Swine Grist

CENTRAL & ATLANTIC EDITION

A PERIODIC NEWSLETTER PRODUCED BY GRAND VALLEY FORTIFIERS

FALL 2024

Dear Pork Producing Friends,

After experiencing a better than average growing season for wheat, forages, corn and soybeans, we are looking forward to what should be a bountiful and high quality harvest. We trust that fall harvested crops will be free of or at least contain very low levels of mycotoxins unlike the 2023 harvest, allowing for maximized performance of the herd and utilization of DDGS to assist in further lowering feed costs.

You are beginning to read the words "sustainability and GHG emissions" in this and recent editions of the Grand Valley Grist as our company continues to research and learn, seeking to assist meat, milk and egg producers in navigating this complicated topic and finding ways for them to further improve their operation's efficiency for improved profitability and carbon credit potential. We are proud of the Canadian meat, milk and egg industry for already being among the most GHG efficient producers highly digestible protein in the world, and we will continue to work together to ensure that this remains the case, while improving Canadian producer profitability and sustainability.

Building on Strong Foundations

by: JP Thibault Business Development Manager

July 12 marked the end of an era for Direct Source Commodities. After more than fifteen years of service to our customers, Steve McGuffin has retired, leaving behind a solid foundation. Over the course of his career, he has not only helped producers navigate through market volatility, but he has also played a key role in the evolution of Grand Valley Fortifiers. Through his constant commitment and approach to customers, he has contributed to the growth of volumes

In this edition of the Grand Valley Grist, we are pleased to announce the appointment of JD D'Elia to President of the GVF group of companies. JD officially stepped into this new role on August 6th having served as Chief Financial Officer for about three years with the company. As CEO, it will be my pleasure to continue to serve and lead with JD for many more years as we continually seek to serve the producers we are privileged work with, empowering them to produce meat, milk and eggs profitably and sustainably for the advancement of human lives, nutrition and health.

We look forward to visiting with you at the upcoming Canada's Outdoor Farm Show in Woodstock, September 10 - 12th

Please visit us at our traditional show booth location (on the corner of 9th Lane and Middle Machinery Mall), grab a coffee, a pork sample, ice cream and hear more about our BioForce® sow and finisher products and the MS Schippers soaps and disinfectants in the new Hybag format, available through Farmers Depot.

Wishing you a bountiful harvest season.

Sincerely,

Ian Ross CEO, GVF group of

companies

traded, building lasting relationships and ensuring client satisfaction regardless of the challenges encountered. I was fortunate enough to witness the impact Steve had on our customers when we went on the road together. Competence, unparalleled communication, and dedicated service are words that I have heard many times in our conversations with you, our customers. His work over the years has set the standard and his departure will leave a personal void for all of us, but let's also take the opportunity to celebrate Steve and his career.

To ensure a smooth transition, I joined the Direct Source Commodities team about 10 months ago to monitor the markets. Cheryl Andela is now in charge of full-time customer service

Tanka Khanal

Youngji Rho

Cheryl Andela Jacqueline McKeon

and logistics. Jacqueline McKeon was hired in May to provide administrative support. We are fortunate to have competent and dedicated employees who are familiar with our customers' expectations and market requirements. The transition, which began with my arrival last September, has gone according to the plan that was established from the outset and I am confident that this team will be able to maintain the quality of service that our customers demand. The team in place is ready to take up the challenge. Looking to the future, the team is determined to go above and beyond our clients' expectations by taking a more proactive approach. We understand that our customers' needs and challenges are constantly evolving, and anticipating these changes is crucial to delivering unparalleled service. We aim to provide expert advice and offer tailored pricing strategies that will help our clients optimize their position in different markets. Also, in order to meet the growing needs of the various customers, Direct Source Commodities now also takes care of the marketing and sales of macro-ingredients (limestone, salt, dical etc.), amino acids, additives and other ingredients. The demand for these types of products is growing rapidly and we are convinced that Direct Source Commodities can be a supplier of choice. These orientations are in line with our desire to be a trusted partner, capable not only of meeting current needs, but also of anticipating future challenges. Through these initiatives, we are confident that we will be able to offer additional high-quality service tailored to each client's requirements, while continuing to build on the foundation established by Steve to ensure our clients' success.

Direct Source Commodities

Let our team help you source off-farm ingredients

1-877-743-4412 | info@directsourcec.com

Sustainability in Ag, it can be Positive!

by: Bruce Schumann, M.Sc. Director of Sustainability, Regulatory and Quality Assurance

One of the most popular buzzwords of today is sustainability, but what does it mean and how does it impact livestock agriculture?

In its simplest definition sustainability is “Meeting the needs of the present without compromising the ability of future generations to meet their own needs.”

Consumers place heavy emphasis on the environmental side of sustainability, but for farmers to be sustainable it is much more than that. Farmers are not only excellent stewards of their land and the livestock they raise, but also take care of the people that work for them, comply with all the regulatory constraints and need to be profitable while doing so. Sustainability is the sweet spot where environment, economic (profitability) and social goals all overlap. Many companies within the livestock supply chains are making voluntary commitments towards sustainability, with a heavy emphasis on reducing the environmental impact. The Canadian Securities Administrators (CSA) are working to establish requirements for Canadian publicly traded companies to make climate-related disclosures in response to demands from investors and other stakeholders for “complete, consistent and comparable” reporting. For many of these companies, most of their greenhouse gas (GHG) emissions (between 50 – 85%), originate from their raw materials coming into their plant (upstream) and the final product destinations (downstream) after they have left the processing plant. So, the commitments publicly traded companies make for reductions in GHG emissions in the livestock sector, will be heavily reliant upon primary producers for that change.

Canada accounts for roughly 1.5% (Government of Canada. 2022 “Global greenhouse gas emissions.”) of the world’s GHG emissions and of that 1.5%, Canadian agriculture (crops & livestock) is responsible for only 8.2% of our total GHG emissions. So Canadian agriculture contributes 0.12% of the Global GHG emissions. To put this into perspective China and the USA jointly account for ~39% of the worlds GHG emissions. Despite our small contribution to the overall emissions in the world, 196 countries around the world, including Canada, have all made climate commitments, through the Paris Agreement, to reduce their total GHG emissions from 2005 levels by 43% by 2030 (United Nations Climate Change).

We are a nation that produces some of the most sustainable pork, chicken, beef, milk and eggs in the world, and we are continually improving. At the farm level, GVF’s purpose is to help our customers, like you, to achieve the best possible production at the lowest possible cost. We firmly believe that the most efficient

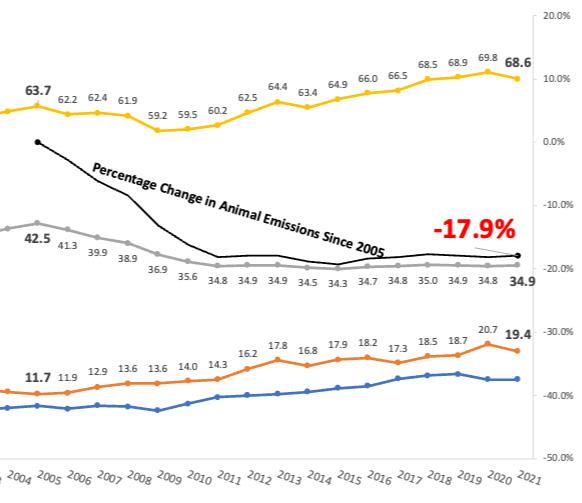

producers will ultimately become the most profitable and the most sustainable. The improvements in economic and production efficiencies will not only put more dollars in the hands of farmers, but it will also decrease the greenhouse gas emission intensities, by producing more with less. Environment and Climate Change Canada in 2023 reported Canadian Livestock Production emissions since 1990 (Figure 1). Livestock numbers in Canada have increased by 46.9% between 2004 and 2021 (predominantly from increasing swine and poultry numbers). Despite producing 47% more livestock, our livestock production emissions have only increased by 13% since 1990. And since 2005, Canadian farmers have reduced total livestock emissions by almost 18%.

It is critical that we capture, track and improve these production metrics on farm. We need to continually measure and relate our improvements in growth and reproduction to palpable reductions in GHG emissions per kg of meat, milk and eggs produced. This information then needs to be shared, telling the great-news story about livestock agriculture in Canada to policy makers, and ensure that most efficient livestock production systems have preferential access to supply global markets.

As a company and as an industry we are committed to advocating for livestock producers and the crucial role livestock has and will continue to play in feeding the world. Grand Valley Fortifiers has commenced some sustainability initiatives, with more to come in the future. We have begun adding pro-agriculture, sustainability messages on our newest trucks to help educate the general public how Canadian farmers already produce some of the most sustainable pork, beef, dairy and poultry products in the world.

We have performed on-farm environmental assessments for some of our pork, dairy and poultry producers. Our initial results confirm what we believed. We know that ~70% of total livestock emissions comes from feed, and so, landbased producers, manufacturing their own-feed on farm and using ingredients grown and harvested under their control, are the most environmentally efficient compared to the national averages. This puts these livestock producers in a powerful position when processors and grocery stores are looking for demonstratable lower carbon-footprint livestock for their supply chain and hopefully to take advantage of carbon credits in the future.

It is therefore critical to track growth and production throughout your entire operation. GVF’s sustainability mission is to enable livestock operations with data-driven insights, and business intelligence solutions to optimize feed & production efficiency, profitability, and resource stewardship, fostering everimproving meat, milk and egg production.

We are working with producers to capture, analyze, interpret and make informed decisions to allow them to be the most efficient, most profitable and most sustainable as they can be. For more information on how GVF can help

Figure 1: Canadian Ag Sector Annual Emissions & Percentage Change in Livestock Emissions

Source: Environment & Climate Change Canada (2003) National Inventory Report 2004-2021: Greenhouse Gas

improve your farm sustainability, contact Bruce Schumann or your GVF Livestock Business Consultant today.

References:

https://unfccc.int/process-and-meetings/the-paris-agreement

https://www.canada.ca/en/environment-climate-change/services/environmental-indicators/ global-greenhouse-gas-emissions.html

Managing Disease Risk to your Farm with SHARC

by: Jessica Fox, M.Sc. Swine Health Ontario Manager

Disease is one of the biggest threats to hog farms, impacting both the health of animals and the viability of farm operations.

Swine Health Area and Regional Control —known as SHARC — is a collaborative risk management tool to help producers anticipate and avoid disease risks to their herd. SHARC currently tracks PRRS (porcine reproductive and respiratory syndrome), PEDv (porcine epidemic diarrhea virus) and PDCoV (porcine delta coronavirus).

SHARC exists to help producers understand and minimize disease risks, to make smart, health-based decisions about operations including premises biosecurity measures, hog movement, manure management and new barn construction.

SHARC offers the Ontario hog industry a whole new level of insight into disease transmission and outbreaks simply by sharing information. Producers and their veterinarians can work together to reduce the risk of disease and keep our animals and farms healthy. This is particularly important when disease prevalence is increased, as we have seen so far in 2024.

SHARC collects herd disease status for PRRS, PED and PDCoV from producers or their herd veterinarian. In turn, program participants (producers and veterinarians) can access information to view results and assess disease pressures in their area. At an industry level, results are cumulative, resulting in a higher level of disease protection for all swine herds — with the potential to support a quicker response to a serious foreign animal disease outbreak, such as African Swine Fever.

To participate in SHARC, producers, with their herd veterinarian, agree to confidential sharing of herd disease status with other participating producers. Collaboration is key, and the more producers who agree to participate, the more effective the program will be.

SHARC mapping software allows participating producers to see disease status and hog density around a premises, using this information to make more timely and effective decisions about disease treatment, vaccination, herd movements, manure management, and new construction.

Operated by Swine Health Ontario, in partnership with Ontario Pork and the Ontario Pork Industry Council, SHARC has been built based on extensive industry feedback, and offers significant improvements for producers compared to previous disease management programs. Sign up today to make the most of this important risk management tool.

SHARC features include:

• Integration of AgManifest movement data to allow health status to follow reported movements

Daily data uploads to decrease lag time in reporting Refinement of PRRS positive status (new break, field, vaccine or mixed) Enhanced disease mapping capabilities, while maintaining confidentiality

• Automated notices to users of farm disease status changes

• Member-only access to disease mapping tools, including radius mapping

• Automated enrollment for all sites related to a producer number

• Genotyping data added to AHL uploads when available

• Addition of Associate user type to allow related staff to register

Value of Monitoring ADG and FCR

by: João Ferreira, Ph.D. FNL Monogastric Nutritionist

There is a common phrase in business management, “you can't manage what you can't measure,” and it applies so well in animal agriculture. If raising pigs was a sport at the Olympics, I believe eye-balling performance metrics would result in a direct red card without a warning. The metrics of growth performance in animal production serve as an excellent compass on a farm, guiding the producer in achieving business objectives. Setting goals, collecting data, and evaluating it periodically is valuable time that producers must invest in their routine. Average Daily Gain (ADG) and Feed Conversion Ratio (FCR) are important metrics that producers can use to correlate feed investment with returns in meat production.

Historical data from your barn is crucial for making informed decisions about investments and budget allocation in your production system or for reformulating diets according to your goals. There are multiple factors that affect your ADG and FCR. For instance, if the animals become sick or if you wish to test a new feed additive, having historical data allows you to monitor changes in real time. Refer to Figure 1 as an example of data collected from previous herd performance. In Figure 2, the cardinal dark red line represents historical recorded data, and the cardinal light red line shows the current batch. The current batch is not gaining weight as expected. A producer with control over farm data could decide to remove or reduce the inclusion of the alternative feed ingredient.

Let us go through a few examples to illustrate the importance of monitoring herd data. The first example is a hypothetical one of introducing an alternative feed ingredient in growing and finishing diets. In Western Canada, there are opportunities to use pulse crops such as field peas, faba beans, chickpeas or other crops as canola meal, rye, sunflower meal, and other ingredients. However, the challenge with alternative feed ingredients is the lack of studies and knowledge regarding their nutrient digestibility, metabolizable energy, and the presence of antinutritional factors. Chickpeas, faba beans, and field peas contain resistant starch, tannins, and trypsin inhibitor factors (Tan et. al., 2021), which, depending on their concentration and the amount included in the diet, can impair pig performance. Similarly, canola contains glucosinolates, high fiber, and low amino acid digestibility. Therefore, caution should be taken before adding substantial amounts of alternative feed ingredients into rations. Another example of the importance of controlling FCR and ADG is related to grain milling on the farm. Grain milling should be adjusted for each growth stage and type of grain. For example, Koo and Nyachoti (2021) studied the effect of three oat particle sizes, 765, 619, and 569 μm, on nutrient and energy digestibility in nursery pigs, resulting in three different metabolizable energy values of 2,091, 2,344, and 2,254 kcal/kg, respectively. In growing and finishing pigs, Rojas and Stein (2015) studied the reduction of corn particle size, 865, 677, 485, and 339 μm, and found metabolizable energy values of 3,313, 3,348, 3,372, and 3,434 kcal/ kg, respectively. In a subsequent study, the same researchers concluded that it is possible to formulate diets with lower soy oil inclusion through corn milling to a finer particle size, while maintaining the same performance (Rojas and Stein, 2016). Other studies have proven that proper grinding of wheat, barley, and corn improves the digestibility of feed ingredients. Incorrect grinding, on the other hand, can impair performance.

Another great example of data utilization in production is basic feed additive testing. By controlling your data and all associated factors (such as the same

Figure 2. Introduction of alternative feed ingredients

feed ingredients, specifications, feeding conditions, etc.), you can evaluate how beneficial a feed additive is for your production. You can assess whether the investment in the feed additive is affordable and yields a good return. Other situations that emphasize the importance of data control include disease outbreaks in the herd, mycotoxin contamination in feed, poor water quality, extreme temperatures, improper feed mixing, and unbalanced diets due to unanalyzed feed ingredients. Conversely, you can associate positive effects on FCR and ADG with factors such as water treatment, the introduction of highquality feed ingredients, pen modifications, increased feeding space, additional drinkers, and barn improvements.

Therefore, controlling and monitoring FCR and ADG is invaluable for your production system. Having control over your data allows you to interpret it in relation to changes in your production system. It helps you understand performance fluctuations in relation to the many variables affecting pig performance and enables you to intervene in real time before a problem becomes severe. The ADG data that was illustrated in this article was captured using one of the almost 100 IoT PigScales that we have in nurseries and grower/ finisher barns across the country.

References:

Rojas, O. J., and H. H. Stein. "Effects of reducing the particle size of corn grain on the concentration of digestible and metabolizable energy and on the digestibility of energy and nutrients in corn grain fed to growing pigs." Livestock Science 181 (2015): 187-193.

Rojas, O. J., Y. Liu, and H. H. Stein. "Effects of particle size of yellow dent corn on physical characteristics of diets and growth performance and carcass characteristics of growing–finishing pigs." Journal of Animal Science 94.2 (2016): 619-628.

Koo, Bonjin, and Charles Martin Nyachoti. "Effect of oat particle size on energy and nutrient utilization in growing pigs." Journal of Animal Science 99.5 (2021) .

Tan, F.P.Y., Wang, L.F., Gao, J., Beltranena, E., Vasanthan, T., and Zijlstra, R.T. “Hindgut fermentation of starch is greater for pulse grains than cereal grains in growing pigs” Journal of Animal Science, 2021, Vol. 99, No. 11, 1–13.

Visit with us at:

Commodity Outlook

by: JP Thibault Business Development Manager

The latest USDA Supply & Demand report from August 12th did confirm what we were all expecting: large and ample US corn/bean 2024-2025 crops. Couple this information with the Hedge Funds being record short on their grain and oil seed positions and you have the perfect storm to drive the prices lower. The solution to low prices is demand. Buyers need to buy, and this is not happening at this point. When will it happen, when prices will be low enough. The cure of low prices is lower prices! As for the meal: supply is a headache, between annual shutdown (ADM), rail on strike/lock-out (CN/CPKS) and Quebec crushing plant also on lock-out, basis values are firm and crushers/resellers are scheduled up weeks ahead.

Join

us

in Welcoming Our New GVF Group of Companies President!

As we approach September 2024, I am reminded that I will be celebrating 33 years of full-time service with Grand Valley Fortifiers and the GVF group of companies. What a wonderful, exciting, challenging, educational and experiential three plus decades it has been! After beginning my career in Human Resources, Marketing and Value Chain Development, it was an honor to become President and Chief Executive Officer (CEO) in April 2006.

Although it is hard for me to believe that 18 years have passed since taking on this role, looking back on these (almost) two decades, it is amazing to consider all that has transpired within the Canadian livestock industry and within the GVF of companies since then. What a privilege it has been to get to know and work alongside of so many progressive livestock producers, ingredient suppliers and professionals across the country who are passionate about the production of meat, milk and eggs to feed Canadians and people around the world!

As the company has continued to grow in size, reach, impact and complexity, and with the ambitious goals that we have set in terms of serving our current and future customers even more innovatively and well while increasing the value we bring to their livestock businesses, we have concluded that it is time to segregate the responsibilities of a President from those of a CEO.

SEPTEMBER

10, 11 & 12, 2024

The farm show is one of our favourite shows of the year and we invite you all to come visit with us at our Grand Valley Fortifiers, Farmers Depot and Direct Source Commodities exhibit space located across from the show office on the corner of 9th Lane and Middle Machinery Mall. Members of our swine team will be ready to answer questions about our Nursery Feeds, sow and finisher nutrition products along with discussing general strategies on profitable and sustainable pork production.

Come and enjoy a smoked chop sample, ice cream and coffee while visiting with us.

WE LOOK FORWARD TO SEEING YOU THERE!

It is within the context of this decision that we are pleased to announce that JD D’Elia is rejoining the GVF group of companies and stepping into the role of President effective August 6th

David Ross and I and the entire team are delighted to have JD rejoin our Senior Leadership Team and take on this significant new role. During his time with us as Chief Financial Officer, JD personified our company’s values, and held the humble strength of character that is becoming of a senior leader at this company.

Ian Ross David Ross

We trust that you will join us in welcoming JD D’Elia back to our GVF family.

If you wish to contact JD for any reason, feel free to email him at: jddelia@grandvalley.com | 519-621-0241 Ext. 2243

Thought of the Day!

“Blessed are the meek, for they shall inherit the earth.” Matthew 5:5

"In popular thinking the term meek implies weakness. The word Jesus used had a different meaning. His picture of meekness is that of a stallion that has been brough into subjection to its master. Whereas it once fought against any attempt to bring it under control, resisting direction with all its strength, now it yields its will to its master. The stallion has lost none of its strength or endurance; it has simply turned these over to the control of the master."

Meekness then, as described in the beatitudes, is strength under control. Re-read the verse above with this deeper understanding of how Jesus is calling us to live.

– An exert from Experiencing God Day by Day by Henry T. & Richard Blackaby

Pigscale: An in-pen scale serving as a management tool to monitor how a group of pigs is growing.