PREMIUM PACKAGE CANADIANPACKAGING.COM JANUARY/FEBRUARY 2023 / $50.00 SERVING CANADA’S PACKAGING COMMUNITY SINCE 1947 AUTOMATE NOW Page 25 FOLDING CARTONS Page 32 SUSTAINABILITY Page 36 Mondelēz unveils full-throttle packaging automation at its landmark Toronto bakery Story on Page 16 ANNAMARIA REDA, P. ENG. SITE ENGINEERING MANAGER, MONDELĒZ CANADA INC. 2023 Pa aging Ma inery Specifications Manual starting on page 45

Mar. 19-21, 2023

Booth 818 Orlando, Florida USA

CANADIANPACKAGING.COM

Videojet 1880 Continuous Inkjet Printer Enabling Industry 4.0 productivity pioneers Discover more at videojet.com/1880 The Videojet 1880 CIJ printer builds upon comprehensive insights gained from the fleet of cloud-connected Videojet printers, the largest in the industry, to enable your journey towards Industry 4.0. Not only does the 1880 enable exceptional uptime, it is expressly designed to help your team improve productivity and help drive lower costs over the lifetime of the printer. Harness the collective intelligence of 10,000 cloud-connected Videojet printers to help keep your lines running ©2021 Videojet Technologies Inc. All rights reserved. Videojet Technologies Inc.’s policy is one of continued product improvement. We reserve the right to alter design and/or specifications without notice.

We Automate VF 1200 Continuous Motion Bagger Up to 180 / minute Compact pick & place cell Accurate to 0.01g WeightCheQ 0-250 High Precision Check Weigher PKR Delta Robot Case & Tray Packer BI 600 + BU 600 Bag Inserter & Bag Uncuffer System 1.833.4PAXIOM PaxiomGroup PaxiomXperience Learn more at paxiom.com LAS VEGAS • MILWAUK EE • MIAMI • TORONTO • MONTREAL • SCHIO, ITALY

DEPARTMENTS

NEWSPACK

6-8 Packaging news round-up.

NOTES & QUOTES

10-11 Noteworthy industry briefs.

FIRST GLANCE

13 New packaging solutions and technologies.

ECO-PACK NOW

14 Sustainable packaging innovations.

IMPACT

15 A monthly insight from PAC Global.

PEOPLE

122 Career moves in the packaging world.

EVENTS

123 Upcoming industry functions.

COLUMNS FROM THE EDITOR

4 George Guidoni

New guidance on precautionary allergen food labeling a big step in the right direction. CHECKOUT

124 Shannon Kaup Joe Public speaks out on packaging hits and misses.

SPECIAL FEATURE

2023 PACKAGING MACHINERY SPECIFICATIONS MANUAL 45 Step-by-step guide to using this one-of-a-kind industry manual.

COVER STORY

16PACK TO SNACK

Venerable Canadian bakery vastly improves its production capacity and capabilities with well-executed facility expansion and massive continuous investment in leading-edge automated packaging machinery.

FEATURES

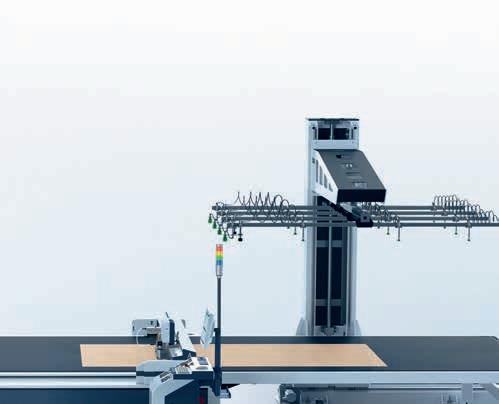

25 De iny Calling

Hardworking manufacturer of inline printing, coating and converting machinery in full control of its own destiny with a an attractive value proposition and high-end automation components and capabilities.

32Rolling with the Times

A landmark paper converting plant in southwestern Ontario rea rms its supremacy in the market for multipack beverage carriers with relentless continuous improvement and proactive investment in high-end production machinery.

36 Cascading E e s

Leading containerboard producer improves its energy management and distribution capabilities with innovative enclosure solutions.

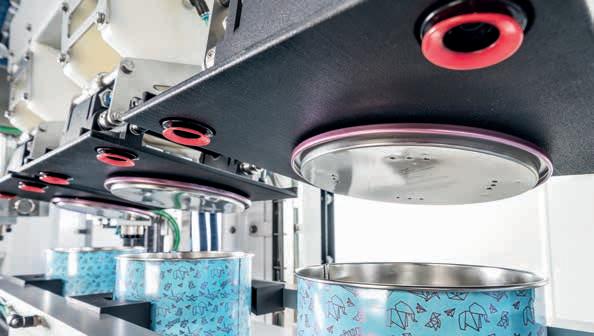

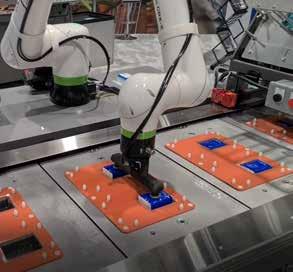

40 Seal theDeal

New sealing system design enables innovative produce of frozen fresh foods to improve its line e ciencies and packaging integrity and precision.

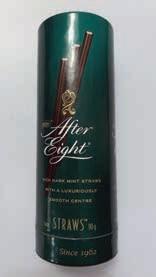

42 Sweet and Simple

Iconic French pastries leap into 21st Century manufacturing with a new fully automated packaging line.

ISSN 1481 9287. Canadian Packaging is published 10 times per year by Annex Business Media. Canada Post Publications Mail Agreement No. 40065710. Return undeliverable Canadian addresses to: Circulation Department, 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1. No part of the editorial content in this publication may be reprinted without the publisher’s written permission. © 2023 Annex Publishing & Printing Inc. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of this publication. Printed in Canada.

Naomi Hiltz

January/February 2023 Vol. 76, No. 1 canadianpackaging.com

16 32 25

THE

CANADIANPACKAGING.COM January/February 2023 · CANADIANPACKAGING 3

ON

COVER Mondelēz Canada’s site engineering manager Annamaria Reda strikes a cheerful pose alongside Syntegon’s high-speed Sigpack TTM toploader installed at the company’s landmark East York facility in midtown Toronto. Cover photography by

New guidance on food allergies to help food firms help themselves

Food allergies are one of the modern science’s greatest mysteries, and one of the industry’s most pressing challenges looking for the right solution.

As deftly noted by the brilliant American scientist and entrepreneur Anne Wojcicki, “I think it is absolutely crazy in this day and age that I have to go through a trial-and-error method to see if my child is allergic to an antibiotic or peanuts. I should just know.”

3+ MILLION

We could not agree more. According to credible statistical surveys, food allergies a ect more than three million Canadians, roughly one in 10 people, for whom trial-and-error can be a very perplexing journey in the age of mass food manufacturing and rapid food SKU (stock-keeping units) proliferation at their local grocers.

For these folks, choosing the right product can be a frustrating, time-consuming experience centered around reading and understanding the vague on-pack ingredient information and warnings—often positioned on the back of the pack as an afterthought in barely legible type, just enough to meet legal requirements but no more.

According to Food Allergy Canada, “Food allergens such as peanuts, shellfish, wheat, eggs, and milk a ect over three million Canadians, including 600,000 children, and impact one-in-two households.

“This community relies on access to accurate ingredient information,” the association notes, “yet current food labeling practices, specifically precautionary allergen labeling, is confusing to consumers—making it di cult to navigate safe food options.”

Commendably, Food Allergy Canada is taking a proactive approach to helping fill this communication gap with its recently-released Allergen Management Guidelines for Food Manufacturers document—providing a practical framework for Canadian food and beverage manufacturers on how to develop an allergen control plan or assess their current plan within their facility. Moreover, the guidelines include thoughtful recommendations on the use of precautionary allergen labeling to ensure it can be used as an e ective risk communication tool.

Developed using multi-stakeholder

approach to incorporate input from food manufacturers, academia, consumers and allergists, this invaluable resource combines thoughtful insights from industry best practices, international industry guidelines, scientific and expert community reports, and Canadian food manufacturer expertise to create a comprehensive, logical and easy-to-grasp manual for helping food manufacturers help themselves by nudging allergy-prone consumers to make safe choices at the shelf level.

Rich in detail, analysis and science-based data, the comprehensive report is freely available for industry professionals for download on the association’s website: www.foodallergycanada.ca

“These guidelines o er Canadian manufacturers a risk-based approach to manage food allergens, with the aim to meet Canadian food regulatory requirements while aligning with the most recent international advice stemming from the WHO/FAO Expert Consultation on food allergen risk assessment methodologies and allergen thresholds,” says Université Laval professor Samuel Godefroy, one of the report’s key researchers.

While it will undoubtedly take time for these guidelines to be widely adopted by the 13,000 or so food and beverage producers across Canada, the early industry feedback sounds promising.

“Food allergy is a serious public health issue and food and beverage manufacturers play a critical role in helping consumers make safe product choices,” says Sharon Mohammed, director of government and industry relations at Maple Leaf Foods. “With the Allergen Management Guidelines, food manufacturers now have an industry informed framework, that provides practical recommendations for all types and sizes of manufacturers.

“Our investment in this initiative will make it easier for food and beverage manufacturers to meet Canadian food safety and allergen labeling requirements, while helping consumers make informed food purchasing decisions.”

Full credit where credit is due.

JAN/FEB 2023 | VOLUME 76, NO. 1

Reader Service

Print and digital subscription inquires or changes, please contact Angelita Potal, Customer Service Tel: 416-510-5113

apotal@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Senior Publisher Stephen Dean | (416) 510-5198 SDean@canadianpackaging.com

Editor George Guidoni | (416) 510-5227 GGuidoni@canadianpackaging.com

Account Coordinator

Barb Comer | (888) 599-2228 ext 210 bcomer@annexbusinessmedia.com

Audience Development Manager Barbara Adelt | (416) 510-5184 Fax: (416) 510-6875 badelt@annexbusinessmedia.com

Media Designer

Brooke Shaw | (519) 428-3471x bshaw@annexbusinessmedia.com

COO Scott Jamieson SJamieson@annexbusinessmedia.com

Annex Business Media

111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1; Tel: 416-442-5600.

Canadian Packaging, established 1947, is published 10 times per year except for occasional combined, expanded or premium issues, which count as two subscription issues.

PRINTED IN CANADA

ISSN 008-4654 (PRINT), ISSN 1929-6592 (ONLINE)

PUBLICATIONS MAIL AGREEMENT NO. 40065710

SUBSCRIPTION PRICE PER YEAR

(INCLUDING ANNUAL BUYERS’ GUIDE: Canada $78.50 per year,USA $179.50 (CDN) per year, Outside Canada $203.50 (CDN) per year, Single Copy Canada $10.00, Outside Canada $27.10.

From time to time Canadian Packaging will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Privacy O icer

Privacy@annexbusinessmedia.com

Phone: 800-668-2374

DISCLAIMER: No part of the editorial content of this publication may be reprinted without the publisher’s written permission. ©2023 Annex Publishing & Printing Inc. All rights reserved. This publication is for informational purposes only. The content and “expert” advice presented are not intended as a substitute for informed professional engineering advice. You should not act on information contained in this publication without seeking specific advice from qualified engineering professionals. Canadian Packaging accepts no responsibility or liability for claims made for any product or service reported or advertised in this issue. Canadian Packaging receives unsolicited materials, (including letters to the editor, press releases, promotional items and images) from time to time. Canadian Packaging, its a iliates and assignees may use, reproduce, publish, republish, distribute, store and archive such unsolicited submissions in whole or in part in any form or medium whatsoever, without compensation of any sort.

We acknowledge the [financial] support of the Government of Canada

GEORGE GUIDONI, editor GGuidoni@canadianpackaging.com

4 CANADIANPACKAGING · January/February 2023 CANADIANPACKAGING.COM

Canadians a ected by food allergies

FROM THE EDITOR

Many players, one team.

Many players working hard to ensure the productivity, safety, and sustainability of our machines are always at their best. One team dedicated to providing exemplary service — every time.

www.syntegon.com

CANADIANPACKAGING.COM January/February 2023 · CANADIANPACKAGING 5

Leclerc starts the year with pure intentions and catchy packaging

Some New Year resolutions are harder to keep than others, but for Canadians pledging to eat healthier and to buy more local, venerable Canadian snack producer Leclerc is o ering a perfect solution with its new line of GO PURE Oatmeal Bars.

Baked and packaged at the company’s state-of-the-art facility in Cornwall, Ont., the

soft-baked bars are made with 100-percent Canadian oats and are available in three tasty flavors including Chocolate Chip, Carrot Cake and Brownies

According to Leclerc, “Oats are high in fiber and contains more protein.

“In addition to being naturally antioxidant, they also contain good fats and a multitude of micronutrients.

“Oats are the choice of active people because of their high-quality carbohydrates content,” Leclerc states. “With oats, you get a fuel that provides long-lasting energy.

Retailing in attractive 175-gram folding cartons packed with five individually wrapped single-serve bars—all incorporating lively brand graphics created by the Montreal o ce of Pigeon Brands—the peanut-free GO

PURE Oatmeal Bars contain no palm oil, according to Leclerc, and have no artificial flavors or colors.

Containing about 30-percent whole grain oats and 20-percent dates, the oven-baked GO PURE Oatmeal Bars have less than seven grams of sugar per bar, according to Leclerc, providing a healthy and convenient snack option for people on the go, such as busy families, athletes, and anyone looking for a tasty, nutritious, wholesome and 100-percent made-inCanada snack.

Chapman’s iconic boxed ice cream gets a new look

With its half-a-century history, the Chapman’s brand of two-liter boxed ice cream has been lovingly enjoyed by many generations of Canadians.

Produced in Markdale, Ont., since 1973, the brand’s coast-to-coast popularity has enabled the family-owned Chapman’s to grow into Canada’s largest independent ice cream producer—a feat that has earned this long-time freezer staple a fresh new look with high-end packaging graphics that incorporate the image of the company’s original creamery into the packaging design.

Now branded under the new Markdale Creamery label, the renamed product line is available in 15 distinct flavor varieties, according to Chapman’s, with all the original recipes left untouched.

“With this initiative we proudly celebrate our history and heritage,” says Chapman’s chief operating o cer Ashley Chapman.

“Community is an important pillar of the Chapman’s brand, and the new product line name pays homage to our small village of Markdale,” she says, noting the updated product line will also continue to be allergy-friendly, along with gluten-free, peanut-free, nut-free, and the new egg-free designation.

To get the new packaging ready for early 2023 rollout, Chapman’s worked closely with the Toronto-based Odessey Business Products Inc. and Reset Branding of Burlington, Ont., to project the desired brand image on new packaging.

“The challenge was to make the packaging still recognizable for loyal customers, while giving it a serious uplift,” says Chapman’s marketing manager Lesya Chapman.

“The design came together quite fast, and everyone quickly felt in love with the new look,” she adds. “The transition was quite rapid: it took was less than a year between the original idea and new packaging getting into stores.”

6 CANADIANPACKAGING · January/February 2023

NEWSPACK

CPK_Plan Automation_JanFeb23_CSA.indd 1 2023-02-03 10:42 AM

The original Chapman’s creamery in Markdale. Ont., circa 1973.

We’ve packed all the multi-ply strength and versatility you’ve come to expect from Kallima® into a foldable, printable, boxable solution for your packaging, cartons, POP displays… and everything in between. Made right here in North America, with its unique high-bulk, low-density construction, Kallima box™ sets you free to focus on what really matters.

1 800 411-7011

Ontario quail eggs farmer makes a clear PCR choice for its new retail packaging

Long lauded for their high nutritional value, creamy taste and texture, and cooking versatility, quail eggs are quickly gaining long-overdue mainstream acceptance across North America thanks to companies like Spring Creek Quail Farms

Located in Saint Anns, Ont., Spring Creek is a family-owned farm on a mission to spice up the Canadians’ egg life with a real alternative by tapping into the growing popularity of quail eggs—beloved by foodies for their looks and taste; health-conscious consumers for their nutritional benefits; and many ethnic consumers excited to find this familiar ingredient at their local store.

To build on that momentum, Spring Creek has recently teamed up with good natured Products Inc., Vancouver-based manufacturer of plant-based packaging materials, to relaunch its eggs in new good natured Bio-Pet packaging to ensure safe delivery of its naturally-raised quail eggs to major grocery store chains across Canada and the U.S., including Costco, Loblaws, Sobeys and Kroger

According to good natured Products, its Bio-PET packaging is made from 30-percent plant-based materials instead of petroleum— meeting Spring Creek’s requirements for recyclability across North America, while also reducing its reliance on fossil fuels.

Operating as a ‘zero-waste’ farm, Spring Creek is dedicated to environmental stewardship through its full supply chain and has committed to 100-percent recyclable packaging and shipping materials, according to the company.

In addition to being fully recyclable, Spring Creek egg packaging must adhere to strict requirements to enable product visibility and ventilation, comply with food safety, and be durable enough to withstand shipping and

ensure on-shelf safety.

According to Spring Creek, lack of product visibility and poor leak and crush resistance are key contributors to egg breakage and food waste during transport, as well as on store shelves.

Moreover, consumers often open up the traditional foam or fiber cartons to inspect eggs prior to purchasing—resulting in safety risks or messy accidents at the store-shelf level.

By utilizing transparent good natured Bio-PET egg containers, grocery customers are able to clearly see the quail eggs at a glance, largely eliminating the need to open up packaging before purchase.

“We believe a business shouldn’t have to compromise great design, product enhancement and durability in the search for environmentally friendly packaging,” says Spring Creek owner and chief executive o cer Aaron Oosterho .

“It’s in our DNA to match our packaging choices with our zero-waste, vertically integrated business practices, and we’re grateful good natured could meet all our requirements,” Oosterho adds.

“The packaging design process with Spring Creek enabled us to fully demonstrate our ability to dig deep into a customer’s unique needs, understand their industry and then fine-tune a design and precise material choice that would check all the boxes,” says Paul Antoniadis, chief executive o ce of good natured Products.

“Great packaging design is a combination of choosing the right material, engineering a solution that considers the full supply chain and making it a ordable,” Antoniadis states.

“I’m proud of our team who worked diligently on iterations until the perfect form and function was achieved for Spring Creek,” he adds, “and we look forward to continuing to make fresh quail eggs readily available throughout North America.”

NEWSPACK 8 CANADIANPACKAGING · January/February 2023

With Kallima®, the possibilities are endless

kallimapaper.com

Call Beneco today for your folding cartons. 1-905-677-2888 sales@benecopackaging.com benecopackaging.comSoOPAK.com Beneco Custom Print Packaging Beneco Packaging announces the opening of its 3rd folding carton plant. We welcome our customers to our new state-of-the-art facility in Cobourg, ON Equipped with the latest printing and converting technology our facility will also be fully food industry compliant. Our 3 production plants and raw materials storage facility ensure there will be no supply chain shortages for all our customers … large and small. Secure your business. 275,000 Added Square Feet Of Folding Carton Production!

more easily find equipment that handles their challenges and seamlessly interacts with available solutions.”

BAK Food Equipment has been selected as the new name for a company formerly known as Equipment Processing Solutions, a major supplier of food processing systems and equipment based in Burr Ridge, Ill. As the exclusive U.S. distributor for Nowicki, Protech and N&N Nadratowski brands, BAK provides a wide range of food processing equipment—from injectors and tumblers to automated smokehouses—generating annual revenues of about US$100 million. “We listened to our customers and developed a new website to improve their experience,” explains company owner John Bobak. “At the same time, it made sense to rebrand with a new name and logo that reminds customers of our rich history with food and food processing equipment, with the goal of helping customers

Mansonville, Que.-based NexKemia Petrochemicals Inc., a subsidiary of Integreon Global and manufacturer of EPS (expandable polystyrene) foam products, has completed the acquisition of Eco-Captation, a prominent polystyrene waste collection and recycling company in Prévost, Que. As the leading recycler of polystyrene wastes in Quebec with

a keen focus on PCR (post-consumer recycled) materials, the company combines artificial intelligence (AI)-enhanced optical sorting technology with a seamless mechanical recycling process to convert plastic waste into highquality raw materials made with post-consumer recycled material, acquiring Eco-Captation represents another step for NexKemia as a major mechanical recycling hub. “We look forward to growing as we learn from Eco-Captation’s substantial recycling expertise,” says Integreon Global’s president and chairman Maurice Barakat. “We are excited to employ technology to reduce the carbon footprint of the packaging and insulation solutions developed for our customers.”

Leading Swedish paperboard producer Billerud says it has secured up to US$200 million in financial support from the State of Michigan to proceed with the company’s ambitious expansion into the North American markets, starting with the planned conversion of the Escanaba paper mill into a paperboard

manufacturing facility to produce primary fiber premium paperboards. As part of the agreement, Billerud will be exempted from paying almost all state and local property taxes at the mill, which is located in the newlydesignated Forest Products Processing Renaissance Zone. For its part, Billerud has promised to invest up to US$1 billion into the conversion project—scheduled for completion in the first half of 2023—while supporting hundreds of high-paying jobs and engaging a significant number of local contractors during the construction period. “Billerud’s transformational investment in their Escanaba Mill underscores the strength of our advanced manufacturing workforce and secures a critical win as we continue working to promote long-term, sustainable investments across the state,” says Quentin Messer, chief executive o icer of the Michigan Economic Development Corporation’s (MEDC) and president and chair of the MSF Michigan Strategic Fund (MSF) board. “Through the steadfast support of our bipartisan legislative partners, the Whitmer-Gilchrist Administration, the men and women

10 CANADIANPACKAGING · January/February 2023 CANADIANPACKAGING.COM KEEP YOUR BUSINESS ROLLING CONVEYORS, BOXES AND MORE π SHIPPING SUPPLY SPECIALISTS COMPLETE CATALOG 1-800-295-5510 uline.ca ORDER BY 6 PM FOR SAME DAY SHIPPING CPK_Uline_JanFrb23_CSA.indd 1 2022-12-14 3:34 PM NOTES & QUOTES

NexKemia general manager Pierre Beaudry (left)and Eco-Captation director of operations Gilles Venne.

of organized labor, and our many local and regional partners across the Upper Peninsula, we are continuing to demonstrate that Michigan, on both peninsulas, is a place for pure opportunity.”

Righteous Gelato, Calgary-based producer of small-batch, plant-based gelato, sorbetto and other frozen desserts, has been selected as the winner of the Real Leaders Impact Awards 2023 list by ranking among the greatest purpose-driven companies in the world. Formed in 2010, Real Leaders is an international NGO (non-governmental organization), based in the Virgin Islands, dedicated to driving positive change by the world’s most progressive corporations. “Our mission statement at Righteous is simple: In

our constant and unwavering pursuit for greatness, we are committed to enriching people’s lives one tiny spoonful at a time,” say Righteous Gelato’s chief executive o icer James Boettche. “And while it sounds very aspirational, it is very operational. Socially, our mission includes poverty reduction, sustainable economic development, ending domestic violence, serving low-income communities, supporting local producers and being a force for good in our community. Environmentally, it includes waste reduction, upcycling, recycling, reducing water usage, conservation and stakeholder relations,” Boettche explains. “The world needs more corporations like ours, and in tandem with our supplier code of conduct, we will share our knowledge and inspire others to want to do the same in their business.”

MD Packaging, Uxbridge, Ont.-based distributor of product inspection and packaging automation solutions for the

manufacturing sectors of food, beverage, pharmaceuticals, consumer goods and industrial products industries., has been appointed as the exclusive Canadian distributor for Matrix Packaging Machinery, a ProMach company specializing in the manufacture of vertical form-fill-seal (VFFS) machinery for high-speed flexible packaging applications. The new partnership positions MD Packaging to sell, service, and provide project management expertise to its Canadian customers on Matrix’s full line of VFFS machines, along with the INVpack stick-pack and sachet systems and Pacraft automated pre-made pouch packaging systems. “The business philosophies of MD Packaging and Matrix are very much aligned [and] the synergies really meshed well in what our cultures stand for,” says MD Packaging chief executive o icer Jaime Alboim. “Matrix wants to understand the Canadian market,” he adds, “and we are very excited to tap into the vast resources we have to help Matrix in this e ort.” As part of the on-boarding process, MD Packaging sales reps and technicians were trained on Matrix equipment at its Saukville, Wis., headquarters.

Global industrial automation and process engineering powerhouse ABB has announced the opening of a new Mexico-based facility in Merida, Yucatan, which the company says will increase its local engineering capabilities by about 25 per cent. Having made an initial US$1 million investment for the new Mexico Technology and Engineering Center (MXTEC) to help the technology leader to reach higher project delivery capacity and increase competitiveness, ABB has plans to recruit 30 engineers, mainly from the local talent pools, while establishing meaningful partnerships with leading Mexican universities. “Our aims for the Mexico Technology and Engineering Center are to grow our engineering competencies and capacity to deliver projects with local resources in the same time zones as Mexico, the U.S. and Canada,” says Michel Blondeau, ABB’s operations manager for the North America hub. “Its success relies on talents and e orts of our new local team,” Blondeau adds, “and we are pleased to see them successfully on-boarded and ready to complement our operations in Europe and India.”

Canadian German Chamber of Industry and Commerce Inc. Your contact: Stefan Egge 480 University Avenue _ Suite 1500 _ Toronto _ Ontario _ M5G 1V2 Tel.: (416) 598-1524 _ Fax: (416) 598-1840 E-mail: messeduesseldorf@germanchamber.ca For Travel Information: LM Travel /Carlson Wagonlit Tel: 1-888-371-6151 _ Fax: 1-866-880-1121 E-mail: ahoule@vovagelm.ca

12 CANADIANPACKAGING · January/February 2023 CANADIANPACKAGING.COM Detection perfection. Leading-edge technology trusted worldwide for superior product inspection and contaminant detection. Your brand is on the line, so you need equipment that’s better than good. Anritsu systems deliver performance, reliability and low total cost of ownership. Plus, we back our long-lasting equipment with unparalleled service and support. Discover what you’ve been missing. PACKAGING | INSPECTION | PROCESSING SALES | SERVICE | INTEGRATION TOLL FREE: (800) 361-5919 ABBEYEQUIPMENT.COM

THE X+ FACTOR

The new DualX+ X-Ray inspection system from Anritsu, distributed in Canada by Abbey Equipment Solutions, o ers elevated detection capabilities with the addition of a new dual energy sensor, making X-Ray transmission images significantly larger. This enhancement makes it possible to clearly display the shadows of contaminants on the targeted objects, as well as foreign bodies that are even smaller in size and thinner in shape—such as small bones, fine metal fragments, etc. In addition, the dedicated detection algorithms have improved the sensitivity to detect fine metals and small bones, which traditionally hard to detect. The new advanced DualX+ inspection system will be displayed live at the upcoming Seafood Expo North America exhibition in Boston (March 12-14, 2023) at Booth #288 Abbey Equipment Solutions

according to PakTech, while o ering plenty of opportunity for scalability without needing a large facility to do so.

PakTech

MICRO ECONOMICS

The new CCA MicroPak can carrier ring applicating system from PakTech is designed primarily as an entry-level solution for emerging brands and startups, as well as for smaller microbreweries, mobile canning operations, etc. O ering space-saving benefits of a remarkably compact footprint, the CCA MicroPak is capable of applying up to 60 cans per minute, and it is able to accommodate both 12- and 16-ounce standard can sizes. Running on standard 120 V power source and less than 1 cfm of air, the versatile machine is built for an exceptionally long service life,

BETTER WITH BACON

Distributed by BAK Food Equipment, the new Spiral Bacon Smokehouse from Protech is a highly automated production line claimed to be a groundbreaking solution for meat processors who want to take their bacon production capabilities to the highest levels of product quality, improved yields and optimized labor. The system features a linear combination of integrated technologies that transform bacon from raw pork belly into a perfectly seasoned, cooked and smoked product—from start to finish—delivering inline injection, optional liquid smoke drenching, drying, natural smoking, and freezing of pork bellies that are ready to press and slice. According to Protech, the finished product is consistent and uniform because every piece enters and exits the oven in the same position and at the same temperature, which is monitored and controlled throughout the cooking, smoking and freezing processes. The patent-pending Spiral Bacon Smokehouse is capable of cooking and freezing 8,800 pounds of product per hour, and the fully-integrated system requires no additional accessories or equipment—such as combs, smoke trollies, or smoke stick—while deploying robust CIT (clean-in-place) technology for quick and easy sanitation. Unlike traditional manual bacon processing operations that can require dozens of employees, the Spiral Bacon Smokehouse needs only two people for full operation.

BAK Food Equipment

BAK Food Equipment

al,and inventory benefits thanks to a unique modular design. When a VZXA actuator is removed for maintenance or changeover, for example, the stem, seat and seal stay inside the valve body to allow the process system to remain pressurized. In applications containing hazardous materials, those materials reside safely within the system, saving cleaning time and lowering health and safety risks of contamination. Reinstalling the actuator is simply a matter of screwing it into the valve body. The actuator does not have to be pressurized, which eliminates strain on the stem, seat and seal, reducing the risk of damaging the valve seat. The modular design is ideal for valve manifold applications requiring speedy assembly, ease of maintenance and compact size, and the valve family’s standardized design ensures every VZXA actuator is compatible with every valve body in the family—facilitating simplified ordering and inventory management. Festo Inc.

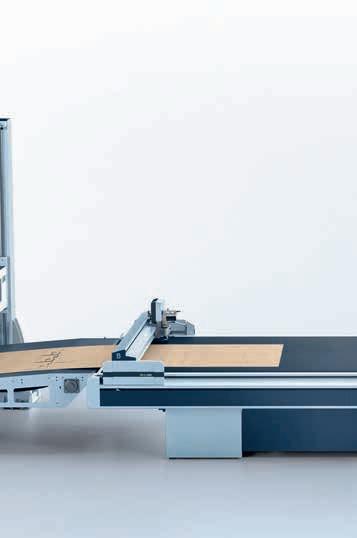

produced on the high-performance machine. BMG

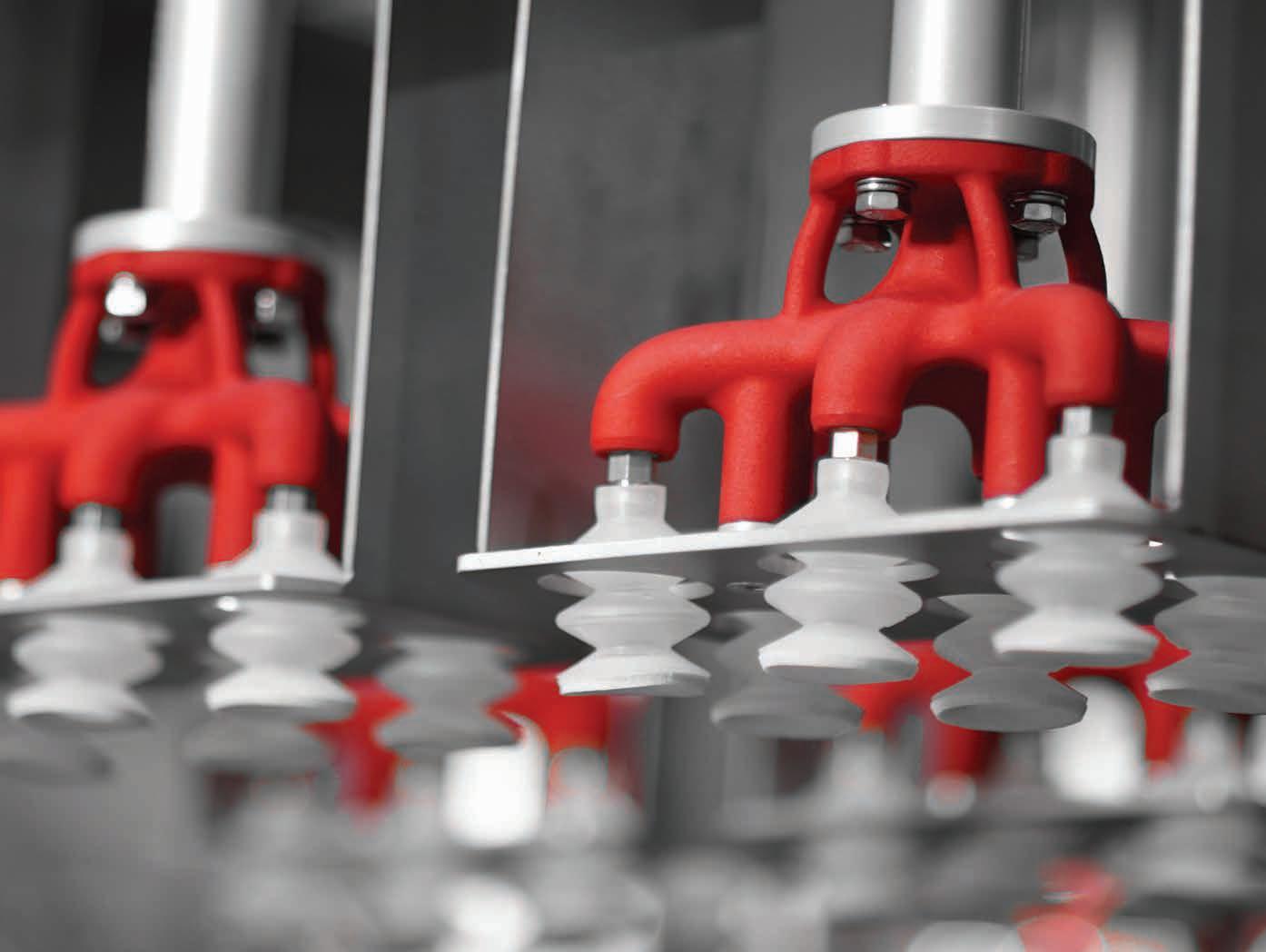

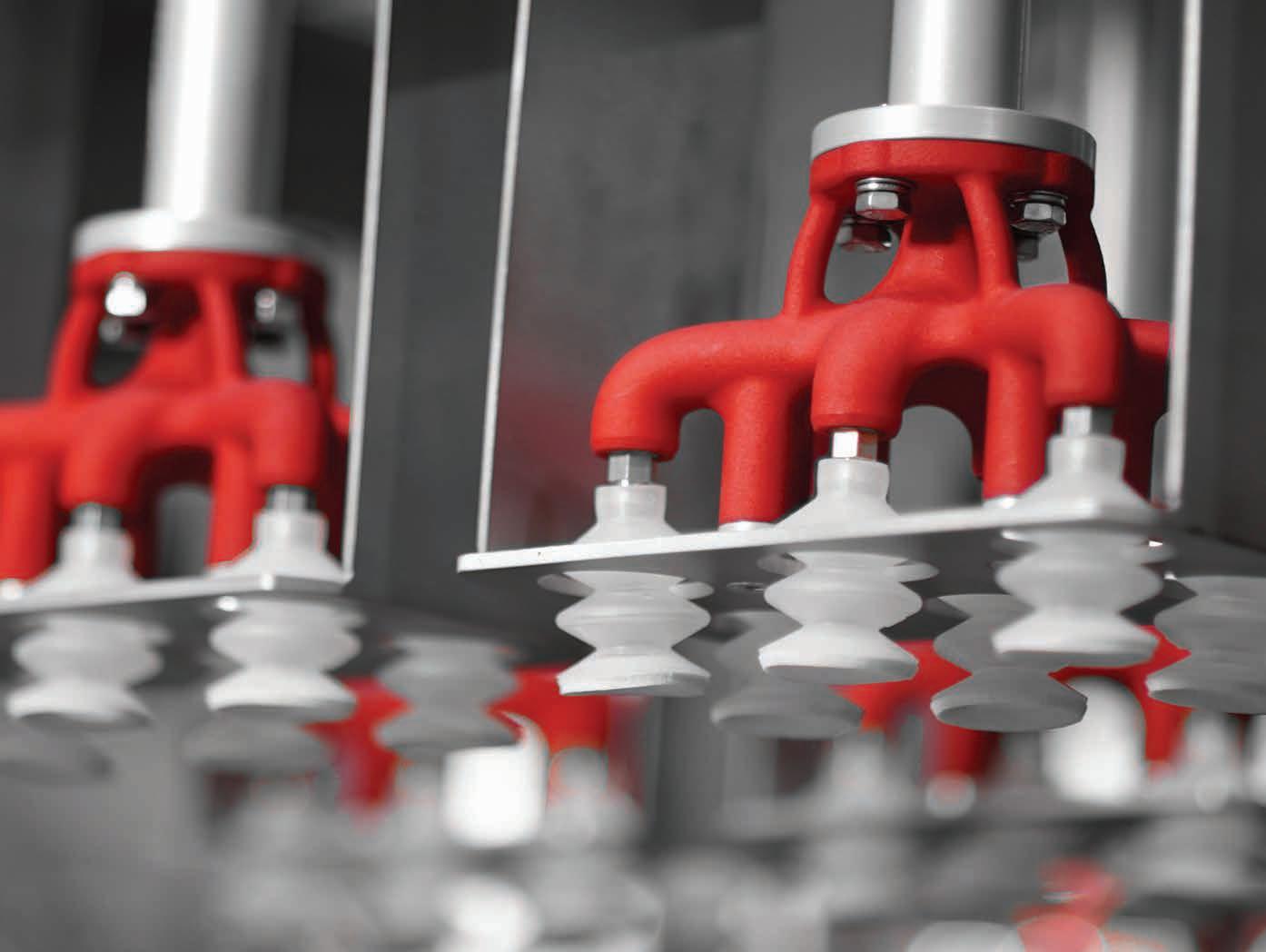

COMING TO GRIPS

The new robust and wear-resistant Monoflex SP-BX1 and SP-BX2 series bellows vacuum cups from FIPA are engineered from special composite material that combines the elasticity of rubber with the durability of polyurethane—making them a perfect fit for gripping cartons and other uneven and porous materials such as cardboard, textured plastics, and composites with a raw surface. Designed for long service life, the new cups provide durable, secure-grip, non-marking product handling by easily adapting to flat and convex product surfaces, with their folds ensuring good height and angle compensation.

FIPA

PAPER TIGER

FRESH ANGLE

The new VZXA family of pneumatically actuated angle seat valves form Festo is designed to deliver multiple installation, maintenance, operation-

The new QuadPro large-bed paper former from BMG employs a patent-pending, continuous forming process developed to provide the highest production output and lowest scrap rate in the industry, according to the company. One significant feature of the QuadPro former is its ability to provide material scoring without cutting blanks while running printed or unprinted paper with automatic continuous decurling and splice detection—enabling easier operation. The system’s automatic splice detection capability also allows it to bypass score and form stations, achieving faster changeovers and less scrap. Moreover, its servo-controlled score depth adjustment allows for easy on-screen adjustments stored in a recipe for recall, as well as on-the-fly adjustments that reduce downtime— helping to achieve consistent, ultra-precise score depth in increments of 0.0005-inch. Other notable benefits of the QuadPro former include its ability to cut and form in place, along with fully-automated product extractions, stacking, counting and conveyance. In addition to running printed and unprinted paper, the system can also form plates, bowls and trays—allowing for a highly diverse mix of products to be

SHOW AND TELL

Sonoco, global supplier of consumer packaging products headquartered in Hartsville, S.C., made big waves earlier this month at the Packaging Innovations & Empack packaging trade shows in Birmingham, England, with a comprehensive display of the company’s sustainable EnviroCan and GREENCAN lines of rigid paperboard packaging solutions. As part of the larger EnviroSense product range, the Envirocan incorporates a paperboard end is made with recycled and recyclable paper fibers. For its part, the can body is made of at least 95-percent fibers with a minimum of 60-percent recycled content, lined with a highly e ective oxygen and moisture barrier layer. Meanwhile, Sonoco’s new monolayer GREENCAN packaging solution—made of 92- to 98-percent paperboard—o ers a wide range of barrier properties and is available in multiple sizes and shapes, including round, square, rectangular, oval, oblong or triangular, with a wide variety of closures.

Sonoco

CANADIANPACKAGING.COM January/February 2023 · CANADIANPACKAGING 13 FIRST GLANCE

Cascades kicks off new year with high-profile recognition

Just named as one of the world’s most sustainable corporations, Kingsey Falls, Que.-based paper packaging and tissue manufacturer Cascades Inc. has announced the commercial launch of a new closed basket made of recycled and recyclable corrugated board for the produce sector.

Developed as an alternative to food packaging that is di cult to recycle, the new multifold basket is the latest addition to the Cascades Fresh line of eco-friendly packaging.

Designed using recognized eco-design principles, this product is in keeping with a Circular Economy approach by using recycled corrugated board in its design, according to Cascades, thereby supporting its customers’ e orts to reduce their environmental impact while meeting consumer demand for increasingly eco-friendly packaging.

The result of the expertise and work of a multidisciplinary team, the innovative design allows for flat shipping, thereby reducing transportation costs and the need for storage space. A mounting jig, designed specifically for both basket formats (two- and three-liter) will also speed up and simplify operations for producers.

“The multiple customization options o er a competitive advantage and will make produce brands stand out on the shelf with high-quality flexographic, lithographic and digital printing options,” according to Cascades.

“This new corrugated basket for fresh fruits and vegetables reiterates our commitment to o er innovative products that meet the highest standards of environmental responsibility,” says Cascades president and chief executive o cer Mario Plourde. “This launch is also in line with the commitment we made in our Sustainability Action Plan to ensure that 100 per cent of our packaging is recyclable, compostable or reusable by 2030.”

Having recently pre-qualified for the How2Recycle program, making it easier for producers to obtain certification, the closed corrugated basket for fresh fruits and vegetables has already made its mark in prestigious food industry competitions.

It was a finalist in the Sustainable Design category for the 2023 PAC Global Awards; for the Prix Innovation en alimentation 2022, awarded by the Conseil de la transformation alimentaire du Québec; and the Grands Prix DUX 2023 in the Eco-Packaging Initiatives category.

This industry recognition is perfectly

Currrently avilable in two standard sizes, the new consumer-friendly Cacades Fresh baskets for fresh fruits and vegetables are made from recycled corrugated materials.

befitting of a company that has just been named the 20th most sustainable corporation on the planet, according to the latest Global 100 Most Sustainable Corporations in the World list compiled by leading global NGO (non-governmental organization) Corporate Knights, and the first among the 53 companies analyzed in the Containers & Packaging category.

The Global 100 Most Sustainable Corporations in the World ranking is the result of a performance analysis of international corporations with more than $1 billion in revenues, based on key performance indicators across four areas—including economy, environment, social impact and governance—with the weighting of these

indicators defined according to each industry.

According to Corporate Knights, Cascades stands out thanks to its high percentage of clean revenue (i.e. from the sale of eco-friendly products), in addition to its sustainable investments; the alignment of its greenhouse gas emission reduction targets with international recommendations; the inclusion of sustainability objectives in the performance evaluations; and gender diversity on its board of directors.

As Plourde notes, this is one of many times that Cascades has been recognized for sustainability over the years, further validating its commitment to outdo itself and always do more for the well-being of communities and the planet.

“The importance of developing a Circular Economy to protect our resources has been at the center of Cascades’ business model for almost 60 years,” Plourde states, noting this is the fourth year in a row that Cascades has made the Global 100 list.

“We have always considered it vital to use as much recycled material as possible in our products, and continually review how we operate in order to be respectful of the environment,” Plourde elaborates.

Says Plourde: “We owe this performance to our employees, who push the envelope and drive positive change every day. It is thanks to them that Cascades is able to continuously reduce its environmental footprint and those of its customers.”

14 CANADIANPACKAGING · January/February 2023 CANADIANPACKAGING.COM ECO-PACK NOW

MVPProgramToday

AGlobalPackagingMarketplaceDesignedtoOfferthe PackagingIndustryaCuratedDigitalExperience

ThegoalforPACGlobalMVPMembersistoreducecosts,savetime, andalleviatethepressureofhavingtoattendallin-person conferences,summits,andtradeshows.PACGlobalstrivestomeet theneedsofthepackagingindustry,connectingbuyersandsellers fromacrossthevaluechain.

ForMVPdetailsandpricing,contactPACGlobalCEO,JimDownham atjdd@leaderlinx.com.

CANADIANPACKAGING.COM January/February 2023 · CANADIANPACKAGING 15 VISITTHEPACMARTATWWW.PAC.GLOBAL/PACMART

JoinPACGlobal'sPACMART

PACK TO SNACK

Landmark snack-food manufacturing facility cranks up its cracker production volumes with cutting-edge packaging automation

By George Guidoni,

Editor

Photos by Naomi Hiltz

With snacking continuing to evolve as a daily eating ritual across the world’s cultures

and geographies—keeping hunger at bay between meals and providing a welcome boost of energy and nutrients— snack-food manufacturing has become an integral part of Canada’s consumer economy, serving a growing domestic market worth an estimated $13 billion annually.

As one of the country’s largest producers of crackers, cookies and other popular snack foods, Toronto-based Mondelēz Canada—part of the Chicago-headquartered multinational Mondelēz International Inc.—puts a high premium on continuous improve -

ment in its production and packaging capabilities to retain and grow its significant share of the fast-growing global market for baked snack-food products. Operating five manufacturing facilities in Canada, the publicly-owned company has invested millions of dollars’ worth of new equipment into its Canadian production assets over the last decade, with particular emphasis on modernizing and expanding its venerable cookie and cracker production site in Toronto’s midtown borough of East York.

Originally opened in 1949, the East York plant has undergone multiple upgrades and expansions over the years under various former owners, but its most recent comprehensive capital upgrade has arguably set a new benchmark standard for successful integration of automated processing and packaging machinery—raising its skillset and eciency levels to the proverbial next level

16 CANADIANPACKAGING · January/February 2023 CANADIANPACKAGING.COM

COVER STORY

Mondelez Canada’s site engineering manager

Annamaria Reda proudly displays colorful packages of some of the most popular brands of crackers and cookies produced and packaged at the company’s’ venerable East York manufacturing facility in midtown Toronto.

of world-class manufacturing excellence.

In 2017, the company expanded the existing East York building on Bermondsey Road to a total of 462,000 square feet of production space, while installing multiple new-generation processing and packaging machinery to accommodate a fast-paced, around-the-clock production environment to enable the peanut-free certified facility to produce over 160 million pounds of product annually for the Canadian and U.S. markets.

“Some of the major brands we make here at East York include Oreo, Premium Plus, Ritz, Wheat Thins, Crispers and Peek Freans cookies,” says site engineering manager Annamaria Reda.

“We have over 100 SKU (stock-keeping unit) o erings—comprising di erent flavors and a wide variety of packaging formats—here on-site,” Reda expands.

“We have the capability to produce cookies in trays—directly in overwrap, or overwrapped and cartooned—stand-up pouches, overwrapped slugs in a carton, and bag-in-a-box formats.”

“The product o erings we manufacture at East York bakery are mostly private-label direct-to-customers,” she adds, “with a small volume of portion-packs made for foodservice clients.”

As Reda explains, the East York plant operates a total of eight high-capacity commercial ovens to make its product range, with each of the ovens feeding multiple processing and packaging lines to produce the final products and ready it for shipment to customers.

“Our eight ovens are evenly split between cookie and cracker lines, as they use unique forming equipment for the di erent types of products,” Reda notes.

“We are busy all year with both,” she says, “but one of the heaviest seasons is the lead-up to the fall and winter seasons, when we see higher cracker sales.”

Making the manufacturing processes run smoothly and seamlessly at all times requires a fairly high level of automation to maintain a high level of product quality and consistency, Reda points out, while ensuring robust productivity levels and reduced reliance on manual labor for some of the more repetitive and physically strenuous tasks.

“Automation is important to help us stay competitive and also to be able to o er higher-skilled jobs in the labor market,” Reda states.

“We do have a combination of fully automated lines where we make consistent products,” she notes, “although we also have some manual packaging lines where we either need more flexibility or have lower volumes.”

As Reda relates, the recent building expansion went hand-in-hand with a multiphase installation of a whole new production line for high-speed, high-volume processing and packaging of cracker products, including the bestselling

CANADIANPACKAGING.COM January/February 2023 · CANADIANPACKAGING 17

“Automation is important to help us stay competitive and also to be able to offer higher-skilled jobs in the labor market.”

Freshly-baked and cooled cracker strip entering the breaker, supplied by Charles Downer & Co., to be separated into individual crackers.

Individual crackers travel in bulk along the the six-lane vibratory coneyorstowards the Syntegon FGMT feeder/ loader.

18 CANADIANPACKAGING · January/February 2023 CANADIANPACKAGING.COM

Premium Plus line of crackers.

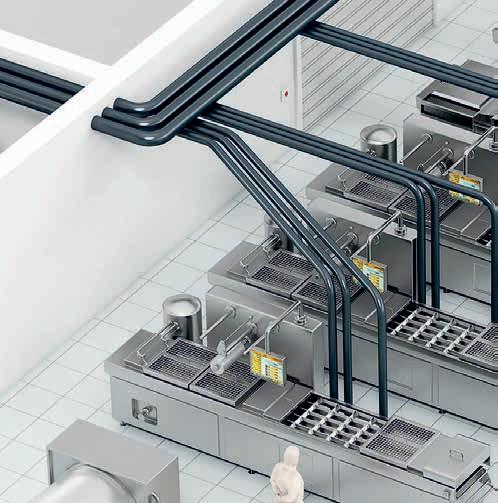

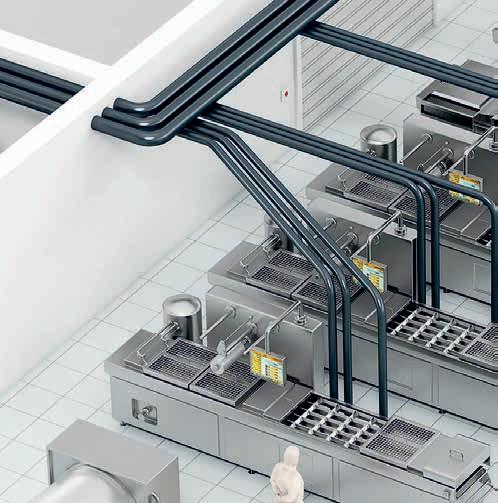

Carried out in step with the ongoing building construction and infrastructure installation, the new L30 line comprises some of the most advanced processing and automated packaging equipment available in the market, including multiple primary and secondary packaging machines manufactured by leading global packaging equipment group Syntegon

“The overall goal was to expand the facility to enable the production of various cracker SKUs here at the bakery,” Reda says.

“The project was installed in a separate building,” she notes, “so our other production lines were able to operate normally, and generally were not impacted.

“As with many large projects, it had its challenges,” she acknowledges, “but overall we have been able to learn the new process and equipment very well over the years.

“We are now running the machines at e ciency levels in the high 90s (per cent),” Reda states, “and Syntegon was a great partner in this project by providing support when it was needed to bring us to these operating levels.

“The Syntegon installation is one of our most fully automated lines end-toend,” she states, “and we operate with the best-in-class crew.

“As a full new line, the L30 installation project added over 65 million pounds of additional output from the East York facility,” Reda says, complimenting the outstanding support and customer service provided to the project by Syntegon’s Canadian distributor and packaging line integration experts Charles Downer & Co. Ltd. of Richmond Hill, Ont.

Actively involved in the L30 line installation from start to finish, Charles Downer provided the required equipment for all the product handling, transfer and packaging stages from the

oven—starting with product breakers and spreaders—right to the end-of-line packaging and palletizing.

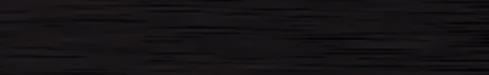

According to Charles Downer’s president and owner Je Downer, the L30 line boasts one of the largest single-line installations of Syntegon packaging machinery anywhere in Canada, including:

• Six Sigpack FGMT feeders with cross-feeding chains.

Designed for high-speed stacking and portioning of crackers, cookies and other dry, oily and brittle baked goods with a separation knife, the Sigpack

Above A close-up of the Syntegon FGMT portioning system dividing the bulk crackers into individual slugs for packaging.

Left

Finished

FGMT feeder is a continuous motion-portioning machine that uses two separating swords per lane to allows the product column to advance continuously, rather than intermittently, to produce up to 400 slugs (stacks) of product per minute on each machine.

After the products are baked in the oven, cooled down and fed into the FGMT by vibratory channels, one sword moves into the product flow, while the second sword holds the leading edge of the formed slug.

Once the swords advance the column to the lowering shovel, an overhead counterholder takes control of the leading edge—allowing for the second sword to return and start the next portion— while the counterholder guides the slug into a shovel for lowering the portion into the cross-chain.

CANADIANPACKAGING.COM January/February 2023 · CANADIANPACKAGING 19 COVER STORY

Pre-printed Z-flute board cartons being formed from blanks inside the Syntegon TTM toploader.

Filled cartons being closed by the robotic closing section of the Syntegon TTM toploader.

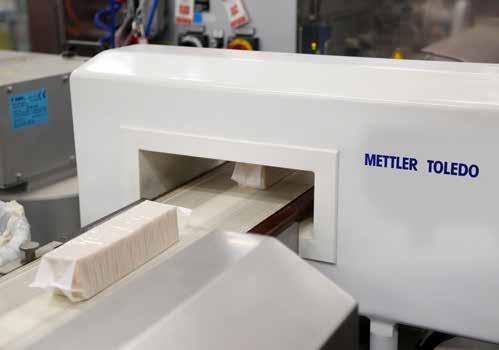

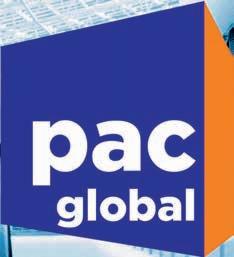

overwrapped slugs of crackers passing through the METTLER TOLEDO metal detector for quality control.

Insights into the Future of PACKAGING AUTOMATION

TOM EGAN, VP INDUSTRY SERVICES PMMI, WILL CO-HOST

AND KICK THINGS OFF BY PRESENTING THE FINDING FROM THE OCTOBER 2022 PMMI BUSINESS INTELLIGENCE STUDY TITLED THE FUTURE OF PACKAGING AUTOMATION. HE WILL CO-HANDLE MC AND QUESTIONING DUTIES.

Register above for this most stimulating discussion on the latest trends, challenges and opportunities in packaging automation.

Get answers to your questions from the experts.

March 7, 11 am till 12:30 pm EST.

20 CANADIANPACKAGING · January/February 2023 CANADIANPACKAGING.COM WEBINAR MARCH 7, 2023

Vice-President Sustainability & Government

Belmont

Premium

MICHAEL

Syntegon Packaging

NICOLAS

Segment

Food & Packaging,

DOUG ALEXANDER

Relations,

Food Group (Div.

Brands Holdings) EMILIE ALLEN Vice president Projects & Logistics, Biscuits Leclerc Ltée.

BUTLER Robotics Product Owner,

Technology

FLEURIOT Industry

Specialist

Festo Canada.

NICHOLAS

Automation

WES GARRETT Executive Director – Global Accounts, FANUC Canada Ltd. TOM EGAN vice president, Industry Services, PMMI

TARABORELLI Vice President of Paxiom

After the portion is released and the empty shovel is raised, the next portion is guided in.

The alternating functions of the two swords allow the product to advance in a continuous flow, according to Syntegon, thereby reducing back pressure and product stress.

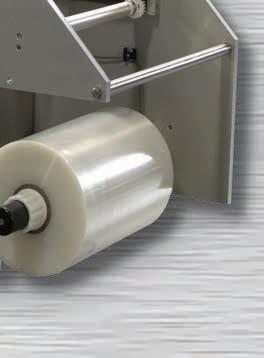

• Six Sigpack FIL with HCS horizontal slug flow wrappers.

The slugs are transferred from the FGMT by the intelligent infeed named FIL, which uses linear motor technology instead of conventional chains.

The main advantage is the extremely gentle handling of the transfer, which is nevertheless still performed at high speeds.

Once transferred to the wrapper, the FIL carries the slugs into the folding box of the HCS wrapper. the slug streams go gently from cross chain unit right into FIL and HCS folding box.

The FIL infeed also acts like a small bu er, which stabilizes the wrapping speed for a highly e cient and reliable system.

The FIL/HSC also allow for very quick changeovers: within 10 minutes from long to short slugs.

The HCS is compatible with a wide range of heat- or cold-sealable monolayer or laminated film structures at speeds up to 400 packs per minute.

Capable of producing longitudinally or cross-crimped end fins with straight, zig-zag or clip cut-o , the machine folds and shapes the film like a hose to wrap around the product, which is then longitudinally and transversely sealed.

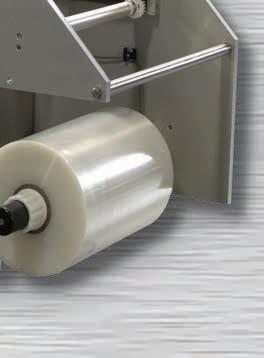

O ering a variety of optional features—including print code, carton insert, label or coupon, tear strip, tear notches and other easy-opening features—the machine’s automatic film splicing enables fast and easy film reel changeovers.

• Six Sigpack TTM top-load carton-

Top Side view of the Sigpack TTM toploader capable of filling up to 150 cartons per minute.

Left

Side view of the Syntegon Elematic case-packer recently installed at the East York facility.

Below The Sigpack TTM toploader design incorporates a Nordson hot-melt applicator for inline gluing of the pre-loaded cracker boxes.

January/February 2023 · CANADIANPACKAGING 21 COVER STORY

ers. Designed for 24/7 production, the Sigpack TTM integrated topload cartoning platform delivers high-speed carton forming, loading and closing many types of cartons—including triseal closure, open tray, tray and hood, or tuck-in lid—at speed of up to 150 cartons per minute.

Requiring only one operator to handle all operations via a touchscreen HMI (human-machine interface) terminal,

the Sigpack TTM can handle both solid paperboard and corrugated containerboard, as it automatically removes carton blanks from the loader, erects the cartons, loads them with the grouped product, closes the filled cartons, and passes the finished cartons on to the outfeed belt.

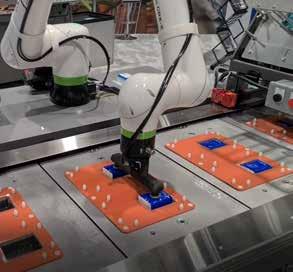

Incorporating a product infeed conveyor, a driven blank magazine, threeaxis robots, controls and drives from Rockwell Automation , and an inte -

grated hot-melt adhesive applicating system, the high-performance machine can handle a broad range of carton sizes, while facilitating remarkably quick and easy changeovers.

In addition to the Syntegon primary and secondary equipment integrated into the L30 line, three Zambelli tray-packing and shrinkwrapping machines, as well as several Euroimpianti robotic palletizers, corner post applicators and RGVs (rail-guided vehicles) at

22 CANADIANPACKAGING · January/February 2023 CANADIANPACKAGING.COM COVER STORY

Above Close-up of robotic grippers inside the Sigpack TTM integrated topload cartoner.

Right A close-up view of the Zambelli tray-packing and shrinkwrapping machine in action.

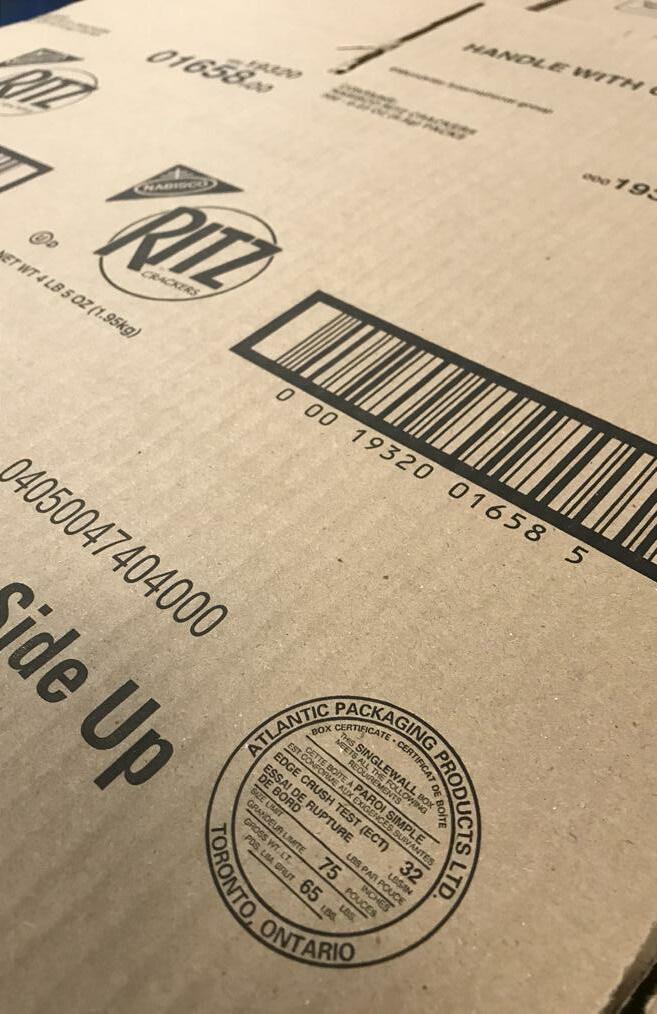

Left Corrugated boxes from Atlantic Packaging Products used to ship the finished cartons.

the end of the line.

“They have expanded the palletizing system twice now in order to handle the entire facility with 10 robotic palletizing systems,” says Downer.

As Reda comments, “Our L30 Syntegon line has a single oven splitting into six packaging legs, which is why we have six full sets of the FGMT, FILHCS and TTM units.

“These feed into the three Zambelli units and four Euroimpianti palletizing robots, which are shared with another line,” she adds.

“It’s very important that all six legs run consistently with little downtime,” Reda points out, “as it would be ine cient to

stop the oven process should one packaging leg stop producing.”

So far, all the Syntegon equipment has worked as well as promised, according to Reda.

In fact, the outstanding performance delivered by Syntegon machinery on the L30 line has enticed the East York plant to invest in yet another fully-automatic Syntegon secondary packaging system— an Elematic case-packer—on another one of the facility’s production lines.

“We have enjoyed good support from the Syntegon team,” Reda states.

“As it occurs in every project, there were some challenges, but overall we’ve achieved good performance results quickly after start-up.

“The service from Syntegon has also been very reliable; their team is highly responsive, and we have a local representative that can support on-site when necessary,” she sates.

As for Charles Downer’s contribution, “We found Charles Downer & Co. to be very knowledgeable on equipment capabilities and new technology o erings,” Reda states.

“They supported the project from end to end, including ideation of equipment selection and layouts, to ensuring we have the right support for the installation

and commissioning phases.”

Reda says Mondel ē z Canada takes pride in sourcing as much of its raw materials and packaging from Canadian suppliers as possible, and working with Canadian packaging automation experts like Charles Downer is a valid reflection of that local sourcing mindset.

According to Reda, the East York’s large-scale investment in packaging automation played a key role in enabling facility to carry on largely “business as usual” even during the peak months of the COVID-19 pandemic, when demand for foods like crackers and cookies actually surged above normal levels.

“The food industry is a very competitive business,” she says, “and our key competitive strength is our team’s ability to react and lead through challenges like that to ensure that products that our consumers love are always available on the shelf.

“Having the right technology in place to ensure that shelf presence is a big part of that competence,” she states.

“As a business, we are always working towards giving people a wide range of high-quality snacks so they can make great informed choices,” Reda concludes.

“It’s about keeping true to our existing brands that our consumers know and love, improving the sustainability of their production, and also o ering new snack options that people truly love and feel good about.”

Please see a video of Syntegon packging machinery in action at Mondelēz Canada’s East York manufacturing facility on Canadian Packaging TV at www.canadianpackaging.com

CANADIANPACKAGING.COM January/February 2023 · CANADIANPACKAGING 23

“As a business, we are always working towards giving people a wide range

of

high-quality snacks so they can make great informed choices.”

Above A Flexlink spiral conveyor moves finished cartons of crackers from Sigpack TTM to the wrapping and palletizing stations.

Above right One of several Euroimpianti robotic palletizers installed at the East York facility.

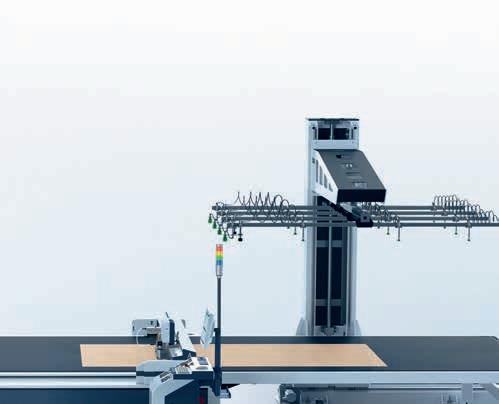

DESTINY CALLING

Canadian inline label coating and converting machinery manufacturer leverages production excellence and technological expertise to redefine the industry’s value chain dynamics

Self-su ciency is a much sought-after core competence for companies in virtually any business field, and for Montreal-based ETI Converting Equipment , being a master of its own destiny has been a driving force behind the company’s success in the global markets for inline label printing, coating and converting machinery.

Long before disruption became the trendy new buzzword and euphemism for game-changing innovation, company founder Francois Bayzelon had already embarked on a bold journey to shake up the existing label manufacturing supply chain models by helping label printers and converters take complete ownership and control of all their production needs in-

house with innovative, leading-edge machinery distinguished by high levels of automation and technological excellence.

After arriving to Canada from France with a degree in mechanical engineering and a strong entrepreneurial spirit, Bayzelon proceeded to put his talents to use by founding Aquaflex in 1980.

Specializing in flexographic printing presses, the company is credited with revolutionizing the printing industry by launching the concept of quick-change cassette system, while becoming renowned for the quality and a ordability of its equipment.

After selling Aquaflex years later, Bayzelon initiated a new project guided by the vision of enabling label printers to manufacture their self-adhesive labels from scratch, than merely decorate them after receiving the label stock from their

CANADIANPACKAGING.COM January/February 2023 · CANADIANPACKAGING 25

AUTOMATE NOW

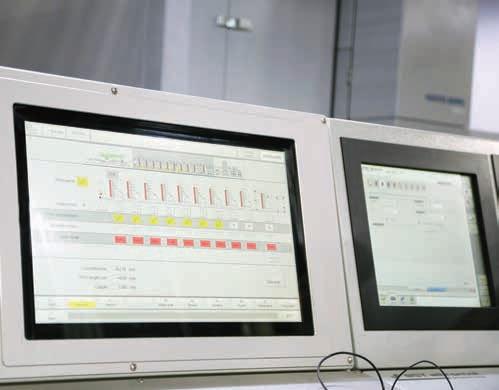

ETI Converting Equipment president Maxime Bayzelon standing next to the touchscreen Bosch Rexroth HMI panel displaying all the critical operating data of an ETI machine located inside the plant’s Technology Centre.

suppliers—essentially eliminating the middleman from the equation.

To realize his game-changing vision, Bayzelon joined forces with an engineering firm IMAC to launch Equipements de Transformation IMAC (E.T.I.) Inc. in 2000.

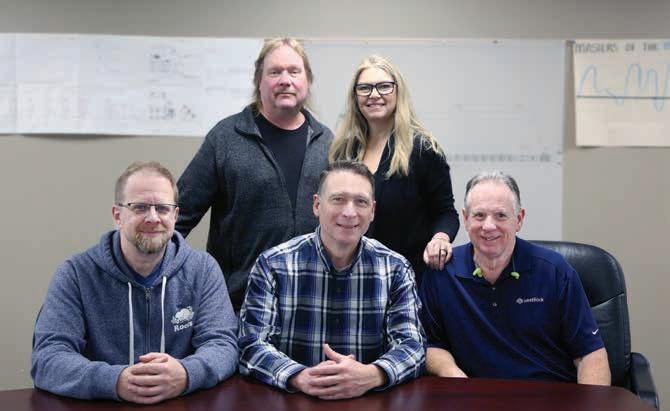

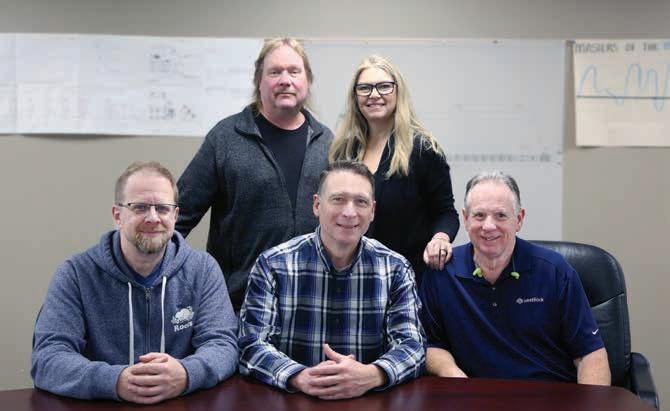

The Longueuil, Que.-based company is now headed by the founder’s son Maxime Bayzelon, the firm’s principal shareholder, in partnership with three other co-owners.

A holder of a bachelor’s degree in mechanical engineering, Maxime joined ETI in 2007 to work in a variety of engineering, manufacturing, product development and market development roles, before becom-

ing company president in 2012.

In 2017, the company moved to its new current location in Longueuil, Que., on the outskirts of Montreal, to accommodate its growing business and to integrate its machining and manufacturing functions under one roof.

Employing 85 people, the rebuilt plant houses all of the company’s departments, including the machining workshop, assembly, engineering, sales and marketing, project management and administration.

This centralized mode of operation allows the company to retain full control of the manufacturing process to produce high-quality inline printing, coating and converting equipment for label producers around the world, building its systems from scratch to match the customers’ exact specifications and applications.

“As a pioneer in the art of in-house coating, our expertise lies in creating specialized equipment for self-adhesive label printing, coating and converting that delivers a unique competitive edge through technical advantages, environmental sustainability, material cost-savings, linerless label capabilities, creativity and flexibility,”

26 CANADIANPACKAGING · January/February 2023 CANADIANPACKAGING.COM AUTOMATE NOW

Above

A bird’s-eye view of the ETI plant’s production floor, with a nearly assembled machine for a U.S. customer in the foreground.

Left Maxime Bayzelon at the entrance to the plant’s Technology Centre area. Bottom

A close-up of the VR Panel PC HMI (human-machine interface) supplied by Bosch Rexroth for all ETI machines.

says Maxime Bayzelon.

“Our equipment is modular, flexible and scalable,” Bayzelon points out, “and our machines are always configured according to our clients’ specific needs, which may include printing, silicone coating, adhesive coating/laminating, die cutting, and/or other converting processes.”

Having sold over 200 machines since its inception, with installations in over 40 countries, ETI enjoys a well-earned reputation as a pioneering trailblazer in many aspects of the label and narrow-web converting businesses, according to Bayzelon.

“ETI was the first to introduce the

concept of inline coating for narrow-web converting,” says Bayzelon, citing other notable patented technological innovations that include:

• Pellicut die-cutting station to cut on very thin liners ;

• Cold slot-die coating station for water-based acrylic adhesive application;

• Pattern hotmelt roll coating station for adhesive application in any shape and size, with capability to produce striped coating at very low coat weights. Says Bayzelon: “ETI has always been able to o er innovative solutions to its

customers and has been recognized for its audacity and ability to undertake special projects that sometimes had a high level of complexity.

“We have sold to all major label printers around the world,” says Bayzelon, citing the company’s stalwart product portfolio o ering label producers powerful in-house converting capabilities, including:

• The Cohesio brand of narrow-web printing, coating and converting equipment for inline label manufacturing;

• The LinerO series of linerless label manufacturing equipment;

• The Acuro line of flexible narrowand mid-web coating and laminating machine for labelstock and tape manufacturing;

• The Metronome range of flexo printing and die-cutting equipment for inline pressure-sensitive adhesive label manufacturing;

• Custom web coating equipment and other custom solutions for made-tomeasure labeling products.

As Bayzelon points out, ETI designs and manufactures all of the production units that go into making its machines, including printing, silicone coating, adhesive coating, and die-cutting stations.

“The fact that the machines are modular and scalable allows our customers to grow their product portfolio over time as needed by adding specific stations to their original machine,” he explains.

With about 95 per cent of its machines exported outside of Canada, “ETI is recognized as the solution that o ers the most ROI (return-on-investment) for clients looking for innovative solutions to produce high volume products at lower costs,” Bayzelon says, “or unique specialty products with technical features that can’t be done otherwise than by coating in-house.

“Our technology represents a real paradigm shift,” says Bayzelon, adding ETI works in close partnership with all its customers to demonstrate many benefits of having more control of their label converting process in-house.

“The technology and solutions we propose create a significant change in their operations: like a shift from purchasing labelstock and printing/converting it, to producing their own self-adhesive materials inline,” he elaborates.

“Once they take the leap and see all the benefits, a large portion of our customers have gone on to purchase subsequent machines,” Bayzelon states.

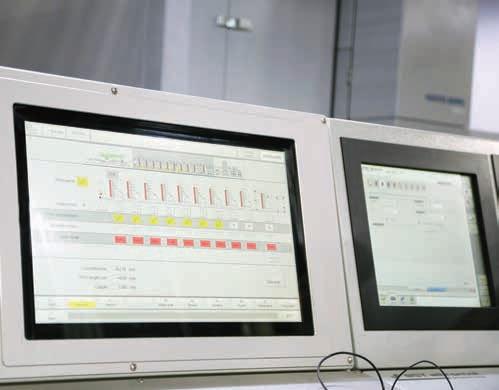

Built with multiple inline operations, ETI machines require skillful integration of various powerful process and motion control technologies and automation technologies to keep these interconnected systems perform with unfailing reliability, precision and accuracy.

To ensure these requirements are met, ETI has leveraged new control and automation technologies from the leading in-

CANADIANPACKAGING.COM January/February 2023 · CANADIANPACKAGING 27

Di erent views of the Bosch Rexroth servomotors and drives controlling the rollers of the ETI machine running in the plant’s Technology Centre area.

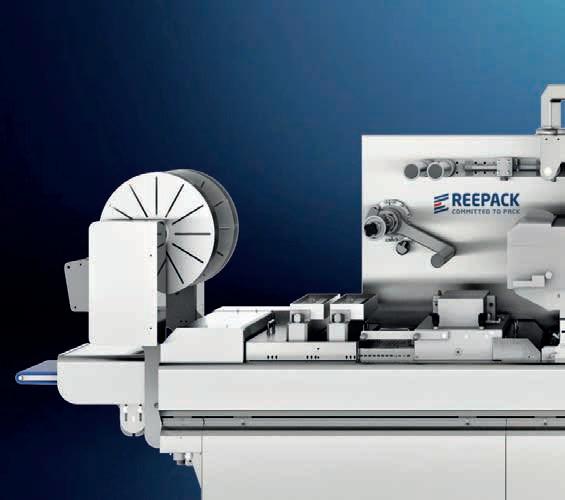

Keep your products fresh and appetizing with Ross

MAP packaging.

n Fully automatic Ross IN inline tray sealer

n High-speed production of lid-only and modified atmosphere packages.

n Reliable, high-quality seals virtually eliminate leakers, extending product freshness and shelf life.

n Uses preformed trays of almost any size or shape.

n Fast, highly flexible, and extremely easy to operate.

n Contact us for sample packages.

www.reiserexperts.com

Reiser Canada • Burlington, ON • (905) 631-6611

Reiser • Canton, MA • (781) 821-1290

Reiser UK • Milton Keynes, Bucks • (01908) 585300

28 CANADIANPACKAGING · January/February 2023 CANADIANPACKAGING.COM

2020.11

dustrial automation supplier Bosch Rexroth Canada to maximize its machines’ performance and reliability.

“We started to do business with Bosch Rexroth approximately 15 years ago,” Bayzelon recalls, “when we switched to servomotors for all our machines.

“The support they have provided has greatly helped us in the realization of some clients’ special projects and has contributed to our own R&D,” says Bayzelon, lauding the Bosch Rexroth components and control software for their leading-edge Industry 4.0 capabilities.

Says Bayzelon: “The connectivity that is made possible by their equipment allows us to be even more e cient when it comes to assisting our clients, since we can access data in real time and intervene in a more targeted manner.”

Some of the most critical up-to-date technologies supplied by Bosch Rexroth to ETI in recent years include:

• New-generation MS2N motors, combining high dynamics with compact dimensions and optimal energy e ciency, while o ering more torque and higher speeds. Available with low- and medium-inertia rotors, the MS2N motors serve as data sources in the Industry 4.0 environment to enable fully intelligent automation solutions.

• The IndraControl XM platform for high-performance automation of a variety of motion logic applications, whereby the local connection of the S20 I/O modules extends the control flexibly for high-performance process connection. The platform allows for easy integration of decentralized I/O stations for a robust design that design simplifies handling and allows for a wider range of applications.

• The SafeMotion drive-integrated safety technology, designed to form the basis for avoiding unintentional machine movements and ensuring safe braking, holding, moving and position monitoring throughout the process.

• The SafeLogic freely programmable safety PLC (programmable logic control) solution designed for complex machines and large-scale sys-

CANADIANPACKAGING.COM January/February 2023 · CANADIANPACKAGING 29 AUTOMATE NOW

Di erent angles of the newly-built ETI machine being tested before shipment to a major U.S. customer.

tems with a decentralized distributed periphery. In terms of hardware, SafeLogic upgrades the standard CML control components through the addition of a function module— enabling the non-safe and safe application to be centrally processed using only one control system.

• The VR Panel PC series from the ctrlX HMI (human-machine interface) range, combining the best attributes of box PCs (PR) and the positioned multi-touch displays (DR). Featuring versatile display format scaling, high performance and a variety of expansion options and standard interfaces, including real-time Ethernet communication, the Panel PCs feature TPM 2.0 chips to provide the necessary safety in the IIoT (Industrial Internet of Things) environment, making it ideal for robust Industry 4.0 applications.

• The compact ctrlX DRIVE modular drive system, providing space-saving dimensions, maximum scalability, wide range of combination options, sophisticated engineering tools, and high energy e ciency.

• The XMD double-axis inverters of the ctrlX DRIVE range, using direct voltage to generate a controlled AC output voltage of variable amplitude and frequency for the operation of two motors.

• Planetary gearboxes and AFX-Series high-speed, high-performance gearboxes from Bosch Rexroth’s technology partner Apex Dynamics, Inc.

As Bayzelon concurs, the technological prowess, quality and reliability of

Bosch Rexroth automation devices and software make it a natural fit for a technology-driven company like ETI, which is fully committed to continuous R&D (research-and-development) and product innovation.

“We have a dedicated R&D department,” says Bayzelon, “and innovation has played a large role in ETI’s success.

“The company has always strived to provide a technical edge to its clients through product development and a high level of expertise,” says Bayzelon, citing the company’s on-site Technology Center as compelling proof of the company’s commitment to customer service excellence.

Says Bayzelon: “It’s a one-stop test and trial facility for label industry suppliers, printers and converters) looking to test and/or develop new label constructions; evaluate sample performance at our inhouse state-of-the-art laboratory; determine ways to reduce the cost of manufacturing; benchmark new products and production methods; and access our team of in-house project managers.”

According to Bayzelon, the company’s worldwide installation base is a testament not only to its technological know-how, but also to its overall strategic approach to the label business.

“ETI has clients worldwide, “ he says, “with a concentration of machines sold in the U.S. and in Europe.

“The proximity of the American market certainly plays in our favor,” Bayzelon notes, “but despite the geographical distance between us and some of our clients, we have always made ourselves available to respond to our clients’ needs promptly at all stages of the cycle, no matter where

they are on the globe.

“We have technical experts who travel for installations, training and support,” says Bayzelon, adding these experts also act as e ective ambassadors for the company’s broader mission of enabling label makers take greater control of their processes.

“By removing the need for printers and converters to outsource the market for labelstock, ETI has created a revolutionary alternative that has led to a seismic shift in the value chain,” he states.

“In essence, we’ve developed the equipment and resources to help customers produce the pressure-sensitive material themselves, using their choice of raw materials including paper or filmic substrate, silicone and adhesive.

“ETI allows pressure-sensitive label manufacturers and converters to have more control over their production and more freedom in label creation,” Bayzelon concludes, “resulting in more economy, greater flexibility in the process, and increased profits.”

30 CANADIANPACKAGING · January/February 2023 CANADIANPACKAGING.COM AUTOMATE NOW

SUPPLIERS ETI Converting Equipment Bosch Rexroth Canada Please see a video of Bosch Rexroth automation components incorporated into the ETI Converting Equipment’s inline label printing, coating and converting machinery on Canadian Packaging TV at www.canadianpackaging.com

“ETI allows label converters to have more control over their production and more freedom in label creation.”

Various Bosch Rexroth controls incorporated into the control panel of a newly-built ETI machine bound for a major U.S. customer.

CANADIANPACKAGING.COM January/February 2023 · CANADIANPACKAGING 31 www.bobst.com For your kind of corrugated board MORE PERFORMANCE, MORE VALUE From pre-feeding to palletizing, BOBST connects every step of the modern corrugated packaging process, to deliver more performance and value for you. Interested? Find your local BOBST representative at www.bobst.com/contact ˍLeading connectivity

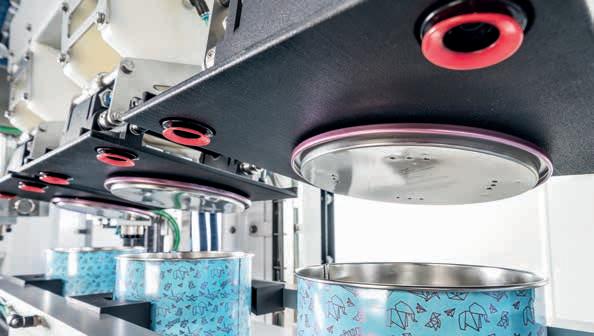

ROLLING WITH THE TIMES

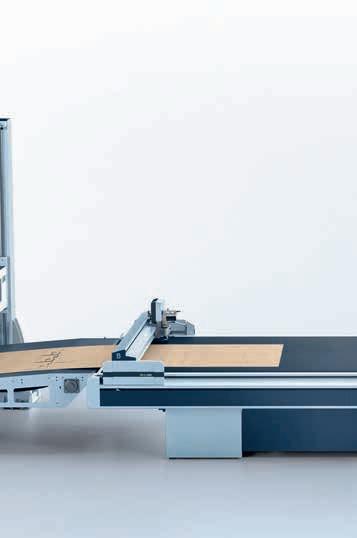

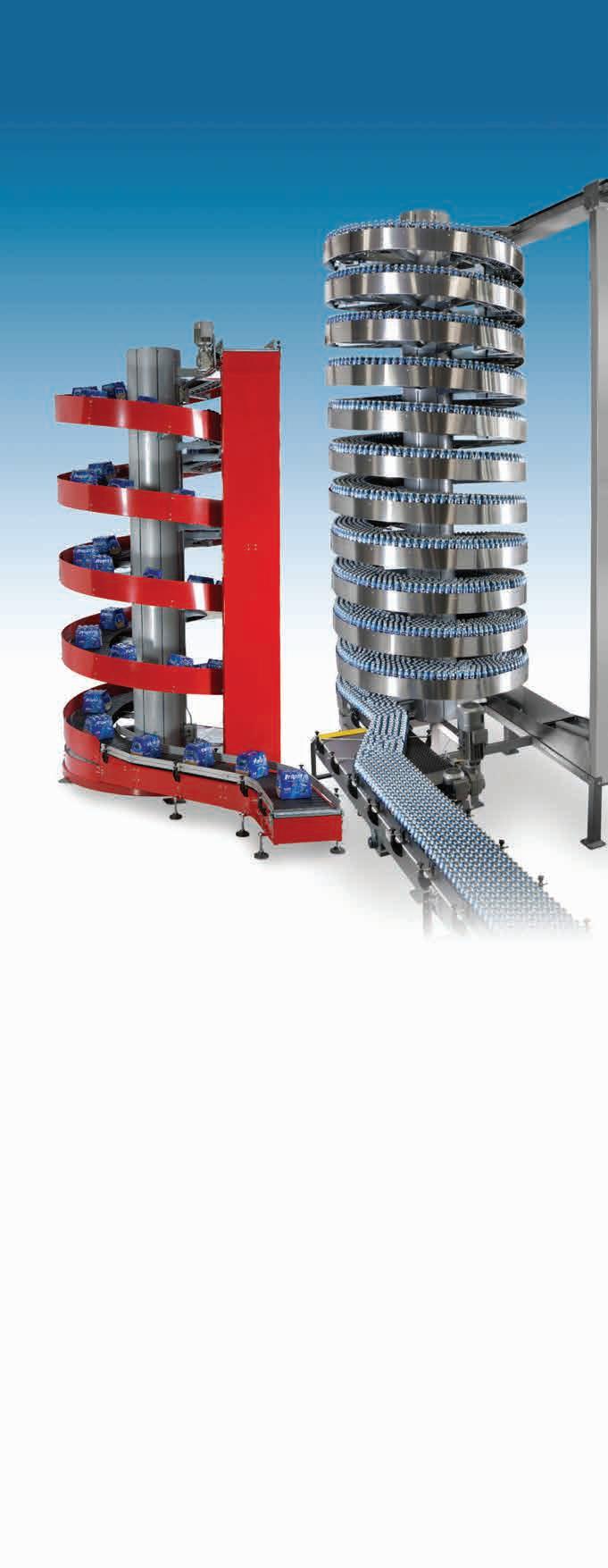

Ontario paperboard converter upgrades its production machinery arsenal with new-generation technologies to retain its supremacy in the beverage carrier markets

By George Guidoni, Editor

Photos by Naomi Hiltz

By George Guidoni, Editor

Photos by Naomi Hiltz

hile it technically falls into the broad industry category defined as secondary packaging, there is little else that is secondary about the critical primary role that paperboard and folding cartons play in global beverage marketplace and supply chain.

Combining all the sustainability benefits of a renewable resource with the material strength, durability, printability and other key functionalities required to produce convenient, attractive, high-impact consumer multipacks for all kinds of bottled and canned beverages, folding cartons are also an integral strategic branding and merchandising vehicle for beverage producers to build brand awareness and loyalty in the fiercely

Wcompetitive, crowded and hotly contested markets.

Nowadays produced in a continually expanding assortment of shapes, sizes and dimensions with a virtually limitless choice of carrying and opening options, beverage multipacks have rightfully earned their place as a mainstay feature of supermarket shelves across North America and much of the developed world.

Ironically, such ubiquity and availability tend to underscore the enormous investment in the capital-intensive machinery, facilities and human talent required to produce this invaluable everyday packaging in su cient quantities to help keep beverage producers on top of their game.

Operating at its current location in Ajax, Ont., since 1966, the WestRock paper converting plant is a veritable showcase of the sheer grand scale of the heavy-duty production and converting

32 CANADIANPACKAGING · January/February 2023 CANADIANPACKAGING.COM

FOLDING CARTONS

WestRock Ajax plant’s converting production manager Peter Nenke strikes a proud pose alongside giant rolls of paperboard being readied for loading onto the facility’s high-performance inline printing presses.

equipment required to turn massive rolls of virgin craft paperboard into fully finished retails cartons ready for shipment to the customer’s beverage packaging lines—often within a day.

Today operating as part of the Atlanta, Ga.-headquartered WestRock Corporation—formed through a landmark 2015 merger of papermaking giants MeadWestvaco Corporation and RockTenn Company—the 300,000-squarefoot Ajax facility is a busy 24/7 operation running flat out throughout the year to produce more than 500 million beverage carrier cartons annually for leading North American beverage brand-owners and co-packers.

Currently employing 180 hourly work-

ers and 29 salaried sta , the Ajax facility is an important strategic asset in the vast global manufacturing and forest management corporate network managed by its vertically integrated parent company that ranks as one of the world’s five largest paper and paperboard producers.

According to Ajax general manager Doug McMillan, operating as an integral part of WestRock has breathed new life and vibrancy into the sprawling production facility, which remains one of the most important and respected industrial employers in this fast-growing community of just over 120,000 residents.

Having recently completed a 90,000-square-foot expansion of the plant’s warehousing space to centralize its

inventory and distribution activities onsite, the Ajax facility has greatly benefitted from the large-scale capital investment upgrades and modernization projects carried out at the facility both by its current and former owners.