2 minute read

BEFORE STARTING THE ENGINE

2

7

Chapter 4 OPeRATING INsTRUCTIONs befORe sTARTING THe eNGINe

1

3

Check the machine each morning before beginning work. For general maintenance of the machine, follow the Lubrication and Maintenance Chart, on page 110. 1. Check if the tires are worn, cut or not properly inflated. 2.

3. Check if the blade, cutting edges and bits are worn or damaged. Check circle adjustment.

4.

5.

6.

7. Check for damaged or failed instruments and other operator’s compartment components. Check leakage on tandem case. Check any leakage or damage to cooling system hoses. Check engine oil and hydraulic lines and hoses for leaks.

4

5 IT’s ALsO ReCOMMeNDeD TO CHeCK

Electrical system Check insulation parts, worn cables and terminals loose Bolts Check for loose or missing parts Hydraulic system Check leakages, twisted hoses, hoses rubbing against other components Lubrication Check all grease points related on periodic maintenance table

6

8. Fill the fuel tank only with the specified fuel. Take care to avoid entrance of dirt or foreign matter while filling tank.

WARNING: Extinguish all smoking materials or open flames before checking and/or filling the fuel tank.

9. Check the fluid levels of the following: a. b.

Engine crankcase

Engine cooling system

c. Transmission system

d. Hydraulic system

e. Axle housing and rear tandem housings.

10. Lubricate all points where lube fittings are rovided. Refer to lubrication and service guide for instructions and location.

11. Check tire inflation pressure.

WARNING: Do not inflate tires with flammable gases or air from systems utilizing alcohol injectors. Explosion and personal injury may be resulted.

12. The cooling system of the unit is filled at the factory with a 50/50 mixture of water and AKCELA PREMIUM

ANTI FREEZE (1060077) for protection to -34ºF (-37ºC). It is not necessary to drain this solution before placing the machine in service. IMPORTANT: Do not use hands to search for pressure leaks. Fluid escaping under high pressure can penetrate skin causing serious injury.

IMPORTANT: Do not run the engine in closed areas without proper ventilation to remove poison exhaust gases. Warn all people who may be working around your machine before starting the engine. Sound horn before starting or operating the machine. Never leave the machine unattended with the engine running. 13.

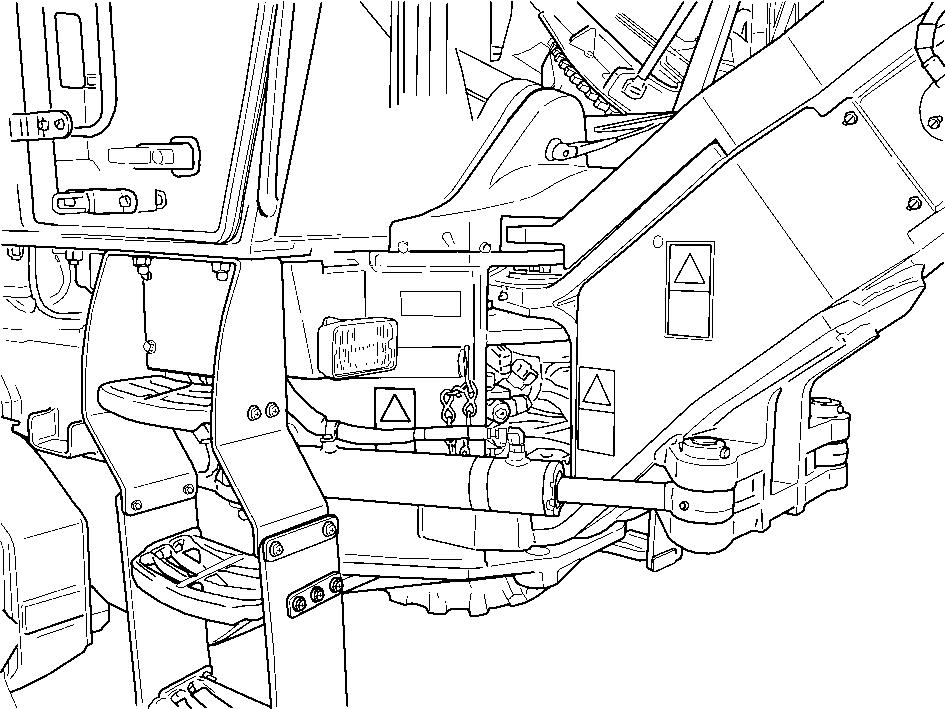

Start engine. Check all instruments and gauges for normal indication. Operate controls and check for normal operation. Stop the engine and check the hoses, piping and gaskets for possible oil leaks. NOTe: To start the engine the parking brake must be applied and the gearshift selector lever in “NEUTRAL” position. IMPORTANT: Remove the articulation lock-pin before operating the machine.

ARTICULATION LOCK PIN (STORAGE POSITION) SHALL BE USED ONLY FOR MACHINE TRANSPORT