Huntsman takes pride in the role we play in creating a more sustainable future.

Our products are critical solutions to today’s most pressing sustainability challenges and are helping society reach its aspiration of carbon neutrality. Whether it is in our operations or our innovative technologies, Huntsman is committed to making a brighter world possible for future generations. In this report, we share how our solutions enable sustainability.

We continue to make progress against our near-term Horizon 2025 targets while looking further toward our long-term aspirations. In this report, we outline how our solutions enable a more sustainable world and how we are improving our operations to further drive meaningful progress.

2023 Achievements 60% Collective Progress on Near-term Horizon 2025 Targets1

Number of Product Safety Summaries Published

Reduction in our Water Consumption Intensity in Areas of Water Stress

1

We invested in our core business, while also streamlining operations and our shared service platform:

• Progressed announced expansions of the product portfolio of our Performance Products business, including catalysts for polyurethane insulation and high value performance amines used in the semiconductor industry.

• Completed the divestment of our Textile Effects business to Archroma, a portfolio company of SK Capital, in February 2023, for approximately $593 million and pension liabilities, further simplifying our overall portfolio.

• Exceeded target savings for our global cost optimization and synergy programs (the “Optimization Program”) with a total annualized run rate of greater than $280 million in savings at the end of 2023.

We continued our strong governance structures and advanced our commitment to planet and people:

• Expanded our two new global business services centers in Latin America and Eastern Europe, with approximately 350 associates working at these sites at the end of 2023.

• Signed an agreement with BASF and our three Chinese partners to separate our Shanghai Lianhang Isocyanate Company joint venture in China and acquire an MDI and HCL recycle facility.

• Published our 2022 corporate sustainability report titled Solutions for Sustainability, which featured Task Force on Climate-related Financial Disclosures (TCFD), further improvements in the quality of our other sustainabilityrelated disclosures, and a limited assurance by a third-party auditor for our operational greenhouse gas (GHG) emissions (Scope 1 and Scope 2) and water consumption.

• Outperformed our target metrics in personal safety and met our target metric for process safety.

• Continued strong philanthropic ideals, contributing to multiple causes worldwide, including sponsorship of local student college funding programs in underprivileged communities for the third year in a row.

We enhanced stockholder return by leveraging our strong balance sheet and divestment proceeds to increase our dividend and repurchased approximately $350 million worth of our stock:

• Increased our quarterly dividend by 12% in February 2023 and distributed approximately $169 million in dividends in 2023, making this the third year in a row we have increased the dividend.

• Repurchased approximately 13 million shares for approximately $350 million over the course of the 2023 year.

A LETTER FROM THE

As we present our annual sustainability report, we reflect on the continuing journey to address the world’s most pressing challenges. Sustainability is about finding innovative solutions to these challenges. Our company remains dedicated to creating a lasting, positive impact through the chemicals and materials we produce.

Our solutions aim to meet society’s growing needs through increased efficiency. We are proud to be part of an industry that plays a crucial role in tackling the world’s sustainability challenges. Through our work, we contribute to making homes and buildings more energy efficient, reducing fuel demand in transportation, enabling alternative energy solutions, and increasing the durability of materials to minimize waste.

We believe that society is currently at a pivotal crossroads in sustainability. It is becoming increasingly clear that society must consider the trade-offs in the steps ahead. The realistic choices do not consist of silver bullets. These choices are also not without their costs or considerations of their socioeconomic, and sometimes, environmental, impacts.

As we navigate these crossroads, flexibility is key. As technology evolves, economic landscapes shift, and societal trends develop, our strategies must adapt accordingly. We remain dedicated to enriching lives through innovation. We are meeting that commitment by providing practical solutions

using technology to make meaningful positive impacts today.

As always, sustainability means not only providing chemical and material solutions, but also providing them in a way that centers on the safety and well-being of our associates, the communities in which we operate, and our customers. We foster a culture that prioritizes safety, and we are proud of the progress we continue to make in this regard. We remain committed to contributing positively to the communities alongside our operations, enhancing their prosperity and resilience.

We look forward to our continued work with our stakeholders to realize a more prosperous and more sustainable future.

Peter R. Huntsman Chairman, President, and Chief Executive Officer

Peter R. Huntsman Chairman, President, and Chief Executive Officer

As the Senior Vice President of Environmental, Health, Safety, and Manufacturing Excellence, and Corporate Sustainability Officer, I am pleased to share our 2023 sustainability report with you.

Sustainability is about making the essential things of life and making them in the right way. There is a natural link between sustainability and manufacturing excellence. Safe and highly reliable organizations such as chemical companies keep their products under control and protect their workers and the communities where they operate. At the same time, those organizations safeguard the environment and find ways to reduce waste. Our commitment to safe, reliable and sustainable manufacturing is unwavering.

2023 has seen economic change that will likely continue through 2024. As we respond to the changing circumstances of the economy, it is ever more important that we continue to maintain our focus on safety. We are pleased to report that our metrics for both occupational and process safety improved in 2023 as compared to 2022. Safety is a core value at Huntsman, and this improvement reflects that value in action.

In this report, we are also pleased to share our progress on our Horizon 2025 goals. Through 2023, we have achieved approximately 60% of these collective targets. Our aspirations of carbon neutrality, full circularity, and continuing to provide safe and sustainable solutions guide our long-term plans. We plan to develop the next set of goals that will guide us towards those aspirations.

For the third year in a row, we have received limited assurance for our greenhouse gas and water use disclosures. Moving forward, we plan to continue to refine our processes to provide reliable disclosures of our sustainability performance.

We are proud of the progress we have made. However, our mission never ends — we have woven continuous improvement into our culture and plan to continue to seek pragmatic ways to improve both our performance and our performance disclosures.

We remain grateful for your support and partnership as we work together to create a more sustainable, inclusive, and prosperous future for all.

Brittany Benko Corporate Sustainability Officer

Senior Vice President,

Brittany Benko Corporate Sustainability Officer

Senior Vice President,

Environmental, Health and Safety, and Manufacturing Excellence

I am pleased to introduce Huntsman’s 2023 sustainability report. Huntsman continues to chart a course to a more sustainable future for society through our people, our processes, and the products we provide.

The chemical industry is a crucial player in creating and delivering sustainable solutions across a variety of industries. As a member of the chemical sector, Huntsman continues to strive for more sustainable alternatives not only in our own operations, but in all aspects of the value chains that depend upon us or our products.

I continue to reflect on a question put to me when I joined the Huntsman Board five years ago. The question was how the chemical industry can cast itself as a sustainability leader, when it depends upon fossil fuels for its raw materials. I am proud to acknowledge that Huntsman plays an important role in taking fossil-sourced hydrocarbons and turning them into solutions that not only reduce energy consumption, but also make alternative forms of energy possible.

Uncertainty has become the hallmark of this decade as it continues to grow and morph in unpredictable ways. Over the coming year, we can expect even more polarization around global geopolitical crises, energy, and environmental policies. Huntsman will keep abreast of the evolving geopolitical landscape, its effect on global markets and policy decisions that affect our business. Amidst this uncertainty, however, Huntsman will aim to do what’s best for both our customers and our shareholders by staying focused on our commitment to provide sustainable solutions in a fiscally responsible manner.

It has been three years since we formed the Board Sustainability Committee, which I am honored to chair. I am proud of the progress Huntsman is making. We measure this progress not only by our advancement towards our Horizon 2025 goals, but by external validation, including our scores from CDP Climate, MSCI, Sustainalytics, and EcoVadis, all of which have improved over the past few years. Despite this progress, we remain dedicated to continuous improvement. We are setting new goals for beyond 2025. We will continue to measure and communicate our progress towards our goals in a transparent manner.

I look forward to working with our stakeholders to meet the challenges before us and continue our mission to build a better tomorrow for future generations.

| GRI 2-1 | GRI 2-6 |

Huntsman Corporation is a publicly-traded corporation, headquartered in The Woodlands, Texas, in the United States of America. Huntsman is a global downstream, differentiated, and specialty chemicals company. For more than 50 years, we have been using science and ingenuity to innovate and create products that enable more sustainable and comfortable lives for millions of people around the world.

In 2023, Huntsman had more than 6,000 associates working in nearly 60 manufacturing, research and development (R&D), and operations facilities in nearly 25 countries. Through our three divisions, we produce more than 6,000 products to serve a broad and diverse range of consumer and industrial end markets, including:

• Aerospace

• Automotive

• Building and construction

• Footwear and other consumer goods

• Power infrastructure

• Energy and fuels

50

More than of innovation YEARS

Operations facilities in nearly

25 COUNTRIES

6,000

More than ASSOCIATES

working in nearly

60 FACILITIES

6,000 Producing more than consumer and industrial PRODUCTS

This division is a leading global producer of MDI-based polyurethanes focused on formulating innovative, differentiated products for key downstream markets, including energy-saving insulation, lightweighting and performance materials for automobiles, comfort foam for bedding and furniture, protective coatings, adhesives, and elastomers for footwear.

This division offers products that provide useful properties in everyday items people want and need. Our leading global positions in the manufacture and sale of amines, maleic anhydride, and carbonates enable us to serve diverse consumer and industrial end markets, including energy, automotive and transportation, coatings and adhesives, building and construction, electronics, and industrial manufacturing.

This division focuses on providing solutions to the material challenges faced across a wide range of industries. Using a broad suite of component and formulation chemistries, we supply enhanced and more sustainable material solutions to the aerospace, automotive, electronics, power generation and transmission industries, among others.

Huntsman Corporation’s global headquarters is in The Woodlands, Texas, USA. As a publicly-traded company, we are listed on the New York Stock Exchange (NYSE: HUN). Countries/regions where we have manufacturing, R&D, and office locations include:

United

United

United

Vietnam

1 Huntsman has announced its intention to exit operations in Russia.

Our overriding aim is to enrich lives through innovation, which includes helping the world become more sustainable. Our people, our operations, and our products work together to enable sustainability around the planet.

You may be surprised to learn that the chemical industry makes up approximately 3% to 5% of total greenhouse gas emissions around the world 1 . For an industry that is frequently criticized for negatively impacting society, actual emissions in the chemical industry are lower than the greenhouse gases emitted by livestock. Even more interesting is that Huntsman products directly improve the performance of the industries that make up the bulk of the world’s emissions with our emissions-reducing innovations, which include solutions for the building and construction, transportation, and industrial sectors. Huntsman solutions represent millions of tons of lifetime emissions avoided each year by these innovative products.

Despite the small percentage of greenhouse gas emissions that the chemical industry contributes, Huntsman remains focused on further reducing its environmental footprint. As a result of our strategy to move further downstream and

closer to the consumer, our Scope 1 and 2 greenhouse gas emissions and water consumption have dramatically decreased. By moving further downstream, Huntsman assets are not only less emission-intensive, but are also helping our customers make a bigger difference in their own environmental footprints.

Despite our reduction in Scope 1 and 2 greenhouse gas emissions and water consumption, we remain focused on monitoring and improving our emissions and consumption performance. In May 2022, we announced the incorporation of greenhouse gas emissions and water consumption intensity into our corporate credit facility — one of a select number of companies who have done so. From our 2021 results forward, we received limited assurance for these two performance indicators.

Huntsman recognizes the important role we play in creating a more sustainable future. Our innovative solutions are the catalysts that enable 80% of the economy to reduce emissions. These contributions to a low-carbon economy can help make society’s goal of carbon neutrality a reality. The fact is, without solutions to improve the efficiency of buildings and homes, to enable the electrification and efficiency of the transportation sector, and to contribute to the advancement of alternative energy, the world will not be able to achieve this challenging goal. Huntsman products are enabling sustainability.

Improves Efficiency of Homes and Buildings

Our spray polyurethane foam insulation reduces air intrusion into homes and buildings, decreasing the amount of energy required for heating and cooling. One ton of our Polyurethanes spray polyurethane foam goes into solutions, resulting in:

• 10 tons of CO2e avoided

• 1.2 tons CO2e to build

• 8x return on invested carbon

Enables Electrification of the Transportation Sector

Our carbonates improve the efficiency of lithium-ion batteries. One ton of our Performance Products carbonates go into solutions, resulting in:

• 1.3K tons CO2e avoided

• 160 tons CO2e to build

• 8x return on invested carbon

Improves Energy Efficiency of the Aerospace Sector

Our resins and hardeners reduce the weight of an airplane by 20% and allow for blended winglets, further improving fuel efficiency. One ton of our Advanced Materials resins and hardeners go into solutions, resulting in:

• 14K tons CO2e avoided

• 350 tons CO2e to build

• 40x return on invested carbon

Enables Alternative Energy

Our specialty amines make the blades of a wind turbine longer, so their operation is more economic. One ton of our Performance Products polyetheramines go into solutions, resulting in:

• 30K tons of CO2e avoided

• 625 tons CO2e to build

• 48x return on invested carbon

Huntsman pursues continuous improvement in our operations. Our Horizon 2025 targets provide key focus areas across the company. These are challenging goals to set, and we strive for higher standards as we produce the solutions that lead to a more sustainable world.

We are targeting a 10% reduction in our energy consumption and Scope 1 and 2 greenhouse gas emissions intensity by 2025 from a 2019 baseline. In addition, we are targeting a 5% reduction in our water consumption in water-stressed areas, total waste production, and our hazardous waste production. The table below captures our progress against these targets. Our efficiency targets are measured against a baseline set in 2019. Our denominator for efficiency is sales volumes. Use of our sales volume in the denominator aligns with our peers’ efficiency metric and with lifecycle measures to communicate to our customers and other stakeholders.

| SASB RT-CH-110a.2 | 2023 Progress 0

Number of Life-impacting or Fatal Events (LIFE) 0 Events

Continuous reduction in OSHA Total Recordable Rate1 Lower than 2019

Number of Tier 1 Process Safety Incidents 2 Events <0.15 Tier 2 Process Safety Incident Rate

30+ Publications of Product Safety Summaries 2 25 Efficiency Targets (on a per unit of production; 2019 baseline)

| SASB RT-CH-110a.2 | | TCFD Metrics and Targets A | 2023 Progress

(Scope 1 and Scope 2)

1 Measure year-over-year

2 A key element of our commitment to the Responsible Care® Product Safety Code. Please see “Product Stewardship” on page 106.

3 Per unit of production on a market basis

4 Please see “Energy Management” on page 76

5 Please see “Water Management” on page 80

6 Please see “Waste Management” on page 86

In addition to our Horizon 2025 targets, Huntsman has announced its long-term aspirations, which include aiming toward carbon neutrality by 2050, becoming a fully circular company, and continuing our processes to assure the safety of our chemicals and materials.

Huntsman is aspiring to achieve carbon neutrality by

Our aim is to engage our suppliers and service providers, who we estimate constitute two-thirds of our non-product use Scope 3 emissions, will establish their own carbon-neutral goal by

Huntsman aspires to achieve carbon neutrality for its combined Scope 1 (direct) and Scope 2 (indirect, market-based) greenhouse gas emissions by 2050.

However, Huntsman cannot achieve this aspiration alone.

Achievement of this aspiration will depend on a myriad of challenging external factors including, but not limited to:

• Pace of technology

• Decarbonization of electricity supply and transportation

• Carbon capture storage and use

• Public policies, regulations, and infrastructure development

We are in the process of developing low-carbon transition plan options and plan to evaluate those options in the

context of these factors. Further details can be found in “Greenhouse Gas Management.”

In addition to our operational emissions, we aim to engage our top suppliers and service providers, including transportation-related providers, on efforts to reduce emissions through our value chain.

We have developed an initial estimate of our Scope 3 emissions. From this initial estimate, we have developed a supplier engagement plan to work toward the 2027 engagement target. Further details can be found in the “Greenhouse Gas Management” section on page 66

There are many efforts around circularity that contribute to reducing the need for new materials to enter the economy. For Huntsman, our Horizon 2025 targets are part of the picture.

Reducing our consumption of energy and water, along with reducing our waste generation, leads to less resource demand and contributes to circularity. Many of our solutions aim to improve the durability of products, which extends the life of these products and reduces both the need for replacement and for waste. Our products also improve the efficiency of our customers, which is highlighted in this report.

While our solutions contribute to sustainability in multiple ways, we recognize that stakeholders want our products to be more inherently circular. To that end, we began in 2023 to measure the portion of our product portfolio that has one or more of the following qualities:

• Sourced from recycled materials

• Bio-sourced

• Recyclable

• Biodegradable

In the future, we plan to develop targets for increasing the proportion of our portfolio that contains one or more of these qualities. We added “Circularity” to our material topics list in 2022 to signify this increase in importance, along with the impact of the role we play to contribute to society’s long-term aims. For more details, please see the "Circularity" section on page 90.

Chemical and material safety has long been a priority at Huntsman. The product safety of our solutions is considered on a caseby-case basis, including assessing the use of substances, existing and potential risk management options, ease of substitution, and solution benefits.

We work with regulators, customers, suppliers, and value-chain partners to make these assessments and develop suitable risk mitigation plans that could include phase-out initiatives, reformulation, or development of alternatives.

We evaluate new solution developments against defined substances of concern (SoC) lists at various stages in the development process, using an award-winning SoC risk-evaluation tool.

Our research and development teams look for SoC issues at all stages of the development process as part of the selection of the preferred technical solution and when screening new raw materials from suppliers.

A formal hazard assessment is completed by our Product Safety Regulatory Compliance (PSRC) team during the new product introduction process.

Products with significant SoC impact may be eliminated, or new product development projects terminated, based on an SoC assessment or if the business case for further development is not viable.

Huntsman plans to continue to proactively screen for, and seek innovative alternatives to, substances of concern. For more details, please see the “Product Stewardship” section on page 106.

<4% of our product sales include materials containing substances of very high concern

Inspired by our support of the United Nations Sustainable Development Goals (SDGs), Huntsman creates innovative products and participates in meaningful community projects that we believe help mitigate some of the world’s most pressing challenges.

Zero Poverty

• Huntsman serves as a premium sponsor and dedicates volunteer hours to local food banks to help eliminate food scarcity and mitigate costs for economically disadvantaged families.

• Huntsman donated to Lifting Hands nonprofit in Costa Rica, which seeks to end generational poverty.

Zero Hunger

• MDI1-based polyurethane systems produce lightweight, insulated sandwich panels for cold chain food preservation.

• Polyurethane-based controlled-release fertilizers increase crop yields for corn, rice, sugarcane, wheat, potato, and other specialty crops.

Good Health and Well-Being

• Development of E-Grade® THEMAH and Choline OH replaces other toxic materials commonly used in cleaning formulations in microelectronics industries.

• Scavenger technology reduces emissions from automotive seating foams by a factor of 10 without compromising comfort.

• Huntsman associates in Poland participated in the Poland Business Run to raise money for people with mobility disabilities.

• Huntsman associates globally contributed funds to partner nonprofits assisting with the 2023 earthquake in Turkey, which was then matched by Huntsman Corp.

Quality Education

• Huntsman awarded annual university and vocational scholarships to pursue degrees and certifications in STEM education.

• Supported local science fair sponsorships and judging in support of STEM education.

Gender Equality

• Dedicated multipurpose medical facility focusing on providing health care for women and children in India.

• Organized skill-building programs for women in India.

Clean Water and Sanitation

• Implemented operational projects in Panyu, China, to effectively route and treat wastewater and eliminate effluent from flowing into a nearby river.

• Partnership with China Green River Environmental Protection Promotion Association to collect plastic waste from the Yangtze River in the Qinghai-Tibet Plateau.

1 MDI: methylene diphenyl diisocyanate

Affordable and Clean Energy

• Epoxy curing agents, composite resin systems, and structural adhesives enable larger, stronger wind blades that can maximize energy and withstand weather.

• Innovative solutions in high-performance insulating materials are extending the reliability and lifetime of electric vehicle motors.

Decent Work and Economic Growth

• Established vegetable nurseries, fish and poultry farms, and livestock management programs for farmers, fishermen, and rural women in India.

• Supported job training and job search programs in communities near our operations.

Industry, Innovation, and Infrastructure

• Thermoset chemistries extend the lifetime of infrastructure and equipment through more durable coatings.

• Supported skill-building and equipment purchases among fire brigades and departments in communities near our operations.

Reduced Inequalities

• Huntsman is the presenting sponsor of the the Cynthia Woods Mitchell Pavilion, a nonprofit ensuring arts access and education to everyone.

• Supported community clinics for underserved communities in the U.S.

Sustainable Cities and Communities

• Spray polyurethane foam (SPF) insulation is the highest-rated insulant available in the market today.

• Huntsman innovations benefiting the electric vehicle market are reducing emissions and contributing to more sustainable communities.

• DaltoPIR® fire-rated panels deliver fire and smoke safety properties without compromising energy efficiency and cost.

• District Central Heating (DCH) project in China reduces PM2.5 dust associated with coal-fired electricity generation and improves ambient air standards.

Responsible Consumption and Production

• Waste polyethylene terephthalate (PET) bottles are transformed into TEROL® polyols, a key ingredient in energy-saving SPF insulation.

• 3D printing technology utilizing Huntsman’s thermoplastic polyurethane (TPU) materials in the footwear industry uses less material and eliminates waste.

• MDI binders turn waste rice straw and rubber crumb into raw materials for new products.

• Bio-based technologies enable automotive OEMs to achieve a 9%+ level of bio-based content.

• Waste-reduction and energy-efficiency projects at manufacturing facilities around the world are reducing water usage, energy usage, and waste production.

• DCH project in China utilizes waste heat to warm millions of homes.

Climate Action

• ARALDITE® adhesives and structural composite systems enable lightweighting in automotive and aerospace applications to reduce fuel consumption, energy use, and CO2 emissions.

• Carbonates create better lithium-ion battery technology to power electric vehicles.

Life Below Water

• Huntsman’s polyurethane-based controlled-release fertilizers utilize technology that reduces nutrient leaching and volatilization losses up to 95%.

Peace, Justice, and Strong Institutions

• Supported court-appointed special advocates for children in foster care in Texas.

Huntsman is proud to be recognized among leaders in safety across the industry and the world for our responsible management of our business and resources. Our 2023 honors include:

Facility Safety Awards

Award of Achievement

Recognizing facilities with zero fatalities and zero days away from work for employees

• Arlington, TX

• Maple Shade, NJ

• Ringwood, IL

Award of Excellence

Recognizing facilities with zero fatalities, zero injury days away from work and zero job transfers/restriction cases for employees and contractors

• Akron, OH

• Ashtabula, OH

• Auburn, MI

• Charlotte, NC

• Conroe, TX

• East Lansing, MI

• Los Angeles, CA

• McIntosh, AL

• Merrimack, NH

• Houston, TX

• The Woodlands, TX

The following are sustainability evaluations for Huntsman at the time of publication.

Ahush swept over attendees at the Woodforest Bank Club each time CEO Peter Huntsman went to announce a winning team at the 2023 CEO Awards for Innovation in Sustainability.

After each reveal, a roar of cheering erupted, followed by celebratory exchanges of congratulations.

For Innovation in Sustainability, Performance Products won third; Polyurethanes won second; and first place went to Advanced Materials for their hydrogen-storage project, Making Hydrogen Mobility Possible.

“We were thrilled to win,” said Austria-based team member, Dana Uhlig. "Our team worked hard on this project and winning only makes us more motivated to do more great work for Huntsman.”

The Manufacturing Excellence category followed, and more cheering erupted, as Huntsman called Advanced Materials to the stage for a second time that evening to take home another firstplace win for their project, Zero Waste Manufacturing at Panyu.

“This is one of the most exciting nights and events to work on all year because it really does showcase the talent of our global associates and how their ideas elevate Huntsman, and keep us competitive in the global marketplace,” said Jeff Morgheim, Global Senior Director of Sustainability and EHS Governance, and chief organizer of the CEO Awards. “I’m also pleased we were able to expand the awards this year and recognize three additional teams, even if it makes it harder for the officers to choose the winners.”

A total of six trophies were given out at the awards dinner — held March 21st at the Cynthia Woods Mitchell Pavilion Woodforest Bank Club.

Each of the six finalist teams, whose projects were chosen and put forward by the divisions this year — another change to the awards format — presented to Huntsman’s executive officers at corporate headquarters in The Woodlands, Texas, two days before the awards ceremony. Teams were given 20 minutes to present, followed by a question-and-answer period for the executives to praise, comment or further examine the projects’ merits.

Following the six-hour judging event, discussion ensued privately on who would take first, second and third.

“Each of the projects and finalist teams showed a tremendous amount of innovation and thoughtfulness,” said Brittany Benko, Senior Vice President of Environmental Health and Safety and Manufacturing Excellence, and awards judge. “Everyone presenting this year was a victor in my opinion and I cannot wait to see what comes to the table next year.”

FIRST PLACE

Advanced Materials

Making Hydrogen Mobility Possible

Stéphan Constantino; Sébastian Panthu; Dana Uhlig; Simon Burkel; John Fraser

SECOND PLACE

Polyurethanes

Sustainable Resilient Flooring

Hugo Verbeke; Olaf Michel; Giacomo Giannini; Hanson Wan; Alex Ziev; Matt Canoy

THIRD PLACE

Performance Products

MEOX

Sarah Jones, George Shan, Jay Henderson, Ke Zhang, Hui Zhou, Thomas Griot

FIRST PLACE

Advanced Materials

Zero Waste Manufacturing at Panyu

Fulton Ma, Terry Chen, Perry Choi, Jules Xu, Harry Wu, Jennifer Huang

SECOND PLACE

Polyurethanes

Wilton Energy Center

Alan Wasson, Tim Hurford, Chris Waugh, Mark Hockborn, Samantha Oldale

THIRD PLACE

Performance Products

Two-Step Polyol at Jurong

Senthil Murugan, Brett Speetzen, Jeff Marten, Brendan Dsouza

“This is one of the most exciting nights and events to work on all year because it really does showcase the talent of our global associates and how their ideas elevate Huntsman, and keep us competitive in the global marketplace.”

—Jeff Morgheim, Global Senior Director of Sustainability and EHS Governance

Stéphan Costantino; Sébastien Panthu; Dana Uhlig; Simon Burkel; John Fraser CEO AWARD WINNER ADVANCED

Project Name: Making Hydrogen Mobility Possible

ith the transportation and industry sector responsible for almost 40% of global CO2 emissions, utilizing hydrogen instead of fossil fuels can make a significant difference in decarbonization efforts. Storage of hydrogen, however, can be challenging. The Advanced Materials finalist team enables a storage solution: safe, lightweight, and high-quality hydrogen composite pressure vessels—made of state-of-the-art epoxy carbon-fiber composites—for use in long-range buses and trucks. It can also be used to transport hydrogen for industrial consumption.

Due to its low volumetric energy density, hydrogen needs to be compressed and stored at up to 850 bar.

Due to its superior strength and stiffness to weight ratio, composites is the safe and lightweight state-ofthe-art material used and enabled with ARALDITE® composite technology. The new epoxy system is enabling a faster automated production with new levels of safety, cost, and performance and up to a 20x market growth by 2034. The sustainability story is even stonger when fossil saving mass balanced ARALDITE® resins are used, which results in a CO2 footprint reduction of up to 95%. Current projects are focused on the automotive industry, but new work with MIRALON® carbon nanotube materials look promising for the aerospace industry as well.

Fulton Ma; Terry Chen; Perry Choi; Jules Xu; Harry Wu; Jennifer Huang

Project Name: Zero Waste Manufacturing at Panyu

Huntsman’s Panyu site set out to create a Zero Waste manufacturing environment in 2023 using a sustainable waste hierarchy plan and 3R principle to reduce, reuse, and recycle. Through a Lean Six Sigma project format, the Advanced Materials team led the Panyu site on a journey to becoming a certified Zero Waste site in 2023. The team first began by educating Panyu associates about the need for change and why achieving Zero Waste would improve operations and reduce overall costs. Waste reduction workshops and trainings were held throughout the year to create an on-site mindset and behavioral approach to accomplishing Zero Waste.

“The project is a demonstration of how sustainable goals can be achieved through guiding principles and a fully functional team.” said team leader, Fulton Ma, Manufacturing Director of the Panyu site. “It is an extremely good example to all Huntsman sites in using Lean tools leading to Zero Waste manufacturing.”

The finalist team focused on optimizing its

planning to reduce waste solvents, such as replacing 200-liter drums with intermediate bulk container (IBC) tanks for RM packaging, among other activities. They also reduced waste from block stock and RM residual in drums after charging (CYC50); reused IBC tanks and the waste they produced after cleaning, and recycled waste toluene as a nitro thinner, once it was purified by a third-party vendor. Zero Waste was further accomplished by eliminating incineration and landfill, which treats waste more sustainably.

By introducing a Zero Waste program at Panyu, the site experienced a 13% drop in total waste generation, an 11% decrease in hazardous waste generation and a 16% reduction in hazardous waste disposal through incineration and landfill. The team also created a stream of revenue through waste reuse and recycling. Reliability of manufacturing processes improved, and safety hazards were reduced overall.

Presenting Team Members: Hugo Verbeke; Olaf Michel; Giacomo Giannini; Hanson Wan; Alexander Ziev; Matt Canoy; Bert Janssens; Bram Vanroy; Vevek Wang; Harrison Wang

Project Name: Sustainable Resilient Flooring

The Polyurethanes finalist team, through the Elastomers business, developed a T EROL -based thermoplastic polyurethane (TPU) to replace polyvinyl chloride (PVC) in luxury vinyl tiles. The new solution was in response to Huntsman’s partner, HMTX, wanting to address some of the key challenges associated with existing PVC solutions related to limited recycling options. Not only is TPU recyclable, it is also more durable than PVC, and when combined with TEROL as the main building block, it reduces the carbon footprint of TPU to historic low levels. The tiles also feature potential for improved locking

strength, better sound insulation, and higher dimensional stability. The equivalent of two PET bottles are upcycled per square foot of flooring, offering additional sustainability opportunities. Both pre- and post-consumer sources of PET are used.

The project began in January 2021, and by Q3 of the same year, a proof of concept was developed in the lab. The new HMTX SRP™ Rigid Core TPU solution was quickly recognized by multiple outlets, resulting in a 2023 Best of NeoCon Sustainability award in the Flooring Category, and was selected by BuildingGreen as one of the Top 10 Products for 2024.

In the first quarter of 2023, the Performance Products finalist team designed a cost-saving, two-step polyol process that was ready for its first trial by September 2023. Polyols are precursors to polyether amines, which have applications in Coatings, Adhesives, Sealants, and Elastomers (CASE) and other markets. In Singapore, specialty polyols are manufactured on the HHT Loop Reactor, and high-volume polyols are manufactured on the Continuous Stirred Tank Reactor (CSTR) systems in a one-step process. With demand for specialty polyols and amines increasing, the team sought ways to free up capacity on the HHT unit to make specialty polyols similar to their two-step polyol, which makes PT225-PC in the first step and then builds up to PT-403 in the CSTR unit in the second step. This allows for available capacity on the CSTR. Other complex polyols can be made similarly via this two-step

process to free up asset space in the HHT unit for new or existing products.

“We are being nimble and proactively responding to market trends by making changes in how we operate,” said Jeff Marten, S&OP manager for Performance Products, mentioning the two-step process moves the production to a higher throughput unit.

The two-step process has the potential to save the company millions of dollars, and therefore use the savings to make more polyols. The two-step process also generates minimal solid waste production and reduces energy consumption overall. By incorporating two independent reactors, the failure risk reduces and thus improves flexibility, efficiency, and time spent in manufacturing. The two-step process is being evaluated in other complex polyols to further free up asset space in the HHT unit.

POH Process Area HHT CSTR

To combat rising costs of the existing external chemical complex steam supply and on-site vent abatement technology, the Polyurethanes finalist team innovated a new, dedicated Energy Center solution for the Wilton Polyurethanes site. The center’s upgrades have already shown to save on energy consumption and could potentially save millions of dollars in operations costs annually over time.

The center, located in the Teesside chemical cluster in northeast England, U.K., has experienced upgrades through the years, both process and capacity, since Huntsman acquired the site in 1999. Some of the new energy upgrades include two-vent burning boilers to generate intermediate pressure (IP) steam, and two compressors to compress low

pressure (LP) steam to IP steam. It also provides boiler feed water and demineralized water to the site. Wider applications of the steam compression could be used within the division and across the organization.

Modern burner and boiler design could also be used at any site requiring steam for both emission reduction and potential vent abatement. Some initial results included significant continuous savings of about $15 million per year, improving the competitive cost base of the Wilton site. The team also noted NOx emissions reduced by about 50%. Finally, the upgrades allow for a reliable 100% redundancy in vent burning boilers, and a steady IP steam supply pressure.

Project Name: MEOX

Improving the safety and reducing a known toxin widely used in paints, coatings and semiconductors, the Performance Products finalist team developed 3-Methyl-2-oxazolidinone (MEOX) as a replacement for the toxic chemical N methyl 2 pyrrolidone (NMP). MEOX, a non-toxic alternative, is an innovative molecule that performs well, is safer to use, and is comparably priced to its competitors. Popular retailers, such as Lowe’s, The Home Depot, and Walmart have already committed to stop selling paint strippers with NMP, allowing for market possibilities for MEOX to become the preferred chemical.

“With the growth of U.S. production of semiconductors and batteries combined with concerns over further

restrictions on the use of NMP, potentially limiting new capacity, MEOX can provide a safer alternative and help ensure supply security for key U.S. industries,” said Jay Henderson, Advanced Technologies Global Applications Manager.

MEOX has similar structure and solubility parameters as NMP and internal studies have confirmed its performance in stripping solvents for semiconductor and display applications.

MEOX also has a favorable EHS profile. Made with propylene carbonate, a byproduct of the reaction of CO2 and propylene oxide (PO), the team is currently exploring a route to use CO2 directly. If successful, it would enable carbon capture, benefitting the planet.

In addition to creating and manufacturing products that make a sustainable impact, Huntsman is also committed to giving back to the communities where its employees live and work. Our corporate contributions take many forms as we invest our time, talents, and resources with the aim of making the world a better place. Huntsman’s approach is simple: We assess the needs in the areas where we do business and plug in to opportunities that meet the needs of those communities. | GRI 203-1 | GRI 203-2 |

Since the company’s founding, Huntsman has prioritized generous giving and aided associates serving in the communities where it does business.

Philanthropy and volunteerism are longstanding traditions at Huntsman, and this spirit of giving has been one of the most consistent legacies of the company from its inception. Globally, associates are encouraged to volunteer and contribute to charitable causes, whether sitting on a board, raising money for an event or cause, or providing much-needed funding to a project. Below are a few examples of how Huntsman, and its more than 6,000 employees, gave back in 2023.

Huntsman and Associates Raise $210,300 for Earthquake Relief

Huntsman and global associates raised approximately $210,000 for humanitarian organizations in 2023, providing aid in southern Turkey following a February earthquake that killed thousands.

At the time, Huntsman employed 80 colleagues in Turkey who worked at the Polyurethanes and since-divested Textile Effects sites, none of whom were harmed in the tragedy. But as the news unfolded worldwide, the company wanted to do more to assist with relief efforts. Huntsman encouraged associates to give, agreeing to match dollar-for-dollar. Funds were sent to several global nonprofits, such as the International Federation of Red Cross and Red Crescent Societies; Doctors Without Borders (Médecins San Frontières); and AKUT Search and Rescue Association.

Huntsman Supports Interfaith of The Woodlands

Wade Rogers, Senior Vice President of Global Huntsman Resources and Chief Compliance Officer, joined

Huntsman’s Chief Executive Officer, Peter Huntsman, on the Interfaith of The Woodlands’ board of directors in 2023. Huntsman has enjoyed a long partnership with the nonprofit, and again served as the presenting sponsor for Interfaith’s Celebration of Excellence Gala, recognizing hometown heroes throughout Montgomery County, Texas. The event helped raise nearly $600,000 for residents throughout the county, assisting with food, clothing, rent, mortgage and utility assistance.

CASA Child Advocates of Montgomery County, Texas, held its annual CASA Speaks for Kids Gala in March 2023, at Jimmy Buffet’s Margaritaville Lake Resort on Lake Conroe. Huntsman served as the event’s presenting sponsor, where more than 300 guests helped raise more than $700,000 to support CASA’s activities throughout the year. CASA trains

court-appointed advocates who assist children in the Montgomery County foster care system. CASA of Montgomery County serves 100% of the county’s children in Texas Department of Family and Protective Services (DFPS) custody.

Huntsman served as a Silver Level Hunger Hero in 2023 for the Montgomery County Food Bank, making a significant financial contribution to the food bank, and serving as the Fighting Hunger, Feeding Hope Gala Sponsor. The donation resulted in the food bank serving 200,000 meals for those facing hunger in the county. Huntsman also completed 100 hours of volunteer services in the Produce Rescue Center, providing 32 volunteers to help assemble more than 15,800 pounds of fresh produce that was then delivered to area residents in need.

Other organizations supported in 2023:

• Light the Night, Leukemia and Lymphoma Society

• Pink of Health Luncheon, supporting women’s cancers, for the Memorial Hermann Foundation

• Run Thru the Woods, for the YMCA of Greater Houston

A workweek of games, storytelling, and interactive lectures doesn’t exactly sound like a hard day at the office. But for Huntsman’s Asia Pacific associates attending the firstever collaborative Zero Harm Week in August, the game-intensive event served as a strategic venue to educate, reinforce, and dialog about Huntsman’s wider safety culture.

“Huntsman APAC is a strong believer in Zero Harm,” said event organizer, Leo Law, APAC’s Environmental, Health and Safety Director. “We wanted to put this concept into action and engage our associates in an entertaining way, while underscoring the belief that Zero Harm is possible.”

Throughout the event, associates across APAC’s 10 manufacturing

sites participated in themed activities and trainings, all of which promoted proper workplace safety practices. Each activity–designed by a committee Law assembled–offered how-to strategies for preventing employee accidents and raising awareness about potential workplace hazards. Zero Harm Week also spurred opportunities for associates to learn from one another’s individual experiences.

EHS leaders from The Woodlands office also attended Zero Harm Week in Shanghai, including Brit Benko, senior vice president of environmental health and safety, and Jeff Bruening, environmental and product safety director.

Bruening described the event as informative and lively, particularly on family day when associates’ children were invited to learn and play alongside their parents.

“The intention behind family day at each site was for the kids to understand ‘Why do your mom and dad work safe?,’ which says to them ‘We care about your parents and want them to work safe so they can come home safe to you,’” Bruening said, lauding Zero Harm Week’s schedule of comprehensive offerings. “What we do at work affects more than our co-workers, and family day was a clever way of getting that point across.”

While on-site, Bruening observed other games that evoked much employee participation and excitement, such as an activity designed to explain the different types of household waste and why it is important to the environment to have clear separation. Another game he said, made employees aware of their reaction times in crisis circumstances. Bruening especially enjoyed watching a storytelling activity where associates regaled colleagues with tales of Zero Harm with a side of humor.

“There were repeated moments of laughter and applause. At the same

time, they were all very sincere about the Zero Harm messages they were sharing,” Bruening said.

“There was a lot of coordination from all the divisions and leadership teams in Asia, who agreed this could

Zero Harm is a term used across a wide body of industries meaning “workplace health and safety.”

set an example for our company and demonstrate that we are responsible in our industry,” Law said, mentioning the many thoughtful hours that went into planning. “What we hoped to accomplish with this event was to promote that Zero Harm is not an EHS program, but rather a Huntsman value.”

The Zero Harm Week event underscores EHS’s global intentionality to raise awareness through leadership, preparedness, and education. As part of Horizon 2025, Huntsman has set targets for safety performance, while always aiming for no safety events.

Like Bruening, Benko, too, enjoyed attending and praised APAC’s thoughtful and entertaining approach to safety education.

“I was thoroughly impressed and energized by what we all encountered at Zero Harm Week, and it was evident that everyone had fun,” Benko said. “The APAC approach to Zero Harm as an enjoyable learning experience could be a model across all Huntsman sites.”

Law agreed, noting preparations for the 2024 Zero Harm Week are already underway.

Huntsman presented a donation of $25,000 (USD) to Lifting Hands, a nonprofit organization in Costa Rica that seeks to improve the quality of life of children and break the cycle of generational poverty.

These funds were committed to one of Lifting Hands’ local community centers near Huntsman’s Global Business Services (GBS) center in San José, Costa Rica, located within the community of El Bajo de los Anonos—supporting the nonprofit’s three most pressing needs:

• Renovations to a counseling room that doubles capacity for mental health services

• A roof for their sports area where children gather to play and exercise

• A roof for their small amphitheater where children take creative classes

Six months later, on Aug. 24, 2023,

Huntsman associates joined leadership from Lifting Hands, along with children from the community center, at a ribbon cutting to celebrate the completion of all three of these important projects.

“As Peter Huntsman said when we started this initiative, the donation is a beginning, not an end,” said Mauricio Gonzalez, General Manager of GBS Costa Rica. “Over the course of this year, I’ve been incredibly proud to witness our people deliver on that promise and we’re all excited to keep the momentum moving forward.”

On July 13, the San José GBS hub hosted its first Career Day with Lifting Hands and invited eight of the older children to participate. The vocational experience began with a welcome message from Gonzalez. Following an office-wide tour where each department explained the significance of their

“As Peter Huntsman said when we started this initiative, the donation is a beginning, not an end. Over the course of this year, I’ve been incredibly proud to witness our people deliver on that promise and we’re all excited to keep the momentum moving forward.”

—Mauricio Gonzalez, General Manager of GBS Costa Rica

contributions, each participant spent an hour shadowing a Huntsman employee to learn more about their respective profession. The event concluded with a training session from the Talent Acquisition team, which highlighted leading practices for developing a resume and preparing for an interview.

Employees have also participated in multiple volunteer initiatives with Lifting Hands this year. In June, a team of volunteers carried out a campaign to collect used clothing for the nonprofit. In April, volunteers provided painting and gardening support for the community center. Additionally, Daniela Rivera, a benefits specialist in the San José hub, teaches a weekly class at Lifting Hands.

More than 36,000 runners from more than 1,500 companies participated in the Sept 3 Poland Business Run 2023—including 20 representing Huntsman. This fiveperson relay event, held in Kraków, raised money to support people with mobility disabilities, those who have undergone limb amputations, and post-mastectomy care.

“We want to promote Huntsman as a fantastic place to work, brimming with development opportunities,” said Paul Rollé, site leader of Kraków GBS. “The Poland Business Run perfectly aligns with this goal, as it’s not just about running a race; it’s about helping people get where they want to be. We are setting an example of why Huntsman could be the best place to grow, much like GBS Kraków, which is growing every day.”

Huntsman was happy to participate in The Poland Business Run

Foundation, which announced this year’s running fees funded 19 prosthetic limbs, 16 wheelchairs or other equipment, and subsidized 71 rehabilitation stays. The Foundation also published personalized summaries on many of these individuals and outlined how charitable funds are being put to use.

Marta Chowaniec, Regional HR Business Partner, said that while she is not the biggest fan of running, she is an advocate for this cause—so she ran.

“It was a really great and memorable experience,” Marta

Chowaniec said. “All of our runners and supporters made a meaningful difference, a badge of pride we can all share with one another.” Huntsman’s 20 runners were organized into four teams. Friends and family members joined the fray as well—with some of the youngest supporters sporting special T-shirts made just for them. Huntsman, as a top sponsor, also hosted a branded refreshments station for runners and other attendees.

The Huntsman Scholarship Program awarded 19 university and trade school scholarships to Spring Independent School District (ISD) students from the Class of 2023 during its annual awards ceremony.

Now in its third year, the event, held at the Randall Reed Center in Spring, Texas, was attended by scholarship recipients and family members, along with Spring ISD educators and leadership, school board members and Spring ISD Superintendent, Dr. Lupita Hinojosa. Huntsman associates and executives were also in attendance, including Peter Huntsman.

Sixteen seniors received scholarships of $5,000, renewable for up to four years for a total of $20,000,

for attending an accredited college or university and majoring in science, technology, engineering or mathematics (STEM) or business-related fields. Three more students received Huntsman Trade Certification scholarships, which awards $1,250 to pursue a certification or vocational track in STEM.

“This scholarship is one that impacts not only the students— making sure they get to a college or university of their choice—but it makes an impact on the entire

family,” Dr. Hinojosa said during the awards ceremony. “And when you touch the entire family … now you’re touching the community. As our students succeed, the families succeed, and, ultimately, our community succeeds.”

Peter Huntsman addressed the audience and shared that the origin of the scholarship program began in 2020, initially as a personal examination of how the Huntsman Corporation could help bring people together within a cultural and political landscape where people

seemed to be growing more distant from one another. He needed, he added, a broader perspective. Kristina Henshaw, a Huntsman investor relations manager, helped him find it.

“Peter came to me to have an open and honest conversation about some very tough subjects,” Kristina recounted following the awards ceremony. “We had multiple, collaborative conversations exploring how to best position any form of support where it was most needed.”

Spring ISD was a very intentional choice, she added. According to public data, nearly 83% of Spring

“These scholarships make a difference. And I’m proud to work for a company that is collaborative and invites perspective and, most importantly, puts its money where its mouth is on these important issues.”

Kristina Henshaw, Manager of Investor Relations

ISD’s more than 34,000 students are categorized as economically disadvantaged. About 60% of these students are considered at risk of dropping out of school.

Demographically, it is also what Dr. Hinojosa described as a “melting pot.” Hispanic students account for 51.7% of its enrollment and Black and African American students represent 37.9%.

“These scholarships make a difference,” Kristina said. “And I’m proud to work for a company that is collaborative and invites perspective and, most importantly, puts its money where its mouth is on these important issues.”

Peter Huntsman’s message to the recipients emphasized his hope that they would use this opportunity to make a difference not only in their own lives, but in the relationships they form going forward.

“I commend each and every one of you. When I’m long gone, I hope that your children will come along and look at your works, your ideas, and your creativity, and thank you for what you’ve done—thanking you for the legacy, not just of academia, but also of kindness, graciousness, forgiveness, and contributing something back to society,” he said.

Huntsman’s industry-leading lower-emissions JEFFCAT® Catalyst portfolio addresses polyurethane foam producers’ environmental, health, and safety requirements. This environment-friendlier spray foam installation helps reduce energy consumption in commercial and residential construction.

Spray foam insulation or spray polyurethane foam (SPF) is a fantastic achievement of modern science that aims to help people worldwide stay warm in the winter, cool in the summer, and safe all year long. The technology also provides an energy-efficient solution that cuts costs for builders and residents. It is a two-component mixture comprising an isocyanate that reacts with a polyol blend consisting of polyols, silicone surfactants, catalysts, blowing agents, and other additives. Like most polymer combinations, SPFs are produced by mixing A with B to create an (AB)n copolymer. A spring-loaded spray foam gun combines the A and B components at the tip to make an

expanding foam sprayed on walls, roofs, attics, floors, and other surfaces that benefit from continuous insulation.

The A and B “sides” of the system are made up of materials that react to create foam when combined. The isocyanate includes A side, such as methylene diphenyl diisocyanate (MDI). The B side, where JEFFCAT® Catalysts are utilized, combines ingredients, including polyols, silicone surfactants, catalysts, blowing agents, and other PU additives. Each system part plays a critical role in creating the desired end product.

In recent years, the United States Environmental Protection Agency (EPA) began to enact laws banning Hydrofluorocarbon (HFC) use in B side formulations because of adverse environmental impacts associated with the blowing agent. The industry adopted a new alternative blowing agent, Hydrofluoroolefin (HFO), to replace the undesirable HFC component. Since SPF systems rely on carefully balanced components to achieve the desired results, the ban created an opportunity for Huntsman to serve this market with new solutions. Huntsman is developing an HFO-stable catalyst that will be introduced as XTA-1094 Catalyst and will further enhance our broad PU additives portfolio, which includes

lower-emission and low-odor amine catalysts and aldehyde scavengers. This innovative amine catalyst is stable in Hydrofluoroolefin (HFO)-based polyurethane systems and provides exceptional front-end blowing reactions and reactivity rates. Its stability seeks to improve shelf life and reduces harmful VOC emissions in polyurethane foams, making it a desirable addition to B side formulations.

JEFFCAT® Catalysts enable new spray foam technologies by providing safer, more environmentally HFO-stable catalysts for energy efficient spray polyurethane foam formulations. Because of its exceptional insulation capabilities, spray polyurethane foam is a comprehensive solution that allows construction companies to reduce energy usage, costs, and greenhouse gas emissions.

Huntsman has developed a new thermoplastic polyurethane (TPU) — containing recycled materials — based on Huntsman’s leading TEROL® polyol for use in the global flooring market. Developed in conjunction with HMTX Industries to compete with polyvinyl chloride (PVC) flooring, Huntsman’s TPUbased solution helps facilitate end of life recycling and can scale across multiple applications.

the second half of 2023 as SRP™ Rigid Core TPU flooring. Huntsman and HMTX partnered to address some key challenges with existing PVC related to limited recycling options.

“There’s a lot of interest in creating a non-PVC flooring segment within our industry,” said HMTX CEO Harlan Stone, mentioning how the market continues to show an uptick in customer interest for luxury recyclable flooring.

Originally envisioned as an alternative to PVC vinyl tiles, HMTX introduced the new tile solution in

A TPU-based alternative, however, helps ensure recyclability, Stone said, and the inclusion of TEROL® polyol also reduces the overall TPU carbon footprint to historic low levels. Each square foot of the new TPU flooring, which come in a variety of sleek colors, utilizes the equivalent of two PET bottles worth of recycled material and enables circularity into the plank using a TPU layer.

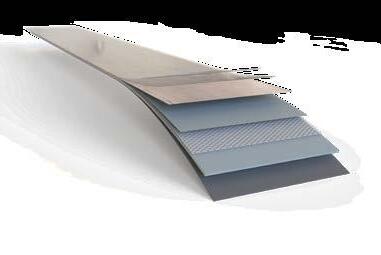

Each plank consists of multiple layers including a polyethylene terephthalate glycol (PETG) top layer, followed by a rigid TPU core and an HDPE bottom layer. The

new SRP solution was quickly recognized by multiple outlets, resulting in a 2023 Best of NeoCon Sustainability award in the Flooring Category, and was selected by BuildingGreen as one of the Top 10 Products for 2024.

While the environmental benefits of the new TPU are key drivers to its future success, there are also some key functional advantages including potential for improved locking strength, enhanced durability and abrasion resistance, and better sound isolation.

A range of flexibility and softness characteristics will suit many commercial environments such as hospitality, retail, office, and hospitals.

“The

opportunity for SRP to be the leader in transparency, sustainability, circularity, and performance using the Huntsman technology is absolutely a winner.”

—Harlan Stone, HMTX CEO

The project, originally unveiled during Huntsman’s 2021 Investor Day, is poised to become one of the largest of its kind in the Americas, representing a major stride toward the commercialization of the innovative MIRALON® technology and the proving ground for a future industrial-scale production facility. “Our business prides itself on bringing advanced materials to market to help our customers solve difficult engineering challenges through innovation,” said Scott Wright, President of Huntsman’s Advanced Materials Division.

“Today marks a significant step forward in the development of a

new class of valuable, sustainable material.”

Huntsman has had the capability of producing about a ton of the material annually at its Merrimack, New Hampshire, site. While the pilot plant will increase that capability by 30 tons, Huntsman has plans for a larger commercial-scale plant generating kilotons of clean hydrogen and MIRALON® carbon nanotube materials in the coming years.

The MIRALON® structural carbon products, stemming from carbon nanotubes, boast versatility in production, taking forms such as sheets, tape, yarn, or additives and dispersions. Remarkably,

these materials are thinner than a human hair yet exhibit a tensile strength up to 25 times that of steel. This exceptional combination of lightweight properties and outstanding electrical and thermal conductivity renders MIRALON® carbon nanotube materials immensely adaptable, with potential applications spanning aerospace, automotive, construction, and beyond.

Key applications include electric vehicle batteries, high-performance composites, engineered thermoplastics, conductive adhesives, specialized concrete formulations, and high-durability tires.

“One of the interesting aspects

of this project is that there are actually two valuable products created through the technology,” said David Hatrick, Vice President of Innovation and Strategic Marketing for Huntsman’s Advanced Materials Division.

“The first product is the MIRALON® carbon nanotube materials, which have tremendous opportunity to create better products and new applications that don’t even exist today. The second product resulting from the process is clean hydrogen—a fuel in high demand as society collectively seeks to lower CO2 emissions and accelerate the energy transition.”

John Fraser, Commercial Director for MIRALON® technology and materials, sheds light on the potential impact in the context of the energy transition.

“The carbon footprint related to our manufacturing process can be up to 95% less, when compared to the

“Our business prides itself on bringing advanced materials to market to help our customers solve difficult engineering challenges through innovation.”

—Scott Wright, President of Huntsman’s Advanced Materials division.

traditional process of steam methane reforming (SMR), avoiding the majority of CO2 emissions normally associated with hydrogen production,” Fraser said. “Co-locating a small MIRALON® manufacturing unit on a customer’s site, creates the opportunity to produce hydrogen right where our customers need it. This will allow companies to reduce their carbon footprint and benefit from the potential of CO2 sequestration/capture credits.”

Commissioning of the plant is underway and technical and commercial teams are actively engaged with customers, exploring innovative applications and solutions utilizing MIRALON® materials. Visit www.miralon.com or listen to our March 2023 Huntsman Knows How podcast on the topic to learn more.

Huntsman’s highest governance body is our Board of Directors.

Executive officers are the primary team responsible for decisionmaking on economic, environmental, and social topics. The Board Sustainability Committee provides oversight of environmental, health, safety, and sustainability-related topics.

The following provides further details on the bodies involved in sustainability for Huntsman.

Huntsman’s highest governance body is our Board of Directors. Nine of the 10 members are independent or non-executive. Peter Huntsman serves as the Chairman of the Board, President, and Chief Executive Officer of the company. As of the issuance of this report, the Board is structured as follows:

| GRI 2-13 | GRI 2-14 | CDP C1.2 | | CDP C1.2a | TCFD Governance B |

Led by Peter Huntsman, the committee is comprised of the executive team along with representatives from key functions.

The committee provides executive direction of the corporate sustainability program and submits regular updates to the board. As of the issuance of this report, the committee is structured as follows:

Peter R. Huntsman

Chairman of the Board, President, and Chief Executive Officer

Philip M. Lister

Executive Vice President and Chief Financial Officer

David Stryker

Executive Vice President, General Counsel, and Secretary

Anthony Hankins

Chief Executive Officer, Asia Pacific and Division President, Polyurethanes

Scott Wright Division President, Advanced Materials

Brittany Benko

Senior Vice President, Environmental, Health and Safety and Manufacturing Excellence, and Corporate Sustainability Officer

R. Wade Rogers

Senior Vice President, Global Human Resources and Chief Compliance Officer

Ivan M. Marcuse

Vice President, Investor Relations and Corporate Development

Kevin Gundersen

Vice President, Corporate Communications and Government Affairs

Jeff Morgheim

Senior Director, Global Sustainability and EHS Governance

| GRI 2-13 | GRI 2-14 | CDP C1.2 |

C1.2a | | TCFD Governance B |

Led by Corporate Sustainability Officer

Brittany Benko, the council is comprised of senior representatives from the company’s divisions and key functions.

The council directs development of the corporate sustainability program and cultivates a common framework for sustainability, ensuring strategic alignment among the divisions, functions, and executive team.

Brittany Benko

Senior Vice President, Environmental, Health and Safety and Manufacturing Excellence, and Corporate Sustainability Officer

Todd Bloomfield Vice President, Purchasing

Twila Day

Vice President and Chief Information Officer

Ralph DiGuilio

Vice President, Global Research and Development, Performance Products

David Hatrick

Vice President, Innovation, Advanced Materials

Ivan M. Marcuse

Vice President, Investor Relations and Corporate Development

Bill McPherson

Global HR Director, Corporate Functions

Jeff Morgheim

Senior Director, Global Sustainability and EHS Governance

Pavneet Mumick

Global Vice President, Technology and Innovation, Polyurethanes

Kevin Gundersen

Vice President, Corporate Communications and Government Affairs

Max van der Meer

Vice President Global Operations and Technology, Polyurethanes

| GRI 2-23 | GRI 2-24 |

At Huntsman, good governance and corporate responsibility are integral parts of our business strategy. The key focus areas of our corporate responsibility program include: our people; our health, safety, and wellness programs; and our environmental stewardship, including our sustainability and product stewardship efforts.

To learn more about our policies, including how we embed our policy commitments, enable the reporting of potential violations of policies, and manage our commitment to compliance with the laws and regulations applicable to our activities, please see our governance disclosures at Governance :: Huntsman Corporation (HUN).

| GRI 2-23 | GRI 2-24 | GRI 2-30 | GRI 2-31 | GRI 205-1 | GRI 205-2 | GRI 205-3 |

Huntsman works to ensure that our corporate policies, procedures, and guidance documents align with the Ten Principles of the United Nations Global Compact (UNGC). The table below identifies relevant Huntsman policies, procedures, systems, and actions that illustrate our progress. Principles | Huntsman Policies and Procedures Systems and Actions

1 Support for human rights 2 Elimination of human rights violations

Since 2012, our Business Conduct Guidelines make specific reference to the UNGC and our commitment to operating under its standards in all communities where we do business. In addition, Huntsman’s Vendor Code of Conduct applies to all vendors and their employees, agents, and subcontractors. See also: Huntsman Human Rights Policy.

3

Ensuring freedom of association

Associates are ensured freedom of association and are reminded of that right through visible postings at our facilities.

4 Abolition of all forms of forced labor 5 Abolition of child labor

In every region of the world, our Human Resources department is charged with ensuring that direct-hire Huntsman associates have necessary and legally required documentation to establish their identity, legal age, and work status. See also: Huntsman Human Rights Policy.

6 Elimination of discrimination

• The Corporate Ethics and Compliance (E&C) department reports any reported human rights violations to the Audit Committee, which is comprised of independent members of the Board of Directors.

• “Speak Up” confidential reporting service for reporting concerns.

• International Trade Compliance risk assessments for at-risk countries.

• Prequalification due diligence of vendors with high-risk profiles.

• Periodic re-qualification due diligence review of highrisk vendors and all distributors.

• Global EHS standards and procedures.

• Of all Huntsman employees, 40% are covered under collective bargaining agreements, including both union and work councils.

• Huntsman engages in planning to ensure employees are treated with respect and dignity regarding operational changes that involve a change in staffing levels or otherwise affect employment.

• Standard contract clauses require each vendor to agree that no child or indentured labor is used by the vendor in the performance of its business.

• Periodic E&C combined policy audits conducted for selected sites that include audits on human rights, child labor, and forced labor.

• Ethics and compliance training.

• Online training regarding harassment in the workplace.

• U.S. Purchasing groups offer technical assistance in the preparation and submission of bids to Huntsman, which can include small or disadvantaged businesses. Huntsman upholds a policy against discrimination, including harassment and retaliation.

Precautionary environmental protection

Huntsman’s EHS Management System includes 7 Global EHS Standards and 70 Global EHS Procedures to ensure safe operation at all its facilities.

Our Product Stewardship Standard EHS-700 outlines global requirements to ensure responsible management of EHS issues relating to Huntsman products throughout their life cycle.

Huntsman’s Environmental Standard EHS-600 outlines global requirements to identify and minimize the environmental impact of our operations and to strive for continuous improvement.

We committed to publish 30+ product safety summaries as part of our Horizon 2025 targets to enhance transparency and provide stakeholders with helpful information.

Huntsman’s Process Safety Standard EHS-400 outlines global requirements to identify and manage risk associated with process safety incidents and their impacts on the environment.

8Initiatives to promote greater environmental responsibility

Huntsman has published our EHS Policy and Commitment on our website, which includes a commitment to the Responsible Care® program and placing care for human health, safety, and the environment at the forefront of everything we do.

Huntsman has developed and published our Horizon 2025 global strategic targets in areas of personal and process safety and environmental performance, including production intensity targets in greenhouse gas emissions, energy consumption, hazardous waste disposal, and net water usage.

• Our Product Safety and Regulatory Compliance (PSRC) team actively manages product and raw material risk, including hazard communication (such as safety data sheets), compliance, customer risk evaluation, and distribution risk management.

• All Huntsman facilities are required to identify, quantify, and minimize energy use, as well as air, water, and waste releases from routine operations.

• Management of Change (MOC) procedures at all facilities require consideration of environmental impacts for new projects and changes in processes.

• Process Hazard Analysis (PHA) procedures identify process safety hazards and the appropriate safeguards to prevent or mitigate impacts to the environment from loss-of-containment events.

• In 2023, Huntsman submitted 292 global substance registration dossiers, 93 of which are under REACH.

• As of the end of 2023, we published 25 product safety summaries that are available on our website, toward our goal of publishing 30 or more by 2025.

• We publish our annual Sustainability Report in accordance with the latest GRI Standards (2021) and provide both an SASB index and Task Force on Climate-Related Financial Disclosures (TCFD) indices to meet growing stakeholder interests and support our ongoing commitment to transparency.

• We developed a predictive chemical risk tool to identify and evaluate substances of concern.

• Of our manufacturing sites, 20 (36%) are ISO 14001 certified.

• In 2023, we completed eight corporate EHS audits and eight corporate process safety management (PSM) audits.

• We have Community Advisory Panels (CAPs) at major facilities.

• We presented CEO Awards for both Innovation in Sustainability and Manufacturing Excellence. See 2023 winners and finalists under the Who We Are section.

9

Development and diffusion of environmentally friendly technology

In our EHS Policy and Commitment, our policy is to place care for human health, safety, and the environment at the forefront of everything we do, and our mission is to provide products and solutions through the applications of science that enrich lives and help create a sustainable future, while doing no harm to people or the environment.

As a member of the American Chemistry Council (ACC), we support ACC’s sustainability principles that commit to achieving measurable reductions in emissions and creating innovative products for a sustainable future and societal benefits.

Measures against corruption

Our Corporate Ethics and Compliance department oversees and supports our compliance with relevant laws, regulations, and related Huntsman policies worldwide. See also: Huntsman Business Conduct Guidelines, Vendor Code of Conduct.

• We use waste PET in our polyols as raw material to produce polyurethane insulation. We have expanded our TEROL® polyols manufacturing to Taiwan—enabling us to meet increasing market demand for recycled content.

• We upcycle the equivalent of over 1.5 billion PET bottles annually, with the equivalent of over 10,000 recycled bottles used in each home, utilizing our spray foam from the newly created Huntsman Building Solutions (HBS) business.