When mechanical strength and corrosion resistance is vital, you’ve got to double down on quality. Macsteel’s patented Tosa WrapTM has a unique triple part system that provides an inner and outer coating, and seals around welds and other surface irregularities.

Scan the QR code to learn more about how our steel products and services can help drive your business forward

and protection that is more than skin deep.

BRANCHES

Eastern Cape: Branch Contact: Dan Abrahams Company: Aurecon Tel: +27 (0)41 503 3929 Cell: +27 (0) 81 289 1624 Email: Dan.Abraham@aurecongroup.com

Gauteng Branch Lead: Zoe Gebhardt Cell: +27 (0)82 3580876 Email: zoe.gebhardt@gmail.com

KwaZulu-Natal

Chairperson: Lindelani Sibiya Company: Umgeni Water Cell: +27 (0)82 928 1081

Email: lindelani.sibiya@umgeni.co.za

Limpopo

Chairperson: Mpho Chokolo Company: Lepelle Northern Water Cell: +27 (0)72 310 7576 Email: mphoc@lepelle.co.za

Mpumalanga

Chairperson: Lihle Mbatha (Acting) Company: Inkomati-Usuthu Catchment Management Agency Tel: +27 (0)13 753 9000 Email: mbathat@iucma.co.za

Western Cape

Chairperson: Natasia van Binsbergen Company: AL Abbott & Associates Tel: +27 (0)21 448 6340 Cell: +27 (0)83 326 3887 Email: natasia@alabbott.co.za

Namibia Please contact the WISA Head Office at admin@wisa.org.za for more information

Over the past few weeks, Minister Senzo Mchunu of the Department of Water and Sanitation (DWS) has gone on record – both at the WISA Biennial Conference and concerning the Gauteng Level 2 water restrictions – to allay fears and assure citizens that there is no water crisis.

In a little over a year, Minister Mchunu has won the trust and loyalty of much of the water and sanitation sector. He has boundless energy, is possibly the most punctual Minister I have ever come across, and is transparent and brave. His commitment to the sector is obvious. He was courageous in releasing the Green Drop Report, he has been open about the challenges facing the industry, is readily accessible to the media (and hence the public he serves), and has pledged improvements.

A statement such as the following has earned my admiration and respect: “When I joined the DWS last year, most of the leadership positions were ‘acting’. This is not Los Angeles. I have permanently appointed everybody; there is now a fully fledged and fully functional DWS that is grappling with all the challenges and problems thrown its way. At the 2024 WISA Biennial Conference, you will be talking about the improvements made.”

But... we do have a water crisis. Certainly, it is a crisis that can be solved. But we are in a crisis. These statistics can be recited by most water and sanitation professionals by rote:

• Our own national government predicts that water demand will outstrip supply by 2025.

• South Africa is classified as being ‘water short’ and moving towards ‘water stressed’ in global terms. The country’s average annual rainfall is 450 mm compared to the global average of 860 mm. Highly variable rainfall has already led to skewed spatial distribution of water resources (Western Cape versus KwaZulu-Natal).

• South Africans’ average domestic water use is an estimated 237 litres per capita per day. This is 64 litres higher than the international benchmark of 173 litres.

• This high use is partly attributed to high municipal non-revenue water. (An average of 41% compared to the global best practice average of 15%.)

• The National Water and Sanitation Master Plan has indicated that a funding gap of R33.3 billion a year over the next 10 years must be reduced.

Obviously, I am a stickler when it comes to words – I work with them all day. But using the phrase ‘water crisis’ is the responsible thing to do. A crisis demands immediate action. A crisis is taken seriously. While the water industry works tirelessly to resolve this crisis, I observe tennis courts being hosed down with potable water, gardens watered during the midday heat, and large swimming pools constantly topped up, with little thought given to rainwater harvesting, groundwater or reuse. We have a water crisis, and it us only until the general public believes this that it can be resolved.

“Once complete, the Coegakop WTW will be the largest biofiltration plant of its kind in South Africa, and possibly the most ambitious biological manganese removal plant in the world (treating high concentrations up to 2.5 mg/ ℓ).”

Dr Matthew Hills, civil engineer: Water & Sanitation Subdirectorate, Nelson Mandela Bay Municipality

“Continuing to use the sewer system is the same as using MS-DOS, but not by choice. We need to drastically shift our thinking and paradigm if we hope to solve the sanitation problem in this lifetime, let alone by 2030. Over the past decade, the only visible solution implemented at scale is the ventilated pit latrine. There is an underlying equity issue at play – the idea that poor people don’t deserve something better because they should be grateful for anything.” Jennifer Williams, executive director, Faecal Sludge Management Alliance

“Market acceptance of nonsewered sanitation systems is driven by SANS 30500 certified products, and SANS 30500 certification will likely only happen once there is a large volume of technologies that are certification ready.”

Dr Preyan Arumugam-Nanoolal, research scientist: Water, Sanitation & Hygiene Research & Development Centre, University of KwaZulu-Natal

“Access to safe sanitation is a growing challenge in informal settlements, where its occupants use ablution blocks, chemical toilets, ventilated improved pit latrines or unimproved pit latrines. With more than 2 700 informal settlements in South Africa and approximately 13% of its population living there, corporates can allocate their CSI towards providing better sanitation solutions (and thereby providing dignity) to needy communities.”

Philip Majeke, commercialisation manager, SASTEP“I believe that the majority of toilets on the market are designed for perfect conditions and are not suited to South African conditions. Toilets are chosen based on their appearance, with little regard to their efficiency and maintenance requirements. Toilets need to be designed as simply as possible. The most basic flushing mechanism often uses the least water and is cheaper to maintain.”

Gerrie Brink, founder,AQUAffection

“Currently, there is a lack of regulatory framework that provides guidance on how to assess and treat sludges, particularly in the case of faecal sludge from on-site sanitation facilities. There are no regulations that provide parameters about how to deal with the different types of product derived from sludge. There is a need to stimulate business interest in sewage and faecal sludge. We must unlock and maximise the potential of sludge as an alternative resource for use.”

“There is a promising future for biogas technology. Suppliers of the engines, boilers and CHPs are progressively manufacturing more efficient, cost-effective equipment and, as a result, the technology is becoming more accessible and the entire biogas process is constantly improving. There are huge incentives for biogas in the European market, where CO2 is removed from biogas; the methane can even be pumped directly into the national gas grid for compensation. However, load-shedding, rising energy costs, limited landfill space and pressure to reduce carbon emissions are still clear drivers for the South African market.”

Rosan

van Wyngaard, tender manager, Veolia Services Southern Africa

“South Africa is not alone in experiencing water challenges: from the record-breaking drought that caused some rivers in China to dry up, affecting hydropower and shipping, to the dire conditions in the USA’s Colorado River Basin dropping to record low levels, and the severe flooding in Pakistan affecting 33 million people. These events – coupled with climate change – put a spotlight on the value of water for nature and climate change.”

Oudi

Oudi

Kgomongwe, member, Young Scientific Programme Committee, World Water Week 2022

“While fixing leaks and using alternative water sources (like boreholes and desalination plants) to augment Nelson Mandela Bay’s existing supply will contribute towards improving its water security, reducing water consumption is key. We are faced with a complexity of reducing water consumption in a city with a growing population; however, our calculations show that reducing consumption to 230 Mℓ/day would alleviate significant pressure on our water supply system.” Lyle Francis, deputy director: Water Demand Management, Nelson Mandela Bay Municipality

“There is still a lack of urgency around addressing water issues. There are clear signs that investors and markets agree on. Perhaps the most telling example is the performance of the S&P Global Water Index. This index tracks water-sector companies (water utilities, infrastructure, equipment and materials) from around the world. Since 2001, it has outperformed the S&P Global Broad Market Index by more than three percentage points annually; this year, that figure is already at 5%.” Chetan Mistry, strategy and marketing manager, Xylem Africa

What a joy to witness the happy faces and heartfelt reunions.

As a sector, we have come through the Covid-19 pandemic, perhaps a little battered and bruised, but we have survived. For many, it has been four long years (since our last inperson conference) since people have physically seen each other.

It is obvious that the water and sanitation sector is like a family – and like a family, there are times when we agree or disagree with each other. Sometimes, there may be absent members; at times, we may not speak to each other for a while; but, at all times, we pull together when needed and support each other, working towards a common cause. The passion between everyone and the industry they work in was obvious.

This family was relieved and energised that leadership was present in the form of the Department of

Water and Sanitation’s Minister Senzo Mchunu and Director-General Sean Philips. Our leaders were transparent, fully acknowledging the difficulties we face and plotting a way forward. There was a commitment to make improvements. WISA looks forward to this leadership filtering down to the various entities within the sector.

I was pleased to see an increase in presentations and workshops around the social science of water and sanitation. Water and sanitation is mostly a social enterprise, requiring dozens to thousands of people working together to build, operate and maintain a complex technical system, often under changing conditions.

There were presentations highlighting how our work deeply affects able-bodied persons and is often a life and death situation for disabled persons. It again highlighted how a lack of water and sanitation will always have a greater

impact on the most vulnerable than anyone else.

When presenting awards at the Gala Event, it was clear to me that the water and sanitation sector deeply cares about its own people and about the public. As a sector, we willingly and proudly carry the responsibility, providing water and sanitation services that are essential for human health and well-being, economic development and the realisation of the constitutional rights of all South Africans. There was a lot of emotion from the award winners.

The water and sanitation sector puts the community first. We have committed leadership, inspired professionals, and I look forward to seeing many papers showcasing the successes and positive change taking place over the next two years at the WISA 2024 Biennial Conference.

After attending the IWA event in Copenhagen, Denmark, as well as the WISA Biennial Conference and IMESA Conference in Johannesburg, it was the dialogue with people from all spheres of government and the private sector that provided enormous value.

By Dan Naidoo, chairman, WISA

By Dan Naidoo, chairman, WISA

Individually we are one drop, but together, we are an ocean.” –

Ryunosuke Satoro (Japanese writer)

We have a better chance of solving water and sanitation issues by intentionally creating working relationships and partnerships with each other; we need to pool our resources together. By collaborating with different institutions, government divisions and private companies, we encourage a broader method of thinking that results in creative solutions to complex water and sanitation challenges.

The water crisis will never be solved by a single engineering discipline or science subject area – we need a multitude of experts with extensive experience in many different fields to tackle these problems. There can only be

knowledge sharing when we begin to appreciate all disciplines and sciences. There are many important aspects of municipal engineering that have a direct bearing on water and sanitation (e.g. pavements and their role with stormwater management).

All professionals and institutions need to band together as members that care for the built environment and work together – this is in the best interest of the communities they serve. There are many synergies and overlaps between institutions that we need to explore.

As professionals in the infrastructure sector, we all share concerns regarding corruption, funding and skills development; we would be more successful if we lobby together.

South Africa could learn from the US, where, through lobbying, President Biden signed a US$1 trillion (R18 trillion) bipartisan infrastructure plan into law, the majority of which was allocated towards water and sanitation. Everyone within the infrastructure sector needs to speak with one voice and lobby for a better South Africa together. I am calling on professional bodies to meet more frequently, support each other, find

ways that we can all collectively add value to our members, and create a united front when lobbying government.

South Africa has a wealth of talented scientists and engineers, as well as a plethora of papers and research on all aspects of water and sanitation. As an industry, as associations, we have an obligation to give this knowledge and research a platform, to share it and take it seriously.

There needs to be a focus on talking to different people, to welcome new people, industries and expertise into to the water and sanitation sector. We cannot solve this crisis on our own. These conferences have brought people together and I hope, in the next few months, we continue with this momentum.

‘Choc-a-block’ is a maritime phrase referencing the placement of wooden wedges to secure moving objects on the decks of ships. But it’s also a term that perfectly describes the packed conference programme, busy exhibition hall and a large influx of delegates at the WISA 2022 Biennial Conference.

The water and sanitation sector arrived in full force at the Sandton Convention Centre to attend WISA’s first in-person conference in four years. There were handshakes, hugs, coffee catch-ups, dancing, spirited debates, new introductions and a lot of knowledge exchange.

It was a place where both the public and private sector came together to discuss South Africa’s water and sanitation problems and plot the way forward (#NavigatingTheCourse).

This year, it was a hybrid event, where the conference presentations could be witnessed in person or online, and all delegates have the opportunity to view any presentations that they may have missed on wisa2022.co.za.

The previous WISA Biennial Conference in 2020 was held virtually due the Covid-19 pandemic. While the world battled a health storm, the 2020 conference called for #AllHandsOnDeck, where the focus was to ‘keep the ship afloat’.

For this conference, the nautical theme was kept and #NavigatingTheCourse was adopted. “As a water sector, we find ourselves off-course when measured by the lived experience of our passengers – both the residents of Southern Africa and the economic activities that support them. It is our responsibility to correct this. We need to evaluate where we have been, where we are and where we want to get to,” says Achim Wurster, organising committee chair, WISA 2022.

The programme had seven sub-themes: 1. Don’t abandon ship: Leave no-one behind – reach SGD 6, listen to our customers’ needs and those of

vulnerable communities that are unserved.

2. Rock the boat: Rethink sanitation in a circular economy – reuse, resource and energy recovery, off-grid solutions and Reinvent the Toilet.

3. Run a tight ship: Improve water-use efficiency and demand management across all sectors of water users – mining, agriculture, industry and municipal.

4. Batten down the hatches: Respond to climate change.

5. Learn the ropes: Harness the technologies of the Fourth Industrial Revolution.

6. Matters ashore: Address environmental water quality and sustainable groundwater issues.

7. Stem the tide: Management and regulatory issues – Blue and Green Drop, professionalisation of the sector, address skills shortages, manage stakeholders effectively, and develop capable institutions.

The sold-out gala dinner was a glamorous, glittering event where WISA handed out a number of awards.

Honorary membership is the highest award bestowed by WISA and is awarded to exceptional water sector professionals in recognition of their outstanding contribution to WISA and/or the water sector and society in general.

Congratulations

This award is presented by the WISA Board to recognise those who have materially contributed to the success and esteem of WISA. The award is handed out to a WISA Participation Structure and an individual.

Participation Structure: Western Cape Branch

Winner – Mbongiseni Dlamini: ‘Enhanced synergistic adsorption and biocatalytic degradation of diclofenac by fungal laccase immobilized on zeolitic imidazolate frameworks’. Presented by Dr Sarah Slabbert (far left) and Dr Lester Goldman (far right)

Winners – Leshego Mulaba and Elke Mugova: ‘Predicting the water quality in flooded underground mines – new insights about the first flush’. Presented by Dr Lester Goldman (far left) and Professor Christian Wolkersdorfer (far right)

First Runner Up – Jessica Fell: ‘Evaluating the multi-functional potential of stormwater ponds: planning support for a Water Sensitive City transition in Cape Town, South Africa’. Presented by Dr Sarah Slabbert (far left) and Dr Lester Goldman (far right)

Second Runner Up – Larona Malope: ‘Investigation of thermodynamic properties and sorption isotherms to determine the moisture boundness on faecal sludge from different onsite sanitation technologies’

2nd Place – Kagiso More: ‘Application of a hybrid neural network model to forecast mining influenced water parameters’. Presented by Dr Lester Goldman (left) and Professor Christian Wolkersdorfer (right)

3rd Place – Tumelo Monty Mogashane: ‘Treatment of acid mine drainage with ROC process for the recovery of drinking water and saleable products’

The conference provided an opportunity for several of the new 2022-2024 committee members to meet in person for the first time and served as a space for many young professionals to connect, gain exposure to the sector and share their work via many presentations. Opportunities for community building and strengthening ties through formal and informal connections are vital to YWP as we empower young professionals to navigate and grow in the sector.

YWP-ZA (South African Young Water Professionals) is one of the many International Water Association (IWA) YWP chapters from all over the world. Several Young Water Professionals Denmark (YWP-DK) committee members also joined the conference, where both YWP-ZA and YWP-DK co-hosted an interactive workshop titled ‘Megatrends and workforce of tomorrow: Young Water Professionals at the forefront’. This was a continuation of a similar workshop that occurred at the IWA World Water Congress & Exhibition. The workshop identified gaps and provided insights to young professionals on the skillsets needed

issues from urbanisation to big data to cybersecurity.

Additionally, the two chapters had a dialogue on high-level water challenges and solutions, facilitated by the Danish embassy in South Africa with Jørgen Erik Larsen (Danish Growth Advisor in the Strategic Sector Cooperation Programme). The discussion covered the respective water challenges facing the two countries, with a South African perspective on socio-economic issues and political, governance and resource constraints and a Danish focus on water quality and pollutant concerns, and partnerships with industry. The meeting of YWP-ZA and YWP-DK at the WISA 2022 Conference and IWA marks an exciting collaboration between the chapters.

new Water Research Commission CEO, Dr Jennifer Molwantwa, a truly inspiring woman in water. Her genuine passion for youth in the sector shone through during the meeting – the committee was thrilled to find out that she was one of the first members of YWP-ZA in 2008. There are exciting areas for potential collaboration between the two organisations such as YWP-ZA linking with the WRC graduate programme, supporting women in STEM and building science communication capacity among young professionals.

A meeting was similarly had with WISA CEO Dr Lester Goldman and other head office staff who will be working together to grow YWP-ZA and WISA. Ahead of Wetskills in early 2023 in Cape Town, YWP-ZA met with Wetskills

managing

YWP-ZA was delighted to be a part of WISA 2022 as the water sector came together again in person following the Covid-19 hiatus.Jessica Fell received the First Runner Up Award for Best Student Presentation Soft skills for women in water workshop

director Johan Oost to explore a partnership and ways to include young professionals. The Wetskills Water Challenge brings together multidisciplinary and international teams to work on real-life cases from companies and governmental organisations. There are collaboration opportunities through YWP-ZA, which supports participants and case study owners, and has a presence throughout the challenge.

Local YWPs were involved with a number of oral and poster presentations and hosted a variety of workshops. Some highlights were:

• Eugene Fotso Simo (national coordination lead) presenting on his Zutari work titled ‘Flexibility in the face of project constraints - A case study of Moorreesburg WWTW’.

• Craig Tinashe Tanyanyiwa (national finance lead) presenting on his University of Cape Town (UCT) PhD ‘Towards urban MAR in Cape Town's retrofitted multifunctional stormwater ponds’.

• Jessica Fell (national marketing lead) presenting her UCT PhD ‘Evaluating the multi-functional potential of stormwater ponds: planning support for a Water Sensitive City transition in Cape Town, South Africa’, for which she received First Runner Up for Best Student Presentation.

• Ashton Mpofu (outgoing national lead) – together with YWP committee members Sibusiso Mhlongo, Nontando Vungwana, Thulani Mlilwani – hosted a workshop on ‘Time value of money and beyond: Promoting SMMEs through timely payment by utilities’. The workshop was mainly attended by representatives from the private sector (SMMEs), and government departments including water service authorities and water boards. The workshop presented the procurement processes, typical reasons for delays, and solutions to improving the payment of SMMEs by government. On top of the list of solutions was raising awareness and educating SMMEs about the procurement processes, how to avoid bottlenecks and eliminating the human impact in the process and delaying authorisations by embracing digitalisation.

Mbali Sibiya, outgoing transformation lead, YWP-ZA, facilitated a workshop titled ‘Water Treatment Quality: A works perspective’, which was held in collaboration with Universal Water Solutions and the WISA Process Controllers Division. The workshop aimed to highlight water quality issues that are experienced in a day’s work in a water treatment works and how these problems are identified and solved. It also aimed to increase awareness in water and wastewater quality standards and guidelines, as well as promote a positive response to water and wastewater quality incidents as outlined in the incident management protocol.

Furthermore, the workshop can be used as a tool to inform trainees and graduates of the water and wastewater quality objectives and how these objectives are met in any water and wastewater treatment works.

Attended by engineers, process controllers, water utility staff, people working in supply chain management and finance, as well as graduate recruitment and private businesses, the workshop was interactive and there was a lot of sharing of information related to the troubleshooting, operation, optimisation and monitoring of water treatment works.

Sibiya also facilitated a workshop titled ‘Soft skills for women in the water sector’. The workshop sought to identify the skills that

women in the water sector needed the most in order to succeed and be visible.

The WISA 2022 Conference provided a space for new connections to be forged, old friends and colleagues to meet, pressing water challenges to be discussed and for YWP-ZA to move forward strengthened. Five female leaders in the water sector facilitated discussions on transformational leadership, women and networking, emotional intelligence, women and finance, and the road travelled by young female professionals withing the sector:

• Dr Jennifer Molwantwa (CEO of the WRC) spoke on transformational leadership, where she shared her own journey and insights, and encouraged women to become transformational leaders that motivate, inspire and transform people. She called on women to be part of the vision of a sustainable water sector by being active and involved.

• Sheila de Carvalho (board chairperson at PLAMA and director: Leading Markets, Royal HaskoningDHV) spoke on women and networking, highlighting the importance of networking in the water sector. She shared her personal growth and development in the sector and encouraged networking.

• Silindile Mtshali (process and quality manager, Umgeni Water) spoke about emotional intelligence and the role that a high EQ plays in ensuring success for female leaders in the water space. She highlighted that women are by nature emotional creatures and this is not a bad thing; it can be used positively to enhance one’s leadership. She also encouraged the participants to be self-aware and empathetic, facilitating an interactive session where participants were able to apply themselves to different scenarios.

• Mendy Shozi (founder and president, South African Youth Parliament for Water) gave her own insights on how

meeting of YWP-ZA and YWP-DK marks an exciting

the sector can be improved to be more inclusive and accommodating to young professionals, in particular women.

• Daya (COO, Universal Water Solutions) closed the session by discussing finance and imparting ways in which women can become financially smart and how to use this skill to grow and develop in the sector. Daya shared her journey in the corporate industry and how that lead her to be a co-founder of her business Universal Water

Solutions, as well as the challenges and successes of being a female water entrepreneur. She encouraged women to be risk takers and use all the skills gained from the workshop – from leadership skills to networking and emotional intelligence – to actualise the ideas they have in mind and become problem solvers in the sector. She encouraged women to “adjust the money mindset” and start looking at water as a source of income.

WISA’s

By Wendy Mey, lead: Innovations for Water Supply and Sanitation Division, WISA

By Wendy Mey, lead: Innovations for Water Supply and Sanitation Division, WISA

South African cities and towns are increasingly pressured to become smarter. For urban areas challenged by water management issues, smart water metering can help to monitor consumption more effectively, reduce leaks, forecast demand and plan for future usage. The cost of implementing smart water metering is usually a one-time cost: once installed, the devices do not need much maintenance, possess a long battery life and are extremely durable.

eThekwini has an extensive water network with roughly of 500 000 installed water meters that are manually read monthly. There are roughly 3 000 zonal meters that represent large sections of the network and around 70 custody transfer meters that represent the full purchase of water for the system. Thus, the initial outlay to transition the eThekwini water network to a smart system based on commercially

available smart water metering devices is exorbitant. Since the water network is expanding, the only way to reduce the implementation cost is to find a way to reduce the price of the smart water metering device.

Learning exchange and hackathon WISA’s Innovation for Water Supply and Sanitation Division, in partnership with eThekwini Municipality, hosted a learning exchange and hackathon at the Durban Botanic Gardens Conference Centre. This event provided a platform to enhance participants’ competence on design thinking and also enabled stakeholders to share ideas on developing a low-cost device with real-time monitoring and data transmission capabilities that can be attached to existing bulk and consumer meters.

Various industry leaders shared experience and knowledge at the event and provided guidance to hackathon participants.

Day 1 of the two-day workshop covered the empathy and synthesis phases of the design process. Day 2 of the event moved on to the ideation and prototyping phases of the design and thinking process.

Keep a lookout on the WISA website and communications for updates on the prototyping and implementation of the low-cost smart water metering device.

The prototyping and development of the device is powered by an EU-funded water operators’ partnership programme managed through UN Habitat’s Global Water Operators’ Partnership Alliance. One of these partnerships was recently established between eThekwini Water and Sanitation in Durban, Hamburg Wasser in Germany and additional partners.

The design of the device developed by the project will be available to other municipalities globally.

Innovation for Water Supply & Sanitation Division hosted a learning exchange and hackathon to address water management challenges through the design, construction and testing of low-cost smart devices that are compatible with existing water meters.

The Coegakop Biofiltration Plant is nearing completion and is designed to treat groundwater rich in dissolved iron and manganese. The plant is designed with a capacity to treat up to 20 Mℓ/day of potable water for Nelson Mandela Bay Municipality (NMBM).

By Kirsten Kelly

By Kirsten Kelly

This is the fourth and final phase of the Coegakop Wellfield project – part of the NMBM Water Master Plan to augment municipal water supply. “Groundwater is being used in the fight against the worst drought in Nelson Mandela Bay’s recorded history. NMBM conducted groundwater investigations during the 2010/11 Eastern Cape drought, and it was found that some properties owned by NMBM had a high groundwater potential. One of the most favourable areas for developing a wellfield was

located at the foot of Coegakop. The wellfield site was therefore named the Coegakop Wellfield,” says Matthew Hills, civil engineer: Water & Sanitation Subdirectorate, NMBM.

Co-funding received in the form of the Municipal Disaster Grant and Municipal Disaster Recovery Grant was essential to getting this project off the ground.

Following an exploration phase in 2014, a decision was taken during 2015 to develop the groundwater resources by drilling five production boreholes in the Coegakop Wellfield.

“The production boreholes themselves are unique for a municipal drinking water supply scheme as they are large-diameter boreholes (300 mm), quite deep (250-300 m) and are artesian

– meaning the water can flow from the boreholes on their own pressure,” explains Kosie Smit, principal engineer, Zutari.

The borehole water from the wellfield is of good quality but contains elevated concentrations of dissolved iron and manganese. The Coegakop Water Treatment Works (WTW) was therefore designed and built to produce water that complies with the water quality requirements of SANS 241:2015 ‘Drinking water’.

Biofiltration Biofiltration refers to the process whereby organic bacteria grown in the filter beds aid in the removal of dissolved minerals.

FIGURE 1 The implementation of the Coegakop Wellfield’s development was split into four phases to accommodate the work requirements and budget limitations

“The Coegakop WTW uses biofiltration technology because it is an affordable, efficient, sustainable and reliable treatment solution with low maintenance costs. The normal filtration process requires the use of more chemicals, so this approach reduces our operational cost and is also better for the environment,” explains Hills.

One Groundwater source identification 2010 - 2013 R11 500 000 R0 Complete

Two Drilling of exploration and probe boreholes 2013 - 2015 R23 000 000 R0 Complete

Three Drilling of production boreholes and pipelines 2015 - 2018 R55 500 000 MDG R19 998 483.85 Complete

Four Construction of treatment works 2017 - 2023 R309 700 000 MDRG R23 444 064.63 Construction

TOTAL R399 700 000 R43 432 548

Preekstoel Plant in Hermanus is the only other filtration plant of this kind in the country, but it treats 10 Mℓ/ day, as opposed to the 20 Mℓ/day treatment capacity of the Coegakop WTW. Once complete, the Coegakop

WTW will be the largest biofiltration plant of its kind in South Africa, and possibly the most ambitious biological manganese removal plant in the world (treating high concentrations up to 2.5 mg/ℓ).

Hills adds that the cost per kilolitre of water is less than other treated water within NMBM because it is being sourced straight out of the ground. “The numbers still need to be verified. However, once the plant is fully operational, NMBM is confident that Coegakop will supply the lowest cost per kilolitre of water within the NMBM water supply system. Aside from the iron and manganese elements, the water is pristine and characterised by low levels of salinity.”

Besides the water purification, there are no additional bulk transfer costs, since the treated water goes straight to the existing Coegakop reservoir approximately 650 m away. From there, distribution pipelines supply Motherwell, the Coega SEZ and an expanding consumer zone.

“Having a second source of water supplying the Coega SEZ is essential for investor confidence and will unlock the potential for further development and job creation,” says Hills.

The proposed treatment process primarily involves biological oxidation and filtration of iron and manganese, as well as the stabilisation and disinfection of groundwater from the Coegakop Wellfield.

Groundwater initially enters the works at the raw water inlet chamber where pH and oxygen levels are adjusted before the water is distributed to the sand filters.

There is a two-stage biofiltration treatment process removing iron and then manganese. The iron and manganese in the groundwater is initially in a dissolved state and cannot be removed by conventional filtration alone. Inside the filters are dedicated strains of bacteria that are cultivated to facilitate the oxidation of iron and manganese. Solid precipitate particles are formed and then filtered out.

The filtrate then flows by gravity through a packed limestone bed, stabilising the pH levels. From there, it moves into a treated water storage tank. A residual dose of chlorine (as calcium hypochlorite) is added into the treated water storage tank, controlled by a chip-feeder dosing system. This is done to protect water against downstream contamination. The treated water is then pumped to the Coegakop reservoir for distribution to NMBM communities.

The filters are backwashed with a combined water/air-scour system, drawing water from the manganese filtrate tank, and supplying air from dedicated backwash blowers. The spent

backwash water is fed to backwash water recovery ponds where the solid residue settles, and the supernatant is pumped back to the head of the works. Settled solids are allowed to dry over time and are periodically removed for disposal off-site.

This treatment process relies on interstage filter feed pumps, backwash pumps, backwash blowers and treated water high-lift pumps.

Automated control and instrumentation systems will ensure that the treatment process operates effectively and that the process controllers can monitor all activities centrally. Automated reporting will be generated, assisting with compliance reporting. This is primarily done through a Scada system.

“NMBM is refining its ability to operate plants remotely as well as record, view and manage data. With the drought, the balance between water demand versus available supply is precarious and we need to react rapidly to any changes within this system. Adopting a modern Scada system is a huge step in the right direction towards achieving an optimised, efficient and reliable water supply system,” explains Hills.

The fourth phase of the Coegakop Wellfield project was co-funded by National Treasury through CoGTA as Municipal Disaster Recovery Grant funding, with the metro supplying the balance through the Urban Settlement Development Grant. NMBM appointed Zutari to provide professional engineering services for planning, design, procurement documentation and construction administration for the project. The Stefanutti Stocks/PCI Consortium was later appointed as the main contractor. PCI Africa is responsible for the mechanical, electrical, control and instrumentation component, with Stefanutti Stocks responsible for the civil construction of the integrated process control and administration building, as well as all related concrete structures. Externally, that includes the construction of the settling ponds. Provision was made for the appointment of 100 emerging micro enterprises to the value of R65 million. In addition, employment opportunities were created for local unskilled and semi-skilled labour drawn from the nearby communities. “The project is scheduled to be completed in January 2023. Before issuing practical completion, NMBM must receive operation and maintenance manuals and there will be a trial operation period for 28 days to ensure that the plant is running efficiently and reliably,” says Hills.

The contract commenced at the beginning of the Covid-19 pandemic – 20 March 2020 and Stefanutti Stocks mobilised on-site on 5 June 2020. “Apart from the short-term impacts like the added difficulty of accessing the sites, as well as the added health and safety protocols, Covid-19 (and the Russia/Ukraine war) have created disruptions in global supply chains, that in turn have caused project delays,” explains Hills.

There has been a global chip shortage, resulting in exceptionally long lead times for equipment like variable-speed drives, flow meters and programmable logic controllers. Worldwide shipping delays caused by military action in the Black Sea and port closures due to Covid-19 have also delayed the delivery of specialised equipment like valves, specialised pipes, pumps and motors.

In terms of pricing, the cost of steel has more than doubled over the project’s time frame. The rise in fuel and crude oil has elevated PVC production costs and negatively affected the availability of raw materials. Transport costs have increased, and the rand weakened against the dollar, resulting in greater costs for imported materials.

“Despite the above challenges, the entire project team has worked tirelessly and in a collaborative manner to mitigate the effects of these delays thereby ensuring that this critical drought mitigation project comes online as soon as possible,” ends Hills.

He adds that digitising an entire water supply system (let alone a WTW) is a lengthy process. “Local support is a key factor. We selected a supplier that has a large local footprint and has resources available in Gqeberha. It was also important that open-source protocol communication be employed, as NMBM did not want to be locked into a single service provider through proprietary software. The use of a gateway manager as opposed to an APN fixed IP solution

gave further control of the Scada network to NMBM. Because of this opensource focus, NMBM is able to modify the Scada system as necessary and is not fully reliant on a third party.

It is essential to have a very clear idea of what one needs and to consider aspects like the type of hardware, security, graphic user interface, alarms, signal tag naming and licensing, but more importantly to have this well documented in a functional design

specification for including within future tender documents. From there, third-party system integrators can be appointed to add to the Scada system within a given scope. Taking ownership of the Scada system is central to digitising your network. Additionally, there must be a designated person to drive the process as well as interact and coordinate between network engineers, hardware and software suppliers, the IT department, and system integrators.

Currently, NMBM is focused on creating interconnectivity between all components of its water and sanitation system, such as boreholes, reservoirs, surface water sources, treatment works, flow meters and pump stations. It is not efficient to constantly send people out to inspect parts of our system when it can be done remotely.

NMBM is using technology to protect its groundwater. “This is a precious resource and we must ensure that our abstraction rate is sustainable. The Coegakop Wellfield is not a short-term emergency drought intervention; it is part of our long-term water augmentation plans,” states Hills.

The boreholes at Coegakop are equipped with level and flow sensors linked to the Scada system. Overall, this determines how abstraction rates affect the overall aquifer. The effects of abstraction are monitored on boreholes further upstream of the Coegakop Wellfield near Kariega. This information is transferred to the Coegakop WTW and shown on the plant Scada. This will ensure that timely interventions can be made to the abstraction rates that would prevent any detrimental groundwater draw-down effects.

The data will also prove invaluable for the Department of Water and Sanitation in monitoring water use in terms of the

licensed aquifer abstraction. The backwash water recovery process and the five production borehole pump stations (spread across the Coegakop Wellfield, extending about 1.5 km away from the WTW) can be controlled remotely.

Operator-centric design

Architecturally, the design of the Coegakop WTW revolves around ease of circulation, putting the people who operate the works at the centre of the design concept. The WTW building was also designed to prioritise the security, safety, comfort, ergonomics, accessibility and work experience of the operators.

“First, most of the treatment processes and equipment, as well as the control room, laboratory, offices and operators’ facilities were in a single building. The operators could view all major equipment from a single, easily accessible position, right outside the control room,” says Smit.

He goes on the state that this created a challenge, as it is easier for designers and the construction team to be able to work on components individually. “The operator-centric approach resulted in a complex, integrated and dense design that combined interrelated treatment processes and equipment, sophisticated control systems, multiple foundation platforms, multistorey/water-retaining structures, all in a single building under one roof.”

It drove the development of a special layout with the aim to assist process controllers by configuring equipment in a logical way, enabling effective control of each system.

This was achieved by locating related equipment close together and ensuring clear visibility for processes that require monitoring. For instance, the upper filter gallery is visible from the control room, while the machine room is visible

from both levels of the filter gallery. The design also facilitated simple circulation for normal routes taken by process controllers by minimising level changes, providing multiple routes within the building and limiting the need for exposure to wind or rain. This plant is a good example of humancentric design, valuing personnel.

3D modelling was used as a design collaboration tool for the various engineering and architectural disciplines, which was later built into the virtual reality (VR) and augmented reality (AR) software.

“We used VR to serve three main functions on this project:

1) “It instils confidence in the client regarding the design of the WTW. They get a personal sense of the plant, which is difficult to achieve from looking at 2D drawings, or a scaled model.

2) “It helps a lot to detect design clashes (civil, mechanical, electrical, services) and to optimise the spatial layout. The spatial design becomes tangible and instinctive, allowing the designers to grasp the relative size and positioning of equipment at a human scale. This helps us simulate the operator’s everyday working experience. (Will pipes be in the way? Will they be able to reach certain valves? Does a room really need to be so big?)

3) “It develops a virtual operation and maintenance/training simulator for future plant operators who can practise various operating scenarios or protocols in a safe, offline environment,” states Smit. VR and AR was also used to: • ensure adequate allowance for

maintenance, dismantling, access, overhead lifting

• allow for improvements in constructability considerations

• aid the construction team in their planning and envisaging of the required product

• present the project to those providing funding.

Since the operators at Coegakop will be stationed there on a 24/7 basis, the WTW was designed to ensure maximum security for them. To achieve this, the process and administration components are housed in one secure, self-contained building. This includes the treatment equipment and laboratory, boardroom, offices, canteen and workshops.

“The project involved rigorous and highly collaborative interaction between the client, engineers, architects, geohydrologists, environmental practitioners, 3D software modellers and VR programmers. Through exploration, innovative use of technology and collaborative use of design, the Coegakop WTW can successfully supply safe water to a water scarce NMBM,” says Hills.

Smit concludes that the engineering team (including the client) for this project comprised an unusually young and talented team (several of whom gained their professional registration during this project) that worked in a highly collaborative way. “The Coegakop WTW is an incredible achievement for us to be able to deliver infrastructure of this quality to the people of NMBM, and a strong reminder that we as South Africans can and should take a leading role in solving our own water challenges,” he concludes.

The interactions between sanitation systems and water resources are complex, with contamination expected to increase with the onset of climate change and increased frequency of heavy rainfall events that can mobilise bacteria and viruses. Sanitation should not compete with water for investment, as polluted water is more expensive to treat. It is important to view sanitation as part of the water system.

Large portions of the population are increasingly relying on groundwater, which may be compromised by increased pathogen mobility in saturated conditions.

There is no magic ‘set back’ distance between a sanitation system and a well, as possible contamination is caused by several factors –density

of systems in an area, soil conditions and rainfall events.

Fortunately, there are improved research methods to better understand links and risk between groundwater and sanitation systems. Source tracking is used to understand where pathogens are moving by using their DNA. By understanding how pathogens move and mapping the environment between a septic tank itself and the leach field, sanitation systems can be optimised.

Surface water is commonly used for piped water systems, but continuing encroachment into catchments leads to increasing contamination from poorly designed sanitation systems. Equally, dry periods reduce the dilution of wastewater discharges, with potential health and environmental impacts.

A recent UN water report states that only 25% of wastewater is treated in subSaharan Africa.

There are new research methods on water quality, such as using satellite data, drones to take water samples, as well as community-based monitoring.

Sanitation and cholera Cholera is an acute diarrhoeal illness caused

by infection of the intestine with Vibrio cholerae bacteria. As a waterborne disease, people can get sick when they swallow food or water contaminated with cholera bacteria. It is mostly present in sub-Saharan Africa and Southeast Asia. Last year, there was the largest cholera outbreak in a number of western African countries in over a decade. There has been an increase in the number of cholerarelated deaths over the past few years.

The primary barrier to cholera infection is sanitation, with water treatment and hygiene as the second and tertiary barriers. Countries are encouraged to create national cholera control plans. The plan must include water, sanitation and hygiene (WASH) measures, cholera surveillance and reporting, the strengthening of healthcare systems, and better coordination between government departments. Even though double vaccination against cholera only lasts five years, vaccination is still recommended. *This article is a summary from a World Water Week presentation by Professor Juliet Willetts, University of Technology Sydney (UTS) and Justine Haag, WHO WASH focal point for the Global Task Force on Cholera Control.

Poor sanitation (open defecation, leaking pipes, overloaded wastewater treatment works) reduces the value of water. Faecal contamination from sanitation systems pollutes water resources. What is the link between sanitation, water and disease?

The Tamil saying ‘Nothing grows under the banyan tree’ rings true for the sanitation crisis. We need a complete paradigm shift (moving away from the old banyan tree) to achieve

Sustainable Development Goal (SDG) 6.2. There is a need for a fresh, fertile meadow where saplings or juvenile trees can flourish.

By Jennifer Williams, executive director, Faecal Sludge Management Alliance

SDG 6.2 aims to achieve access to adequate and equitable sanitation and hygiene for all and end open defecation, paying special attention to the needs of women and girls and those in vulnerable situations. And yet, 4.5 billion people do not have access to safely managed sanitation. The sewer systems that many of us are used to are failing due to ageing infrastructure that cannot be easily replaced. Why do we continue to literally flush clean drinking water down the drain to move our shit across cities for treatment?

Continuing to use the sewer system is the same as using MS-DOS, but not by choice. We need to drastically shift our thinking and paradigm if we hope to solve the sanitation problem in this lifetime, let alone by 2030. Over the past decade, the only visible solution implemented at scale is the ventilated pit latrine.

There is an underlying equity issue at play – the idea that poor people don’t deserve something better because they should be grateful for anything.

In 2015, Rubayat Khan wrote an article in The Guardian, which discussed the important distinction between ‘beneficiary’ and ‘consumer’, and the power dynamics that are associated with each: “What has survived in the world of global development is the treatment of clients as ‘beneficiaries’, not consumers. There seems to be an expectation that if you do not pay for a service in cash, you at least owe unquestioning gratitude.

“Contrast this with how a business – even a business exclusively catering to the same poor people – would design its products. It would spend countless hours doing market research, identify real problems, develop prototype solutions and market-test them through several iterations, then continuously examine data on everything from sales volume to customer satisfaction. The company would even make minor tweaks to the product’s

scent or packaging to appeal to the rural consumer’s tastes.”

Khan goes on to explain that the moment one makes the mental shift from beneficiary to customer or client, the power dynamics also shifts. So does the approach to working with communities. The solution design also changes, and one brings in established methodologies like behaviour change, community engagement, and user-centred design. Ownership and accountability also shift, as now the beneficiary is seen as a buyer, who has purchasing power (albeit maybe limited purchasing power) but is also the owner of the solution, and therefore responsible for its upkeep.

We’ve made strides but we still have a long way to go.

The initial deadline for the UN’s SDGs was set for 2030, which is now just eight years away. The recent global Covid-19 pandemic caused a lot of the world to quickly shift their thinking and what we at the FSM Alliance observed was how many

What is happening?

of our established ways of thinking and our approaches showed the limitations of a siloed approach.

The current sanitation problem has largely been approached by engineers as a technical problem. Our failure to provide improved access to sanitation has been mostly viewed as not having the right technical solutions. But despite more than 20 years of work, we still don’t have 100% safely managed sanitation.

of behaviour What trends are there over time?

Systems structure

How are the parts related? What influences the patterns?

What values, assumptions and beliefs shape the system?

This diagram, taken from the Academy of Systems Change, shows what is missed by only looking at factors above the water. This image is a powerful representation of what we have been missing in our approach.

We need to change our approach and use a more complex systems thinking approach. This type of integrated systems thinking will be necessary as the threats to our modern world continue to ignore the neatly drawn paradigms we’ve built in the past to categorise and respond to societal challenges.

Scientific American published an article, written by engineering student G Wickerson, on the limitations of looking at the world’s problems from only an engineering perspective or viewed from the framework of “technical-social dualism, the idea that the technical and social dimensions of engineering problems are readily separable and remain distinct throughout the problem-definition and solution process.” There are numerous nontechnical parameters that must be considered when thinking about sanitation planning like the taboos surrounding sanitation and the core of our nature as humans to hide our waste or, if we are lucky, to flush and forget about it.

Deepak Chopra has been viewed as controversial at times in the medical community; however, I found his quote below on how we move forward very

Structural change (explicit)

Relational change (semi-explicit)

Transformative change (implicit)

Systems Change Theory defines six conditions of change, divided into three key levels.

Structural change is often the easiest and what development funding has typically been based on. But as we dig deeper underneath the iceberg, we see that implicit and semi-explicit, which are harder and more time consuming, but just as important. In order to effectively implement change, we need to shift relationships, power and mental models. This type of change is much more fluid and based on relationships, not project outcomes. We need a shift in funding mechanisms to better support this type change. I have often asked myself how we are supposed to create sustainable change with project-based funding that has a finite start and end date. If funders want to see sustainable change, then they need to fund the mechanisms that create it – despite being non-linear and harder to measure.

Systems change work is hard, messy, time-consuming but all the more rewarding. Most importantly, it is sustainable. This paradigm shift is needed to meet the demands of the 21st century and for the future of the next generation and our planet.

relevant to how sanitation has been viewed in the past. “We use reductionist mental models that break up complexity into small pieces to examine the components of things at ever finer levels of granular detail – hoping we can put them back together coherently. But escalating crises prove we have exhausted the usefulness of this paradigm. Almost every major challenge humanity is facing, from cancer and climate change to food and consciousness, needs complex systems thinking to solve.”

The City-Wide Inclusive Sanitation (CWIS) framework has also pushed our sector to expand out from purely an engineering point of view. “With its focus on equity, a CWIS approach challenges investment and service delivery norms that have excluded many communities and marginalised groups from safe sanitation facilities and services. A CWIS approach includes their interests and voices as core objectives of and resource for planning, design and implementation of services.” The CWIS framework also pushes us to shift our thinking to a systems change approach, as opposed to an engineering approach.

The FSM Alliance is a global member-based network, created to support organisations and individuals working in faecal sludge management (FSM) or non-sewered sanitation (NSS). Our goal is to create a collaborative, responsive, and collective platform to advocate for the adoption and implementation of FSM/NSS as a utility service and public good. We also aim to support our members in their work in helping to achieve SDG 6.2 and improve access to safely managed sanitation. To learn more about our work or to join as a member, visit us at www.fsm-alliance.org or follow us on LinkedIn.

We also host the world’s only conference on FSM/NSS. Recorded sessions from the 6th International FSM Conference are available on our YouTube channel. FSM7 will be co-hosted with the African Water Association in Abidjan, Ivory Coast on 19-23 February 2023. Learn more about the event at www.abidjan2023.com.

Due to the high level of South African representation on the international panel that supported the creation of ISO 30500, we were one of the first countries in the world to identically adopt the standard as SANS 30500 in 2019. However, setting up a certification scheme has remained a challenge.

Dr Preyan Arumugam-Nanoolal By Kirsten Kelly

By Kirsten Kelly

There are many non-sewered sanitation systems (NSSS) that exist worldwide, yet, even today, there has been no technology that has been certified against ISO 30500.

“This is due to the stringent requirements of the standard as well as the costs associated with testing. Moreover, laboratories that would be responsible for testing need to be SANAS 17025 accredited. It is expensive to get accredited and maintain that accreditation. From a capacity point of view, we have found that the laboratories that are SANAS accredited do not typically have capacity for testing NSSS and currently do not see the business case, as there is very little demand for NSSS testing. On the other hand, laboratories that have capacity to measure most of the parameters required for NSSS testing reside at universities and research institutions and are not SANAS accredited. This is a stumbling block when developing a certification scheme,” says Dr

Preyan Arumugam-Nanoolal, research scientist: Water, Sanitation & Hygiene Research & Development (WASH R&D) Centre, University of KwaZulu-Natal. “Furthermore, there needs to be a critical mass – enough technologies need to be certified to justify the cost embedded into becoming a third-party certifier of SANS 30500. They are linked to each other – market acceptance of NSSS is driven by SANS 30500 certified products and SANS 30500 certification will likely only happen once there is a large volume of technologies that are certification ready,” she adds.

A substantial amount of work was done on ISO 30500 prior to the launch of the standard development processes at the International Organization for Standardization (ISO). TÜV SÜD – a global leader in product testing and certification – and the American National Standards Institute were tasked with drafting a pre-standard that could serve as a basis for the ISO

standard. Currently, ISO 30500 tests can be conducted by TÜV-SÜD in Singapore and they have been identified as the certification body to drive ISO 30500.

A training programme on the standard was recently hosted by TÜV-SÜD and they are providing advice to South Africa on how to set up the certification scheme. “Parts of the standard are very specific and raise a number of questions around technical issues, testing and feasibility. There are plans underway to train all South African stakeholders,” explains Arumugam-Nanoolal.

TÜV-SÜD has also developed an ISO 30500 certification readiness index that provides technology developers with a self-assessment of their technology and its readiness for certification against the standard. It is based online, whereby technology developers need to answer various questions, the first of which is to ascertain if the technology is classed as NSSS and fits within ISO 30500. It also includes questions around various

• The standard specifies general safety and performance requirements for design and testing, as well as sustainability considerations for nonsewered sanitation systems (NSSS).

• NSSS are prefabricated integrated treatment units containing a front-end component (such as low-flush, vacuum and urine-diversion dry or flushing toilets) and a back-end treatment component (ranging from biological to chemical or physical processes, or a combination of these).

• NSSS exclude conventional water-intensive flushing toilets.

• ISO 30500 covers aspects and criteria related to safety, functionality, usability, reliability and maintainability, as well as the system’s compatibility with environmental protection goals.

• ISO 30500 is identically adopted by South Africa as SANS 30500.

• The Bill & Melinda Gates Foundation decided to initiate the development of the ISO 30500 international standard. This was done with the intention of enhancing efforts to widely manufacture, market and deploy technologies (developed from their Reinvent the Toilet challenge).

• A project committee comprising 36 participating countries (including South Africa) and 13 observing countries assisted in developing the standard.

• South Africans helped to develop the standard: Dr Konstantina Velkushanov, previously senior research associate: WASH R&D Centre, University of KwaZulu-Natal (now a senior lecturer at IHE, Delft, the Netherlands), and the late Professor Chris Buckley, research professor and head of the WASH R&D Centre, were part of the panel of technical experts; while SABS had representation supported by Jay Bhagwan, executive manager: Water Use and Waste Management, Water Research Commission.

thresholds and parameters that help assess if the technology complies with the standard.

“We are looking at developing something similar that can assist technology developers in determining if they are ready to be certified. They can then avoid the excessive costs involved in repeatedly submitting variations of the NSSS technology for certification. It will also further guide technology developers in creating NSSS that meet the criteria found in SANS 30500,” states Arumugam-Nanoolal. Locally, UKZN is assisting Agrément

SANS/ISO 30500 FAST FACTSThere needs to be a critical mass – enough technologies need to be certified to justify the cost embedded into becoming a third-party certifier of SANS 30500. They are linked to each other – market acceptance of NSSS is driven by SANS 30500 certified products and SANS 30500 certification will likely only happen once there is a large volume of technologies that are certification ready.”

with creating the certification scheme. “The certification scheme will be based on performance criteria that are dictated by SANS 30500 and then developed on the certification processes of Agrément. Databases of technical experts and laboratory partners have been prepared. A specialist is needed for each category of testing who would be responsible for signing off on testing reports,” explains Arumugam-Nanoolal.

To further support SANS 30500, the Department of Water and Sanitation (DWS) has developed a Sanitation Technology Technical Coordinating Committee (STTCC). The function of the STTCC is to facilitate the development of a process to assess and validate appropriate sanitation technologies, aid in their certification and accreditation, and guide their adoption and commercialisation.

“While the DWS can make recommendations regarding certain technologies, it is ultimately the municipality’s choice with regard to the type of sanitation solutions that will be implemented,” says Arumugam-Nanoolal.

Previously, municipalities had been confronted with new sanitation technology but because there was no national standard, the onus and responsibility were placed on public officials to provide the guidance and position in terms of validating these technologies. It also disadvantaged many good solutions providers from entering the market.

Since the creation of SANS 30500, manufacturers are provided with strategic guidance that reduces costs by minimising waste and errors, increasing productivity and facilitating free and fair trade. Products that have gone through the certification scheme will give assurance to governments, regulators and end-users that the NSSS they use are safe, reliable and of good quality.

“The certification scheme and standard will permit the creation of a new market with a lot of innovative NSSS and will drastically reduce the diseases linked to a lack of sanitation. It is the first step toward the development of a local circular economy with the transformation of human wastes into valuable resources. Importantly, the standard and the scheme are about capacity building. It’s the opportunity to identify laboratories and build capacity in terms of instrumentation and skills. In addition, it will build awareness around not just the standard, but the entire sanitation space, to spark innovation in South Africa,” concludes Arumugam-Nanoolal.

SABS’ mandate is to provide standardisation, voluntary conformity assessment, and local content verification services to enable the achievement of the country's industrial, economic, and developmental objectives.

Now more than ever our industry needs Quality Assurance through standardasation! Start your Certification journey today and Contact us!

SANS/ISO 50001 Energy Management.

For organisations committed to addressing their impact, conserving resources and improving the bottom line through efficient energy management, SANS/ISO50001 was developed. Designed to support organisations in all sectors, this ISO/SANS standard provides a practical way to improve energy use, through the development of an energy management system (EnMS).

SANS/ISO 50001 is based on the management system model of continual improvement also used for other well-known standards such as SANS/ISO 9001 or SANS/ISO 14001. This makes it easier for organizations to integrate energy management into their overall efforts to improve quality and environmental management.

SABS provides services to assist the implementation of best practice solutions such as:

• Laboratory Testing Services for a diverse range of Products. Supporting of South African Manufacturing industry as well as Municipal delivery through: Testing of water quality, Testing/Certifying Water Meters, Smart Meters, and other products/systems.

• Certification of Companies to International Management System Standards such as SANS/ISO 50001, SANS/ISO 14001, SANS/ISO 45001, SANS/ ISO 9001 and much more.

• Certification of Products and the Application of the SABS Mark Scheme.

• Training of Management and Employees on Implementations of SANS/ISO systems

• Local Content Verification for South African

The Water Research Commission (WRC) believes that companies can contribute to bringing dignity to those communities around their operations through their CSI budgets.

Access to safe sanitation is a growing challenge in informal settlements, where its occupants use ablution blocks, chemical toilets, ventilated improved pit latrines or unimproved pit latrines. With more than 2 700 informal settlements in South Africa and approximately 13% of its population living there, corporates can allocate their CSI towards providing better sanitation solutions (and thereby providing dignity) to needy communities.

There are innovative solutions that can contribute to addressing the lack of access to dignified sanitation in informal and rural communities. These solutions can provide full on-site sanitation solutions that include generation and containment, as well as treatment of waste in areas without access to sewer systems and limited water supplies. These inventions can be suited to residential consumers, schools, public spaces, commercial settings and clinics.

The WRC is currently demonstrating some of these innovative sanitation solutions in the informal settlements of Soweto, Johannesburg:

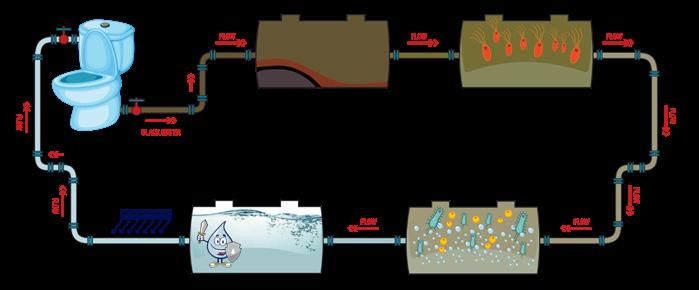

• Clear recycle toilet system in Soweto, Mofolo North informal settlement: Using bacteria to biodegrade the organic pollutants contained in wastewater, the clear recycle toilet system has a membrane biological reactor to separate pollutants and treat wastewater.

The treated water is then disinfected using ultraviolet process before being recirculated for flushing purposes.

• NEWgenerator recycle toilet system in Soweto, Slovoville informal settlement: The system uses an anaerobic baffled reactor design followed by a nanomembrane filter. Permeate from the filter is treated for reuse as flushing water by electrochemical chlorine production from table salt. The front-end unit consists of a toilet that uses recycled water and potable water for handwashing.

These full recycle toilet systems have the following benefits:

• recovers and reuses water (closedloop system)

Last year, the Trialogue Business Society Handbook: 24th edition reported that South African companies spent R10.3 billion on corporate social investment (CSI), of which R52.3 million was allocated towards water and sanitation projects.

By Philip Majeke, commercialisation manager, SASTEP• can be set up off-grid (no connection to water, sewer and electricity)

• provides full flushing sanitation solution

• no need for reticulation infrastructure. Corporates are encouraged to adopt these full-recycle toilet systems, especially in areas with little water or where it is not feasible for sewer systems. Through the South African Sanitation Technology Enterprise Programme (SASTEP), the WRC can offer advisory support for companies interested in taking up these innovative sanitation technologies as part of their CSI budgets.

The pilot testing at these schools has reduced absenteeism by 80%, while pilot testing at the informal settlement has been widely accepted.

A first of its kind in South Africa, the Clear Enviro Loo Sanitation Treatment Plant is a new-generation ‘Reinvent the Toilet’ system, introduced locally as part of the South African Sanitation Technology Evaluation Programme, an initiative spearheaded by the Water Research Commission.

Originally developed in China by Clear (Suzhou) Environmental Technology Company, the system is now locally manufactured at the Enviro Loo factory in Gauteng. A solar option allows for the system to be 100% off-the-grid. One Clear Enviro Loo Sanitation Treatment Plant can save more than 16 million litres of water at an approximate value of R576 000 over five years.

Without the need for sewer connections and a continuous water supply, the Clear Enviro Loo Sanitation Treatment Plant treats wastewater and kills pathogens by means of a natural, organic process.

The odourless, zero-discharge, selfcontained treatment plant can be located near classrooms, ensuring the safety of learners and alleviating long walks to ablution blocks traditionally located on school boundaries. New or existing ablution facilities with multiple toilet seats can be utilised, making the Clear Enviro Loo Sanitation Treatment Plant ideal for schools, clinics, housing projects or anywhere that does not have access to a continuous water supply.

This aspirational product is able to transform the lives of individuals, as well as empower communities, by providing an off-the-grid, fully recycling and flushing, cost-effective, sustainable, and dignified sanitation system. In line with the Enviro Loo philosophy of empowerment through job creation, contractors, servicing and janitorial staff are sourced as far as possible from local communities.

or existing ablution facilities with multiple toilet seats can be utilised, making the Clear Enviro Loo Sanitation Treatment Plant ideal for schools

Bacteria is introduced into a closed-circuit tank that biodegrades the organic pollutants contained in black wastewater and reduces their concentration. The wastewater is treated within a membrane biological reactor, which separates the pollutants. The treated water is then further disinfected via an ultraviolet process before being recirculated for the next flush.

This process ensures an odourless system with clear water that does not stain the ceramic toilet bowl. The spread of harmful pathogens is prevented, reducing the risk of infectious disease caused by poor sanitation – all the while saving water resources.

The Clear Enviro Loo Backend Sanitation Treatment Plant has achieved good results, following the two-year evaluation and pilot testing of the recycling toilet system in two schools, as well as in an informal housing development.Diagram depicting how the Clear Enviro Loo Backend Sanitation Treatment Plant works Clear Enviro Loo Backend Sanitation Treatment Plant at the Tsholetsega School New

According to Gerrie Brink, founder of AQUAffection, saving water by increasing efficiencies and doing preventative maintenance is not glamorous work and seldom makes headlines. But it also does not require vast capex – by simply inspecting toilets, huge water savings can be achieved.

Gerrie Brink, founder, AQUAffectionDual flush, double cyclone flush, toilets with old 20-litre cisterns, toilets with newer 9-litre cisterns, toilets with concealed cisterns, built-in toilets, gravity flush, pressure assisted toilets – whatever the type or brand, toilets are found in every commercial building. Are they working? Are they leaking? And are they using water efficiently?

Brink did an MBA at the University of Stellenbosch Business School with a research paper on ‘Factors influencing water demand in commercial buildings’. His findings showed that if no cooling towers or water irrigation is present, 90% of water consumption is from toilets. This is supported by the years of data that AQUAffection collects via its monitoring tool to assess various companies’ water usage.

Losing litres of water a day From a freshwater perspective, a toilet has two main components – the inlet side and the outlet side, and a lot can go wrong with either. “Often, a toilet inlet valve is stuck, and this is largely due to lack of maintenance and failing infrastructure on main lines where small pieces of debris flow into the inlet valve, preventing it from closing properly.

When this happens, water continuously flows into the cistern. To prevent the cistern from flooding, the outlet valve is designed to lift up and empty the cistern, causing water to flow into the toilet bowl,” explains Brink.

The quantity of water flowing into a toilet bowl can vary between 10 to 640 litres an hour. To further complicate the matter, leaks between 10 and 30 litres of water per hour cannot be detected easily. Often a stain in the bowl of a toilet may be visible, and that is caused by water continuously leaking into the bowl. If a toilet is losing 20 litres of water an hour, that equates to 15 000 litres a month.

“This is a common occurrence; in fact, we rarely come across a building that does not have litres of water constantly running into a toilet bowl. What happens is that someone flushes a toilet, walks away and is completely unaware that water is continuously flowing,” adds Brink.

Another challenge is worn or broken

outlet valves. Sometimes, due to wear and tear, these valves may become misaligned and sit askew, causing the cistern to never fill up while constantly dumping water into the toilet bowl. Rubber seals may also break (usually due to hard water) or ball valves can get stuck, resulting in water loss.

AQUAffection monitors and collects data on a number of schools.

“There was a school that had an R80 000/month water bill. After conducting a full site audit and installing monitoring devices, it was found that 80% of the toilets had constant water flow. By simply paying attention to their toilets, we reduced their water bill to R8 000/month.”

When working with a client, AQUAffection will install monitoring devices to identify areas where water can be saved. “Most of the time, it’s toilets. Once leaking or running toilets are fixed, the entire water demand profile drops. We

further increase efficiency by converting toilets to interrupted flush, bringing down the peak flows and reducing the amount of water to 1.3 litres per flush. The user has the option to hold down the handle for as long as needed to clear the bowl. Another advantage of an interrupted flush system is that the flow is better, and it seals better, reducing the chances of the outlet valve leaking. We also recommend the installation of a strainer on the line feeding the toilet. This will debris from getting stuck in the inlet valve,” explains Brink.