5 minute read

12/ Factory Habitat Advanced VI, GSAPP, 2020

12/Factory Habitat

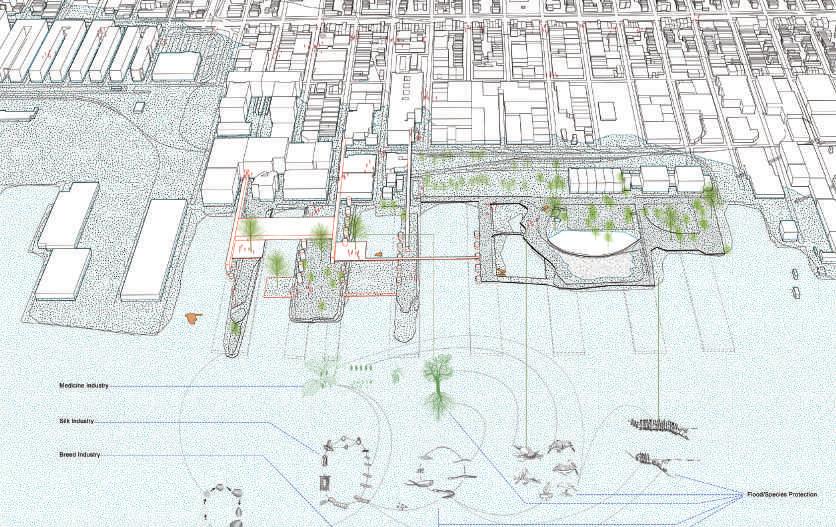

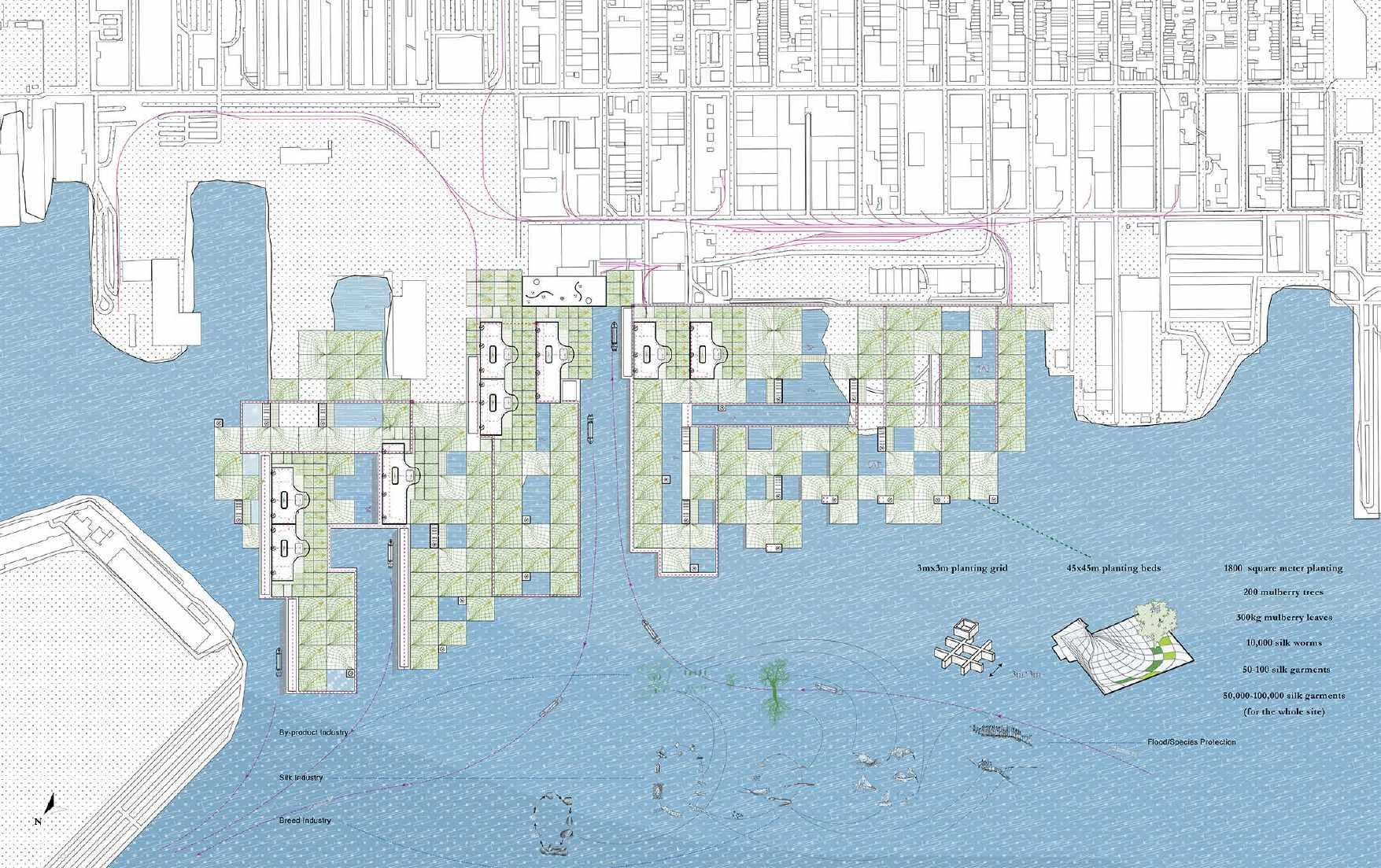

Program: Silk Garment and Manufacturing Factory +Mulberry Planting Orchards Location: Bush Terminal, Brooklyn, New York

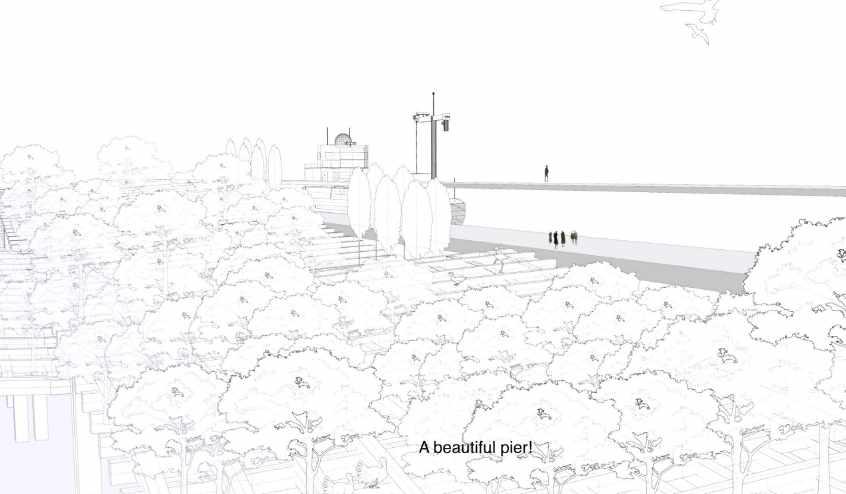

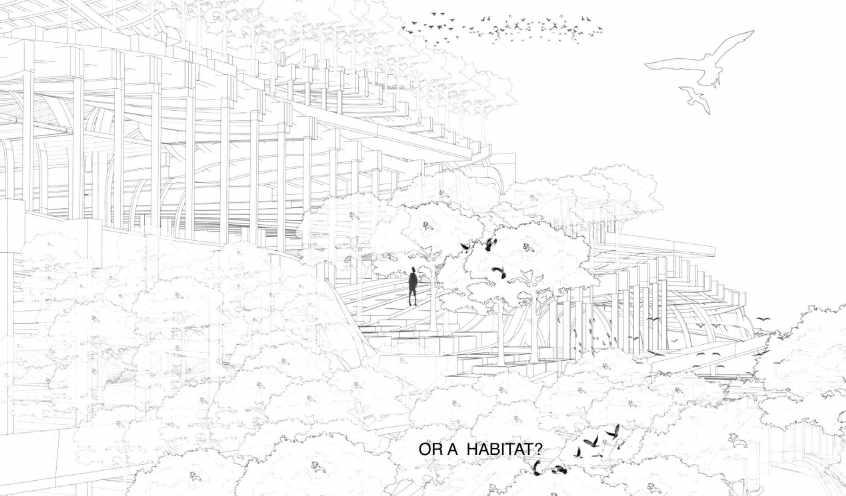

The Factory Habitat reinvents the typology of pier, factory and park through interweaving the production spaces of silk and garment with mulberry planting and the coastline habitats. The landscaped structure creates a thickened city edge that resists the degradation of the harbor and challenges the dichotomy between nature and city, and between efficiency and natural cycles.

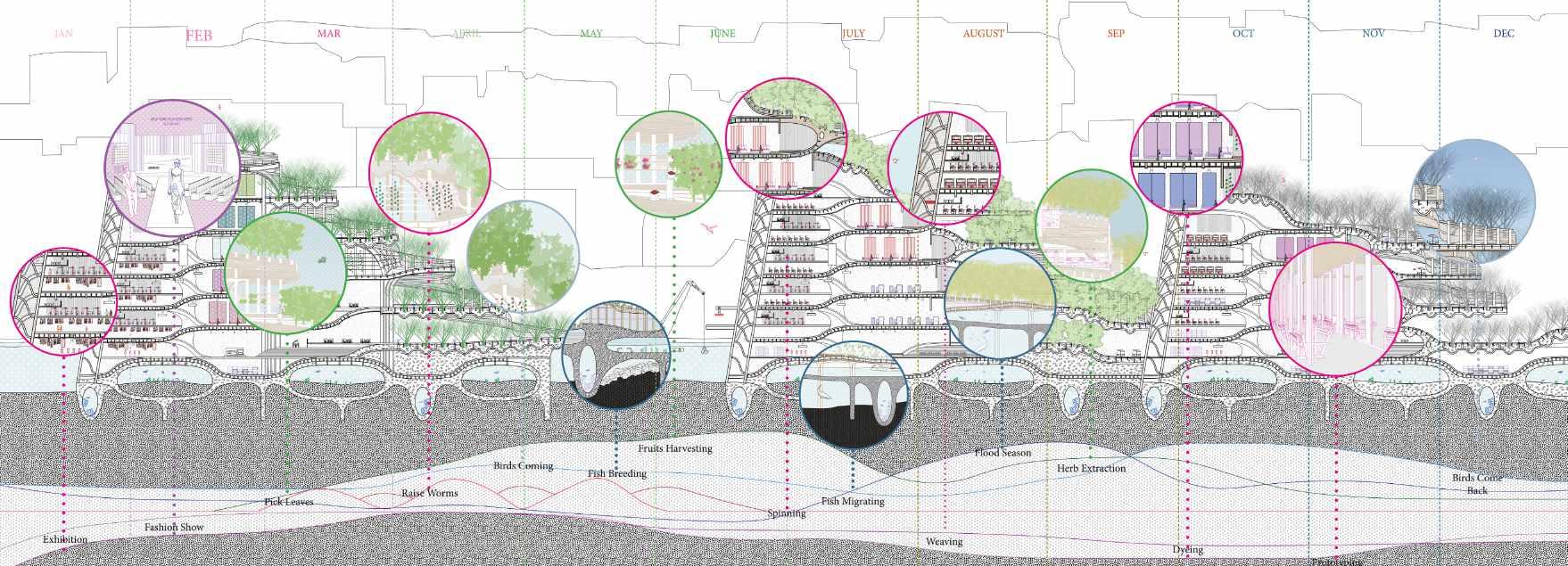

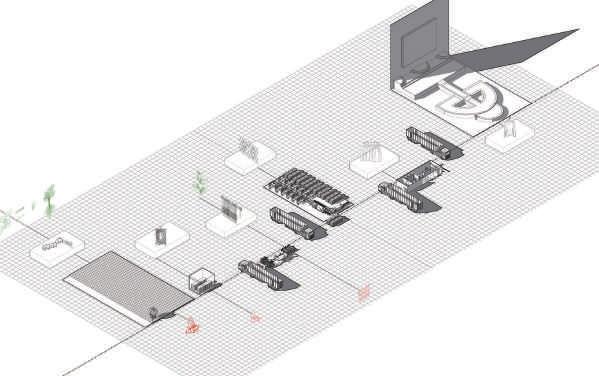

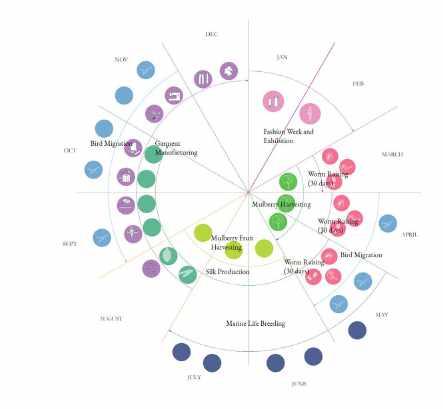

The factory is organized both through a system of interrated modules of rhetoric surfaces that trasnfer from planting beds to architetural elements, as well as through time, the cycle of events and seasons.

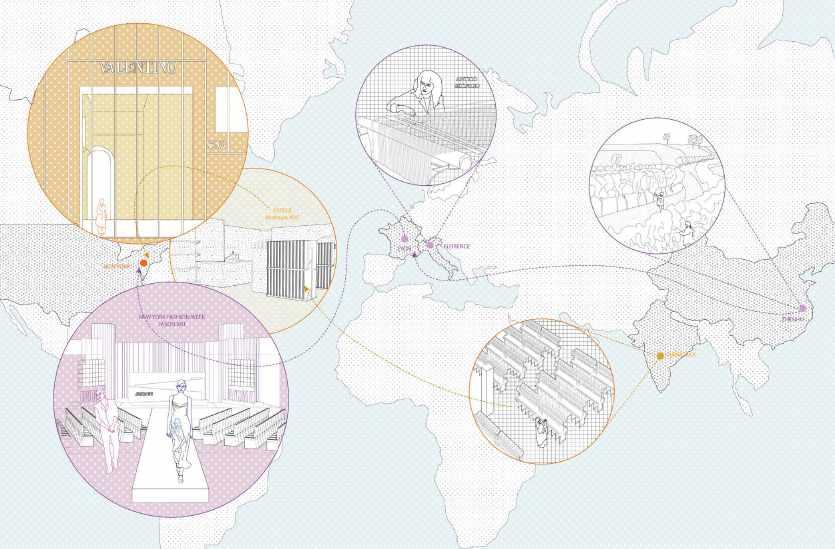

Social Invisibility: Although New York City is the international center of the luxury goods such as silk, the production process is usually invisible to us. The silk garments in the Valentino store or on the Fashion Week stages comes through a lot of invisible steps acorss Asia and Europe all the way to NYC. Together with the Made in NYC initiative, the factory wants to bring the invisible production process visible to the City.

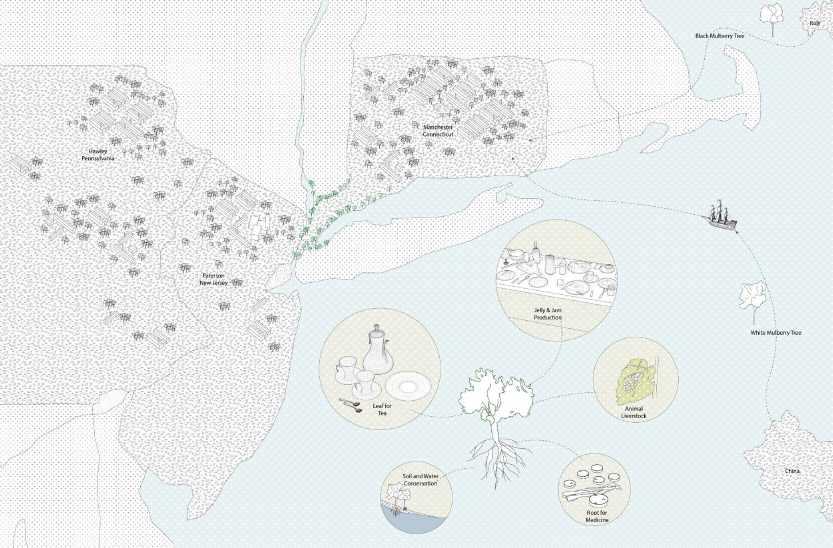

Mulberry History in New England: suprisingly, there was a long history of seri-culture (rasing of silkworms and the production of silk) in the States around us during the colonial period. With the downfall of this factory, the mulberry trees were still left there but are considered invasive species right now. Considering the great ecological and commercial potentials of the mulberry trees, especially its role in consolidating the soil and creating habitats for birds, we want to bring them to our coastline.

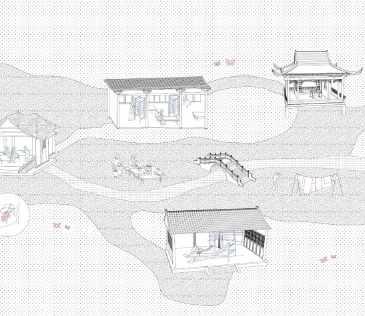

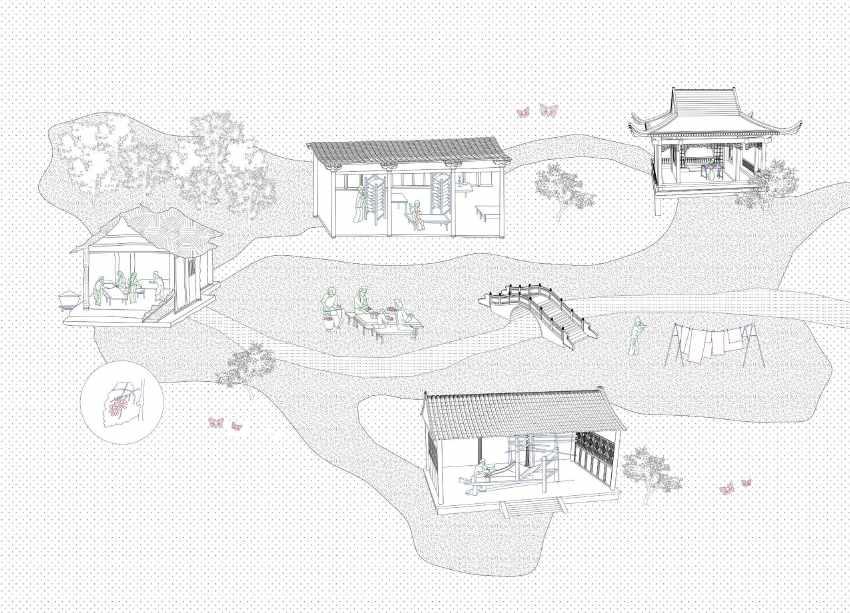

Traditional Silk Production creates a closed loop of ecosystem in a scale of village. The different processes, from growing mulberry to raising worms to embroidery, are all connected and happen in intimate and residential setting. The product of one process is used in another process and invisible benefits are created.

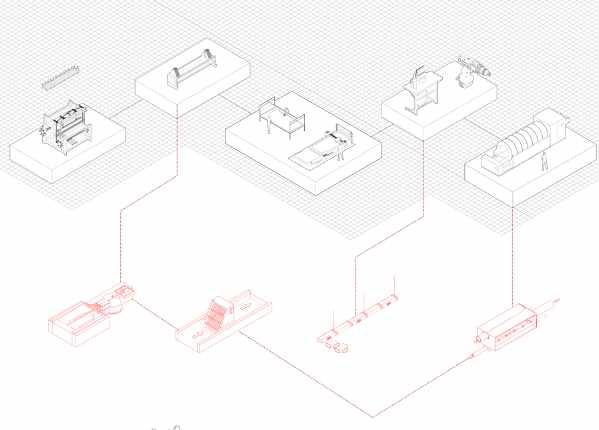

Pollutents, such as chemicals, fibers, crops, produced along the process, require secondary steps to process the invisible wastes behind the garment factory.

Modern Garment and Silk process is much more linear and automated. Each step is isolated and invisible to each other. Instead of invisible ecological benefits, "invisible" wastes are usually created that need additional machines to process them.

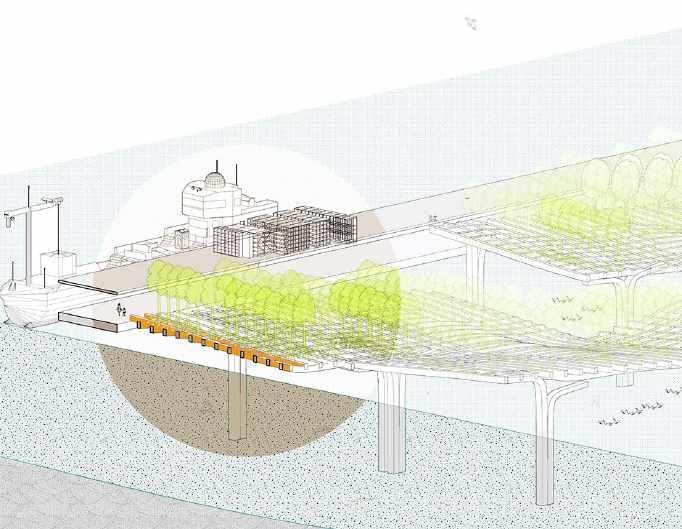

Existing Pier is degrading and collapsing into the water. Birds and fish are competing with humans, many of them also could not afford the increasing rent, for habitats. So, why don't we create habitats for mulberry trees, animals and workers at the same time?

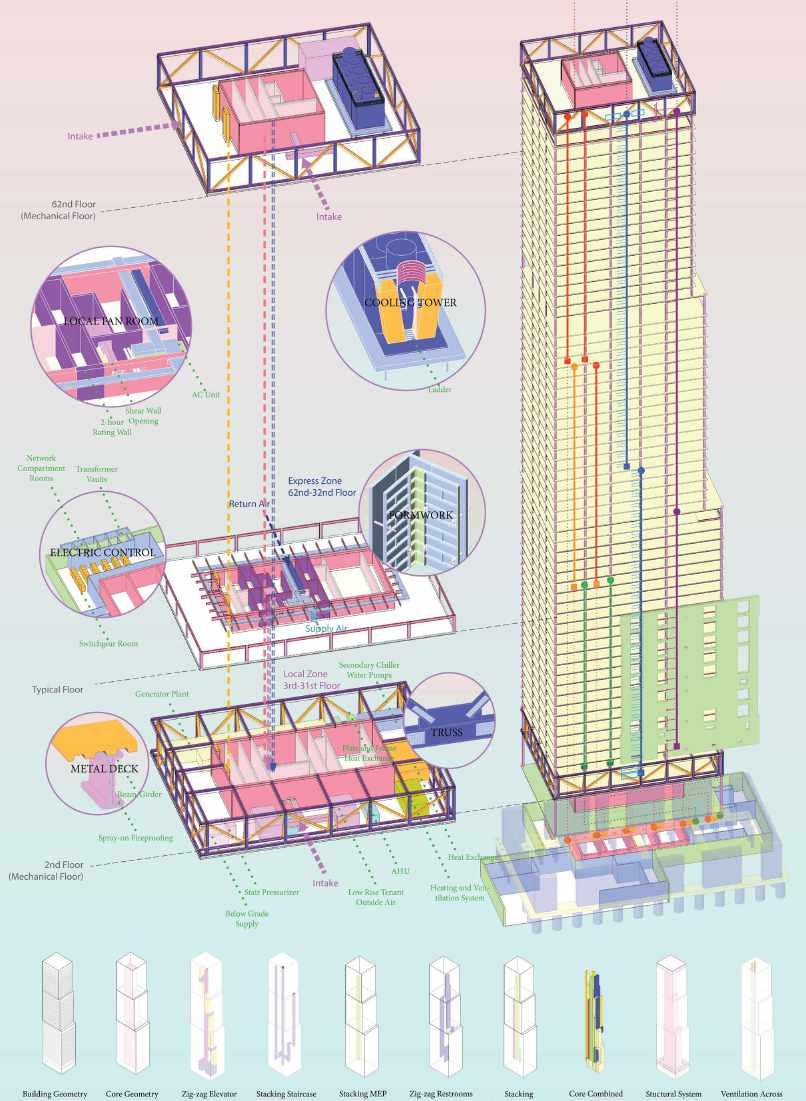

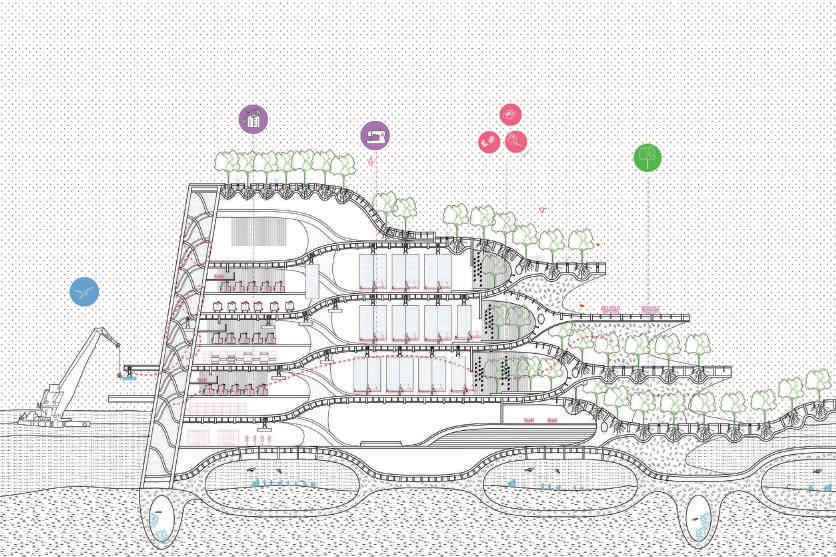

Site Strategy is shaped by its contexts. The planting modules are sloped towards south to maximize sunlight. The complex creates a thickened city edge to act as a coastline buffer. The production and shipping happens on the north-east side of the complex, where loading deck is connected to the planting beds and creates a interconnected network with the transportation networks in the city. Ships bring both people in and goods out of the factory.

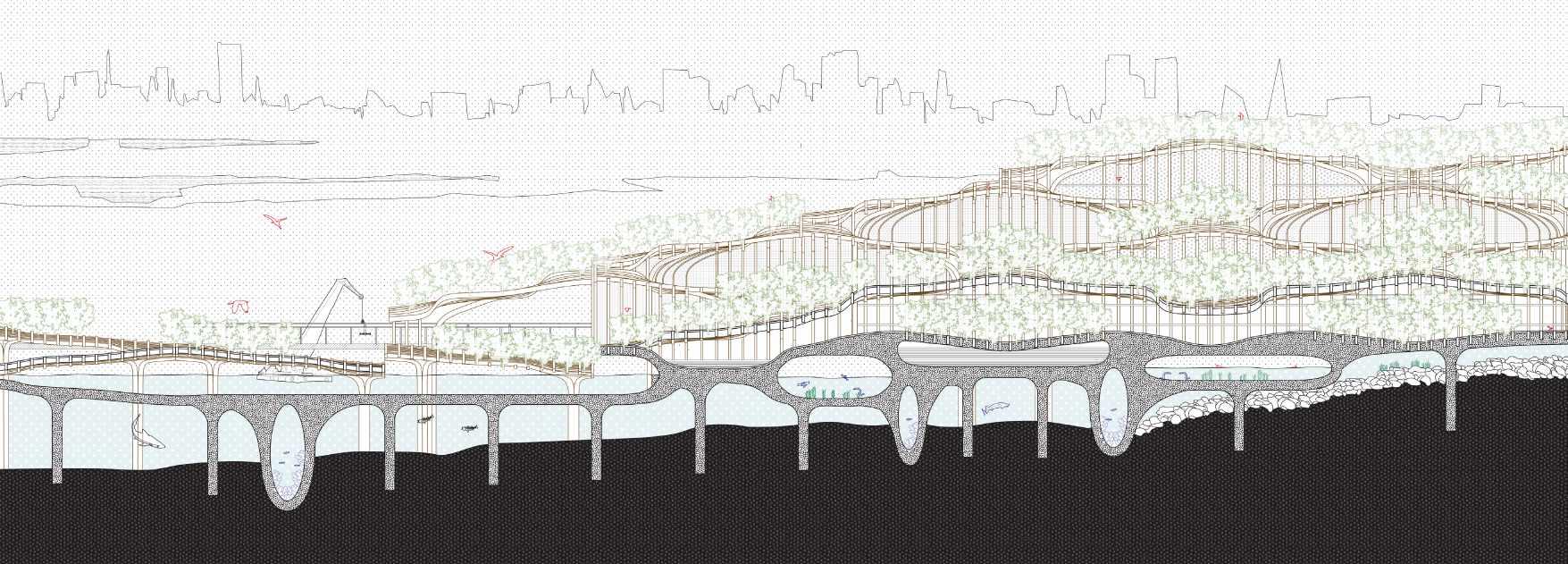

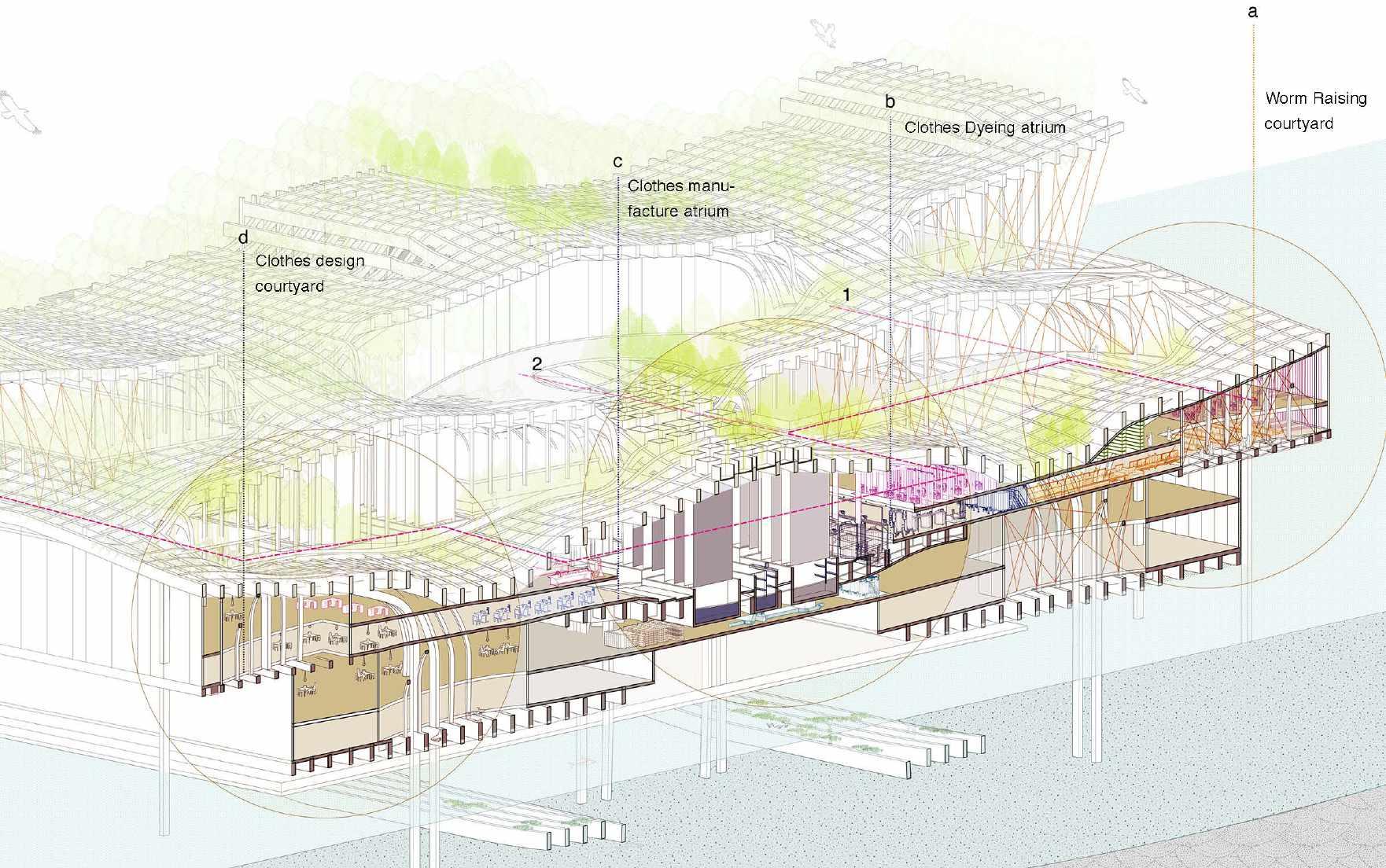

Section b

Section a

Longitudinal Section (a) parallelto the waterfront shows the stepping of the buildings to maximum the agriculture of the mulberry trees, and the flow of goods across the buildings. The quantative lines below shows the changing quantites of both the materials, habitats and the goods across time.

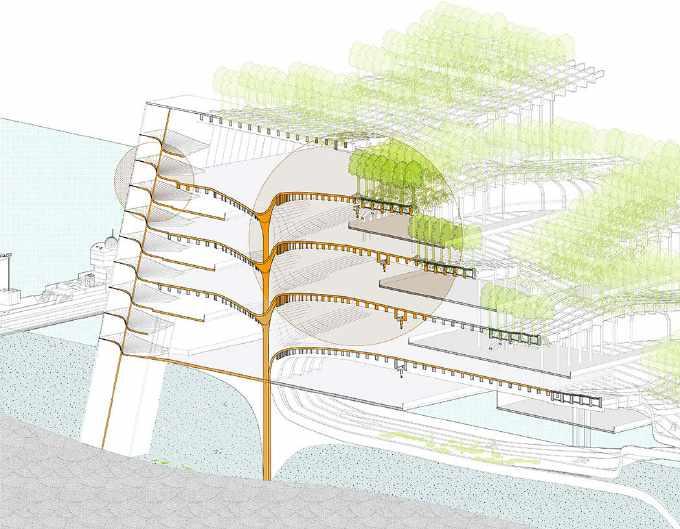

Longitudinal Section (b) perpedicular to the waterfront shows the interweaving of the factory spaces, the mulberry planting beds and the coastline habitats.

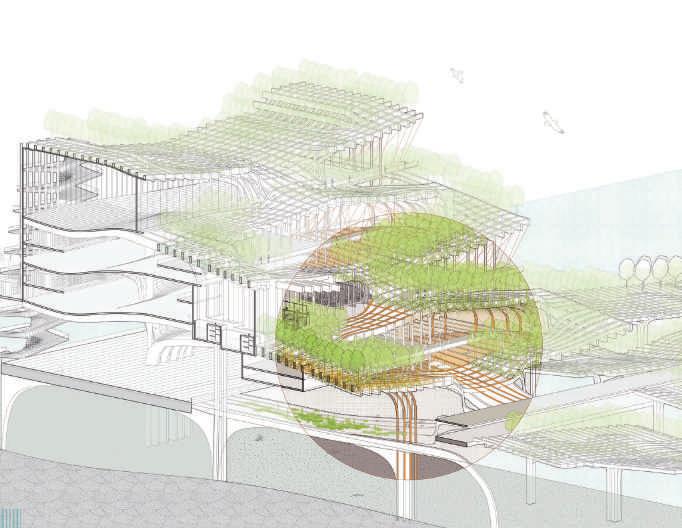

Section c Planting beds are consisted of 3x3 modules with thickness of 2 meter of provide depth for soil. Except for the purpose of circualtion, they are all sloped towards south for sunlight. They are ocnnected to the elevated locking dock for shipment of goods and

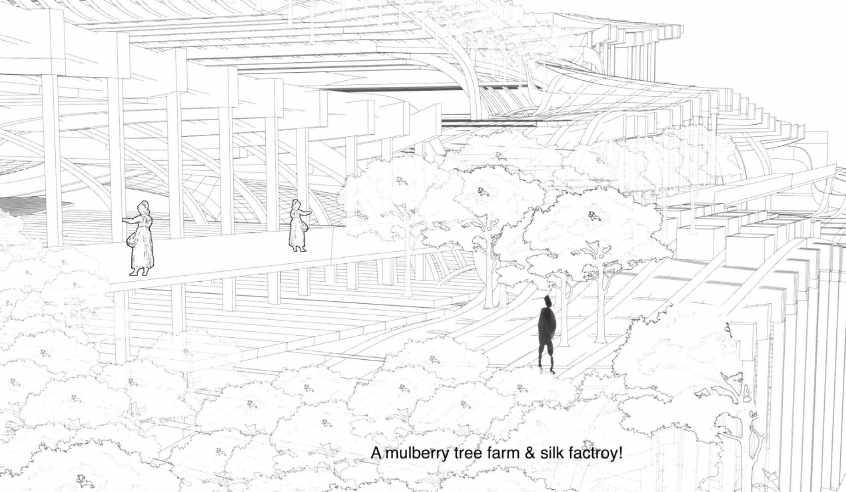

Section d The module of planting beds transition to the balconies of the factory where the workers could pick leaves for rasing the worms and dyeing the clothes. The structure of the planting beds were transformed to become the columns and the beams of the

Section e Into the building, the module is scaled to transform to the vertical structures of the building for circulation. The double-curved circulation allows for the double circulation of people and goods to the pier. The structure also accomodates the conveyor belts, the circulation of the goods.

The Wormy Interface is where the exterior planting balconies meet with the interior factory space to form a semi-outdoor semiindoor space. The bending structures creates frames for the raising of worms, and the workers could also easily transfer the leaves into the factories.

Materials and products are flowed from the south to the north of the individual building from raw materials all the way to shipment. The different porocities of the structure allow for soil, sunlight, conveyor belfts and mechnical system and irrigation at different points.

Factory as a clock: since both the materials and the products, as well as the habitats all follow seasonal cycles, our factory also function as a clock. To prepare for the Fashion Show in Februry next year, the Factory start to prepare since March.