2 minute read

Crowd Machinery Components

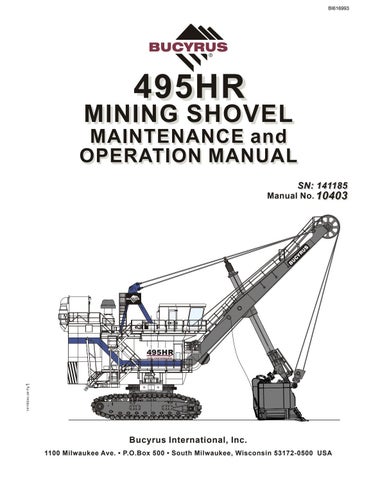

REVOLVING FRAME

The revolving frame is the main structural member of the rotating deck. It is a welded, stress relieved structure with integral lugs for mounting the Aframe, crowd machinery and boom. Provisions are made for mounting deck extensions, operator’s cab, ballast box and swing gearcases. Machined pads on the deck locate the hoist drive motor and machinery frames.

Refer to the following page for a view of the revolving frame assembly with deck extensions and ballast box.

The revolving frame is connected to the truck frame by the center pintle.

CENTER PINTLE

The center pintle is a large diameter, hollow cylindrical forging with a flange at the top. It is threaded at the bottom with a lower nut used to hold it in place. A bronze coated steel core spherical thrust washer between the lower adjusting nut and the bottom surface of the truck frame provides a wear surface for pintle loads. The upper clamping collar at the top of the center pintle is doweled and bolted to the revolving frame to keep the center pintle from rotating.

The hollow pintle provides passage for air and grease lines and electrical cables from the revolving frame to the lower works using a swivel and collector ring assembly.

DECK EXTENSIONS

Right and left side deck extensions are bolted to each side of the revolving frame. They provide a mounting area for the electrical transformers and accessory machinery as well as supporting the machinery house walls.

BALLAST BOX

Deck Extensions and Ballast Box

The ballast box is an all-welded steel fabrication located at the rear of the main revolving frame. A series of vertical plates in the box form compartments for holding ballast.

MACHINERY HOUSE

The machinery house encloses the revolving frame, ballast box and deck extensions. It is constructed of self-supporting steel panels with built-in framing. Removable roof sections are provided over the swing machinery and to the side and rear of the A-frame. The house also provides mounting for the air ventilation and pressurization system. A separate electrical room is located over the ballast box. Platforms and stairs facilitate access to the sides and tops of the house for inspection and maintenance purposes. Boarding stairs and/or ladders permit easy access onto the machine.

BOARDING STAIRS

A set of boarding stairs is attached to the machinery house platform - either on the left side of the machine, the right side or both. When lowered, the stairs allow entrance to the machinery house from ground level. These stairs must be in their raised and latched position to enable the operator’s controls.