Dairy Grist

CENTRAL & ATLANTIC EDITION

A PERIODIC NEWSLETTER PRODUCED BY GRAND VALLEY FORTIFIERS

VOLUME 25, ISSUE 2 | FALL 2023

Dear Friends,

With the “sudden” arrival of September, dare I say, “Fall Greetings” from all of us at Grand Valley Fortifiers! Since our last Grand Valley Grist, Ontario producers have experienced a very wet and seemingly cooler summer than anticipated. I say “seemingly cooler” because in an excellent article in this edition of the Grist, Adam Parker of Maizex Seeds indicates that as of July 24th, the summer of 2023 has in fact provided more heat units than historical averages in every province in the chart except for Quebec. With first and second cut forages in Ontario being high yielding, but of variable quality, Adam provides some tips and sound advice on how to maximize the yield, the quality and the storage of this year’s corn silage harvest. We are excited to not only announce the addition of Jeff Vandendool and Gennadii Bondarenko to our Ruminant team in Ontario, but also to allow them to show case some of their knowledge and expertise through the articles that they have authoured in this Grist. Both of these gentlemen join our team with great knowledge and experience in various aspects of dairy production. Joining us from the Ukraine, Gennadii comes to the Ontario dairy industry with some very interesting perspectives and experiences having consulted with numerous multi thousand cow dairies around the greater Kiev area. Gennadii, has been amazed at the quality of the forages that Ontario dairy producers harvest and feed and is quickly understanding how Canadian dairy producers are already the most efficient and sustainable producers of milk in the world. We have been privileged to work with Hannah Simpson throughout this summer as she has interned with us and has completed a heifer project with the very applicable and impactful findings described here through a co-authored article with Nutritionists, Kathleen Shore and Sarah Parsons . We have appreciated Hannah’s work with us this summer and wish her very well as she returns to University of Guelph to pursue her Masters of Science under Dr. Katie Wood. We are very much looking forward to visiting with you at Canada’s Outdoor Farm Show on September 12-14. Our outdoor booth is located on the corner of middle machinery mall and 9th line. Be sure to visit with us, and enjoy a coffee, along with a pork and ice cream sample, pull up a chair and catch up!

HEIFER GROWTH – DO OUR HEIFERS MEASURE UP?

by: HANNAH SIMPSON, Summer Intern, SARAH PARSONS & KATHLEEN SHORE, Ruminant Nutritionists

As dairy producers, nutritionists, and sales representatives all know, heifers are the future of the milking herd. Since heifers are the future of any dairy operation, striving for optimal nutrition and management practices to ensure they are reaching their full genetic & milk production potentials should be a primary goal.

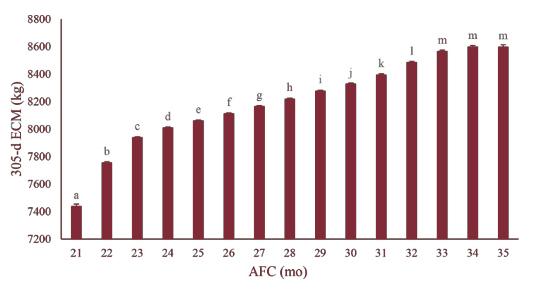

Unfortunately, this is not the case for many farms. We tend to take good care of newborns, but once calves are weaned, we often forget about them until they have entered the milking herd. As the cost of rearing a heifer continues to rise, breeding younger and getting the heifer in the milking herd quicker can become tempting. The evaluation of heifer success has traditionally been tied to reproductive efficiency by chasing the age at first calving, however, this method is not always the most profitable and reduces the animal’s lifetime productivity. This is demonstrated in Figure 1, where 305-d Energy Corrected Milk is shown by age at first calving (months). Calving too early has significant

Sincerely, Ian Ross, President & CEO, GVF group of companies

negative impacts on milk production, however, calving too late can impact your economics, so finding a balance provides you the best of both worlds by focusing on breeding based on weight, rather than age.

Why do we care about heifer growth?

Although heifers begin cycling around 6 months of age, they do not have enough body structure to maintain a healthy pregnancy. To have a successful

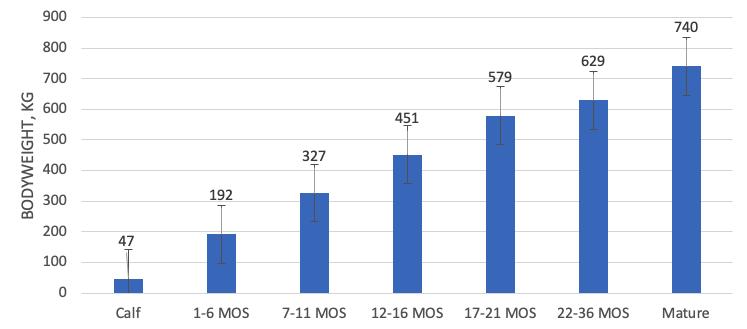

pregnancy in a heifer, and achieve optimal lifetime milk productivity, you need to be breeding after they have reached puberty. Many producers aim to breed their heifers at a certain age, so they can begin their first lactation by 2 years of age and start paying back. Despite a heifer being mature enough to maintain a pregnancy once puberty has been reached (typically 9-11 months), they may be too small, which results in poor performance in both first & future lactations. To set up our heifers for success, producers should aim to breed their heifers when they are at 55% of the herd’s mature cow body weight. Prior to calving, heifers or springers, should weigh in at approximately 85% of the herd’s mature cow body weight in order to achieve their full genetic potential for first lactation milk production.

The size and health status of heifers calving into their first lactation is highly associated with first lactation performance; a heifer that is calving at 85% of her mature body weight will have a far more productive first lactation than a heifer who has calved in smaller.

The next time you go to breed a heifer, remember the following:

1. Heifers who are undersized at first calving will put more energy towards energy intake & GROWTH than to MILK PRODUCTION (Overton, 2010)

2. More milk in first lactation = greater lifetime productivity! (Overton, 2010) *KEY POINT – Do not stunt your future milking herd by breeding heifers too small!

Grand Valley Fortifiers summer 2023 heifer project findings:

Although the importance of good heifer growth on milk production is clear, they are often the forgotten ones or where farms tend to cut corners and costs. Grand Valley Fortifiers wanted to create a database of heifer body weights from calf to calving, to determine if farms are reaching growth goals. Based on 840 weight tape measurements across 13 farms, no two farms had similar results with many not reaching growth targets. Farms were selected based on heifers housed where head locks enabled safe measurement. Not all farms were Grand Valley customers to eliminate bias around feeding programs.

One thing is for sure, heifer success depends on a variety of factors such as genetics, plane of nutrition, and farm management practices. It is difficult to manage something that is not measured and taking the time to measure your heifers body weight at breeding and calving, relative to mature cow body weight, allows areas of opportunity to be identified and management changes to be implemented.

Key Findings:

How does knowing heifer bodyweights affect management?

Now that we have this data there are several takeaways.

• Measuring heifers can be used to improve accuracy of heifer rations to achieve these targets.

» Ration formulation for heifers is driven off body size, average daily gain goal and dry matter intake. Having farm specific inputs allows nutrition to cater to your farm and your heifers.

• You can identify when your heifers are reaching 55% of mature body weight to ensure you are breeding at the right time.

• You can set growth targets and programs to move your herd in the direction you would like. Based off our measurements to get a heifer from calfhood to bred at 14 months means we need to see an average daily gain of 860 g per day.

• Combine barn management: dry environment, access to good nutrition and clean water and a non-competitive group dynamic. This is all a part of the puzzle for getting heifers into the milking herd on

time with maximum efficiency and maximum lifetime productivity.

Your replacements are your future, so it is important to provide good management and nutrition to heifers from the day they are born, to the day they enter the milking herd. We can’t forget, heifers are still growing while also growing a calf and preparing for milk production, and calving them too immature, will result in the animal focusing on growth over production and ultimately impact what they put in your bulk tank.

To see how your heifers measure up reach out to your Grand Valley representative.

SILAGE HARVEST TIMING: BE READY

by: ADAM PARKER, Maizex Seeds

by: ADAM PARKER, Maizex Seeds

The 2023 corn crop season got off to a timely start across the country this spring. This will hopefully allow for a full growing season and provide producers with ideal quality and yield potential for their corn silage. With the timely planting and Corn Heat Units (CHU) accumulation that is above average in many areas so far, harvest is shaping up to be ahead of schedule. This is important given the need to monitor and harvest corn silage at the right maturity.

The most important part of silage harvest is getting the crop in the silo, bag, or bunker at the correct moisture content! When corn silage matures in the early part of the fall, it will dry faster than later in the fall. In the past, we have seen hot, dry days in early September take whole plant moisture content down by over 1% per day.

2023 CHU Accumulation Across Canada

Determining the Correct Silage Moisture for Your Farm

The type of storage is the main factor that determines the ideal moisture content to harvest. Since your storage is already in place, it is easy to match the ideal moisture content to your storage type. The principle on proper silage storage is to pack the silage tight enough to remove as much of the oxygen as possible. This helps reduce the amount of aerobic bacterial growth.

The goal is to begin anaerobic fermentation as quickly as possible. Higher moisture silage will pack tighter; however, too much moisture can cause seepage from the silo. The taller the silo, the larger the bunker pit, and the heavier the packing tractor will all allow you to move to the lower end of these moisture ranges, as the weight of the silage will help compact and displace air pockets. See the chart below to determine your ideal silage moisture content and some guidelines for moisture testing and dry-down.

How to Determine Moisture Content of Your Standing Corn Silage

Milk-line Estimate

The milk-line is a physical line that marks the separation between solid starch and milky starch. It progresses from the top of the kernel at early dent down to the tip of the kernel where it will eventually black layer at maturity. This is a guideline that helps producers estimate whole plant moisture while in the field. There will be some variation on accuracy depending on weather and the individual hybrids. Note that ½ milk-line is approximately 65% moisture. This should only be used as a guideline. Actual sampling to determine moisture content is much more precise.

Chipper Test

This is a great way to get an accurate sample of your whole plant moisture. Take 6–12 representative stalks of corn from your silage field and process them through a woodchipper or silage harvester. Collect the sample and mix thoroughly so that the sample contains a homogenous blend of cob, leaf, and stalk. Use a Koster tester, microwave, or accredited lab to determine the moisture content of the silage. These need to be done prior to harvesting (see

Table 1. GVF Benchmarks based on 13 Ontario Farms 5/13 farms met both the minimum breeding and calving size requirements (38%) 3/13 farms had heifers that were too small at breeding and calving ages (23%) Figure 2. GVF Data across all farms.milk-line targets above) to give an estimate of how long to wait until the corn has reached a desired moisture. For example, if the sample came back at 68% but the producer wants their silage to be 65%, then the corn will reach the desired moisture content approximately six days from the sample being taken (0.5% moisture loss per day on average).

Physical Appearance of the Corn Plants

Generally, the visual appearance of corn plants can provide some indication of moisture content. However, this is very subjective to each individual and varies from year to year. There are many different factors such as hybrid characteristics, leaf diseases, fertility, and environment that can alter the appearance of corn plants. Modern hybrids also have better “stay green” traits that make them appear ‘wetter’ in the fall than they may be. The improved stay green will allow the plant to stay alive longer while starch accumulates in the kernels and the cob moisture content decreases.

Factors Affecting Dry-down in Corn Silage

GSilage-specific hybrids are selected and bred for corn-silage production. Generally, these hybrids will have a slower dry-down curve to allow for a wider harvest window in the fall. This is due to kernel texture and the husk on the cob. Some of these hybrids will have a longer and/or tighter husk, which slows down the grain content dry-down.

Dual-purpose hybrids are generally grain-corn hybrids that have suitable characteristics for silage production. Because these hybrids are selected primarily for grain production, fast dry-down is often sought after. For silage, this can narrow the ideal harvest window, which can prove challenging to target the correct harvest date. Producers using dual-purpose varieties need to be diligent to catch the rapid dry-down curves of these hybrids at the right point.

Hybrid Maturity for Your Area

The dry-down of a corn plant is a physiological process. Today, we have hybrids that range from 1950 CHU to 3300 CHU. It is important to know the maturity of your hybrids and how they will adapt to your area. Matching up maturity with planting date, maturity zone, and expected harvest date will all help you target the ideal moisture for harvesting your silage. Generally, the recommendation is to grow a silage variety that is 150–200 CHU longer than adapted grain corn for the area. If your silage hybrid tends to be close to adapted grain hybrids, you should expect to harvest early in the season. If you have an ultra-long maturity hybrid, you should expect to be toward the end of the season for harvesting.

Fungicides on Corn Silage

When fungicides have been applied to corn-silage fields, this also needs to be considered when evaluating harvest date. Fungicides will tend to keep the corn plants healthier and alive longer, essentially delaying their maturity and dry-down. Side-by-side comparisons of corn treated with/without fungicides will show that treated corn will be approximately 3% wetter on average. During some harvest periods, this may add a week delay in harvest to get to the ideal moisture content.

Weather

As farmers, we are always at the mercy of the weather. The weather that we encounter each harvest season will greatly affect how fast your silage dries down. Hot, dry weather can greatly accelerate dry-down to over 1% loss per day. And cool, wet weather can virtually stall dry-down. On average, we tend to say that corn silage will drop 0.5% moisture per day or 3–4% per week.

Why It is Important to Have the Right Moisture Content

Silage Too Wet Silage Too Dry

Seepage from bunk or silo (loss of nutrients)

Clostridia fermentation

Higher loss of dry matter during fermentation

Sour-smelling feed

Lower yield

Lower feed intake

Lower starch content

Final Thoughts

Not packed enough

Heating during fermentation

Mould and toxin issues

Shorter silage storage life

Higher loss of dry matter during fermentation

Lower fibre digestibility

Lower starch digestibility

It is critical for you to know your ideal moisture content for corn silage— and even more important to harvest at your preferred moisture accordingly. As outlined above, there are several ways to determine the moisture content of your corn silage, with a physical test being the most accurate. Patience and attention to detail at harvest time will pay dividends for you as you feed through the next year.

Sources: are available upon request

JEFF VANDENDOOL Ruminant Specialist, Grand Valley Fortifiers

Robot feed does not always have to be a pellet

As labour challenges continue to grow on farms many producers are beginning to look to robots as a solution. Robots offer an effective way to decrease labour requirements while in many cases increasing production. One of the common downfalls often experienced when transitioning to robots is increased purchased feed cost. This is mostly due to the purchase of pellets fed through the robot to attract the cows to visit. Although it has often been the belief that pellets must be used, with a properly formulated ration producers have other options available. Many farmers have experienced success while feeding mash feed through their robots.

Custom on-farm mashes can be formulated for producers who want to utilize on-farm commodities to save additional cost. One common key to success is ensuring the mash flows through the augers well. It is important to discuss with your GVF Dairy Specialist if your feeding system will be able to handle the robot mash. The best time to consider if you will feed a mash is when you are designing your auger system during construction or renovation. This is the cheapest and easiest time to make minimal changes that allow you to have this option in the future. Another key factor for success is that the feed is palatable. Cows must enjoy the feed they are receiving through the robot to continue to visit the robot. Many farms utilizing mash feeds have experienced an increase in visits as well as refusals. This has allowed some to decrease the amount of mash fed in the robot and feed more concentrates in the PMR at a lower cost. Farmers have been able to decrease kilograms of concentrate fed per 100 kilograms of milk below 10kg. Many farms have achieved feeding rates of 4kg of concentrate or less in freeflow traffic barns with some guided flow barns feeding rates of around 2kg per cow. Producers have now experienced improved robot performance at lower concentrate feeding rates with all types of robots.

Recently I completed a study analyzing 34 robot farms with 21 feeding pellets and 13 feeding a mash. Feeding a mash was correlated with approximately a 1kg increase in the amount of milk produced per cow. Additionally, these farms had the highest income over feed cost averaging $0.75 above farms feeding a pellet. These farms had the lowest cost of concentrate per 100kg of milk produced averaging $0.76 less in concentrate cost for every 100kg of milk produced. Feeding mash also correlated to a 0.15 increase in milking frequency.

When comparing purchased robot mash vs. a pelleted robot feed, switching to a Robolac Mash has saved producers around $40-$50/tonne depending on current commodity pricing. Mash feeds also allow for a larger selection of ingredients that are best for the cow performance, instead of having to consider if the ingredients will pellet properly. Further savings upwards of $100 a tonne can be realized if farmers can mix their own ingredients on farm to create a robot mash. This flexibility allows the ration cost to decrease while still seeing strong performance.

As expenses for farmers continue to rise, feeding a robot mash has allowed many producers to adopt robotic milking without seeing a substantial increase in total ration cost. To learn more about feeding a robot mash and how it can fit into your current feeding program please contact your Grand Valley Fortifiers Dairy Specialist or contact one of our nutritionists at Nutrition Direct.

with GENNADII BONDARENKO Ruminant Nutrition ConsultantQHow can we extend the productive life of our aging/ thinning alfalfa stand?

Fall is a good time to review the current condition of alfalfa fields at the farm, evaluate haylage/hay yields achieved from the fields in the current forage production season and make a proper decision on continuing the use of the alfalfa field in the next growing season or rotating it to another crop.

Industry standards recommend stopping using an alfalfa field when the plant density thins to 60-70 plants per square meter. The reasons for this decision are lower yields and impaired quality of hay/haylage due to the large presence of “opportunistic weeds” in the alfalfa stand.

One option to help extend the productive life of an alfalfa stand, is to interseed winter triticale into the stand in the fall. In 2018 we successfully tested this idea on one of the Ukrainian dairies (1300 cows, 38-39 kg milk) that

I worked with. We had two fields with thin alfalfa on the farm and decided to try interseeding winter triticale on one field and leaving the other as a control. We followed the recommendations out of New York, where agronomists/ producers had previously been doing this practice successfully.

We interseeded with a no-till drill at 90 kg/ha (80 lbs/ac) of triticale at seed depth 3-4 cm (see the photo 1 below).

We interseeded with a no-till drill at 90 kg/ha (80 lbs/ac) of triticale at seed depth 3-4 cm (see the photo 1 below).

If a no-till drill is not available, then some conventional grain drills may work. The best conventional drill for interseeding is a double disc type with a heavy base and high spring tension to achieve adequate penetration into the soil, with a packing wheel on each row unit. If seed depth and soil contact are variable, then increase seed rate to 100-110kg/ha (90-100 lbs/ac) to compensate for reduced catch.

For fertilizer, we applied 23 kg/ha (20 lbs/ac) N and 120 kg/ha (107 lbs/ac) K at planting and 120 kg/ha (107 lbs/ac) of N was applied in the early spring. Although alfalfa does fix nitrogen, it cannot supply the high rates of N needed for triticale growth, so fertilizer with N is essential. Application of potassium should be adjusted to existing soil fertility and typically varies from 60-120 kg/ ha (60-107 lbs/ac).

As a result of interseeding winter triticale, we obtained a nice triticale-alfalfa stand at the time of first cut. Triticale was at the flag leaf stage while alfalfa was at the bud stage (see the photos below).

GVF OFFICIALLY WELCOMES NEW SPECIALISTS TO OUR TEAM!

Grand Valley Fortifiers is excited to announce that Jeff Vandendool joined our Grand Valley Fortifiers ruminant team on May 1st, as a Dairy Support Specialist. In this role, Jeff will be working with and advising a producer base in Oxford County and surrounding areas as well as helping with data analysis for GVF customers that are working with robots or other herd management software.

JEFF VANDENDOOL Ruminant SpecialistJeff was born and raised on his family’s dairy farm where he currently has an active role in managing their high production 2 robot facility. He is a graduate from the University of Guelph with his Bachelor of Food and Agriculture Business. With his excellent work ethic, depth of knowledge of dairy farming, and eagerness to help producers, we are confident Jeff can be an asset to help dairy producers reach their operational goals.

Jeff can be reached at: jeffvandendool@grandvalley.com

|

226-228-2381

We are excited to announce that a new Ruminant Nutrition Consultant, Gennadii Bondarenko Ph.D., has joined ruminant team. Gennadii came to us after leaving the Ukraine with his family, where he obtained his Ph.D. in Agricultural Sciences at the National Agrarian University in Kyiv.

Photo 2 shows almost complete absence of any weeds in the stand. We may say that triticale acted like a biological herbicide and successfully outcompeted so called “opportunistic weeds”, which otherwise would quickly occupy the empty areas in the alfalfa stand.

The control field, not interseeded with triticale, demonstrated quite a different picture at the time of first cut – the weeds occupied a significant portion of that field (Photo 3).

In the Ukraine, Gennadii worked as an independent nutritionist for more than 20 years, where he serviced dairy herds ranging from 5003000+ cows throughout the country. Gennadii also worked with a local university in the Ukraine, to help educate producers and students and has experience with advising starting up dairies in developing nations. Gennadii, his wife Anna and their daughter have recently moved to Cambridge where he will be based to serve dairy producers in Ontario. Gennadii is excited to meet Canadian dairy producers and help advise on reaching their production and profitability goals.

Gennadii can be reached at: gennadiibondarenko@grandvalley.com | 613-806-8218

The difference in visual appearance of these fields was supported by results of haylage analysis. Alfalfa-triticale haylage samples shown 21-22% DM crude protein (CP) and 37-41% NDF with excellent fiber digestibility (58-62% NDFD at 30 hours), while the not interseeded alfalfa-weed haylage was only 1618% DM CP, over 45% NDF with fiber digestibility below 45% NDFD at 30hrs. Interseeding with winter triticale brought to the stand additional digestible fiber from triticale leaves, while maintaining high protein of alfalfa as a legume plant.

With fiber digestibility being the most critical factor that regulates feed intake, forages with lower fiber digestibility have higher content of indigestible fiber (literally saying “wood chips”), and those “wood chips” dramatically limit the amount of forage dry matter that the cow will consume voluntarily, thus reducing achievable milk yield from forages and increasing the amount of purchased feeds in the ration.

In addition to improved quality, we achieved a significant difference in dry matter yields from these two fields. The alfalfa-triticale field produced 4 tonnes DM/ha (1.6 tonnes DM/ac) of haylage at first cut, while alfalfa-weed field made only 2.8 tonnes DM/ha (1.1 tonnes DM/ac).

The achieved results clearly demonstrated that interseeding winter triticale allowed us to successfully extend the productive life of aging/thin alfalfa stand and increase yield and quality of haylage. In addition, this technological approach allowed us to improve the root mass in the soil, increase the carbon sequestration and soil fertility which are additional ecological benefits. When assessing your hay crop fields this fall, interseeding winter triticale into your aging alfalfa stands could be an excellent opportunity for you.

GVF Dairy team expands to welcome Sarah Parsons, PhD as a Ruminant Nutritionist. Sarah Parsons is a graduate from the University of Guelph where she studied “Management and Nutritional Factors that Influence Weaning Success in Dairy Calves” with Trevor DeVries. Sarah is no stranger to the industry having worked with producers improving calf health and management on farm for the past couple of years after graduation. Sarah’s love of cows and passion for science make her a wonderful addition to our Nutrition team. She is based out of Cambridge and will be available to visit farms for troubleshooting. Please help us welcome Sarah and feel free to reach out to her in her new role.

Sarah can be reached at: sarahparsons@grandvalley.com