3 minute read

2.2 Fuel system

DME Engine electronics 2

The specifications and safety instructions in the PIWIS information system Group 2 must be observed when working on the fuel system.

Fuel quality

The engine is designed for unleaded fuel 93 octane ( ). Adaptation is performed byR+M 2 the knock control if fuels with a fuel quality of at least 90 octane are used.

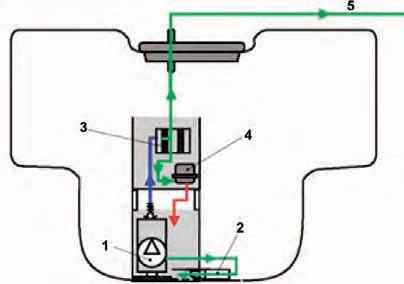

Fuel tank

The capacity of the standard fuel tank is 16.9 gal. (64 l). The fuel reserve is 2.6 gal. (10 l). The fuel tank contains the electric fuel pump, the fuel filter (lifetime filter), the fuel pressure regulator and the fuel-level sensor. The pump chamber is filled by a sucking jet pump, which works according to the Venturi principle.

1 - Electric fuel pump 2 - Sucking jet pump (Venturi nozzle) 3 - Fuel filter 4 - Fuel pressure regulator, approximately 79.75 psi (5.5 bar) 5 - Fuel low-pressure line to the high-pressure pumps

02_01_14

Fuel low-pressure side

On the low-pressure side of the returnless fuel system (RF), fuel is supplied by way of the electric fuel pump in the tank. The fuel low-pressure is maintained at maximum 79.75 psi (5.5 bar) using the fuel pressure regulator. The nominal values for the fuel low-pressure, holding pressure and the fuel delivery rate can be found in the PIWIS information system.

The electric fuel pump is activated when opening the driver’s door, switching on the ignition, starting the engine and while driving. Depending on the amount of fuel required, the electrical current and thus the delivery rate of the electric fuel pump is maintained at between approximately 5 and 15 A via a PWM signal from the DME control unit.

The electrical current can be measured at the fuse for the electric fuel pump. The control unit (see 02_02_14) for electric fuel pump flow control (1) and the NVLD control unit (2) are installed under the battery tray (3) as on the 911 Carrera models (991).

Fuel high-pressure side - direct fuel injection (DFI)

Compared with the direct fuel injection system used in the current 911 Carrera models, the new 911 GT3 is fitted with its own separate injection system (Bosch MED 17.1.11). Two high-pressure pumps are used to build up the fuel high-pressure. The injection pressure of the multi-hole injectors is 362.5 psi (25 bar) (idle speed) up to 2,900 psi (200 bar) (full load), making it much higher than on the 911 Carrera models (991). The fuel high-pressure is generated by two high-pressure pumps - one on each cylinder bank - which are driven by the relevant intake camshaft. This permits realization of the design requirements for VarioCam with additional exhaust camshaft control.

1 - High-pressure pump 2 - Roller tappet 3 - Quantity control valve (for high-pressure control)

The high-pressure pump (see 02_04_14) is driven by a drive cam (1) on the intake camshaft (2). This drive cam has a total of three lobes, resulting in three lifts per camshaft revolution and for every two crankshaft revolutions.

Fuel high-pressure pump 02_03_14 DME Engine electronics 2

02_02_14

02_04_14

DME Engine electronics 2

The fuel high-pressure is approximately 362.5 psi (25 bar) at idle speed and is regulated to maximum 2,900 psi (200 bar) at full load and high engine speed. This results in a further increase in the amount of injected fuel and even finer atomization of the fuel in the combustion chamber compared with the 911 Carrera models (1740 psi/120 bar). A high-pressure pump with a quantity control valve and a fuel rail with a high-pressure sensor are installed on each cylinder bank.

1 - Fuel high-pressure pump 2 - High-pressure line 3 - High-pressure rail 4 - 6-hole injectors 5 - Installation position of high-pressure sensor

Fuel high-pressure system, left cylinder bank 02_05_14

6-hole injector

6-hole injectors are used. These injectors enable a high maximum flow for high engine power in addition to sensitive injection for small flow quantities.

6-hole injector 02_06_14