15 minute read

MAINTENANCE SAFETY

Instructions are necessary before operating or servicing machine. Read Operation & Maintenance Manual, Handbook and signs (decals) on machine. Follow warnings and instructions in the manuals when making repairs, adjustments or servicing. Check for correct function after adjustments, repairs or service. Failure to follow instructions can cause injury or death.

W–2003–1289

Safety Alert Symbol:This symbol is used for important safety messages. When you see this symbol, follow the safety message to avoid personal injury or death.

Correct

Correct

Correct

Never service the Bobcat® Skid Steer Loader without instructions.

Use the correct procedure to lift or lower operator cab with lift arms down.

Cleaning and maintenance are required daily.

Have good ventilation when welding or grinding painted parts. Wear dust mask when grinding painted parts. Toxic dust and gas can be produced.

Vent exhaust to outside when engine must be run for service. Avoid exhaust fume leaks which can kill without warning. Exhaust system must be tightly sealed.

Never work on loader with lift arms up unless lift arms are held by a lift arm support device. Never modify equipment or add attachments not approved by Melroe Company.

Wrong Wrong Wrong

Stop, cool and clean engine of flammable materials before checking fluids.

Never service or adjust loader with the engine running unless instructed to do so in the manual. Avoid contact with leaking hydraulic fluid or diesel fuel under pressure. It can penetrate the skin or eyes.

Never fill fuel tank with engine running, while smoking or when near open flame.

Keep body, jewelry and clothing away from moving parts, electrical contacts, hot parts and exhaust. Wear eye protection to guard from battery acid, compressed springs, fluids under pressure and flying debris when engines are running or tools are used. Use eye protection approved for type of welding. Keep rear door closed except for service. Close and latch door before operating the loader.

Lead–acid batteries produce flammable and explosive gases. Keep arcs, sparks, flames and lighted tobacco away from batteries. Batteries contain acid which burns eyes or skin on contact. Wear protective clothing. If acid contacts body, flush well with water. For eye contact flush well and get immediate medical attention.

Maintenance procedures which are given in the Operation & Maintenance Manual can be performed by the owner/operator without any specific technical training. Maintenance procedures which arenot in this manual must be performed ONLY BY QUALIFIED BOBCAT SERVICE PERSONNEL. Always use genuine Bobcat replacement parts.

Service Schedule

Maintenance work must be done at regular intervals. Failure to do so will result in excessivewear and early failures. The service schedule is a guide for correct maintenance of the Bobcat loader.

Instructions are necessary before operating or servicing machine. Read Operation & Maintenance Manual, Handbook and signs (decals) on machine. Follow warnings and instructions in the manuals when making repairs, adjustments or servicing. Check for correct function after adjustments, repairs or service. Failure to follow instructions can cause injury or death.

W–2003–1289

Engine Oil

Check the oil level & add oil as needed.

Engine Air Cleaner Replace the outer filter element only when the red ring shows in the indicator window. Check for leaks and damaged components.

Engine Cooling SystemClean debris from shrouds & grills. Check coolant level in the recovery tank and add as needed.

Tires Check for damaged tires and correct air pressure.

Seat Belt and Seat BarCheck the condition of seat belt. Check the seat bar for correct operation.

Safety Signs (Decals)Check for damaged signs (decals) and safety treads. Replace Safety Tread any signs and safety treads that are damaged or worn.

Lift Arm and Bob–TachAdd grease to the fittings until extra grease shows.

Pivot Areas

Engine Fuel Filter Remove water from filter.

Operator Cab Check the fastening bolts, washers and nuts. Check the condition of the cab.

Wheel Nuts Check for loose wheel nuts. Tighten to correct torque if loose.

Engine Oil and Filter Replace the oil and the engine oil filter.

Battery Check the water level. Check battery cables for corrosion. Check that the battery cables are tight. Check covers.

Parking Brake Check operation and adjust as needed.

Hydraulic Fluid, TubelinesCheck the fluid level and add as needed. Checkfor damage and and Hoses leaks and replace as needed.

Alternator Drive Belt Check the tension and adjust as needed.

Chaincase Check the fluid level and add as needed.

Controls & Brake Check operation and adjust as needed.

Spark Arrestor MufflerRemove the plug and clean the spark chamber.

Seat Bar Grease pivots as needed.

Steering Shaft Pivots Grease two (2) fittings. Add oil to steering shaft.

Hyd. and Hydro. FiltersReplace filter elements.

U–Joint Grease three (3) fittings with correct grease.

Engine Fuel Filter Replace the filter element.

Hydraulic/HydrostaticReplace breather cap.

Reservoir Breather Cap

Chaincase Replace the fluid.

Hydraulic Fluid ReservoirReplace the hydraulic fluid.

Check wheel nut torque every 8 hours for the first 24 hours. Also replace hydraulic/hydrostatic filter element when the transmission warning light comes ON. Or every 12 months.

Lift Arm Support Device

NOTE:Lift arm support devices are available from your Bobcat loader dealer.

Never work on a machine with the lift arms up unless the lift arms are secured by a lift arm support device. Failure to use an approved lift arm support device can allow the lift arms or attachment to fall and cause injury or death.

W–2059–0991

Maintenance and service work can be done with lift arms lowered. If the lift arms are raised, use the following procedure:

Place jackstands under the rear corners of the loader.

One person must be in the operator’s seat, with the seat belt fastened and seat bar lowered, until the lift arm support device is installed [A].

Start the engine and raise the lift arms all the way up. Have second person install the lift arm support device over the rod of one of the lift cylinders [A]

The lift arm support device must be tight against the cylinder rod. Lower the lift arms slowly until the support device is held between the lift arm and the lift cylinder.

Operator Cab

The Bobcat loader has an operator cab (ROPS and FOPS) as standard equipment to protect the operator from rollover and falling objects. Check with your dealer if the operator cab has been damaged.

Never modify operator cab by welding, grinding, drilling holes or adding attachments unless instructed to do so by Melroe Company. Changes to the cab can cause loss of operator protection from rollover and falling objects, and result in injury or death.

W–2069–1285

OPERATOR CAB (Cont’d)

Raising The Operator Cab

Stop the loader on a level surface. Put the lift arms all the way down.

If the lift arms must be up while raising the operator cab, install a lift arm support device (See Page 26.)

Before the cab or the lift arms are raised for service, jackstands must be put under the rear corners of the frame. Failure to use jackstands can allow the machine to tip backward causing injury or death.

W–2014–0895

Remove the two fasteners (including washers and plates) at the front corners of the operator cab [A]

If the lift arms are down, or are held up by a lift arm support device, stand in front of the loader. Lift on the grab handle and bottom of the operator cab slowly until the cab is all the way up [B] & [C]

Lowering The Operator Cab

If the lift arms are down, or are held up by a lift arm support device, stand in front of the loader. Pull down on the bottom of the operator cab and use the grab handle until the cab is all the way down [B] & [C]

Install the two fasteners (including washers and plates). Tighten the nuts to 40–50 ft.–lbs. (54–68 Nm) torque[A]

Both sets of fasteners at the front of the operator cab (ROPS) must be assembled as shown in this manual. Failure to secure ROPS correctly can cause injury or death.

W–2005–1189

Seat Bar System

The seat bar system has a pivoting seat barwith arm rests and has spring loaded latches for the lift and tilt control pedals. The operator controls the use of the seat bar. The seat bar in the down position helps to keep the operator in the seat and unlocks the foot pedals. When the seat bar is up, the lift and tilt pedals are locked in neutral position.

Avoid Injury Or Death

The seat bar system must lock the lift and tilt control pedals in neutral when the seat bar is up. Service the system if pedals do not lock correctly.

W–2105–1285

Seat Bar Inspection

Sit in the seat and fasten the seat belt. Engage the parking brake. Pull the seat bar all the way down. Start the engine. Operate each foot pedal to check both the lift and tilt functions. Raise the lift arms until the bucket is about 2 feet (600 mm) off the ground.

Raise the seat bar. Try to move each foot pedal. Pedals must be firmly locked in neutral position. There must be no motion of the lift arms or tilt (bucket) when the pedals are pushed.

Pull the seat bar down, lower the lift arms and place the bucket flat on the ground, Stop the engine. Raise the seat bar and operate the foot pedals to be sure that the pedals are firmly locked in the neutral position. Un–buckle the seat belt.

Seat Bar Maintenance

Clean any debris or dirt from the moving parts [A] & [B]

Inspect the linkage bolts and nuts for tightness. The correct torque is 25–28 ft.–lbs. (34–38 Nm).

Use a general purpose grease to lubricate the seat bar pivot points on each side of the cab [A]. If the seat bar system does not function correctly, check for free movement of each linkage part. Check for excessive wear. Adjust pedal control linkage. Replace parts that are worn or damaged. Use only genuine Melroe replacement parts.

Avoid Injury Or Death

Never service or adjust the machine when the engine is running unless instructed to do so in the manual.

W–2012–0497

Open the rear door to service the engine. Pull the door latch up and turn to the left to release the door latch [A].

Pull the rear door open.

Keep the rear door closed when operating the machine. Failure to do so could seriously injure a bystander.

Adjustment

Loosen the set screw (Item 1) [B]

Loosen the nut (Item 2) [B]

Turn the bolt (Item 3) [B] in or out, until the door contacts both the top and bottom of the loader from (Item 1) [C] with the door lever in the latched position.

NOTE:It takes approximately 50 lbs. (223 N) of force to push the lever down when the latch is adjusted correctly.

With the set screw up, the flanges at the bolt (Item 2)[C] must be to the side so that the set screw aligns with the flat surface at the end of the bolt.

Tighten the set screw (Item 1) [B]

Tighten the nut (Item 2) [B] to 65–70 ft.–lbs. (88–95 Nm) torque.

Air Cleaner Service

See the SERVICE SCHEDULE Page 25 for the interval to service the air cleaner system.

Check the air intake hose for damage. Check the air cleaner housing for damage. Check to make sure all connections are tight.

Replace the large (outer) filter element only when the red ring shows in the window of the condition indicator (Item 1) [A].

NOTE:Push the button on the condition indicator (Item 1) [A] and start the engine. If the red ring does not show, do not replace the filter element.

To replace the filter element, use the following procedure: Loosen the clamp on the dust cup [B]

Remove the dust cup and outer filter element [C]

NOTE:Replace the inner filter every third time the outer filter is replaced or when the red ring still shows in the indicator window after the outer filter is replaced.

Clean the inside of the air cleaner housing. Install the new filter element.

Install the dust cup so the arrow on the cup is up. Tighten the clamp.

Record the operating hours of the loader on the decal (Item 1) [D] inside the rear door.

Fuel System

Fuel Specifications

Use only clean, high quality fuel. Use Grade No. 2 fuel above 40° F (4° C.). Use Grade No. 1 fuel at temperatures below 40° F. (4° C.).

Filling The Fuel Tank

Stop and cool the engine before adding fuel. NO SMOKING! Failure to obey warnings can cause an explosion or fire.

Remove the fuel fill cap (Item 1) [A].

Use a clean, approved safety container to add fuel of the correct specifications. Add fuel only in an area that has free movement of air and no open flames or sparks. NO SMOKING! [B]

Install and tighten the fuel fill cap [A].

Fuel Filter

Always clean up spilled fuel or oil. Keep heat, flames, sparks or lighted tobacco away from fuel and oil. Failure to use care around combustibles can cause explosion or fire which can result in injury or death.

See the SERVICE SCHEDULE Page 25 for the service interval when to remove the water from the fuel filter.

Loosen the drain (Item 1) [C] at the bottom of the filter element to drain the water from the filter.

See the SERVICE SCHEDULE Page 25 for the service interval when to replace the fuel filter.

Clean the area around the fuel filter.

Loosen the filter element [D]

FUEL SYSTEM (Cont’d)

Remove the water trap and filter element [A].

Put oil on the seal of the filter element.

Install the filter element, water trap and tighten.

Remove the air from the fuel system.

Removing Air From The Fuel System

After replacing the fuel filter element or when the fueltank has run out of fuel, the air must be removed from the fuel system to start the engine.

Loosen the plug at the top of the filter housing [B]

Operate the priming bulb until fuel flows from the plug with no air bubbles showing [C]

Tighten the top plug on the filter housing.

Loosen the plug at the fuel injection pump (Item 1) [D]

Operate the priming bulb until fuel flows from the plug with no air bubbles showing [C].

Tighten the plug on the fuel injection pump.

Always clean up spilled fuel or oil. Keep heat, flames, sparks or lighted tobacco away from fuel and oil. Failure to use care around combustibles can cause explosion or fire which can result in injury or death.

Engine Lubrication System

Check the oil level every day.

Stop the engine and remove the dipstick [A]

Keep the oil level between the marks on the dipstick.

Use a good quality motor oil that meets API Service Classification of CC, CD, or CE (See Oil Chart.)

Replacing Oil And Filter

See the SERVICE SCHEDULE Page 25 for the service interval for replacing the engine oil and filter.

Use the following procedure to replace the oil and filter:

Run the engine until it is at operating temperature. Stop the engine.

Open the rear door and remove the cap (Item 1)[B] from the end of the hose and drain the oil into a container.

Turn the plug on the oil filter hosingout about three to five turns to drain the oil in the filter element into the crankcase

NOTE:This plug must be tightened after the oil is removed from the filter element, because if it is not, there will be no engine oil pressure and engine damage will result.

AVOID INJURY OR DEATH

Engines can have hot parts. Wear protective clothing when removing oil filter to avoid burns.

W–2128–0788

RECOMMENDED SAE VISCOSITY NUMBER (LUBRICATION OILS FOR ENGINE CRANKCASE)

ENGINE LUBRICATION SYSTEM (Cont’d)

Remove the filter element [A].

Clean the filter housing surface. Put clean oil on the gasket of the new filter. Install the filter element and hand tighten only.

Turn the plug (Item 1) [A] on the filter housing. Install the cap on the end of the drain hose and tighten.

Remove the oil fill cap [B].

Fill to capacity (SeeSPECIFICATION Page 53 for correct capacity) [C]

Start the engine and let it run for about 5 minutes. Check for leaks at the filter.

Stop the engine. Check the oil level. Add oil until the level is at the Full mark on the dipstick. Install the fill cap.

Cooling System

Check the cooling system every day to prevent over–heating, loss of performance or engine damage.

Wear safety glasses to prevent eye injury when any of the following conditions exist:

• When fluids are under pressure.

• Flying debris or loose material is present.

• Engine is running.

• Tools are being used.

W–2019–1285

Checking The Coolant Level

Open the rear door. Check the coolant level in the coolant recovery tank (Item 1) [C] on the left side of the engine.

The coolant recovery tank must be 1/3 full.

Add pre–mixed coolant, 50% water and 50% ethylene glycol to the recovery tank if the coolant level is low.

Removing Coolant From The Cooling System

Do not remove radiator cap when the engine is hot. You can be seriously burned.

W–2070–1285

Open the rear door. Open the rear grill. Remove the radiator cap.

Open the engine block drain valve and drain the coolant into a container [C]

After all the coolant is removed, close the drain valve.

NOTE:Protect the cooling system by adding pre–mixed 50% ethylene glycol and 50% water to the system. This mixture will protect the cooling system to –34° F. (–36° C).

Mix the coolant in separate container (See SPECIFICATIONS for correct capacity, Page 53.)

Fill the radiator with the pre–mixed coolant. Install the radiator cap.

COOLING SYSTEM (Cont’d)

Fill the coolant recovery tank 1/3 full.

Run the engine until it is at operating temperature. Stop the engine. Check the coolant level in the recovery tank when cool. Add coolant to the recovery tank as needed.

Cleaning The Cooling System

To clean debris from the coolant system, use the following procedure:

Open the rear door.

Remove the panels above the engine underthe oil cooler. Clean the oil cooler area of all debris. Install the panels under the oil cooler.

Lift the rear grill.

Clean the top of the radiator.

To clean the debris between the radiator andoil cooler use the following procedure:

Wear safety glasses to prevent eye injury when any of the following conditions exist:

• When fluids are under pressure.

• Flying debris or loose material is present.

• Engine is running.

• Tools are being used.

W–2019–1285

Have a second person in the operator cab, with seat belt fastened and seat bar lowered.

Engage the parking brake and start the engine. Run the engine at full RPM.

Use air pressure to blow debris down from the top side of the radiator [A]

Direct the air pressure from side to side starting at the rear of the radiator and moving forward.

Alternator Belt

Adjusting The Alternator Belt

To adjust the belt tension, use the following procedure: Stop the engine. Open the rear door. Remove the belt shield [A]

Loosen the mounting and adjustment bolts [B]

Move the alternator until the belt has 5/16 inch (8 mm) movement at the middle of the belt span with 15 lbs. (67 N) of force [C]

Tighten the adjusting and mounting bolts. Install the belt shield.

ELECTRICAL SYSTEM Description

The loader has a 12 volt, negative ground alternator charging system. The electrical system is protected by fuses located in the instrument panel. The fuses will protect the electrical system when there is an electrical over–load. The reason for the over–load must be found before starting the engine again.

Electrical System Service

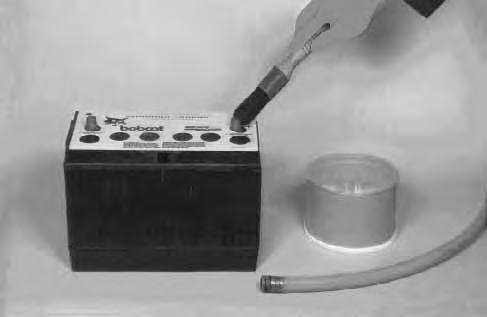

The battery cables must be clean and tight. Check the water level in the battery. Remove any acid or corrosion from the battery and cables with a sodium bicarbonate and water solution [A]

Cover the battery terminals and cablesends with grease. Using A Booster Battery (Jump Starting)

If it is necessary to use a booster battery to start the engine, BE CAREFUL! There must be one person in the operator’s seat and one person to connect and disconnect the battery cables.

The ignition must be in the OFF position. The booster battery to be used must be 12 volt.

Connect the end of the first cable (Item 1) [B] to the positive (+) terminal of the booster battery. Connect the other end of the same cable (Item 2) [B] to the loader battery positive (+) terminal.

Connect the end of the second cable (Item 3) [B] to the negative (–) terminal of the booster battery. Connect the other end of the same cable (Item 4) [B] to the engine. Keep cables away from moving parts. Start the engine (See Cold Temperature Starting Condition, Page 12.)

After the engine has started, remove the ground (–) cable (Item 4) [B] first. Remove the cable from the loader battery.

Keep arcs, sparks, flames and lighted tobacco away from batteries. When jumping from booster battery make final connection (negative) at engine frame.

Do not jump start or charge a frozen or damaged battery. Warm battery to 60°F. (16°C.) before connecting to a charger. Unplug charger before connecting or disconnecting cables to battery. Never lean over battery while boosting, testing or charging.

Damage to the alternator can occur if:

• Engine is operated with battery cables disconnected.

• Battery cables are connected when using a fast charger or when welding on the loader (Remove both cables from the battery).

• Extra battery cables (booster cables) are connected wrong.

I–2023–1285

Battery gas can explode and cause serious injury.

W–2066–1296

Batteries contain acid which burns eyes and skin on contact. Wear goggles, protective clothing and rubber gloves to keep acid off body.

In case of acid contact, wash immediately with water. In case of eye contact get prompt medical attention and wash eye with clean, cool water for at least 15 minutes.

If electrolyte is taken internally drink large quantities of water or milk! DO NOT induce vomiting. Get prompt medical attention.