AEROSPACE PARTS TEST WITH HANDHELD XRF ANALYZER

AEROSPACE PARTS TEST WITH HANDHELD XRF ANALYZER

AEROSPACE PARTS TEST WITH HANDHELD XRF ANALYZER

AEROSPACE PARTS TEST WITH HANDHELD XRF ANALYZER

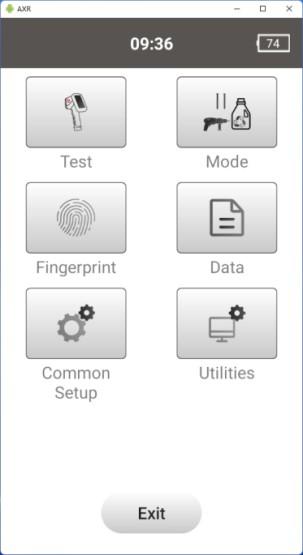

AXR Scientific currently offer handheld XRF analyzer, handheld alloy analyzer, handheld soil analyzer, handheld lithium battery analyzer, precious metal analyzer, coating analyzer, gold analyzer and online XRF analyzer etc. to global customers.

We keep serving global customers in the fields of machinery manufacturing, metal processing, aerospace, petrochemical, mining and geology, food safety, environmental protection, scientific research and etc.

AXR Terra900 series are good choice for metal analysis in many fields, delivering rapid, accurate results right in your hand. Due to the advanced electronics and state-of-the-art mathematical algorithms, Terra900 series provide ultimate quality of measurement within a couple of seconds, which makes it the ideal solution for checking and analyzing incoming material, finished goods and in process production parts with a non destructive way. With operating simplicity, you can view the alloy grade and chemistry on the touch screen display with just a few seconds to obtain lab-quality chemistry, requiring minimal training and little or no sample preparation for all shape and size of sample.

Scrap metal recycling

Scrap metal recycling

PMI(Positive Material Identification)

PMI(Positive Material Identification)

QA/QC for fabrication

QA/QC for fabrication

FAC(Fluid accelerates corrosion)

FAC(Fluid accelerates corrosion)

Precious metal analysis

Precious metal analysis

Coating analysis

Coating analysis

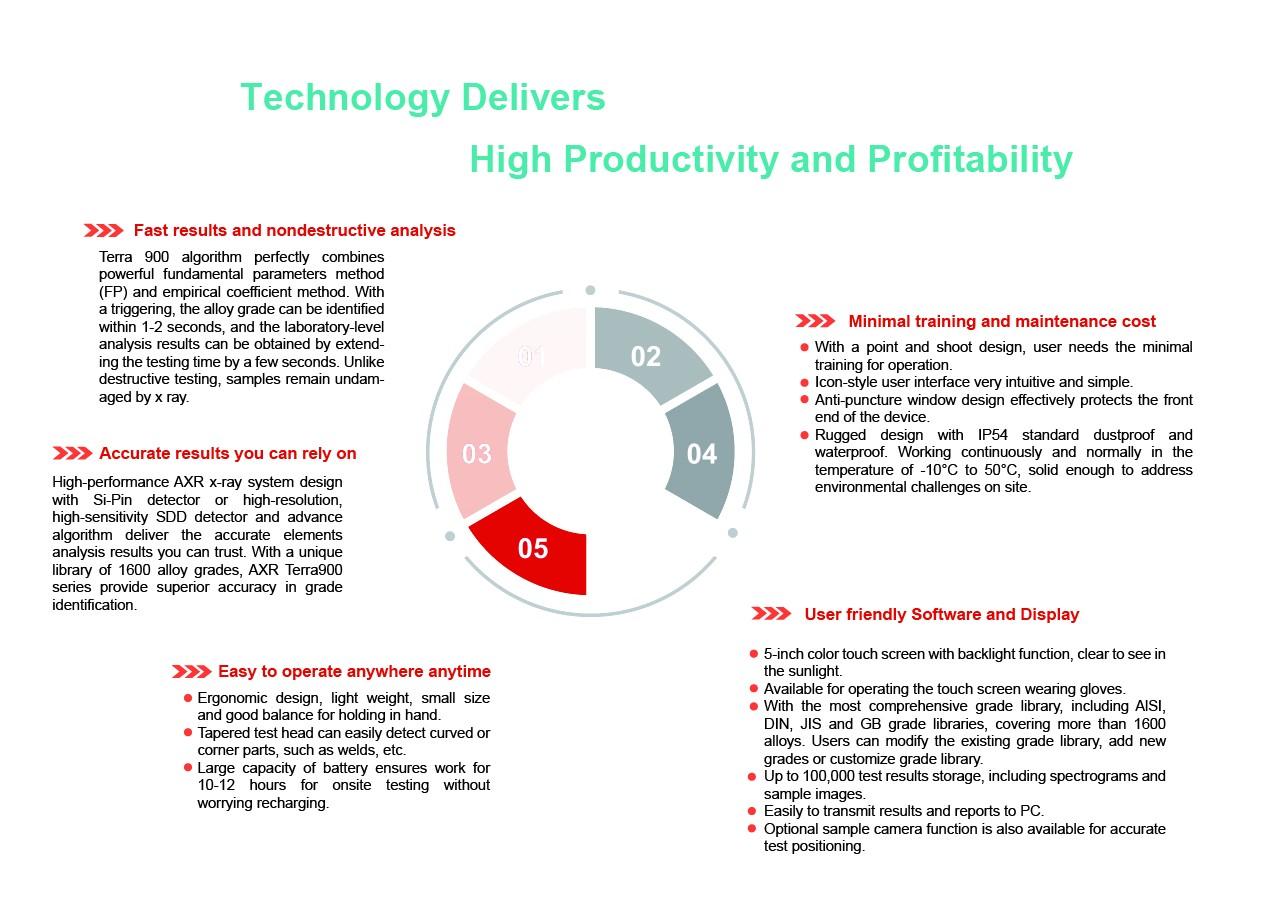

Terra 900‘s algorithm perfectly combines powerful fundamental parameters method (FP) .With a triggering, the alloy grade can be identified within 12 seconds, and laboratory-level analysis results can be obtained by extending the testing time by a few seconds. Unlike destructive testing, samples remain undamaged by X ray. .

Ergonomic design, light weight, small size with good balance. Large capacity of battery ensures work for 10-12 hours for onsite testing without worrying recharging.

Rugged design with IP54 standard dustproof and waterproof. Working continuously and normally in the temperature of -10°C to 50°C, solid enough to address environmental challenges on site.

High-performance AXR x-ray system design with Si-Pin detector or highresolution, high-sensitivity SDD detector and advance algorithm deliver the accurate elements analysis results you can trust. With a unique library of 1600 alloy grades, AXR Terra900 series provide superior accuracy in grade identification.

5.5-inch color touch screen with backlight function, clear to see in the sunlight, available for operating the touch screen wearing gloves. Up to 100,000 test results storage, including spectrograms and sample images

Easily to transmit results and reports to PC

Optional sample camera function is also available for accurate test positioning

High-performance 4W micro X-ray tube, 50kV/80μA, wider detection range of elements, especially more sensitive to heavy metals

Large-size capacitive smart touch color LCD screen (5 inches), the display is clearer and convenient for users to operate

Small spot mode (1mm) easily solves the problem of small sample testing

With the most comprehensive grade library, including AlSI, DIN, JIS and GB grade libraries, covering more than 1600 alloys. Users can modify the existing grade library, add new grades or customize grade library.

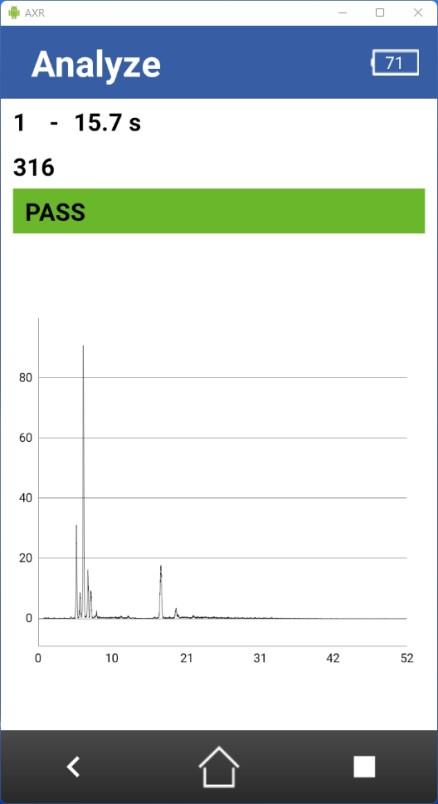

The fingerprint pattern is matched with the previously selected comparison fingerprint. If the result is consistent, it will show a pass (PASS), and if it is inconsistent, it will show a failure (FAIL).

Model Terra 900

Excitation

High performance 4W X-ray tube with Ag anode,50kV/80μA ( max )

Detector High performance Silicon detector, Resolution<140eV FWHM at Mn Ka

Filter Multi position automatic filter changer

Components i.MX 8M Mini Quad Core 1.8GHz, DP5 DSP, 80 MHz ADC DSP, 4096 Pixel Multichannel Analyzer, DDR4 2GB

Window Kapton window and anti-puncture window optional

Collimator 3mm collimator

Display Capacitive touch color display (5 inch 720P)

Battery 7.2V Li-ion battery , 6800mA Elements

One touch testing

When measuring soil samples, the "one-button test" mode can be selected to avoid the operator pulling the trigger for a long time and relieve work fatigue

Data storage automatic sorting and naming of soil detection and analysis results in different regions

Radiation safety Safety guard device, tube shutoff while no sample

Structure design The integrated design of engineering plastics and aluminum alloy is in line with the best ergonomic principles; the internal unique super heat sink design

Data transfer WiFi 、 USB

Data safety Multi lever Password-protected data security

Optional accessories

Proper use of the test stand can effectively shield scattered radiation

Use bench top test stand: Hold the analyzer and align the analyzer window with the bottom window of the test stand, push upward. After hearing a "click" sound, the instrument is fixed in place, put the sample to be tested into the analyzer window, and cover the box to start testing.

Allows hands-free measurement of samples. Completely shielded to protect the operator from any scattered radiation.

Folds up for easy transport and portability. Allows hands-free measurement of samples. Completely shielded to protect the operator from any scattered radiation.

A flexible and robust shield attaches to the analyzer’s cone, protecting the operator from any backscattered X ray during analysis.

Carbon fiber anti-puncture windows can be used to effectively protect the window film from damage by irregular samples testing.

Keep the detector window safe during use. As one of the core components of the instrument, the detector is mainly used to receive Xfluorescence signals and distinguish them according to different energies. The window of the detector is metal Be, and the interior is a vacuum part. The thickness of the Be window is about 13um. If it is damaged by external force, it will be irreversible.

Be careful not to drop it during use. When you go out to work, tie the wrist strap to prevent damage to the screen of the instrument or damage to the internal components of the instrument.

When storing and using the instrument, try to avoid being too close to strong magnetic fields. Strong magnetic fields can affect the life of electronic components.

The instrument will generate a certain amount of X-rays, which should be used in accordance with the instructions for use of the instrument.

Currently there are a number of aerospace alloys, including Al- and Mg-, Ni-, Co- and Ti-based alloys. In aluminum-based alloys, Al is the predominate metal in the system along with alloying elements such as copper, zinc, manganese, silicon and magnesium.

Two main classifications of Al-based alloys are cast and wrought alloys, both of which are subdivided into heat-treatable and non-heat-treatable categories. More than 80% of Al alloys are produced by the wrought process in the form of rolled sheets and foils because of their higher strength and lower density.

The following Al alloys are commonly used in aircraft and other aerospace applications (helicopters and spacecraft): 7075, 6061, 6063, 2024 and 5052. Among these, the 7075 Al alloy is most preferred by the aircraft industry. The composition of this specific Al alloy is 5.1–6.1% zinc, 2.1–2.9% magnesium, 1.2–2.0% copper and less than 0.5% of silicon, iron, manganese, titanium, chromium and other trace metals.9

Aluminum alloys are widely used in aircraft fuselages and other engineering structures and compounds in which light weight and corrosion resistance are highly desired.

In addition to Al-based alloys, specially designed alloys make it possible for the aircraft industry to produce high-strength parts for jet engines and airframes where high pressure, temperature and vibration are greatly considered during their design and manufacturing.

Stainless steel, titanium, nickel, copper and their alloys are the major components of aerospace alloys utilized for engine blocks, providing high strength and/or the ability to perform at extremely high temperatures. The ratio of engine power to weight, airframe strength and many other factors drastically affect jet performance. Also, these alloys are designed to be strong, resistant to corrosion and able to maintain their integrity at any temperature.

As we all know, for the aerospace Industry, passengers’ lives rely upon the right overall performance of plane components,therefore testing for aerospace substances will become a crucial issue. A mixup on a spacecraft or business satellite wil cost and wasted a lot of effort, whilse on a business plane it could be disastrous. Application of improvements of hand held XRF Analyzer for aerospace include:

--Quality check for high-temp, nickel, titanium, aluminum alloys and superalloys;

--Quality check for high-temp, nickel, titanium, aluminum alloys and superalloys;

---Analysis of light element for aero aluminum and titanium alloy;

---Analysis of light element for aero aluminum and titanium alloy;

--- Chemical identification of selenium, cadmium and zinc coatings for space applicatons

--- Chemical identification of selenium, cadmium and zinc coatings for space applicatons

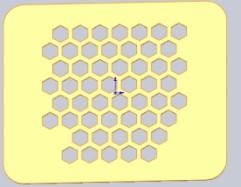

Aerospace applications demand high-precision parts that are oxidation and corrosion resistant, and have surface finishes that are free of defects. This is due in part to the extremely high temperatures at which these parts must function. Aircraft engines run at such extreme temperatures to burn fuel efficiently. Gas turbine blades are made of nickel-based superalloys for their tolerance to high temperatures as well as their strength and wear resistance.

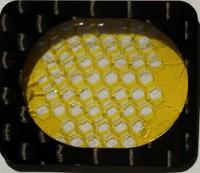

Turbines are then coated with Thermal Barrier Coating (TBC) to protect the base metal from operating environment. TBC makes it possible to increase the operating temperature of gas turbines. Turbine blade repair requires removal of the TBC coating without damaging the base metal. Handheld XRF can be useful in this application because it can determine TBC coating thickness for either the coating removal process or the recoating process.

Nickel is also used in the aerospace industry because it can be made to plate with little or no stress and is therefore appropriate for applications where stress needs to be minimized.

Cadmium coatings are also commonly used in the aerospace industry.They are applied to bolts and other fasteners, chassis, connectors, and other components and provide excellent corrosion resistance, good lubricity, electrical conductivity, and easy solderability.

Aerospace programs call for excessive-precision elements which are oxidation and corrosion resistant, and feature floor finishes which are freed from defects. This is due in element to the extraordinarily excessive temperatures at which those elements should function. Aircraft engines run at such intense temperatures to burn fuel efficiently. Gas turbine blades are product of nickel based superalloys for the tolerance to excessive temperatures in addition to their power and wear resistance. Turbines are then lined with Thermal Barrier Coating (TBC) to defend the base metallic from running environment. TBC makes it feasible to growth the running temperature of turbines. Turbine blade reparis calls for elimination of the TBC coating without detrimental the bottom metallic.

Handheld XRF may be beneficial on this utility due to the fact it could decide TBC coating thickness for both the coating elimination procedure or the re-coating procedure.

Nickel is likewise used withinside the aerospace fields due to the fact it could be made to plate with very little pressure and is consequently suitable for programs wherein pressure desires to be minimized.

Cadmium coatings also are typically used inside the aerospace fields.They are applied to bolts and different fasteners, chassis, connectors, and different additives and offer splendid corrosion resistance, suitable lubricity, electric conductivity, and smooth solderability.

Non-destructive nature: The alloy isn`t affected during the test, which means that it doesn`t lose its commercial value.

Fast and accurate research: It takes only a few seconds to get the result that will display the grade and elements concentration of the components.

Safety: Firstly lower exposure to x-rays. Secondly, an alloy analyzer has several safety protection to minimize the impact.