1 minute read

1.7 Valve drive

Engine 1

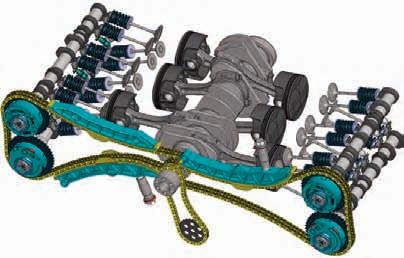

The two timing chains on the GT3 are the same as the ones used on the current 911 Carrera models (991). The use of valve lever control for the valves is new, combined with lightweight aluminum pistons, forged titanium connecting rods and, hollow-drilled valves (intake and exhaust), allows for high engine rpm.

01_06_14

High engine speed concept

The high engine speed concept for increasing engine output and performance has been further improved for the new 911 GT3. The maximum engine speed of the new 911 GT3 is 9,000 rpm, which is 500 rpm higher than the previous model (997 GT3 II: 8,500 rpm). This is possible thanks to the low moving masses of the crank and valve drive. In addition to the low translational masses (pistons, connecting rods, valves, valve levers), the rotating masses of the drive system have also been reduced on the new 911 GT3. The reduced translational and rotating masses not only ensure a low weight, but above all high engine speed dynamics.

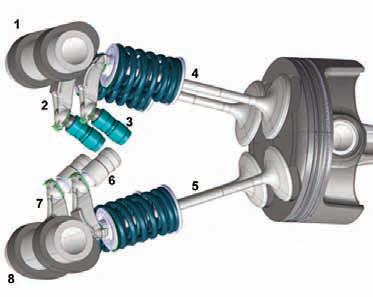

Valve levers with hydraulic valve clearance compensation is new to the 911 GT3 engine. The intake and exhaust valves are controlled by valve levers. This technology was taken from motor racing and is used to achieve high engine speeds as well as power-oriented camshafts. The technical advantage of valve lever control is above all the associated low moving masses.

1 - Intake camshaft 2 - Intake valve lever 3 - Hydraulic valve clearance compensating elements - Intake 4 - Intake valves 5 - Exhaust valves 6 - Hydraulic valve clearance compensating elements - Exhaust 7 - Exhaust valve lever 8 - Exhaust camshaft

01_07_14 Engine 1

Valve lever with hydraulic 01_08_14

valve clearance compensating element - Intake

Valve lever with hydraulic valve clearance compensating element - Exhaust 01_09_14