3 minute read

Select and turn on control valve for directional

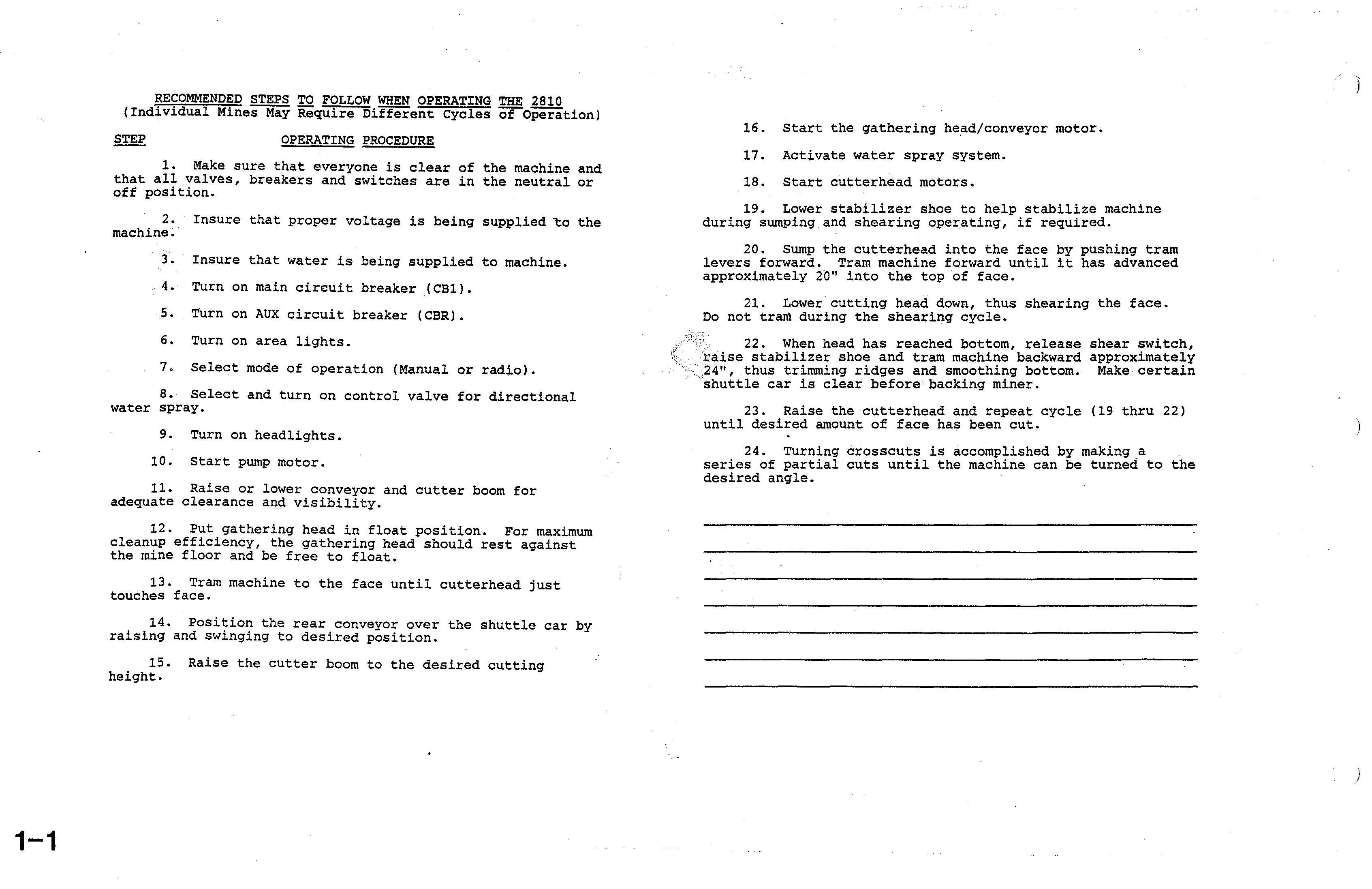

RECOMMENDED STEPS TO FOLLOW WHEN OPERATING THE 2810 RECOMMENDED STEPS TO FOLLOW WHEN OPERATING THE 2810 (Individual Mines May Require Different Cycles of Operation) (Individual Mines May Require Different Cycles of Operation) STEP OPERATING PROCEDURE OPERATING PROCEDURE 1. Make sure that everyone is clear of the machine and 1. Make sure that everyone is clear of the machine and that all valves, breakers and switches are in the neutral or off position. that all valves, breakers and switches are in the neutral or off position.

3. Insure that water is being supplied to machine. 3. Insure that water is being supplied to machine. 4. Turn on main circuit breaker (CBI). 4 • Turn on main c ircui t breaker ,( CB 1 ) . 5. Turn on AIJX circuit breaker (CHR). 5. Turn on AUX circuit breaker (CBR). 6. Turn on area lights. 6. Turn on area lights. 7. Select mode of operation (Manual or radio). 7. Select mode of operation (Manual or radio). 8. Select and turn on control valve for directional water spray. 8. Select and turn on control valve for directional water spray. 9. Turn on headlights. 9. Turn on headlights. 10. Start pump motor. 10. Start pump motor. 11. Raise or lower conveyor and cutter boom for adequate clearance and visibility. 11. Raise or lower conveyor and cutter boom for adequate clearance and visibility. 12. Put gathering head in float position. For maximum 12. Put gathering head in float position. For maximum cleanup efficiency, the gathering head should rest against the mine floor and be free to float. cleanup efficiency, the gathering head should rest against the mine floor and be free to float. 13. Tram machine to the face until cutterhead just touches face. 13. Tram machine to the face until cutterhead just touches face.

16. Start the gathering head/conveyor motor. 17. Activate water spray system. 18. Start cutterhead motors. 19. Lower stabilizer shoe to help stabilize machine during sumping and shearing operating, if required.

20. Sump the cutterhead into the face by pushing tram levers forward. Tram machine forward until it has advanced approximately 20" into the top of face. 21. Lower cutting head down, thus shearing the face. Do not tram during the shearing cycle. 22. When head has reached bottom, release shear switch, raise stabilizer shoe and tram machine backward approximately 24" thus trimming ridges and smoothing bottom. Make certain shuttle car is clear before backing miner. 23. Raise the cutterhead and repeat cycle (19 thru 22) until desired amount of face has been cut. 24. Turning crosscuts is accomplished by making a

19. Lower stabilizer shoe to help stabilize machine during sumpingand shearing operating, if required. 20. Sump the cutterhead into the face by pushing tram levers forward. Tram machine forward until it has advanced approximately 2lJ" into the top of face. 21. Lower cutting head down, thus shearing the face.

Do not tram during the shearing cycle. 22. When head has reached bottom, release 'raise stabilizer shoe and tram machine backward .-<,24", thus trimming ridges and smoothing bottom. "shuttle car is clear before backing miner. shear switch, approximately Make certain 23. Raise the cutterhead and repeat cycle (19 thru 22) until desired amount of face has been cut.

24. Turning crosscuts is accomplished by making a series of partial cuts until the machine can be turned to the desired angle.