated motions and subsequent machine effectiveness are achieved.

PROPEL MOTION

Propel motion is controlled by placing the propel transfer switch in the propel mode and actuating the hoist master switch control and/or crowd master switch control. To propel in a straight forward direction, push forward on both the hoist and crowd master switches at the same time. The speed is increased as the levers are displaced farther from neutral. To propel straight in reverse, pull equally both joysticks to the rear.

NOTE: The control stop pushbutton must be pressed before the propel transfer switch can be activated.

DANGER: THE HOIST BRAKE MUST BE SET WHENEVER IN THE PROPEL MODE.

Propel - Straight Forward/Reverse

SWING MOTION

Swing motion is controlled by the operator’s right joystick. To swing in either direction, move the joystick lever in the direction of swing. Practice swinging in each direction until a “feel” is developed for start-up and stopping.

NOTE: The joy stick also controls the hoisting and lowering of the dipper through forward and backward motions.

DANGER: Each motion - hoist or swing - is fully operational throughout the complete movement of the other motion.

NOTE: When this joystick is used for propelling the machine, the hoist and swing motions are electrically locked out.

PROPER SWING MOTION

Proper swing motion means smooth control and an efficient swing cycle. The swing motion is begun toward the haulage unit when the dipper is filled and is clear of the bank.

DANGER: Extensive damage to the dipper handle and dipper can occur if the machine is swung before the dipper clears the bank. The swing motion begins with acceleration to an optimum point at which the excavator is brought to a stop over the haulage unit. Maximum efficiency and minimum swing machinery wear are direct results of mastering the swing motion.

NOTE: Improper swing motion results in erratic control, and an inefficient swing cycle.

DANGER: The dipper should never be swung over personnel, trail cables, related electrical equipment or other equipment. When the dipper is loaded, accidental tripping of the dipper door could result in death or serious injury to personnel, and extensive damage to equipment. Empty dippers may contain small fragments of material that can be extremely dangerous when dropped from a considerable height. On long moves it’s best to have the door open on an empty dipper and the dipper lowered to a point that permits moving without striking the ground.

Time is required to accelerate any motion from zero to working speed, and also to decelerate from working speed back to zero. The time expended for accelerating and decelerating the swing represents the major part of the entire dig cycle. Therefore, the swing arcs must be kept to a minimum to obtain maximum operating efficiency. As an example: assuming that a 90° swing results in 100 percent of the maximum output, increasing the swing arc to 180° reduces output to 70 percent, while decreasing the swing arc to 45° increased the output to 126 percent. Therefore, a swing arc of 90° or less should usually be used.

Haulage units should be positioned so their center line is approximately under or not more than slightly outside the swing path of the boom point. This substantially reduces the amount of dipper maneuvering required of the operator when positioning the dipper for dumping. Positioning of the haulage unit inside or outside the boom point makes it necessary to retract or crowd the dipper handle and dipper, which breaks the operator’s natural rhythm.

A clean, level pit floor must be maintained. A good operator will always clean the floor before moving into the bank. A clean and level floor grade is a requisite to safe and stable machine operation, and reduces damage to crawler links and related components.

DANGER: “Sweeping” should never be attempted with the machine. Sweeping consists of lowering the dipper to the ground and using the swing motion of the machine to move the dipper from side-to-side and “sweep” the pit floor. The dipper, dipper handle and boom structures can be damaged by this tactic. A bulldozer or loader should be used to help the machine operator maintain a clean pit floor in conjunction with the machine.

STEERING

To make a gradual forward right turn, move the LEFT joystick (crowd) forward and leave the right joystick (hoist) in neutral.

To make a gradual forward left turn, move the RIGHT joystick (hoist) forward and leave the left joystick (crowd) in neutral.

Whenever possible, gradual turns should be made in short increments of 15° to 20° maximum. Propel straight for a short distance (usually 1/2 the length of the crawler belts) to clear the crawler belts of stone and other debris; then make another 15° to 20° turn. Continue until the turn is completed.

NOTE: When steering in soft material such as sand, clay, etc. Increments of less than 15° to 20° might be used to minimize material build up on the crawler belt roller path.

A single sharp turn should be avoided to minimize material build up on the crawler belt roller path and subsequent high loading of crawler belt and associated propel components.

COUNTER-ROTATION TURNS

Although possible, a single sharp turn should be avoided to minimize material build up on the crawler belt roller path. This results in high loading of the crawler belt and associated propel components.

To make a sharp right turn, move the LEFT joystick forward and pull the RIGHT joystick to the rear.

To make a sharp left turn, move the RIGHT joystick forward and pull the LEFT joystick to the rear.

CAUTION: When using the counter-rotation method for turning, have a helper insure that the trail cable does not get fouled and/or torn from the machine.

NOTE: The ability of the machine to turn sharply is dependent on the surface on which the machine is setting. A soft surface will cause the crawlers to dig-in and machine to bogdown.

CAUTION: The propel brakes are released when either joystick is moved from neutral. The propel brakes are set when both joysticks are returned to neutral.

When moving the machine in a straight line, propel forward, which is in the direction of the take-up axle to reduce strain on the crawler belts and propel mechanism. When not possible and propelling to the rear, make sure the trail cable is clear of the machine and follow the signals given by the helper. The machine should be rotated in a position to allow the operator to face the direction of travel.

NOTE: Turning when propelling to the rear requires that the master control be positioned in a direction opposite the actual direction in which the turn takes place.

The machine should be moved close to the bank in short and frequent moves to maintain digging efficiency. Movement should occur between the loading of haul units.

POSITIONING THE MACHINE

There are two basic methods for positioning an excavator at a bank working face. The first method is the “back-up method”. The second method is the “drive-by method”. Both methods are acceptable and effective when set up correctly.

BACK-UP METHOD

When using the back-up method, the excavator is placed in the bank with the front of the machine turned directly toward the digging face. The haulage units are spotted on both sides of the machine. The bank is worked until a 180° semicircle has been excavated. When the point is reached where a 90° swing to either side is required to load haulage units, the excavator is moved to a new cut.

Move the machine right to left along the bank. The operator should set the left brake first. In increments, back the machine until the crawlers are at a 45° angle to the original digging path. Then, back the machine straight until the right crawler crosses the corner of the excavated semicircle.

Lock the left track, propel forward turning the crawler in increments. When the right crawler is in line with the corner of the semicircle, move forward and proceed to load the haulage units.

The back-up method will minimize the swing arc and reduce moving time. Other advantages are less bank toe area clean up and simplified handling of the trail cable, cable standard and trail cable boat.

DRIVE-BY METHOD

NOTE: If the machine and haulage units cannot be set up as described below, the drive-by method should be avoided.