11 minute read

SAFETY INSTRUCTIONS

SAFETY IS THE OPERATOR’S RESPONSIBILITY

The Bobcat Hydraulic Excavator is a highly maneuverable and compact machine. In operation, it is rugged and useful under a wide variety of conditions. This presents an operator with hazards which are common for off highway, rough terrain applications but not unique for use of Bobcat Hydraulic Excavator. The excavator has an internal combustion engine with resultant heat and exhaust. All exhaust gases can kill or cause illness so the excavator must be used with adequate ventilation. The excavator must not be used in an area with explosive dusts or gases or so that the engine exhaust can contact flammable material. The excavator has a spark arrestor muffler which is required for operation in certain areas. The dealer recommends the capabilities of the excavator and attachments for each application. The dealer demonstrates the safe operation of the excavator according to the manufacturer’s instructional materials which are also available to all operators. The dealer can also identify unsafe modifications or use of unapproved attachments. The attachments and buckets are designed for rated capacity and secure fastening to the Bobcat Hydraulic Excavator. The user must check with the dealer or Melroe Company literature or load diagram to identify safe loads.

The following publications provide information on the safe use and maintenance of the excavator and attachments:

• The Delivery Report is used to check whether complete instructions have been given to the new owner and that the machine is in safe operating condition.

• The Operation & Maintenance Manual delivered with the Bobcat Hydraulic Excavator gives operating information as well as routine maintenance information. It is a part of the machine and must stay with the machine when it is sold. Replacement Operation & Maintenance Manuals can be purchased from your dealer.

• Every Bobcat Hydraulic Excavator has machine signs (or decals) which instruct on the safe care and operation. The signs and their location are shown in the Operation & Maintenance Manual. Replacementsigns are available from your Bobcat Hydraulic Excavator dealer.

• The Bobcat Hydraulic Excavator has a plastic Operator Handbook fastened to the operator cab. Its instructions are available to the operator. The handbook is available from your dealer in an English edition or one of the following languages: French, German, Italian, Dutch, Spanish, Portuguese, Finnish, Danish & Swedish.

• The CIMA safety manual contains information for safe operation and maintenance.

• The Service Manual and Parts Manual are optional manuals available from your Bobcat Hydraulic Excavator dealer for use by mechanics to do shop–type service and repair.

• The Hydraulic Excavator Operator Training Course is available through your local dealer. This course is intended to provide rules and practices of correct operation of the Hydraulic Excavator.

• The Bobcat Compact Excavator Safety Video is available from your Bobcat Dealer.

The dealer and owner/operator review the recommended uses of the excavator and attachments when excavator is delivered. If the owner/operator will be using the excavator for a different application than was originally demonstrated by the dealer, ask the dealer for recommendations on the new use.

Before Operating The Bobcat Loader

Safety Alert Symbol: This Safety Symbol is used for important safety messages. When you see this symbol, follow safety message to avoid personal injury or death.

Operator must have instructions before running the machine. Untrained operators can cause injury or death.

Warnings on the machine in the manuals are for your safety. Failure to obey warnings can cause injury or death.

This notice identifies procedures which must be followed to avoid damage to the machine.

SAFE OPERATION NEEDS A QUALIFIED OPERATOR*

A QUALIFIED OPERATOR MUST DO THE FOLLOWING:

• UNDERSTAND THE WRITTEN INSTRUCTIONS, RULES AND REGULATIONS

• The written instructions from Melroe Company include the delivery report, operator handbook, Operation & Maintenance Manual, and machine signs (decals).

• Check the rules and regulations at your location.

• HAVE TRAINING WITH ACTUAL OPERATION

• Operator training must consist of a demonstration and verbal instruction. This training is given by your excavator dealer before the excavator is delivered.

• The new operator should start in an area without bystanders and use all the controls until he can operate safely under all conditions of the work area.

• KNOW THE WORK CONDITIONS

• For each material to be handled, the operator must know how to avoid exceeding the rated lift capacity of the excavator. For example, you should not use the excavator for lifting heavy objects.

• The operator must know any prohibited uses or work areas, for example, he needs to know about excessive slopes.

• Know the location of any underground lines. Call local utilities or ONE CALL before you dig.

• Wear tight fitting clothing. Always wear safety glasses when maintaining or servicing excavator. Safety glasses, hearing protection or an excavator special application kit are required for some work. See your dealer about Melroe Safety equipment.

* For an operator to be qualified, he must not use drugs or alcoholic drinks which impair his alertness or coordination while working. An operator who is taking prescription drugs must get medical advice to determine if he can safely operate a machine.

Fire Prevention

The excavator has several components that are at high temperature under normal operating conditions. The primary source of high temperatures is the engine and exhaust system. The electrical system, if damaged or incorrectly maintained, can be a source of arcs or sparks. These conditions make it important to avoid applications where explosive dust or gases can be ignited by arcs, sparks or heat.

Flammable debris (leaves, straw, etc.) must be removed regularly. If flammable debris is allowed to accumulate, it will increase the fire hazard. The excavator must be cleaned as often as necessary to avoid this accumulation. This flammable debris in the engine compartment can be a fire hazard when the machine is parked with a hot engine.

The spark arrestor muffler is designed to control the emission of hot particles from the engine and exhaust system, but the muffler and the exhaust gases are still hot. This spark arrestor muffler does not change the need to avoid use of the excavator in an atmosphere with explosive dust or gases or where the exhaust can contact flammable material.

• Do not use the Hydraulic Excavator where explosive dust or gases can be ignited by arcs, sparks, hot components or exhaust gases.

• The engine compartment and engine cooling system must be inspected every day and cleaned if necessary to prevent overheating. Remove all flammable material.

• Check all electrical wiring and connections for damage. Keep the battery terminals clean and tight. Repair or replace any damaged part.

• Check fuel and hydraulic tubes, hoses and fittings for damage and leakage. Tighten or replace any parts that show leakage. Always clean fluid spills.

• Do not use ether or starting fluids on any engine which has glow plugs. These starting aids can explode and injure bystanders.

• Always clean the excavator before doing any welding. Cover rubber hoses, battery and all other flammable parts. Keep a fire extinguisher near the machine when welding.

• Stop the engine and let it cool before adding fuel. No smoking!

• Use the procedure in Operation & Maintenance Manual for connecting the battery.

• Use the procedure in the Operation & Maintenance Manual for servicing the spark arrestor muffler every 100 hours of operation.

MACHINE SIGNS (DECALS)

Follow the instructions on all the Machine Signs (Decals) that are on the excavator. Replace any damaged machine signs and be sure they are in the correct locations. Replacementmachine signs are available from your Bobcat Excavator dealer.

MACHINE SIGNS (DECALS) (Cont’d)

Getting On And Off The Machine

Use the grab handles, the tracks and the safety treads to get on and off the machine [A]

Lower the control console(s) before starting the engine [C]. (See STARTING THE ENGINE, Page 14).

Pull the lever (Item 1) [D] to the rear to release and raise the control console.

NOTE:On Excavators equipped with ROPS canopy, both the left and right control consoles can be raised for operator access. On Excavators with enclosed cab, only the left control console can be raised.

Seat

The operator seat can be adjusted as follows:

Use the lever (Item 1) [A] to slide the seat backward or forward for easy reach of the machine controls.

The handle (Item 1) [B] has three adjustments for operator weight.

Turn the knob (Item 2) [C] to angle the back of the seat for operator comfort.

CONTROL LEVER (JOYSTICK) LOCK

The control lock micro–switch (Item 1) [D] disconnects the hydraulics from the joystick control levers when the control console(s) are in the raisedposition. (The joystick control levers will not operate with theconsole(s) raised).

NOTE:The travel levers, blade lever, boom swing pedal and the attachment operation pedal functions are NOT affected by the control lock micro–switch.

CONTROL LEVER (JOYSTICK) LOCK (Cont’d)

Lower the control console(s) to engage the joystick control levers [A]

Instrument Panel

The right control console has the following indicator lamps [B]:

1. Engine Temperature Lamp – (Overheat indicator) When the engine coolant temperature exceeds the allowable temperature range, the lamp comes ON and the audible alarm sounds. STOP the engine.

2. Engine Oil Lamp – When the engine oil pressure is low, the lamp comes ON and the audible alarm sounds. STOP the engine.

3. Charging Lamp – The lamp comes ON when the alternator is NOT charging the battery.

4. Preheat Indicator Lamp – When turning the key switch to the HEAT position, the lamp comes ON showing the glow plugs are heating.

NOTE:To check oil pressure and water temperature lights, turn the key to the ON position. Lights should stay on for 10 seconds. Allow 5 seconds cooling time before trying again.

The left control console has the following indicator lamp and instrument [C]:

1. Low Fuel Indicator Lamp – When the fuel is low, (.8 gal. [3.1 L]), the lamp comes ON. Add fuel.

2. Fuel Gauge – Shows the amount of fuel in tank.

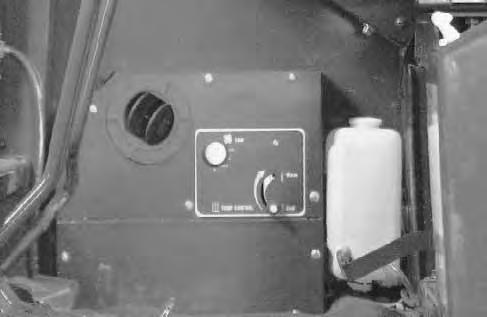

Inside the engine compartment are the following instruments and fuses [D]:

1. Hourmeter – Records the total operating hours. (If the ignition key is left in the run position, with the engine OFF, the hourmeter will continue to run and the audible alarm will sound).

2. Fuse – Ignition (25 Amp) – This fuse supplies the power for the work light circuit and power to the cab (if equipped).

3. Fuse Accessories (25 Amp) – This fuse supplies power for engine start–up, gauge functions, horn, audible alarm, control console micro–switches, auxiliary power outlet and the hourmeter.

4. Fuse – Lights (25 Amp) – This fuse supplies power for the cab heater (if equipped) and the rear accessory wire.

Audible Alarm

An audible alarm (Item 1) [A] located in the right hand console, will sound when these conditions exist:

When the key is in the ON position with the engine OFF.

When low engine oil pressure exists.

When high engine coolant temperature exists.

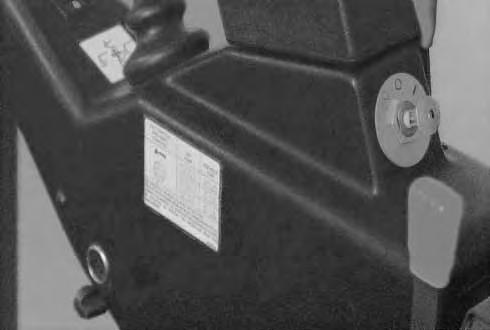

Key Switch

The key switch has the following functions [B]:

A.Key switch is OFF.

B.PREHEAT position – Hold switch in this position to activate the glow plugs for startingin cold weather conditions. See decal (Item 2) [D] for glow plug heating times and see also Page 15.

C.START the engine.

D.ON (run) position – When the engine is running release the key and this position is obtained automatically.

NOTE:Always turn key switch and all accessories to OFF position after the engine is stopped or battery will discharge. Audible alarm will sound if the key is in the ON position with the engine stopped.

See Pages 14 and 15 for the starting procedure.

Light Switch

The light switch (Item 1) [C] has the following functions:

A.Light switch is OFF.

B.Strobe light/flasher (if equipped).

C.Front work lights and the fuel gauge back light (plus any lights used with position B).

D.Additional work lights (if equipped) – (plus any lights used with positions B and C).

Auxiliary Power Outlet

The auxiliary power outlet (Item 1) [D] is used for supplying electrical current for field installed electrical options (such as rotating beacon). This is a 12 volt supply outlet.

CAB ELECTRICAL (If Equipped)

The cab overhead console has the following components [A]:

1. Fuse (5 Amp) – This fuse (Item 1) [A] supplies the power for the wiper/washer and for the interior light.

2. Wiper/Washer Switch – Turn the switch (Item 2) [A] to activate wipers, OFF–LOW–HIGH. Push switch IN to activate the washer.

3. Interior Light – Push the button (Item 3)[A] on the side of the light to illuminate.

Heater

The heater has the following controls:

1. Fan Switch – Turn the switch (Item 1) [B] to activate fan, OFF–LOW–MED–HI.

2. Temperature Control – Move the lever (Item 2)[B] up to increase the temperature; move the lever down to decrease the temperature.

WINDSHIELD WASHER TANK (If Equipped)

Remove the window washer tank cap and fill with washer fluid (Item 1) [C]. (Wiper/Washer switch (Item 2) [A] is used to activate washer pump.)

NOTE:The entire bottle can be lifted from the mounting bracket for better access for filling fluid.

CONTROL LEVERS (JOYSTICKS)

The work equipment is operated by using the left and right control levers (joysticks) [A] & [B]

Operation Of Left Control Lever (ISO)

Arm and Swing (Decal P/N 6587426).

The left lever is used to operate the arm and to swing the upperstructure [A]:

1.Arm Out

2.Arm Out and Swing Right

3.Swing Right

4.Arm In and Swing Right

5.Arm In

6.Arm In and Swing Left

7.Swing Left

8.Arm Out and Swing Left

Before swinging the upper works, make sure the swing lock is disengaged. I–2051–0189

Operation Of Right Control Lever (ISO)

Boom and Bucket (Decal P/N 6587425)

The right lever is used to operate the boom and bucket [B]:

1.Boom Lower

2.Boom Lower and Bucket Dump

3.Bucket Dump

4.Boom Raise and Bucket Dump

5.Boom Raise

6.Boom Raise and Bucket Curl

7.Bucket Curl

8.Boom Lower and Bucket Curl

Before leaving the machine:

• Lower the attachments to the ground.

• Stop the engine & remove the key. W–2167–0195

CONTROL LEVERS (JOYSTICKS) (Cont’d)

The work equipment is operated by using the right and left control levers (joysticks) [A] & [B]

Operation Of Left Control Lever (STANDARD)

Boom and Swing (Decal P/N 6587428)

The left lever is used to operate the boom and swing the upperstructure [A]:

1.Boom Lower

2.Boom Lower and Swing Right

3.Swing Right

4.Boom Raise and Swing Right

5.Boom Raise

6.Boom Raise and Swing Left

7.Swing Left

8.Boom Lower and Swing Left

Before swinging the upper works, make sure the swing lock is disengaged.

I–2051–0189

Operation Of Right Control Lever (STANDARD)

Arm and Bucket (Decal P/N 6587427)

The right lever is used to operate the armand bucket [B]:

1.Arm Out

2.Arm Out and Bucket Dump

3.Bucket Dump

4.Arm In and Bucket Dump

5.Arm In

6.Arm In and Bucket Curl

7.Bucket Curl

8.Arm Out and Bucket Curl

Before leaving the machine:

• Lower the attachments to the ground.

• Stop the engine & remove the key.

W–2167–0195

Swing Lock

When the swing locking lever (Item 1) [A] is engaged (locked position), the upperstructure of the excavator is locked to the track frame and will not pivot.

The upperstructure must be parallel to the track frame to engage the swing lock.

Use the left joystick [C] to swing the house until it is parallel to the track frame.

Lift the swing lock lever (Item 1) [B] to disengage the upperstructure from the track frame. Put the lever in the unlocked position.

Avoid Injury

The swing lock lever must be engaged when transporting the machine.

The horn button (Item 1) [D] is located in the right control lever (joystick) grip.

Speed Control Lever

The speed control lever is used to control the engine speed [A]

1.LOW IDLE POSITION – Pull the lever backward (position 1) for low idle, (approximately 1000 RPM).

2.HIGH IDLE POSITION – Push the lever fully forward (position 2) for full engine RPM, (approximately 2500 RPM).

Engine Stop Control

Pull the knob (Item 1) [B] up to STOP the engine. (When the engine has stopped, push the stop control knob down to the operating position. This will avoid possible starter damage if engine start–up is attempted and the stop control knob has been left in the OFF position.)