3 minute read

Rear axle

power take off on the tractor, reducing gear and drive transfer box of the front axle of tractors Belarus-92.

Gear shift mechanism

On the deck of gear shift casing (pic. а) is settled the gear shift mechanism. Gear change is realized by means of plugs, connected with flash welded pads 9. There are on the top pads places are diametrical holes that include spring-mounted balls 11, insuring plug fixing in defined position and inhibiting self-coupling of gears under load. Pass of gearing shifting is realized with lead 48, connected with bead 47, in which is fastened the plug 50, moving the gear 36. The plug pads are provided with splines that include the underside end of the shift lever 15, fixed in the cover 12 on the trunnion ball 14 by means of pin 17, that block the lever turn regarding vertical axle. The tractor gear shifts are equipped with device, blocking the starting engine operation by any switched gearing.

Rear axle

Main gear: couple of conical gears hooked teeth.

Differential: conical, four-satellite.

Final drive: couple of cylindrical gears.

Differential lock: hydraulically operated dry friction clutch.

Rear axle:

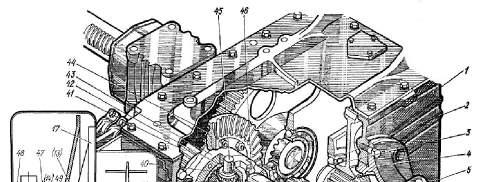

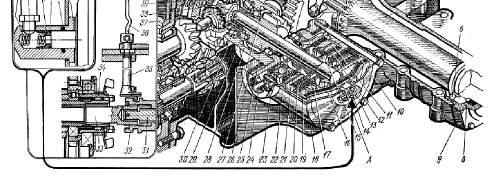

1 — casing; 2 — bearing (217А) of half-axle; 3 — driven gear of final drive; 4 — half-axle sleeve; 5— half-axle; 6 — bearing (217А) of half-axle; 8 — cover; 9 — collar; 10 — expansion springs; 11 — pressure plate; 12 — brake disc; 13 — adapter connector; 14 — ring; 15 — coupling spring; А — working space of lockup clutch; 16 — diaphragm cover; 17 — backing plate; 18 — pressure disc; 19 — diaphragm; 20 — spacing disk; 21 — clutch housing of GB; 22 — clutch casing of GB; 23 — brake casing; 24 — plug; 25 — left drive gear of half axle; 26 — adjusting shims; 27 — clutching axle of GD; 28 — left bearing cup; 29 —drive gear bearings of final gears; 30 — left differential bearing (7215А); 31 — crown gear shafting; 32 — clutching; 33 — inner shafting; 34 — gear of synchronous power take off; 35 — operation roller; 36 — power take off lever; 37 — half-axle gear; 38 — back-up plate of half-axle gear; 39 — differential cover; 40 — sattelite; 41 — right drive gear of final gear; 42 — ball washer of satellites; 43 — differential casing; 44 — axle driven gear; 45 — crossing; 46 — tightening bolts of differential casing; 47 — bush; 48 — spring; 49 — ring.

Brakes

Main brakes: rear wheel: double-disc, dry, with mechanical servo-drive. Disc diameter 204 mm. Parking brake: disc, dry, with mechanical hand drive. Disc diameter: 180 mm.

Front driving axle

Type: portal, with retractable casings of conical wheel reduction gear. Main gear: pair of conical gears with spiral teeth. Differential type: conical, latching, limited split with frictional clutching. Final drives: with conical wheel reduction gears. Gear oil: Тап-15В, ТСп-15К or ТСп-10 (SAE 80W-90); ТАД-17И. Drive: from transfer case by means of two drive shafts with intermediate support. Power take-off operation: mechanical, with level for right hand of the operator. There are 3 running conditions: Power take off is off; Power take off is off/ witched automatically; Power take off is switched on compulsory.

Power take off (PTO) drive

Type: separate, double speed and synchronous. Master clutching: planetary reduction gear with clamping band. Power take off operation: mechanical.

Termination point rotary speed of power take off: Separate drive:

• 540 rev/min at 2081 rev/min of diesel engine; • 1000 rev/min at 2302 rev/min of diesel engine. Synchronous drive: 3,4 rev/meter of road at placing of back tyre 15,5R38 mounting.

Removable power take off shank end:

according SAE with 6 and 8 splines for 540 rev/min and 21 splines for 1000 rev/min. Direction of rotation: clockwise, while looking gear end.

Hydraulic system:

Type: universal, aggregative, with autonomous power cylinder. Maximum hydraulic system pressure is 180... 200 kgf/cm2 .

Distributor:

valve type: • Р80-3/1-222-ЗГг (Р80-3/1-111-ЗГг) — for tractors without force regulator; Hydraulic system outlets: two side way. Control system of back hookup has the following operating condition: • high-altitude.

Hydraulic system oil:

• from -40°С to +5°С - М-8Г2К (SAE 15W-40); ВЕСНЕМ STAROIL №32;. • от +5°С до +50°С - М-10Г2, М-10Г2К (SAE 15W-40); ВЕСНЕМ STAROIL №32;

Rear hitch attachment

Type: three-point lift linkage of cat. 2 Carrying capacity: 3200 kg across longitudinal drafts.

Electrical equipment

Tractor-system voltage: 12 V. Power supply system: two storage batteries, 12 V each, parallel connected.

Alternating current generator

14V, power 1150 W.

Illumination and light alarm system:

• front road headlights with lower and higher light; • front and rear operation headlights; • front and rear lamps; • illumination of instruments panel and license plate;