1 minute read

Lubrication Room

A single line type automatic lubrication system applies open gear lubricant (OGL) and grease via a programmable logic controller (PLC). The system has six lube pumps (four for OGL and two for grease), each feeding individual PLC controlled circuits. Lincoln Powermaster Four (75) to (1) air powered pumps are mounted on two reservoirs; one 100 gallon and one 200 gallon. High pressure hoses with reusable fittings are utilized.

Lubrication Room

The six separately controlled lube circuits provide selective distribution frequency and quantity resulting in reduced lubricant usage and cost.

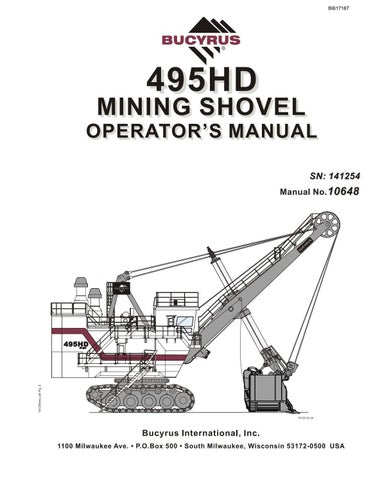

FRONT END EQUIPMENT

The front end equipment consists of the boom, boom point sheaves, padlock, saddle block, dipper handle, dipper, dipper trip mechanisms, running ropes and boom suspension strands.

SUSPENSION STRANDS

The suspension strands are designed to maintain the proper 43 degree boom angle. These are fixed-length strands that support the entire weight of the boom and the load.