4 minute read

General safety instructions

safety equipment

symbol plates EMERGENCY-STOP

lock-out

moving parts

means of attachment

replacing components

Familiarise yourself with your working environment. Start the crusher plant only when it is in a good and safe condition and all protective devices, e.g. EMERGENCY STOP devices, cover plates, etc. are correctly installed.

Danger! It is forbidden to stay in the area of possible falling material! The operator must fix, mark and if necessary enlarge this area during test run and commissioning!

Keep the signalling and lighting systems in a proper functional condition. Observe the acoustic and optical start-up warnings of the crusher plant. Observe the symbol plates on the crusher plant. Press the EMERGENCY-STOP switch immediatelyin the event of faults or irregularities in operation. Report any peculiarity to your superior so that the necessary measures can be taken immediately. Secure the crusher plant against unauthorized and unintentionally restarting while performing: maintenance work inspection work repair work Attach a sign at the possible restarting point with the reference that work are proceeding and restarting is forbidden. Never enter a conveyor if the crusher plant is not secured against restarting. Never allow parts of your body to come between parts which could move, such as e.g.: rolls hydraulical height adjustments Couplings and drive flanges

Storage and transport

Secure all moving parts. Never stay under unsupported parts or suspended loads. Connect the lifting equipment only to the points of attachment provided for that purpose. Observe the different load limits of the attachment points. Also observe the instructions on the transport sheets. Only use means of attachment which are in good condition. Never use chains or steel cables without approval. Do not damage the machined or polished surfaces of shafts, sealings, etc.

Maintenance and repair

Be sure to observe the specified maintenance and inspection intervals. Inform the supervisory personnel and the crew about maintenance and repair work. Sign dismantled, defect components. So you avoid the mistakenly reinstallation. Check these components immediately and lead them to repair if possible.

protective devices

handling of hydraulic fluids

maintenance, repair

Refit protective devices removed immediately after completion of the work and check that they function properly.

Work on hydraulics (if any)

Notice! Only use hydraulic fluids approved by Hazemag. These fluids have been tested at Hazemag and ensure a reliable operation of the hydraulic system. Be sure to observe the manufacturer's instructions for use. We expressly point out that the approval of the listed products relates only to the pure technical use in our hydraulic systems. The responsibility for the constituents used in the hydraulic concentrates lies solely with the respective manufacturer. Further important information is given in DIN 24320 respectively 51524 parts 1 and 2. Avoid direct contact between the skin and hydraulic fluids. Hydraulic fluid can penetrate the skin and cause serious infections. You are only allowed to work on the hydraulic system if you have and can prove to have special knowledge of hydraulics. Important! Inspect and maintain all components of the hydraulic system such as e.g. pump stations, filter systems etc. as specified in the respective operating manuals. Ensure that no dirt enters the hydraulic system during repair work. Dirt in the hydraulic system can cause great damage to the complete hydraulic system. Flush out the hydraulic lines thoroughly before connecting.

Warning! Hydraulic fluids escaping under high pressure can cause serious injury or death. Be sure to depressurize the hydraulic system.

After finishing repair work, check all connectors and connections for leaks before pressurizing the system again. Observe the date of manufacture stamped on the hydraulic hoses. Never use any hydraulic hoses which are more than 2 years old, even if they show no visible signs of damage.

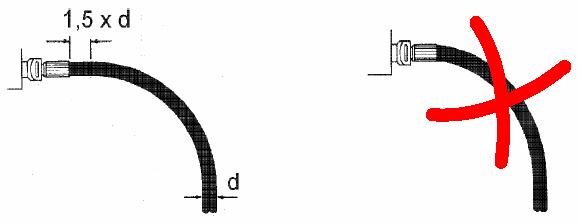

Figure 1: Typical hydraulic hose

Manufacturer Date of manufacture Hose type with internal diameter

laying hydraulic hoses

Never try to hold a jumping hose. Depressurize the respective line immediately. Never try to repair damaged hydraulic hoses. Replace hydraulic hoses at the first suspicion of damage. Lay the hydraulic hoses properly behind the backets and clamps provided for that purpose.

Lay hydraulic hoses such that they: always have a little slack.

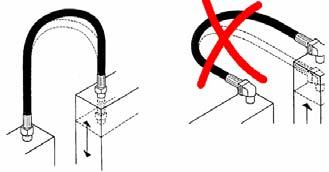

Figure 2: Laying hydraulic hoses, slack

CORRECT WRONG

are not twisted.

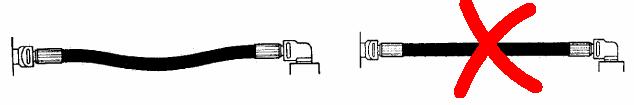

Figure 3: Laying hydraulic hoses, twisting

CORRECT WRONG

are not bent directly behind the connections (distance min. 1.5 x nominal diameter)

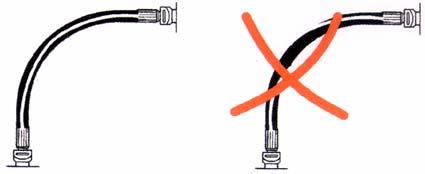

Figure 4: Laying hydraulic hoses, bending

CORRECT WRONG

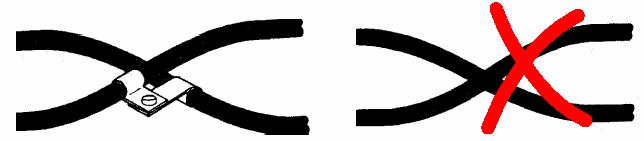

cannot chafe.

Figure 5: Laying hydraulic hoses, crossing

CORRECT WRONG

are not kinked. are not subjected to tensile loads.

are protected against thermal radiation. are accessible at all times.

Push hydraulic hoses into the sockets only by hand. Never try to drive the hydraulic hoses in with a tool as this may damage the connections. When installing the hoses ensure that they cannot be: torn out, kinked, squeezed, driven over or twisted (Figure 6). by the movement of the crusher plant.

Figure 6: Laying hydraulic hoses, connection to moving parts

CORRECT WRONG

Others

Always wear your personal protective equipment. This also includes ear protectors as the noise emitted by the crusher plant may at times exceed 85 dB(A), (e.g. when the plant is being emptied). When working with oils, greases, and other chemical substances, observe the safety regulations applicable to the respective product. Dispose of cleaning rags etc. which have been soiled with oil, grease, or other chemical substances in an environmentally safe manner.