PO Box 726, Cambridge ON, N1R 5W6

1006704

PO Box 726, Cambridge ON, N1R 5W6

1006704

CENTRAL

A PERIODIC NEWSLETTER PRODUCED BY GRAND VALLEY FORTIFIERS

Spring greetings from all of us at Grand Valley Fortifiers. This edition of the Grand Valley Poultry Grist is chock full of technical, yet practical information written by our growing team of Poultry Nutritionists and Specialists, Aline Pereira, Bram Evers, Tanka Khanal and Jan Huisman. This edition of the Grist focuses significantly on the impact of air quality on the health and performance of flocks – the importance of ventilation and ammonia mitigation. Additionally, with 40-60% of undergrade eggs coming from shell cracks, Tanka provides for a nutritional approach to maximize egg shell quality. At Grand Valley Fortifiers, we are blessed to have assembled this team of Poultry experts and most recently have expanded the team to include Joao Ferreira Phd., a poultry and

To ensure that chickens provide quality eggs and meat for consumers and are also profitable for farmers, it is essential that they are healthy. One contributor to overall health is minimal exposure to high levels of ammonia. Therefore, it is important to understand the implications of ammonia on poultry health. Ammonia is a colourless gas that is formed from the microbial decomposition of uric acid eliminated by birds and irritates the mucous membranes. Birds' tracheas (windpipe) are covered with a thin layer of cilia that act as a barrier against the entry of foreign particles, such as viruses and bacteria. These cilia also help move inhaled particles back to the beak, allowing them to be swallowed

swine nutritionist who will soon move to Calgary, working to support our sales and technical support team in Alberta, Saskatchewan, and Montana.

We trust that you will find the articles in this edition of the Grist to be helpful and applicable to your poultry operation. If you have any questions or desire additional information, please do not hesitate to reach out directly to anyone of the authors of these articles. They would each appreciate the opportunity to speak with you. Wishing you a smooth and timely planting season.

Sincerely,

Ian Ross President & CEO, GVF group of companiesand digested or eliminated. However, when the concentration of ammonia reaches 25 ppm - a level imperceptible to the human sense of smell - some of these cilia are paralyzed, preventing the removal of materials from the trachea. When the concentration of ammonia reaches 50 ppm - a level slightly perceptible to the human sense of smell - these cilia are destroyed, leaving the birds vulnerable to a range of respiratory diseases. This includes conditions such as Infectious Bronchitis, as well as other illnesses resulting from the penetration of E. coli bacteria into the respiratory tract, such as aerosaculitis, pneumonia, pleuropneumonia, and pericarditis. In addition, at this level of ammonia, there is an increased risk of secondary infections after vaccination. If the concentration of ammonia in the environment reaches 100 ppm, there is a reduction in the rate of respiration, impairing the physiological processes, like energy metabolism. Continued exposure to 60 – 200 ppm ammonia levels over five weeks can cause conjunctivitis. This disease can be identified with birds moving to darker corners of the barn, eyelids can be swollen and almost closed, eyes will show signs of rubbing, and also a gray cloudy-looking eye (cornea) can be observed.

Ian Ross, President & CEO

David Ross, VP of Customer Advocacy & Experiential Marketing

Tanka Khanal | Aline Pereira | Youngji Rho | Kayla Silva | Adam Totafurno | Drew Woods, Monogastric Nutritionists | Curtis Ebanks, Layout Editor

Source: Cornell University

In addition to facilitating the entry of disease-causing microorganisms and causing conjunctivitis, ammonia, being an irritant gas, increases bird stress. Stressed birds reduce their feed consumption and their immunity is compromised, resulting in impaired development and body weight gain, reduced egg production and quality, and delayed onset of egg production up to 15 days. Studies carried out over the last 20 years have consistently shown that ammonia levels of around 50 ppm lead to weight losses of up to 250 g per bird and an 8% increase in FCR. In addition, high-ammonia environments have toxic effects on organs such as the spleen, liver, brain, and intestines. Usually, no clinical signs are observed, but a decline in performance and egg production will be noticed often.

like to cover some aspects of management and more specifically, ventilation. We anticipate warmer weather, which for most farms makes ventilation easier. However, we may still have some very cool nights, causing temperatures to fluctuate drastically within a 12 hour span.

Before you can smell ammonia, you can feel it in your eyes. If your eyes start burning or watering, this is the first sign of poor air quality. It is often a particularly good indicator, but it is important to note that this only works the first few seconds, as our eyes rapidly get used to it. Often, we think the climate is better in the middle of the barn, but usually it’s remarkably similar throughout and we just do not feel or smell the ammonia anymore. If you are looking for more advanced or constant monitoring, you can use instruments like a portable emission meter, or a probe connected to your barn computer.

Dust is bad for humans and animals alike, but a chicken cannot even cough (more on this later)! When stepping inside a barn you may think that the air quality is fine, and you do not see a lot of dust in the air. An easy test is involves your mobile phone camera and taking a picture using the flash. It will become clear how much dust there really is. Doing this only one time is not too helpful, but if you do it every week, you will be able to compare pictures and hopefully make adjustments that improve the air quality for your birds!

The average emission of ammonia from litter increases as the birds grow, and after the 20th day of life for broilers, the concentration of this gas increases significantly. In the case of birds with compromised gut health, ammonia levels after this age will be even more critical. Gut health disorders that increase water content of manure or any instance of diarrhea will increase ammonia release from the litter.

Although the presence of ammonia in the barn is unavoidable, it is possible to control its levels through litter management, adequate ventilation, and adequate bird density. Adding natural zeolites (clinoptiloite) to the litter helps to retain water and adsorb ammonia from the litter. From a nutritional point of view, the use of mycotoxin inhibitor products in feed, as well as feed additives that improve gut health, are complementary tools for litter and ventilation management. In addition, reducing protein in a diet supplemented with synthetic amino acids is also an auxiliary nutritional strategy.

The combination of a well-balanced diet, litter management, and ventilation is the best strategy for preventing high levels of ammonia in the barn. Always remember that prevention is the best option and the team at Grand Valley Fortifiers are available to help with any aspect of production or nutrition.

When looking at performance in poultry barns, we can identify four main factors that play a role in the performance of the birds:

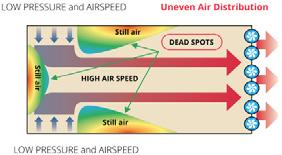

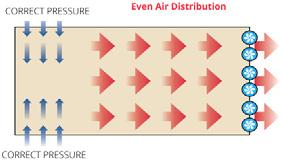

Using a negative pressure ventilation system is the most efficient way to accomplish air distribution for minimum ventilation. The pressure “drop” across the inlets and the amount the inlet is opened should be adjusted to ensure that the incoming air jet “sticks” to the ceiling and drops no sooner than when the fresh air has had enough time to acclimatize. The pressure drop selected will depend on the barn width, how far the incoming air jet must travel once it enters the barn, and the outside temperature (Figure 1). When outside temperatures are below 5 ⁰C (40 ⁰F), the inlet pressure drops, and opening size must be increased. A way to achieve this is to close 50% of the inlets, for example. As a result, the other open inlets, will open twice a much. The ability of the incoming air jet to stay close to the ceiling depends on the temperature differentials between outside and inside the barn. When the inlets are exclusively positioned on the side walls, always use a smoke test to ensure that the incoming air reaches the center of the barn. Smoke tests should only be done when the outside temperatures are significantly colder than inside, and when there is no wind.

When it is cold, many poultry farmers choose to reduce the ventilation level in the barn to keep the barn warm and reduce heating costs. If the ventilation is set too low, this can lead to high ammonia concentrations, higher relative humidity (RH), and an increase of dust in the barn.

Extensive (international) poultry research has been done on the effects of different ammonia levels. Chickens are more sensitive to ammonia than mammals, because they do not have the ability to cough. High concentrations of ammonia lead to excessive mucus formation and cilia damage in the trachea (windpipe), eye inflammation, and E. coli infections. It has also been shown that an ammonia concentration of 50 ppm increases susceptibility to viral infections and can negatively affect resistance to viruses.

Research shows that hens that were exposed to 200 ppm ammonia during the last 17 days in the pullet barn came into production later, had a lower production peak, and a higher mortality rate than the control group1

With breeders and layers, not only is production negatively affected, but also the egg quality. Ammonia levels above 50 ppm leads to problems with feed intake, production, and egg mass decreases after a few weeks.

In the last Grist we covered water. One of the questions we raised was: “Would you drink the same water your birds are drinking?”. Some farmers have taken this principle as a guide for their barns. If this is done, there isn’t usually a need for many other (expensive) tools to see if the water your birds are drinking are suitable or not (of course mineral analysis is advised). In this issue, we would

With heat exchangers, the incoming outside air is heated by the outflowing barn air to an efficiency of up to 80%. The fresh air has a lower RH, which means that this air has a higher moisture absorption capacity (Table 1)

Table1: Benefits and drawbacks of heat exchangers.

Are you looking for more information regarding your poultry, or more specifically, ventilation?

Bram Evers, Poultry Specialist 905-329-6103 | bramevers@grandvalley.com

Jan Huisman, Production Improvement Specialist 226-753-7650 | janhuisman@grandvalley.com

Reference: 1Beware of Ammonia in Cold Weather (gddiergezondheid.nl)

In Canada, the egg consumption per capita has increased by more than 30% over the last decade (2012 to 2022). If we look at 2022, more than 1200 registered egg producers in Canada produced more than 2.32 million dozen of eggs daily on average. Unfortunately, not all eggs produced are of the same quality and undergrade eggs are one of the major problems of the Canadian egg industry.

Graders in Canada categorize eggs in nine different grades: jumbo, extra-large, large, medium, small, peewee, class B, cracks, and rejects. Class B, cracked, and rejected eggs are combined to give total undergrades and account for about 3-5% of total egg production (Figure 1). The cracks contribute a major proportion of undergrades, ranging from 40 to 60% of the total undergrades, followed by rejects and then class B (Figure 2). The cracks and rejects (C+R) contribute more than 80% of total undergrades. Therefore, this article will focus on how to control cracks and rejected eggs through layer nutrition.

Nutrition plays a significant role in controlling cracks and reject eggs. Part I of this series will cover calcium utilization by hens for eggshell quality, which eventually lowers the total undergrades. Calcium utilization will be covered in relation to applying the concepts of limestone particle size distribution, its impact on fractional passage rate of calcium from gizzard to duodenum, calcium digestion and absorption, and vitamin D3 activity on active calcium utilization. Part II of the series will discuss other aspects of nutrition that contribute to eggshell strength.

In general, the limestone particle size is maintained through the specified ratio of fine to coarse limestone. A nutritionist should also focus on distribution pattern of limestone particle size in the given limestone type. Determining the limestone particle size distribution, and adjusting the ratio of fine to coarse limestone accordingly, could give a better ratio of fine to coarse limestone. The particle size distribution will affect the fractional passage rate of calcium from the gizzard to duodenal loop and will significantly affect the calcium utilization from intestine to uterus during active eggshell formation process during the night. Better calcium utilization will impact eggshell thickness, breaking strength, and eventually crack percentage. Limestone particle size is not the only factor influencing calcium utilization. The activity of vitamin D3 must also be considered.

Vitamin D3 is an essential nutrient to optimize calcium (directly) and phosphorous (indirectly) utilization in laying hens. Vitamin D3 improves apparent retention of calcium. Poor eggshell quality and eventually higher undergrades are due to a larger proportion of cracks in the late lay phase, which is a common problem in the Canadian egg industry. Addition of extra vitamin D3 could enhance performance, fix temporary abnormal gait, and enhance eggshell thickness and breaking strength. Now, an important question is “How much of vitamin D3 or activated vitamin D3 (25 hydroxycholecalciferol, 25OHD3) is required to get a better result when there is incidence of poor eggshell quality?” The answer to this question depends on the level of vitamin D3 in the current diets. If vitamin D3 level in the current diet is less than 4000 IU/kg of the complete ration, supplementing an extra 5000 IU/kg (125 µg/kg) of vitamin D3 or activated vitamin D3 for a short period (1.5 -2 weeks) improves performance, eggshell quality, and cracks.

The per capita consumption of eggs by Canadians has increased over the last decade and that trend is continuing. Persistent lay with better grades out is one of challenges of our egg industry and nutrition plays a vital role in reducing poor grading eggs. When considering calcium supply for eggshell quality and undergrade eggs, it is important to consider the distribution of limestone particle size, rather than only the ratio of fine to coarse limestone in formulation. Determining limestone particle size distribution and adjusting the ratio of fine to coarse accordingly could give a better supply of calcium for eggshell formation. Better utilization of calcium through vitamin D3 fortification could also provide better eggshell quality and could significantly prevent structural bone mineral loss. Supplementing extra vitamin D3 or activated vitamin D3 for a short period at regular intervals could be a practical application to improve undergrades.

With today’s technology and the genetic potential of the animals being raised, it may seem that the possibilities to optimize production are endless. However, considering all these opportunities, it can be become difficult to keep an overview of the production on-farm. To be able to support our customers in the best way possible, Grand Valley Fortifiers is building a dedicated technical support team to assist our Livestock Business Consultants where needed. Production Improvement Specialists work together with our colleagues Canadawide to offer technical support to our customers. As a livestock premix and feed supplier, we have a talented team of nutritionists to manage the feeding programs for our customers. But there is more to raising a broiler chicken or a laying hen than high quality nutrition and this is where technical support roles come into play. This team can help with all areas of production, including general technical support, troubleshooting, and training.

In general, looking at the production level at a farm, “there is always room for

improvement” is a saying that is used often. By looking at the whole picture, we try to look for opportunities to improve.

Production can be influenced in many ways, either positively or negatively. Below are a few examples:

Management throughout the production cycle

• Feeding and water systems available

• Farm layout and ventilation systems

• Health status of the flock

A combination of barn visits and data analyses from the feed systems, and/or ventilation systems, can give great insights.

Keeping the overview is key and it needs to be quick and easy to see this whole picture for regular monitoring. This allows farm owners and managers to quickly determine the areas that need more attention and decide with their team how to move forward. At Grand Valley Fortifiers, we can assist with creating this overview, while utilizing the current systems in the barn, and provide timely advice if desired by the customer. Please reach out to your Livestock Business Consultant if you would like to learn more.

Another part of technical support is troubleshooting when there are changes in the production level, either suddenly or as a trend over time. It is not always obvious why the production level changes, and this is where the Grand Valley Fortifiers technical support team can be of assistance. These “fresh set of eyes” can be helpful in determining the cause of the issue. The strategy created to recover production levels is always a customized approach, considering the individual farm. Having a useful overview of your farm’s production is key to understanding what is going on at the farm. However, to improve your production level, having a dedicated team on-farm is the key to success. Given our exposure to many farms across the country, we are in a unique position to see more than one example of a well-running farm. If there are areas of production that you would like to improve, specific on-farm training for staff can be organized in cooperation with the farm owner or manager. This ensures a customized approach, given an individual farm’s production level and what is truly feasible on-farm.

The creation of a technical support team aims to provide our customers with an additional resource to help their businesses be more profitable. A tailored approach to provide a valuable and regular overview, troubleshoot production issues, and offer supplemental training is a step in the right direction. Despite the unique challenges that producers may face, we believe that by working together, we can go further.

Managing all the aspects of running a business can be challenging and managing a feeding program just adds another layer of complexity. What is the name of the feed that you should be ordering? When did you order it last? Did you remember to place the order? At Grand Valley Fortifiers we understand that our customer’s time is limited, and sometimes ordering feed falls off the radar. We also recognize that customers are always looking for ways to keep costs down, while also trying to increase efficiencies on farm. As a result of these realities we are always looking for diverse ways to provide the best customer service experience possible. One way of doing this, is through our proactive ordering services.

Proactive ordering works by keeping track of inventory levels on-farm and ensuring that orders are placed in a timely fashion so the feed bin or feed room,

never run empty. The Grand Valley Customer Service team can take away the worry of ensuring you order product on time, by keeping track of inventory levels for you. By engaging in proactive ordering, our customers can enjoy the advantages of grouping products together and capitalizing on volume discounts based on total tonnage. The more you order at once, the larger the available discount. Both our customers and Grand Valley Fortifiers benefit from proactive ordering as it enables our dispatch team to optimize the routes we send our trucks on, while also ensuring that customers receive nutrition products on time. Although we work hard to provide best in class biosecurity via our GVF trucks and drivers, proactive ordering can limit the number of times a feed truck enters your property – which will help reduce your biosecurity risk. Currently, Grand Valley Fortifiers offers 2 different proactive ordering programs to help take the burden of feed ordering off your plate.

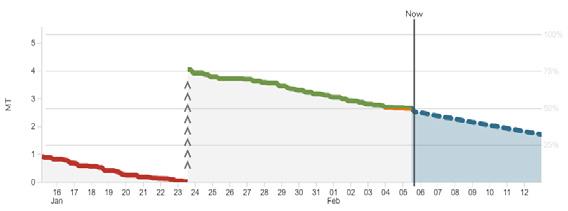

01. Bin sensors: A sensor is mounted within the lid of an outside bin using magnets (no holes), and readings are taken every 4 hours producing a 3D image of the feed in your bin. Feeding rates are calculated based on how much is consumed daily, weekly, and monthly. Based on those rates, a predicted empty date is generated by an algorithm running in the background. The Grand Valley Fortifiers Customer Service team will monitor the bins and arrange for a feed delivery when you are running low. There is no cost for the sensor, so it truly is a win-win for everyone.

02. Reoccurring orders: Do you have a bulk product that is not in a bin? Do you need a certain bag order on a regular schedule? Our reoccurring order program is a good option if you purchase product that falls under either category. The customer service team will set up an order cycle based on a product use rate and will reach out based on when our calculations predict you will need feed. Since we cannot see what is in your bin or feed room, we can adjust the order quantity or delivery date based on your needs. This program is also offered at no cost to the customer.

If you are interested in signing up for one of our proactive order programs or would like more information, please reach out to the customer service team using the contact details below.

Phone: 1-800-567-4400 | Text: 519-239-6859

Email: customerservice@grandvalley.com

We are looking at a vastly different story since the last time. Adverse weather in South America is now an old story, and we are talking about a record crop. To add on top of this, USDA has increased corn and bean yields for the 2023 crop. World corn/bean supply is ample, and demand is low: the perfect mix to get low prices. Also, Hedge Funds have sold their long positions in corn, bean, and meal. There is not a story that the Funds can get behind to cause them to want to go back long. Since mid-November, meal has dropped by 200$CDN/mt and corn by 20$CDN/mt. The meal market is volatile but still has room to go down, do not buy too much in advance.

“God does not give us everything we want, but He does fulfill His promises, leading us along the best and straightest paths to Himself.”

– Dietrich Bonhoeffer