3 minute read

Chapter 4: Body

Brake adjustment

NOTE: When performing a brake adjustment, inspect the brake components for signs of wear or damage.

1. Block the front wheels.

2. Lift and safely support the rear of the mower.

NOTE:

Make sure the parking brake is released. Castellated nut

3. Remove the cotter pin locking the castle nut on the brake caliper. See Figure 3.3. 4. Back the castle nut off a few turns using a 9/16” wrench.

NOTE: Even if the brakes are set to the correct clearance, inserting a feeler gauge between the rotor and the brake puck can be very dif ficult. Loosen the castle nut first, then insert the feeler gauge and tighten the nut to set the proper clearances Cotter pin

Figure 3.3

5. Insert a 0.030” (0.8 mm) feeler gauge between the brake rotor and the outboard brake puck. See Figure 3.4. NOTE: The tolerance for the brake clearance is 0.020” - 0.040” (0.5 - 1.0mm). The 0.030 feeler gauge will set the clearance at the midpoint.

6. Tighten the nut until there is slight drag on the feeler gauge. NOTE: For even braking, both sides should be set to the same clearance.

7. Install a new cotter pin. 8. Repeat same procedure on the other side. 0.030” feeler gauge

Figure 3.4

9. Take the mower off of the jack stands. 10. Open the by-pass valves and check the parking brake before returning the mower to service. • With the brakes released, the mower should have only hydraulic drag when it is pushed. • With the brakes engaged, the wheels should slide before they rotate when the mower is pushed. 11. Test drive the mower in a safe area before returning it to service.

Brake puck/rotor replacement

On HydroGear transmissions, the brake pucks are wearing parts that will need to be serviced from time to time. If a mower is operated with the parking brake dragging, the pucks will wear out rapidly and the brake rotor will develop hot spots. If the mower is operated long enough, the rotor may have grinding marks on it with excessively worn pucks.

! CAUTION

If the rotor shows hot spots or any other signs of damage, including warpage, it must be replaced. Failure to do so can result in the failure of the brakes

The brake pucks and the rotors are serviced at the same time. To service the brake pucks:

Brake spring

1. Lift and safely support the rear of the mower. 2. Make sure the parking brake is released. 3. Disconnect the brake springs. See Figure 3.5.

Figure 3.5

4. Loosen the rear mounting bolt. See Figure 3.6.

Loosen this bolt

Figure 3.6

Remove this bolt

5. Remove the front mounting bolt, allowing the caliper to swing down. See Figure 3.7. 6. The outboard brake puck should fall out when the brake caliper swings down. If it did not, it can be removed now.

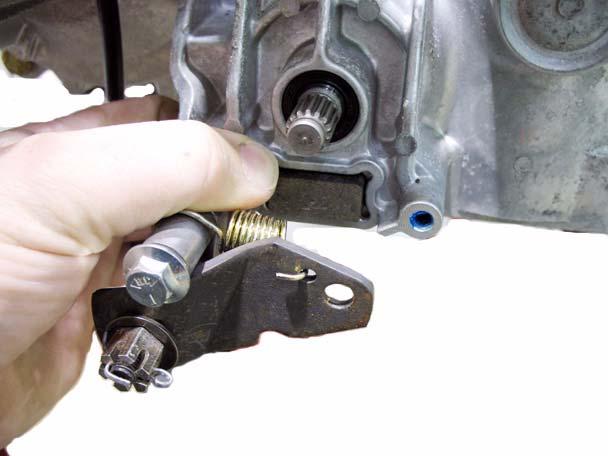

7. Slide the brake rotor off to reach the inboard brake puck. See Figure 3.8. 8. Remove the caliper for inspection when servicing the brake pucks. To do this, remove the rear bolt loosened in step 4.

9. With the caliper on a work bench, remove the brake puck, backing plate and the two brake pins. See Figure 3.9. 10. Check for free movement of the brake pins. A dry lubricant can be used on the brake pins sparingly.

Never put grease or anti-seize on ! CAUTION brake pins. It can migrate to the brake pucks, preventing the braking action of the pucks.

11. Slide the brake pins into the caliper. 12. Place the backing plate in the caliper. Caliper

Figure 3.7

Figure 3.8

Inboard brake puck

Figure 3.9

Brake caliper

Brake pins

Backing plate

Brake puck